26.08.2025

Putting heads together for the last diesel engine

Fine boring tools from MAPAL for MAN diesel tools

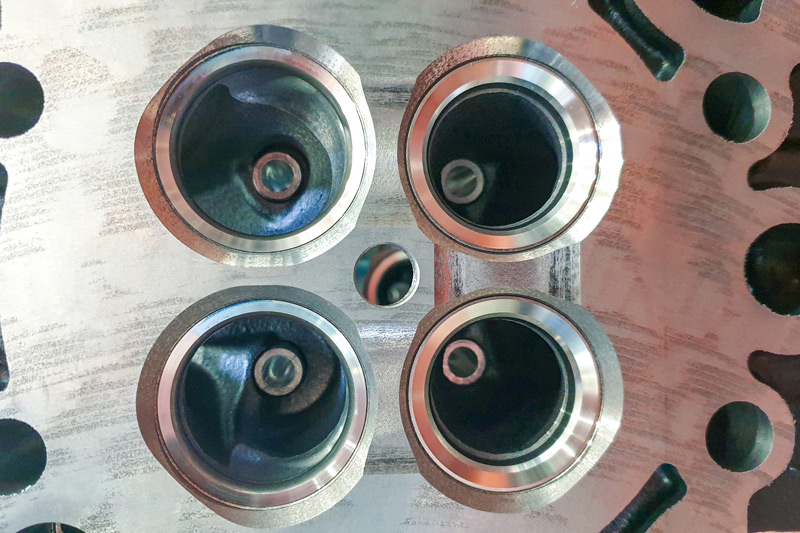

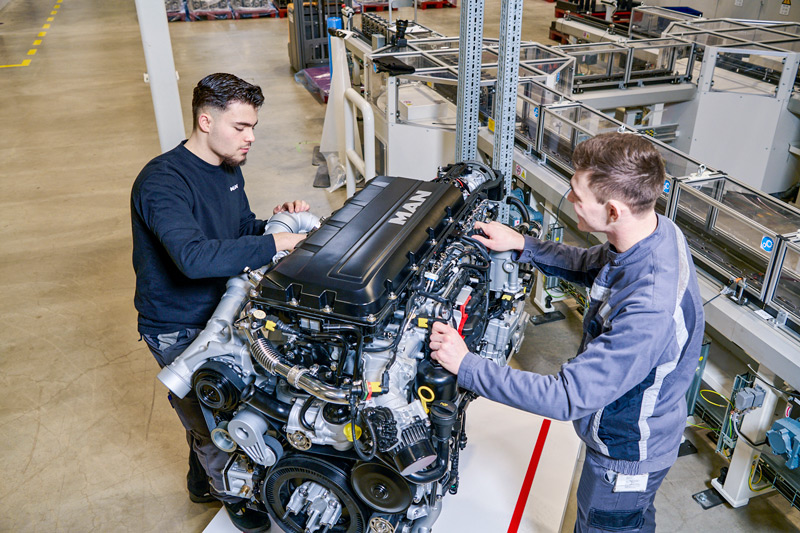

At commercial vehicle manufacturer MAN Truck & Bus’s Nuremberg plant, production of an ultra-efficient new 13-litre diesel engine has begun. As a joint engine platform, it is intended for use across the group. Fine boring tools from MAPAL are used for the cylinder heads. These machine valve guide and valve seat blind bores.

An engine for all brands

MAN has invested around EUR 220 million in the production of the new engine, which will see up to 160 highly qualified employees work in three-shift operation. Technical capacity enables production of around 50,000 engines per year. “The actual production volume is based on demand. Whether this is used to its full potential is ultimately decided by the customers”, says Singer. They have been somewhat reserved in recent years. For commercial vehicles, like for passenger cars, discussions on the shift to the electric drive have also caused uncertainty. As production starts up, work will initially be carried out in one shift.

MAN has been working with MAPAL for decades. When tendering for the D30 project took place in 2019, the Aalen-based tool manufacturer was again awarded the contract for the fine machining of the valve guide and valve seat bore. This was down to the years of shared experience and a recommendation from the machinery manufacturer Grob, which is responsible for the complete process and tool design.

The engine’s six cylinders each have two inlet and outlet valves. This means 24 bores must be drilled into the cylinder head bank. As the inlet and outlet diameters vary, tools of different sizes are required for their machining. Machining takes place on a double-spindle machine. It is embedded in a linked system with individual Grob machines that are loaded using linear gantries.

Proven technology produces reliable process

A further tool manufacturer was entrusted with fine machining in the project’s initial phase. As a stable and cost-efficient process was not possible with its tools, however, MAN ultimately shifted its full focus to the collaboration with MAPAL. The Aalen-based company’s first contribution was a fine machining system which has run on many machines in two production halls at MAN for many years. In close coordination with the client, however, the partners continued to develop the system and achieved significant progress.

Singer hails the achievements: “The machining changed fundamentally. For instance, we saved a semi-cut and were able to do without pilot friction. Instead, we simply moved to our pre-machined diameters with the indexable insert tool, ensured a good bore entrance for the reamer, and then ultimately reamed through once. Experience helped us design the process in the best possible way.” The production concept achieved a good machining quality and complied with the specified cycle time of around five minutes in total for fine machining of the valve seat and valve guide. The desired reliable and economical process was achieved. “This was accomplished despite the increased quality requirements for manufacturing the new engine”, says Markus Meyer, who works closely with MAN as a technical consultant at MAPAL. For the valve and both valve seat blind bores, the tolerances are less than 20 µm. A tolerance of approximately 50 µm must be maintained from the seat to the guide. There must be no offset between the valve seat and the valve guide that could lead to undesirable shear forces. The surface finishes required are specified at an Rz of less than 20 µm. The cylinder head bank consists of GJV 450 cast iron into which more wear-resistant materials for the valves are pressed in the form of a ring and a guide.

Modern technology reduces unit costs further

However, a series of joint workshops had further improvements in its sights, particularly with regard to unit costs. The aim was to reduce them further before series production began. MAPAL and MAN achieved significant improvements together through their professional partnership.

Simplifying tool handling provided the necessary leverage to lower costs per part – specifically the reduction of configuration time, making things simpler for the operator. For this purpose, MAPAL brought its EA (EasyAdjust) system into play. It was installed for the valve seat tool. In this system, the back taper on the blade is already integrated into the cassette, which acts as the connection for the insert. This feature completely eliminates the need to set the back taper on the minor cutting edge. Only the diameter needs to be adjusted. Thomas Teuber, Head of Product and Application Management Fineboring at MAPAL, summarises the practical benefit: “The operator no longer needs to keep an eye on two dial gauges. They can focus on just one dial gauge, which they can use to adjust the insert’s protrusion compared to the guide pads. That’s much faster.” The EA system also involves an improvement in the inserts: The TEC indexable inserts used in the EA system have four cutting edges, i.e. twice as many as a conventional MAPAL reaming inserts. An optimised cutting material and innovative coating increase tool life and ensure an even more reliable process.

The modifications proved effective: In comparison to the original machining concept, valve seat and valve guide machining costs were reduced by around 40%. “I’m very happy with the milestone that has been achieved”, says Singer, singling out the effective partnership with MAPAL for praise. The ambitious process planner aims to keep pushing forward with the continuous process of improvement.

The assumption at MAN is that the D30 will be the company’s last entirely newly developed diesel commercial vehicle engine – after over 100 years of diesel engine construction at the Nuremberg site. As of 2030, every second vehicle delivered to customers should have an emissions-free drive.

Contact

Mathias Ostertag Public Relations mathias.ostertag@mapal.com Phone: +49 7361 585 3566