Industries

-

24.02.2026

MAPAL and bavius develop prototype component for aerospace industry

In a joint project, MAPAL and the machine manufacturer bavius have developed and produced a prototype component for the aerospace industry.

-

03.02.2026

New presetting device for fine boring tools with large diameters

With the new UNISET V basic plus tool presetting device, MAPAL closes the gap between simple mechanical and high end CNC presetting devices.

-

27.01.2026

New process plant technology brochure for pumps, compressors, and valves

A new MAPAL brochure presents procress plant technology solutions for the three key component areas of pumps, compressors, and valves.

-

02.12.2025

Large tool package for Mangner Zerspanungstechnik

MAPAL has equipped Mangner GmbH with a comprehensive tool package for drilling operations.

-

15.10.2025

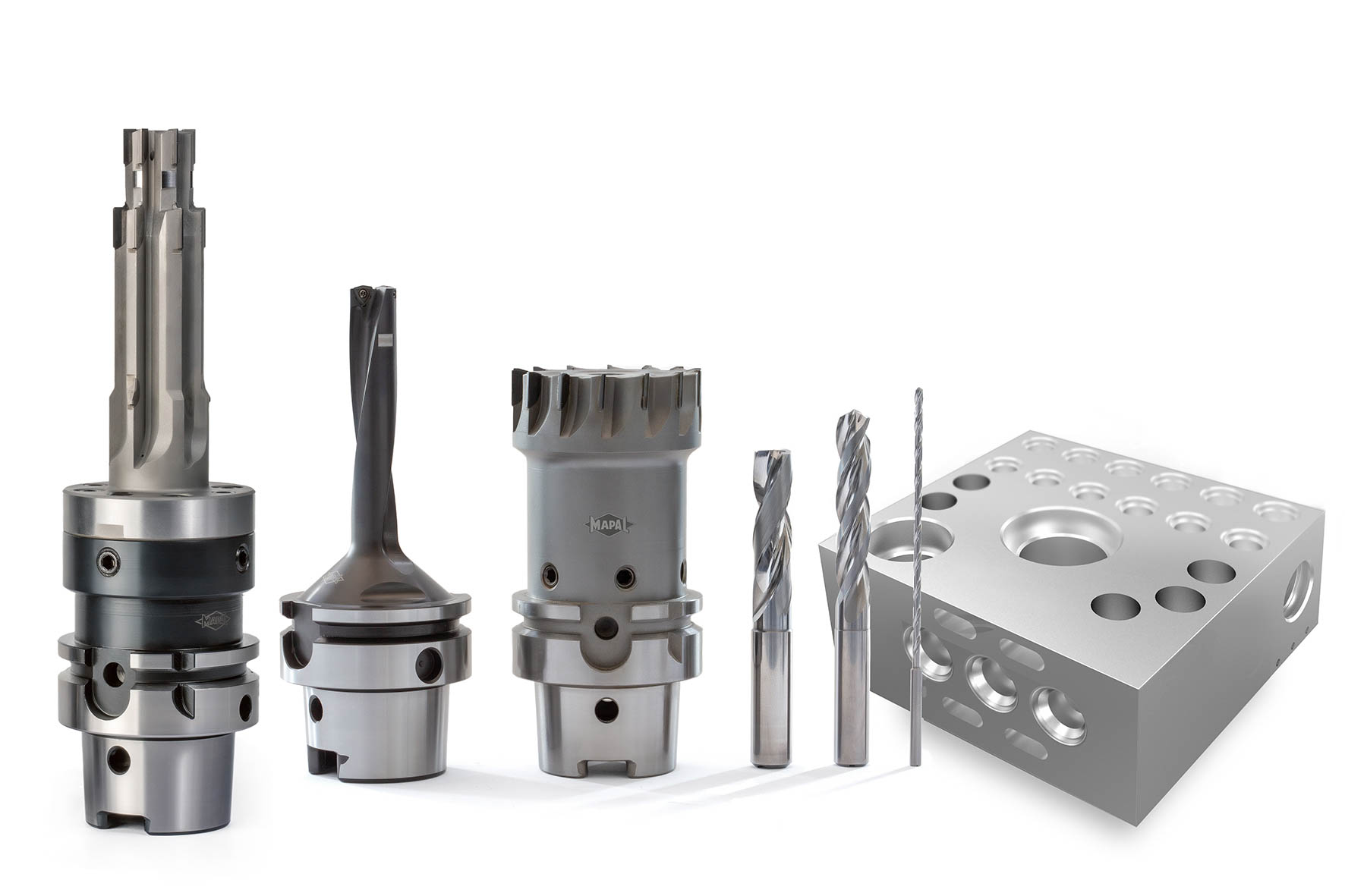

Successful tooling solutions from MAPAL increase productivity for customers.

Increasing customer productivity is at the heart of MAPAL’s standard processes for the industrial manufacturing of strategic components.

-

06.10.2025

Innovations and solutions of MAPAL

MAPAL presents its 2026 innovations and solutions in a comprehensive brochure.

-

24.09.2025

IMPULSE 85 has been published

Innovations and solutions of the year 2026 are in the focus of issue 85 of the technology magazine IMPULSE

-

26.08.2025

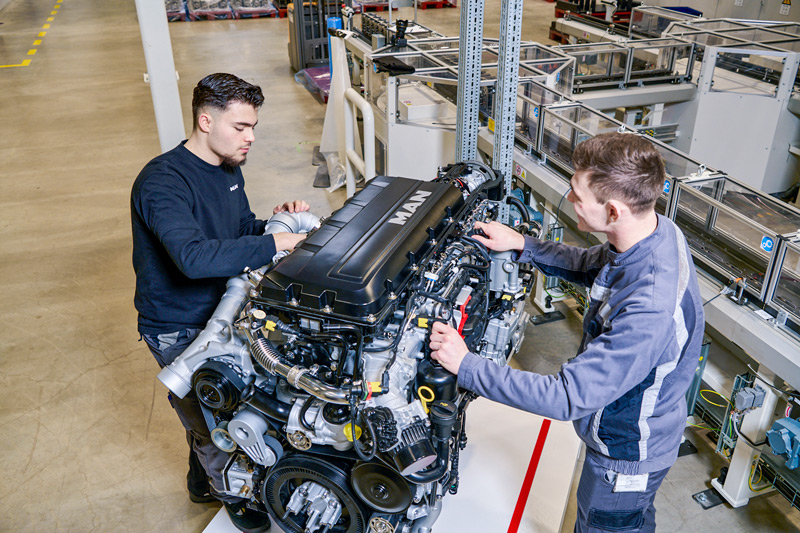

MAN uses MAPAL fine boring tools for machining cylinder heads

At MAN engines, fine boring tools from MAPAL are used to machine the valve guide and valve seat counterbores of cylinder heads."

