Empower Your Aluminium Machining

L'ingénierie, la clé du succès

Fort de plusieurs décennies d'expérience en matière de conception, de production et d'utilisation d'outils pour l'usinage de l'aluminium, MAPAL est le partenaire technologique leader en matière d'usinage des composants en aluminium. Afin d'offrir des processus d'usinage optimaux à ses clients, MAPAL leur propose son expertise du marché, des matériaux et de l'ingénierie, en plus d'une gamme complète de produits et d'applications. Ce n'est qu'en favorisant l'interaction de tous les facteurs d'influence et une collaboration basée sur des partenariats qu'il devient possible d'exploiter pleinement le potentiel d'un processus d'usinage – tels sont les fondements de l'ingénierie chez MAPAL.

Focus on the customer

Industries and components

Challenges of aluminium machining

Products and applications

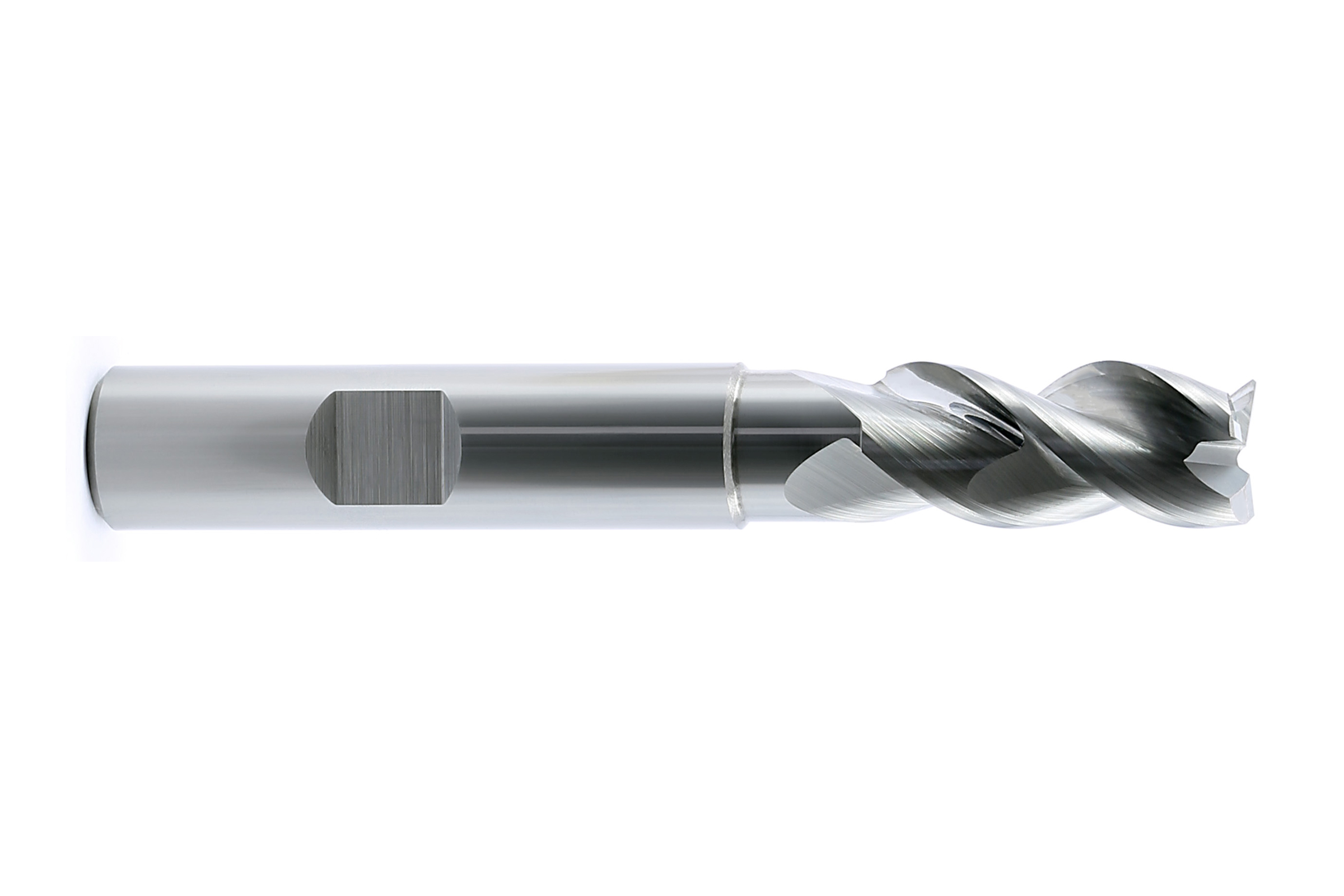

Milling with solid carbide

Milling with PCD

Milling with indexable inserts

Drilling

Reaming

Clamping

Examples from practice

MAPAL Services

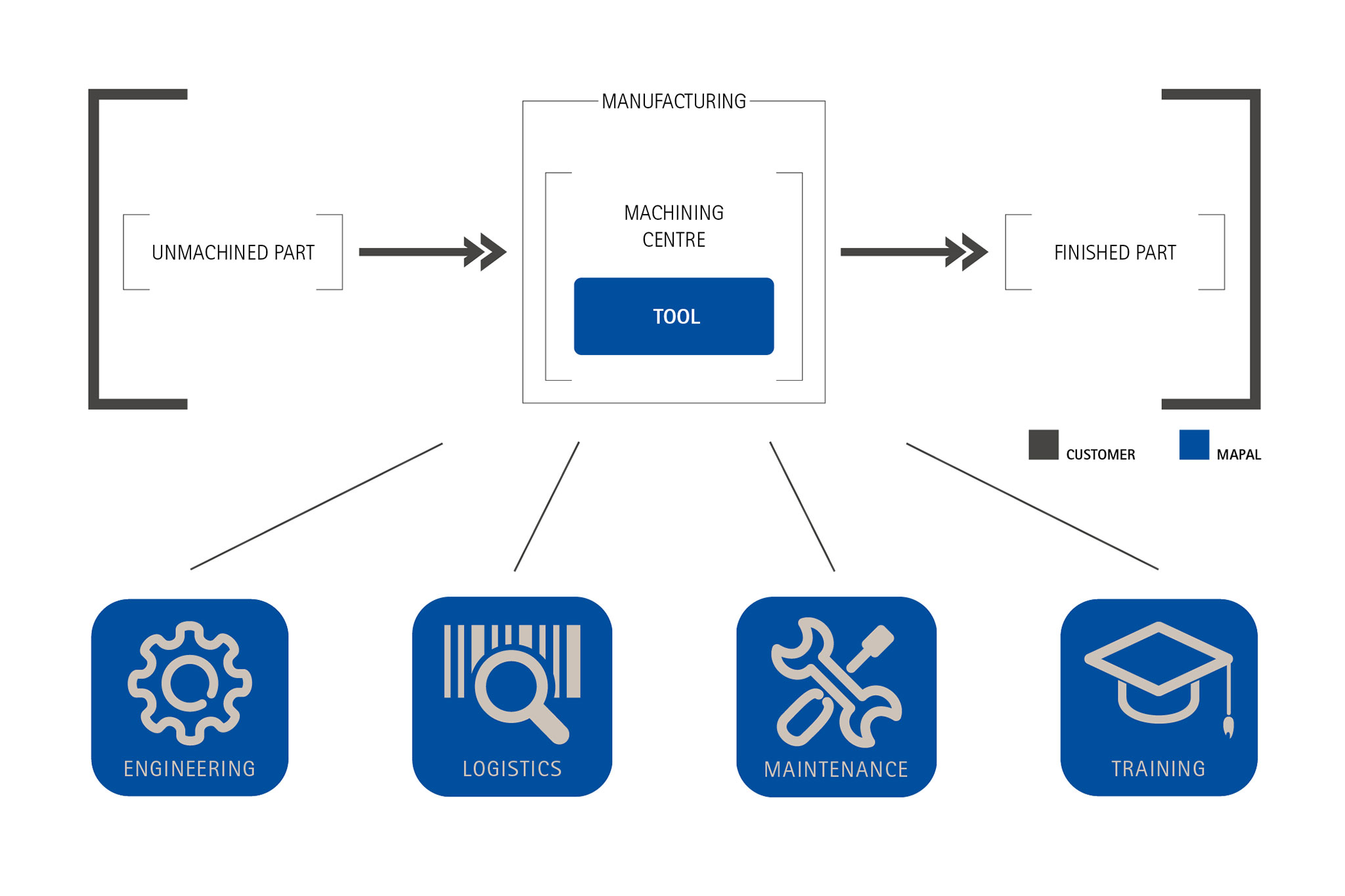

With the engineering service module, MAPAL guarantees fast, precise and safe manufacturing. Further savings potential can be tapped in the area of logistics and maintenance. And in the area of training, MAPAL ensures that the specialist know-how it has gathered is transparently and completely available to the customer – this gives customers a decisive lead over their competitors.

All of the services offered by MAPAL focus on optimal processes and comprehensive support on the way to Industry 4.0. The goal is to always significantly assist the customer in achieving smooth, productive and economical manufacturing.

Advantages:

- Solutions for complete workpieces including tools, devices, NC programs and commissioning

- Complete process design and implementation from a single source

- Fast and flexible on-site support worldwide

- Efficient and cost-optimised tool technology

- Optimum coordination of tool, workpiece, equipment and machine

- Highest product quality, process reliability and cost-effectiveness right from the start

- Fast throughput from planning to implementation with maximum planning security

/-P3A1692-1-.jpg)