-

12.08.2025

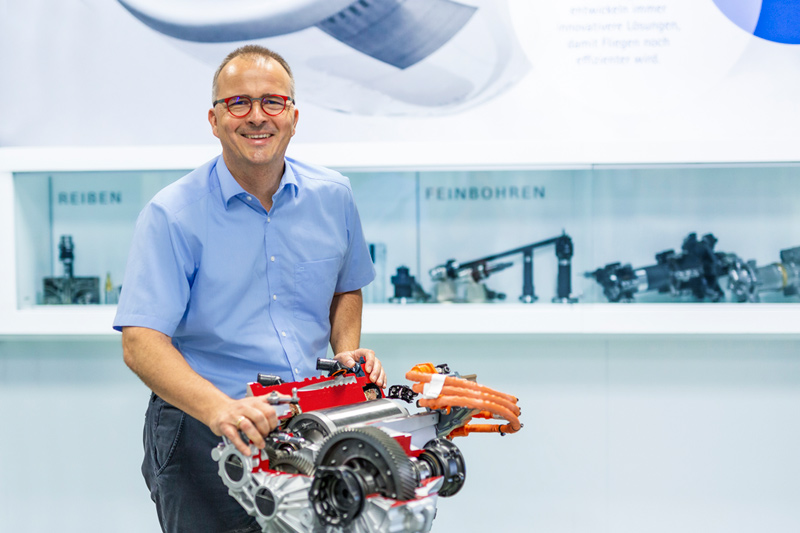

Matthias Winter on key focus areas in the automotive segment

The technological transformation driven by electrification and autonomous driving is placing new demands on the automotive segment. Matthias Winter discusses the key focus areas.

-

29.07.2025

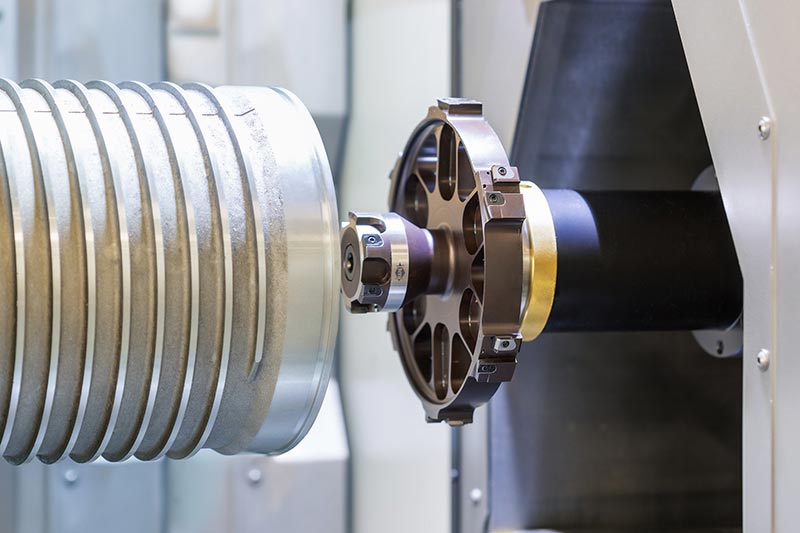

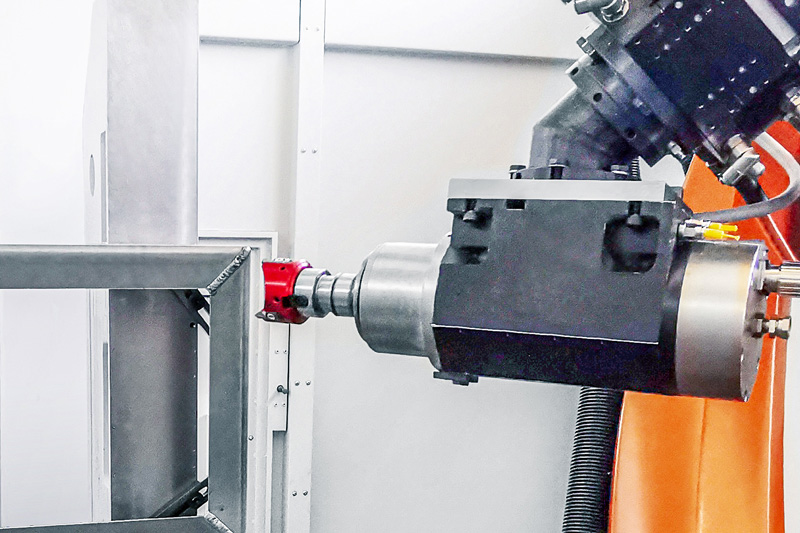

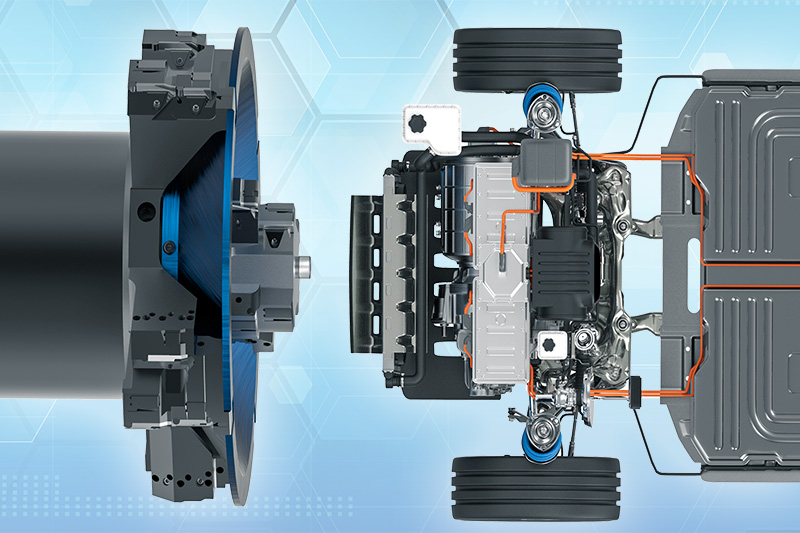

NILES-SIMMONS and MAPAL are setting standards in stator housings

The process developed by NILES-SIMMONS and MAPAL for the complete machining of stator housings for electric vehicle motors is ready for series production.

-

22.07.2025

Crankshaft and valve seat machining: MAPAL sets standards

Optimised machining of crankshafts and valve seats: MAPAL offers innovative tool solutions for modern combustion and hybrid engines.

-

02.06.2025

IMPULSE 84 has been published

The automotive industry is the focus of issue 84 of the technology magazine IMPULSE

-

05.05.2025

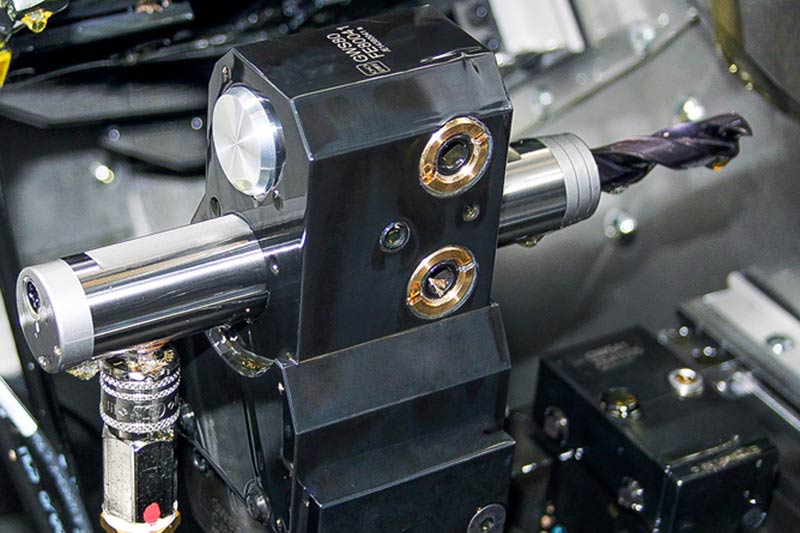

MAPAL is a partner and tool supplier for CHIRON turnkey machines

CHIRON America upgrades standard machines to turnkey machines at its plant in Charlotte. MAPAL is the tool supplier for a machine for manufacturing truck components.

-

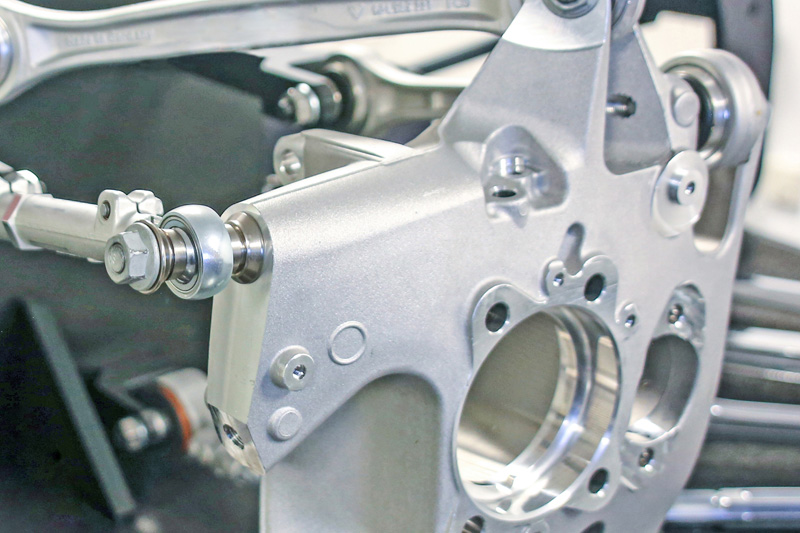

09.04.2025

MAPAL develops two generic components for the aerospace industry

MAPAL has developed two sample components for the aerospace sector. The Generic Components, a valve housing and a torsion joint, cover all the demanding machining steps.

-

28.03.2025

Suitable tools for combined brake housings

Combined brake housings unite the brake master cylinder, brake booster and ABS/ESP in one component and pave the way to autonomous driving. MAPAL offers solutions for machining complex aluminum workpieces.

-

04.03.2025

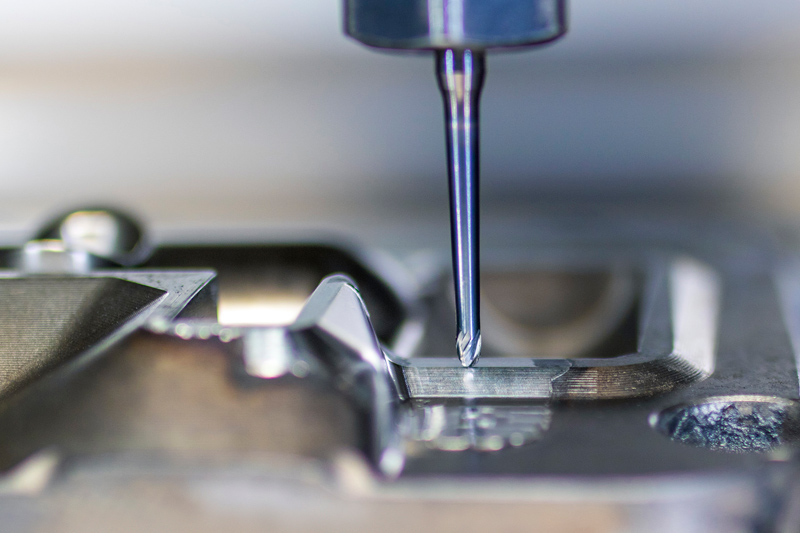

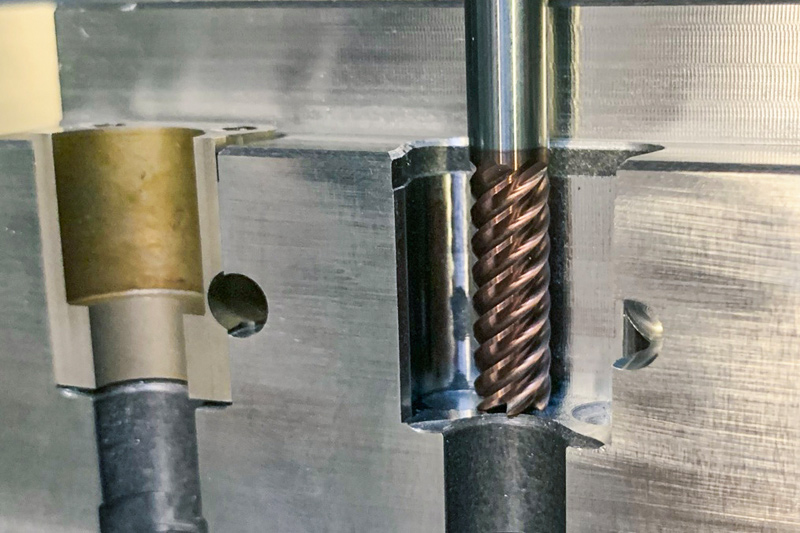

CORMOL relies on milling cutters such as the OptiMill-3D-HF from MAPAL for tool making

CORMOL from Portugal manufactures stamping tools, for which it has been working closely with MAPAL since 2022. With the OptiMill-3D-HF, CORMOL has found a reliable and economical tool solution.

-

26.02.2025

Another design award for the UNIQ hydraulic chucks from MAPAL

Following the iF Design Award and the Good Design Award, the UNIQ hydraulic chucks from MAPAL have also been honoured with the Green Design Award, which focuses on sustainability.

-

11.02.2025

MAPAL underlines its aluminum competence for pneumatics with focus components

For the machining of a pneumatic valve housing and a pneumatic cylinder, MAPAL can draw on its expertise and product portfolio for aluminum machining.

-

05.02.2025

MAPAL at the intec in Leipzig

"Empower Your Aluminium Machining" is the motto of MAPAL's intec presentation in March. Aluminium machining is an important focus, as are the Innovations 2025.

-

16.01.2025

Tool management from MAPAL completed for DEUTZ in record time

MAPAL completed the entire engineering including tool design, cycle time study and cost calculation for the engine manufacturer Deutz in the Spanish plant in Zafra within a very short time.

-

19.12.2024

IMPULSE 83 has been published

Innovations and strategic focus areas are in the spotlight of issue 83 of the technology magazine IMPULSE

-

06.11.2024

Optimum processing through component and market expertise: solutions for the scroll compressor

Machining solutions for scroll compressors: MAPAL offers precise, durable tools for electromobility. Focus on quality, efficiency and application-orientated processes.

-

07.08.2024

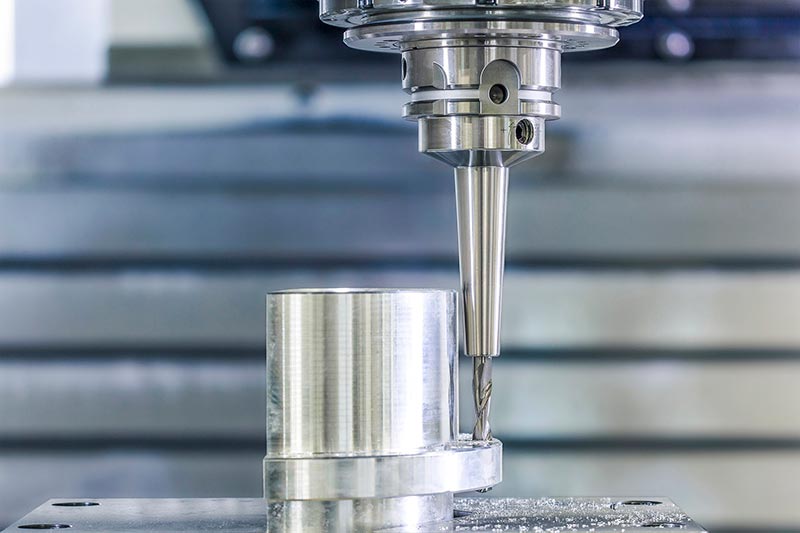

Empower Your Aluminium Machining

Aluminium materials are increasingly being used in various industries. MAPAL is the leading technology partner for the machining of aluminium components.

-

02.08.2024

MAPAL at the AMB in Stuttgart

"Empower Your Aluminium Machining" is the motto of MAPAL's AMB presentation. Aluminium machining is an important focus, as are the Innovations 2025.

-

02.07.2024

Aluminium expertise in focus at the annual press conference

At the annual press conference in Aalen, the focus was on the annual report, innovations for AMB and aluminium machining.

-

25.06.2024

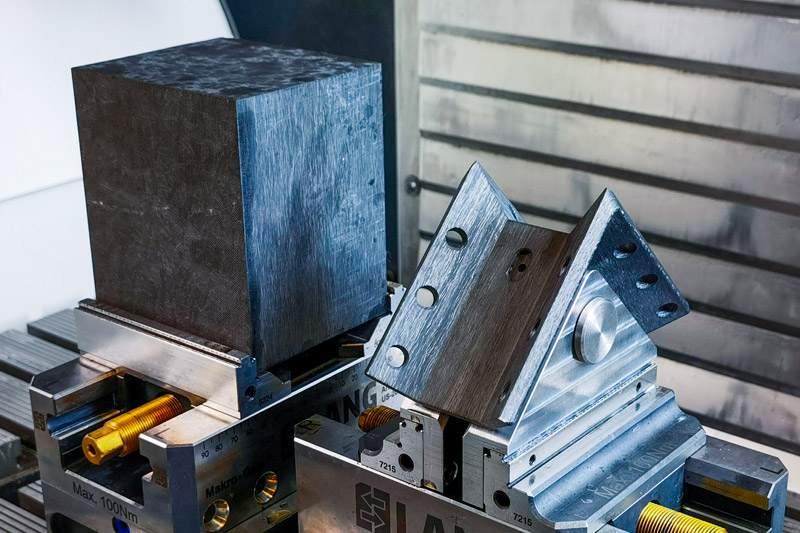

Efficient production in die and mould making: Krämer+Grebe and MAPAL

The mouldmaking company Krämer+Grebe optimises production with MAPAL reamers and milling cutters and ensures process reliability in international competition.

-

17.05.2024

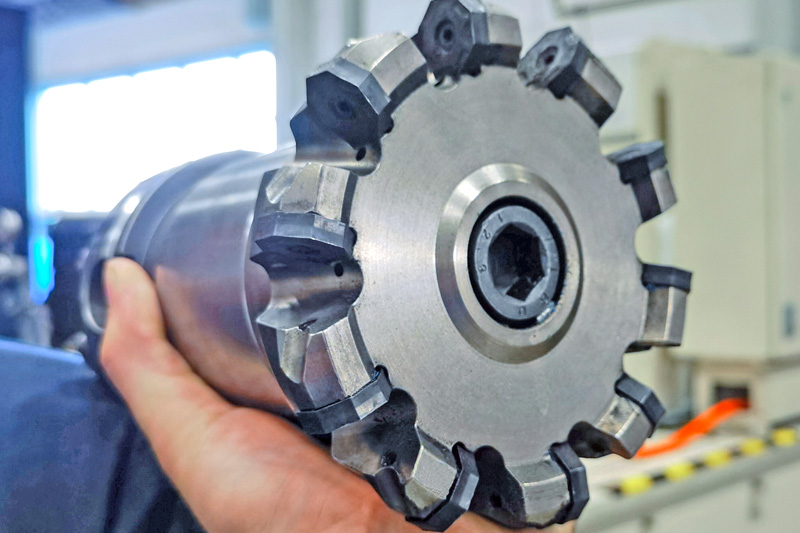

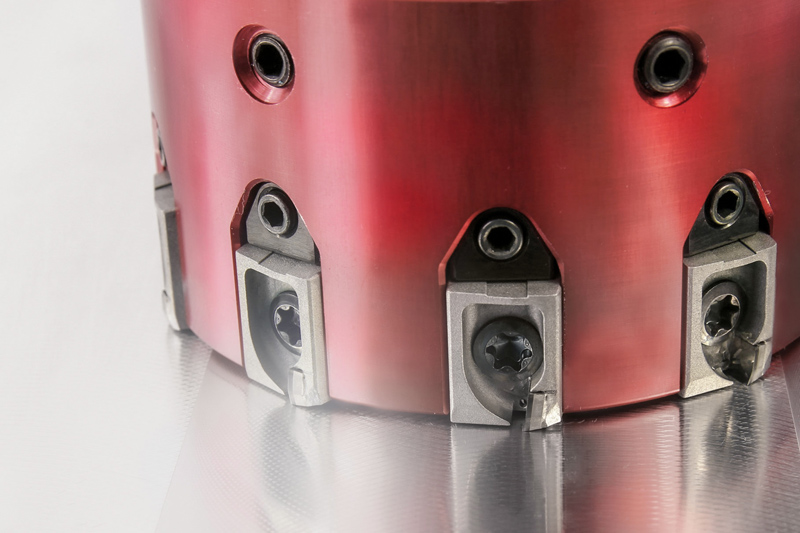

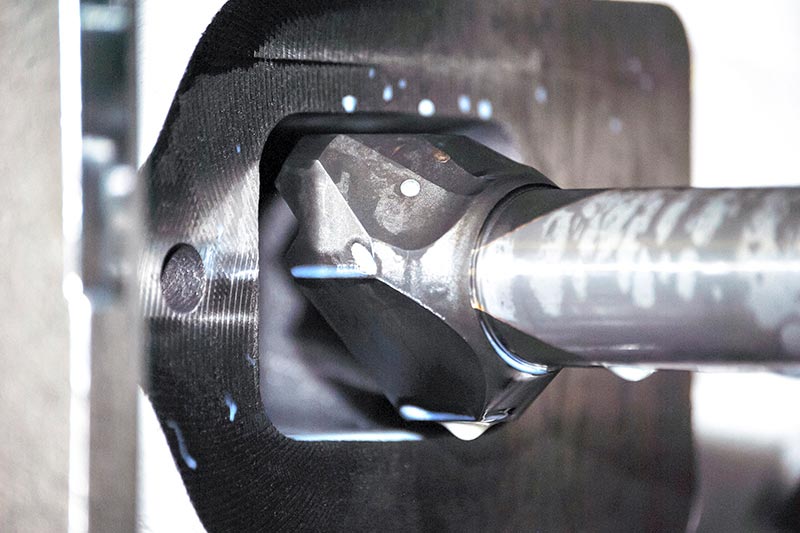

NeoMill-Alu-QBig: High-volume milling of aluminium materials

With material removal rates of 18 l/min and more, the NeoMill-Alu-QBig indexable insert milling cutter from MAPAL stands for top performance in high-volume milling of aluminium.

-

12.04.2024

MAPAL bundles activities in aircraft assembly

In order to optimally and intensively support the area of final assembly in the aerospace industry, MAPAL has created a new department.

-

08.04.2024

IMPULSE 82 has been published

Developments, solutions and applications for the aerospace industry are the focus of issue 82 of the MAPAL technology magazine IMPULSE.

-

25.03.2024

Collaborative partnership in the end machining of steel

GABO STAHL relies on an automated special machine from Mössner and tool technology from MAPAL for the end machining of round steel.

-

01.02.2024

Lifecycle Management from c-Com increases transparency at thyssenkrupp Presta Schönebeck

The automotive supplier thyssenkrupp Presta uses c-Com's Lifecycle Management at its Schönebeck site and achieves transparency and considerable savings.

-

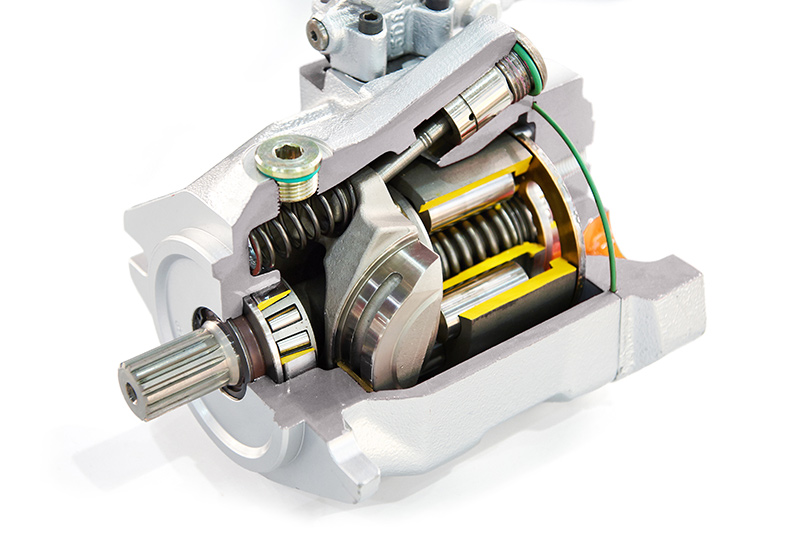

11.01.2024

Major process improvements in the machining of axial piston machines

MAPAL has developed profound process solutions for the economical and precise machining of axial piston machine components.

-

13.12.2023

Sound solutions for fluid power components

MAPAL manages fluid power technology as an independent market segment and supports customers in demanding machining operations as a solution provider.

-

04.12.2023

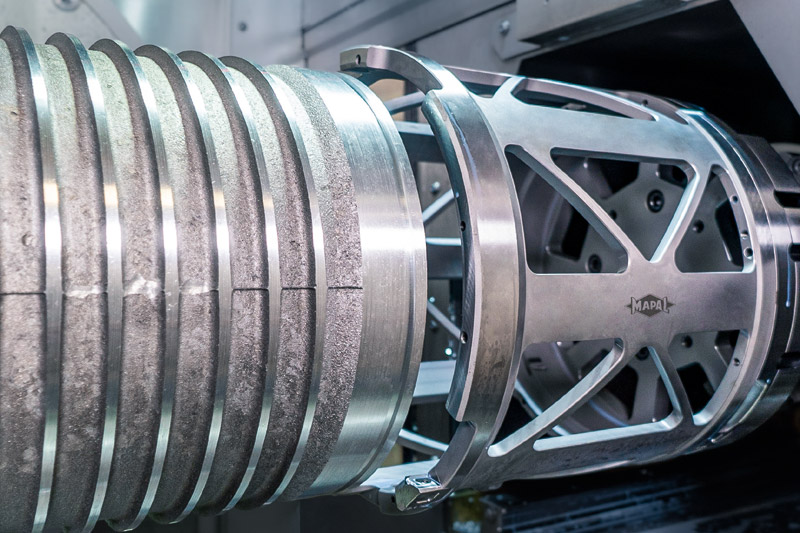

Aluminium machining in new dimensions

Impressive material removal rates - bavius cuts over 20 liters per minute with aluminum high-volume milling cutters from the tool manufacturer MAPAL.

-

22.11.2023

Development of customised diamond coatings

MAPAL develops extremely hard and wear-resistant diamond coatings for machining materials such as CFRP, ceramics, graphite and aluminium alloys.

-

09.11.2023

Twice as fast to the titanium component with MAPAL

Aircraft supplier SME Aerospace Malaysia optimises its titanium component machining together with MAPAL and saves 3 hours per component.

-

19.10.2023

"MAPAL's focus has always been and will always be on the customer."

CTO Jacek Kruszynski on structures, development priorities and plans in the area of digitalisation.

-

28.09.2023

Structural parts in record time

Wenzler and MAPAL combine their expertise and provide answers to the question: How can aluminium components be manufactured quickly and precisely?

-

07.08.2023

MAPAL at the EMO 2023

MAPAL will be presenting itself in Hall 4, Stand A18 with the focus industries, Innovations 2024, the Online Shop and new developments on the subject of sustainability.

-

02.08.2023

Well positioned for e-mobility

The die-casting foundry 2A is ready for the transition to electric mobility. MAPAL is at 2A's side as an experienced tool partner.

-

17.07.2023

IMPULSE 81号が出版されました

Solutions and applications in fluid power technology as well as sustainability are the focus of issue 81 of the MAPAL technology magazine IMPULSE.

-

12.07.2023

ドリル加工の代わりのフライス加工

Why milling instead of drilling can be a sensible alternative? MAPAL shows how higher process reliability and shorter machining times can be achieved.

-

27.06.2023

High process reliability when milling CFRP composite materials

The OptiMill-Composite-Speed-Plus milling cutter from MAPAL stands for high process reliability due to long tool life, high breaking strength and the best cutting quality.

-

19.06.2023

The best deep bores with PCD

The automotive supplier Schlote converted the deep drilling of oil channels in clutch housings and reliably achieves five times the service life.

-

30.05.2023

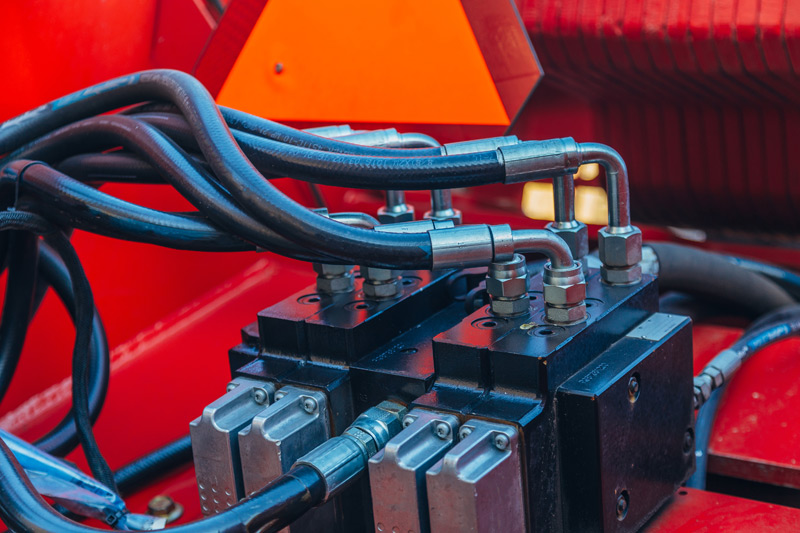

Precisely fitting solutions for hydraulic valve housings

The production of valve housings is the supreme discipline in the world of fluid technology. As a technology partner, MAPAL supports the customer with the complete process design.

-

11.05.2023

A strategy for battery frames

MAPAL’s electric mobility experts have designed a generic component that encompasses the main machining operations of a battery frame.

-

10.05.2023

Precision, durability and process reliability from a single source

At Moulding Expo 2023, MAPAL will present the complete range of tools and solutions for die and mould making and the new online shop.

-

23.03.2023

The production must go on

Digital tool management with more than 750 tools from MAPAL ensures smooth large-scale production at Schabmüller Automobiltechnik.

-

09.03.2023

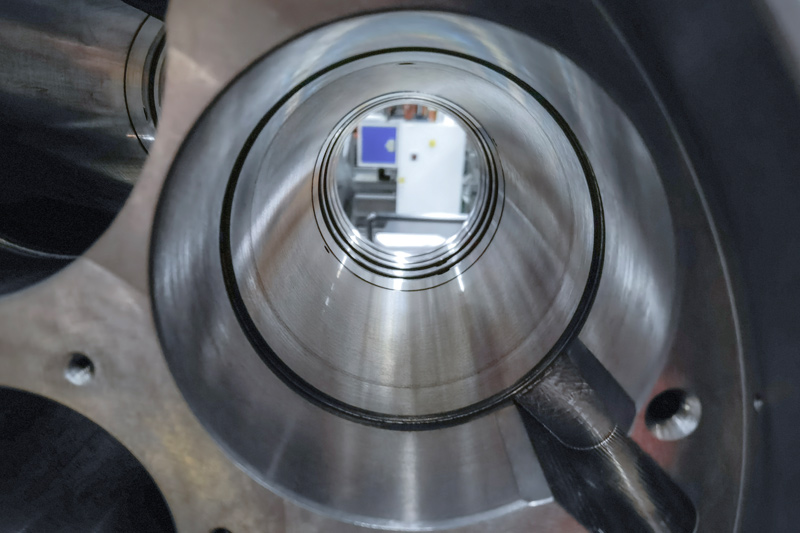

Four inserts for stator bores

Actuating tool with four facing slides and HSK100 connection for finishing the stator bore combines precision, flexibility and long tool life.

-

02.03.2023

The overall process makes the difference

In direct comparison to the previous machining process, the MAPAL solution brings clear advantages. The consideration of the overall process is decisive here.

-

14.02.2023

Help for Hatay

The regional aid alliance “Erdbebenhilfe Hatay” got a donation of 5.000 Euro from MAPAL. Dr. Kress visited the donation collection center.

-

25.01.2023

Gnutti Carlo Group relies on c-Com digital tool management

The Gnutti Carlo Group implements a digital tool management solution from c-Com for its worldwide locations.

-

12.01.2023

Basic–Performance–Expert

MAPAL clusters its machining solutions for electromobility components into solution stages, depending on the precision requirements and production volume.

-

21.12.2022

MAPAL receives three supplier awards

Bosch, Bocar and Gnutti Carlo awarded MAPAL as a preferred supplier for above-average performance in innovation and service.

-

23.11.2022

Sights set firmly on supply chains and key components

Matthias Winter in an interview about the market development in the automotive sector, MAPAL's focus within the e-mobility sector and challenges in machining.

-

03.11.2022

Efficient deburring with robots

The FlyCutter from MAPAL is ideally suited for deburring battery trays. Robot manufacturer KADIA is enthusiastic about the PCD-tipped milling tool.

-

28.09.2022

Adapted hydraulic chuck as a problem solver

Simple, fast, safe and reliable – how the Swiss lathe manufacturer TORNOS is optimising the application performance of its multi-spindle lathe with the help of MAPAL hydraulic chucks.

-

12.09.2022

Customer needs as an impetus for innovation

At the AMB in Stuttgart, MAPAL will be presenting new products and innovative machining solutions for the focus industries, thereby increasing the competitiveness of customers.

-

22.08.2022

A new turn for e-mobility

-

11.08.2022

MAPAL at the AMB 2022

At AMB 2022 in Stuttgart, MAPAL will be presenting innovations for the focus industries and options for increasing sustainability in Hall 1, Stand D10.

-

28.07.2022

Strategic partnership in mould making

Röders GmbH and MAPAL jointly develop the machining strategy for a generic component. The approach is convincing - both in the CAM simulation and on the machine.

-

30.06.2022

Even more cost-effective turbochargers

How the complete machining of turbochargers becomes even more productive with indexable insert milling cutters from the NeoMill range.

-

02.06.2022

3D milling of CFRP prototypes from batch sizes of one

MAPAL supports ERIKS Deutschland GmbH with process expertise and an extensive range of tools for turnkey CFRP machining.

-

05.05.2022

Problem solver even for tricky cases

MAPAL tools demonstrate their performance potential in several problematic applications at the mould making company HaGeForm Sachsen.

-

28.04.2022

Automotive technology for aeroplanes

Machine manufacturer F. Zimmermann GmbH and MAPAL jointly set standards in the project implementation and machining of an aerospace component.

-

13.04.2022

A multi-stage fine boring tool for the highest precision

Multi-stage fine boring tool from MAPAL machines component made of GGG40 with six bores, each with three merging cylindrical areas.

-

17.03.2022

Electronic actuating tool makes milling-turning centre an all-rounder

The integration of the TOOLTRONIC mechatronic tool system into the RX18 milling turning centre from Reiden Technik AG met the customer's high requirements.

-

14.03.2022

Sponsorship of the "Marktspiegel Werkzeugbau" cooperative

MAPAL has been a sponsor of Marktspiegel Werkzeugbau eG since 1 March 2022. The cooperative supports die and mould makers with industry knowledge.

-

10.03.2022

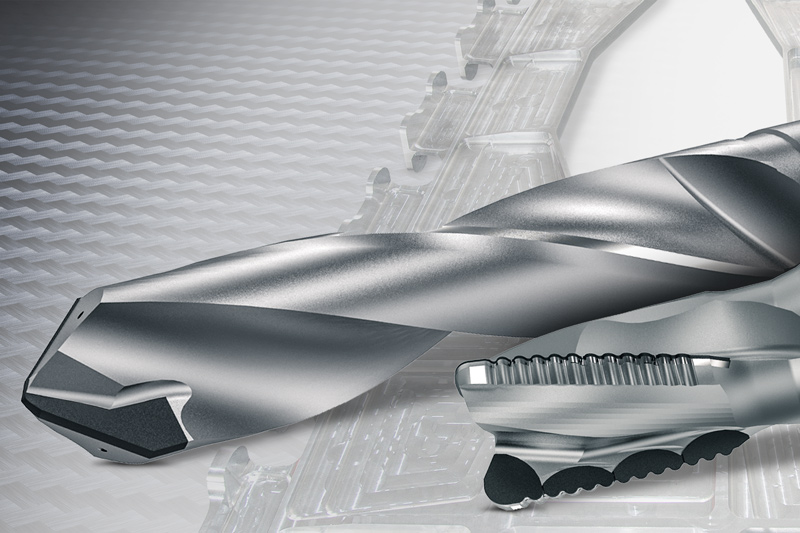

Titanium Machining Takes Off

MAPAL is making drilling and milling of the ductile, high-strength workpiece material more productive, thereby reducing costs.

-

13.01.2022

Performance boost with NeoMill face milling cutter

NeoMill face milling cutters from MAPAL cut machining times of screw compressors at BOGE Kompressoren by fifty percent.

-

15.12.2021

Optimisation in mould making

On the way to industrial toolmaking, Schülken Form is optimising its production processes. MAPAL tools play an important role in this.

-

04.11.2021

Wide field of applications for PCD tools

PCD tools from MAPAL demonstrate their performance in a wide range of applications and industries. Respirators or spectacle lenses are examples.

-

25.10.2021

IMPULSE — edition 76 is available

News on e-mobility. New tools for machining titanium as well as valve housings and pot-shaped stator housings. A new module from c-Com.

-

13.10.2021

MAPAL Focuses on Fluid Technology

The spool bore in valve housings has particularly tight tolerances. The machining process from MAPAL fulfils the specifications reliably and with high economic efficiency.

-

04.10.2021

Continuous process for electromobility

Topfförmige Statorgehäuse für Elektromotoren sind aufgrund ihrer Dünnwandigkeit und engen Toleranzen anspruchsvoll zu bearbeiten. MAPAL liefert den kompletten Prozess.

-

04.10.2021

MAPAL receives state funding for digital project

Umwelt- und ressourcenschonende Zerspanung – MAPAL forscht mit renommierten Partnern. Kern des Projekts ist die genaue Analyse von Daten.

-

16.08.2021

IMPULSE — edition 75 is available

Discover smart solutions as well as the potential of MAPAL’s Tooltronic and the radial milling cutters NeoMill.

-

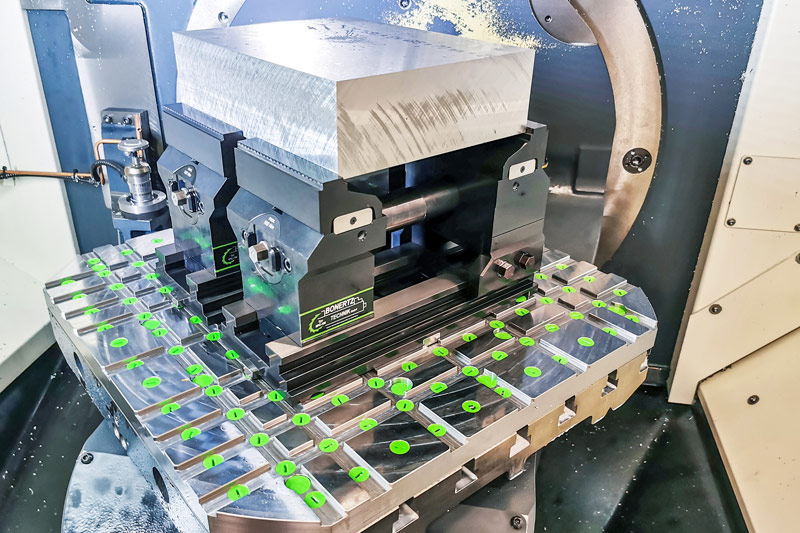

14.07.2021

When tool expertise and consulting quality match

For the production of sophisticated clamping devices for machine tools, Bonertz Technik GmbH relies on the performance and process reliability of MAPAL tools.

-

01.07.2021

Sophisticated PCD tool concepts for machining aluminium

Carl Hirschmann GmbH processes aluminum forged parts for sports vehicles with multi-stage combination tools from its development partner MAPAL.

-

22.06.2021

“We are very well positioned”

Dietmar Maichel and Uwe Rein report on MAPAL's market entry into die and mould making industry and present the company’s value proposition.

-

01.06.2021

PCD for machining challenging aviation components

MAPAL solutions for aerospace: 60 percent longer tool life when drilling CFRP materials and long-chipping aluminum alloys with process-reliable dry roughing.

-

20.05.2021

Membership of the VDWF: MAPAL expands its activities

MAPAL is now present as an entire company in the German Die and Mouldmaking Association. Do you know why the association is an important network partner?

-

11.05.2021

High performance in precision machining of aluminium

Aluminum structural components for aircraft are mostly machined from solid. This requires enormous performance and high precision from machines and tools.

-

28.04.2021

Market segments are defining the clamping technology of the future

In the interview, Dennis Minder and Jochen Schmidt explain the new structures in clamping technology at MAPAL and the great advantages of the new hydraulic expansion technology.

-

07.04.2021

IMPULSE edition 74 is available

The latest edition of Impulse is available. One of the main topics is the market launch of MAPAL in the die and mould sector.

-

01.04.2021

E-Mobility: New Catalogue

Electrified components, their structure, their requirements and MAPAL's machining concepts –useful tips and detailed illustrations.

-

08.03.2021

Partner in the mining industry

Tool life and feed more than doubled, with excellent surfaces. The Rockbit-Drills from MAPAL machine the seats for bit inserts in mining tools.

-

08.02.2021

Economical and reliable machining of steel beams

The flexible use of steel beams in many areas goes hand in hand with closely defined manufacturing tolerances. How MAPAL contributes to high process reliability.

-

26.06.2020

Walter Formenbau trusts in MAPAL’s expertise

In order to achieve its goal of fully networked production, owner Dr Jens Buchert brought MAPAL on board as a complete supplier.

-

15.01.2020

New chucks for standardized Processes

Mitsubishi Motors Corporation relies on the expertise and service of MAPAL when planning a new engine production line at its Kyoto plant.

-

01.01.2020

Complete Supplier in Tool and Mould Making

Why MAPAL has a unique selling point as a complete supplier in die and mould making and how customers benefit from this.

-

09.12.2019

Highly precise machining of truck engine cylinder bores

High-precision MAPAL actuating tools and a special setting fixture ensure precise and economical production at Mercedes-Benz in Mannheim.

-

08.11.2019

Reliable and Cost-effective Manufacture of Turbochargers in Series

Manufacturers of turbochargers face challenges in machining. How MAPAL makes the entire process cost-effective and efficient.

-

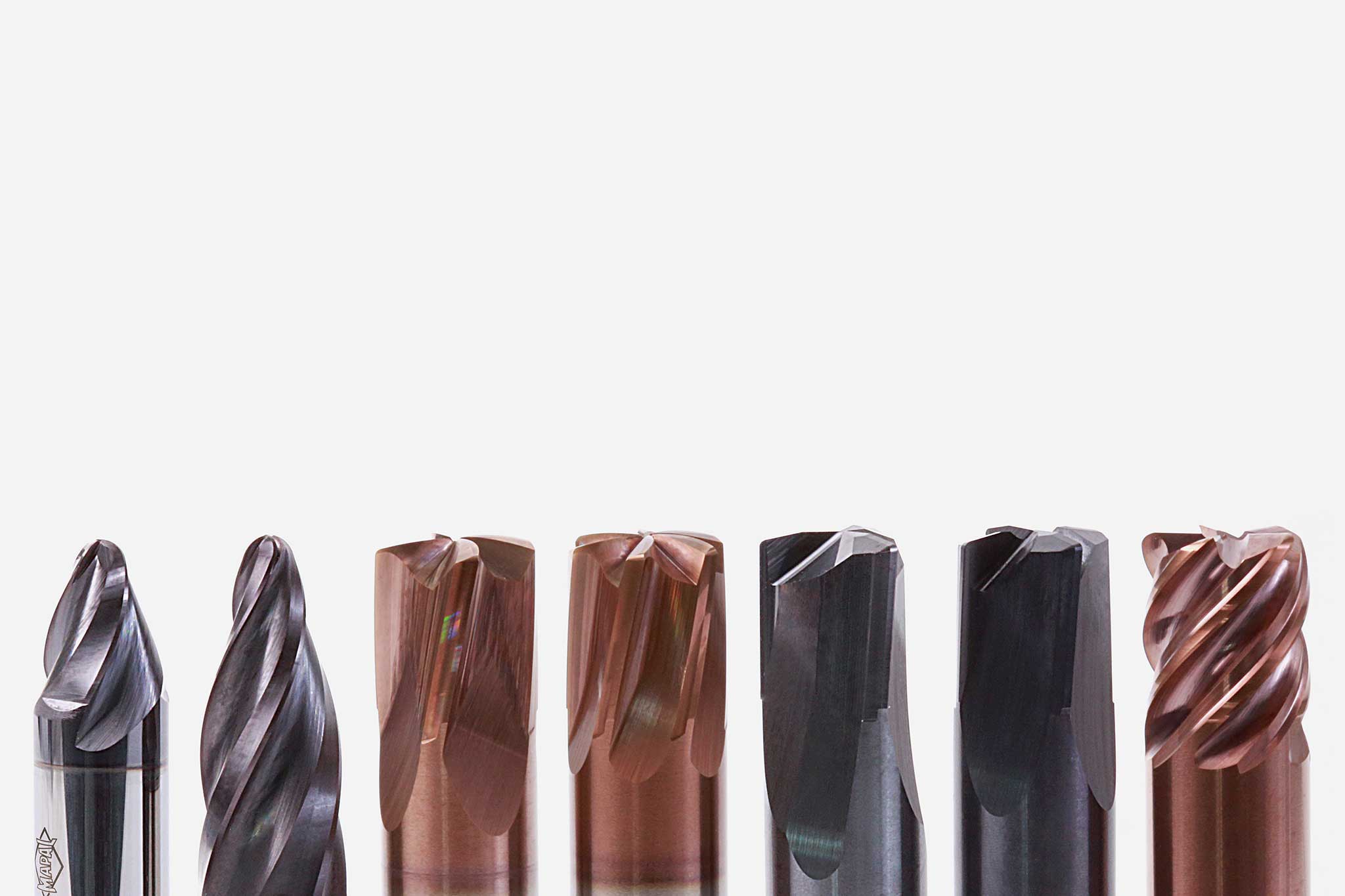

13.09.2019

High speed in die & mould sector

MAPAL presents performant and precise solid carbide cutting tools for various applications and machining processes for die & mould.

-

01.09.2019

High-performance Milling Cutter for the Machining of Structural Parts

Axel Fleischer speaks in an interview about challenges, opportunities and new potential in the aerospace industry with high-performance milling cutters from MAPAL

-

01.09.2019

Aircraft Industries depends on milling cutters for high-volume machining from MAPAL

High volume milling cutters, drilling/countersinking combination tools and reamers in use in the parts production and final assembly of aircraft manufacturer Aircraft Industries.

-

01.07.2019

Electric motor housings reliably enter large-scale production

For the complete machining of housings for electric motors, MAPAL is offering tool solutions which are ready for series production, reliable and absolutely precise.

-

01.01.2019

Changing Mobility

How machine manufacturer Heller together with tool manufacturer MAPAL brought the manufacturing of a newly designed stator housing to series maturity.

-

01.01.2019

Yet more expertise in tool and mould making

MAPAL is strengthening its activities in die & mould sector. By acquiring voha-tosec from Lindlar, MAPAL is integrating a proven specialist into the MAPAL Group.

-

01.11.2018

Constant velocity joints for electro mobility

Why Neapco relies on ball nose milling cutters from MAPAL for hard machining the homokinetic outer joint of a drive shaft.

-

01.10.2018

Excellent result thanks to close, partnership-based cooperation

MTU Friedrichshafen converts finish machining to minimally invasive face milling. They also achieve evenness improved by a factor of 10 with milling cutters from MAPAL.

-

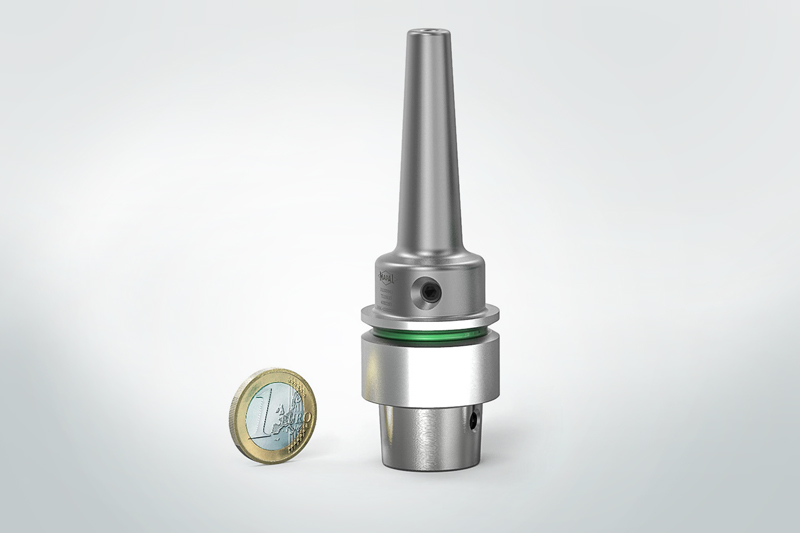

01.09.2018

Miniaturisation in clamping technology thanks to additive manufacturing

Additively manufactured hydraulic chucks in small format from MAPAL are following the trend towards miniaturisation. They meet the highest standards.

-

01.06.2018

Great potential in drilling from the solid carbide on heat exchangers with the TTD-Tritan

A higher efficiency in production is achieved through the usage of heat exchanger. Even more potential can be reached with the usage of economically made high precision tools. As a TTD-Tritan proves to reduce the cycle time by 57 percent...

-

01.02.2018

Concentrated flexibility and efficiency – facing heads and mounting tools from MAPAL

Bühring is tasked with machining complex contours on components for straw balers. Why the company has decided to go for a tool solution from MAPAL

-

01.01.2018

Dry Machining of Multilayer Composites in Aircraft Construction

The final assembly of aircraft presents special challenges for tool manufacturers. MAPAL has developed special tools just for this.