Entraînements électriques

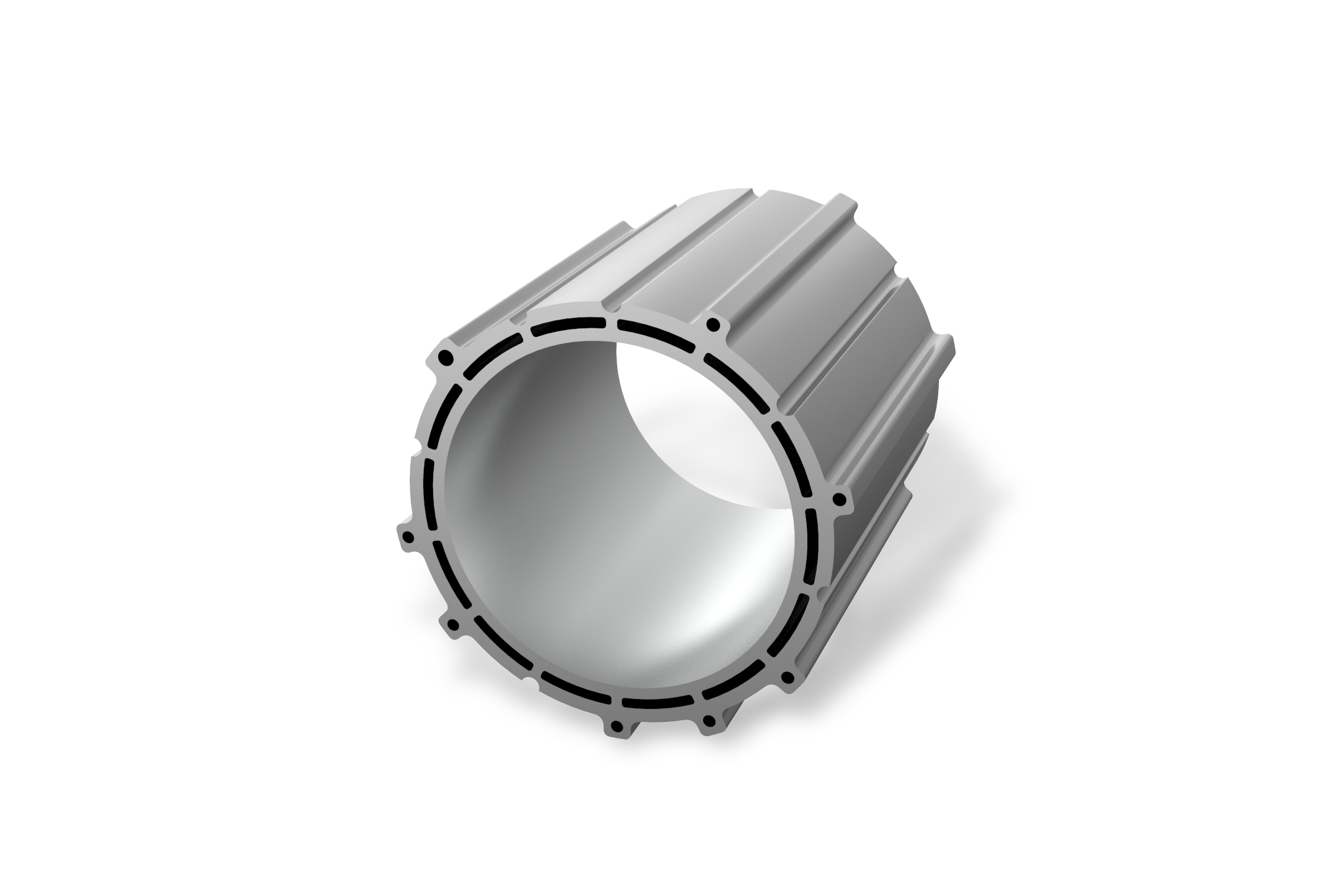

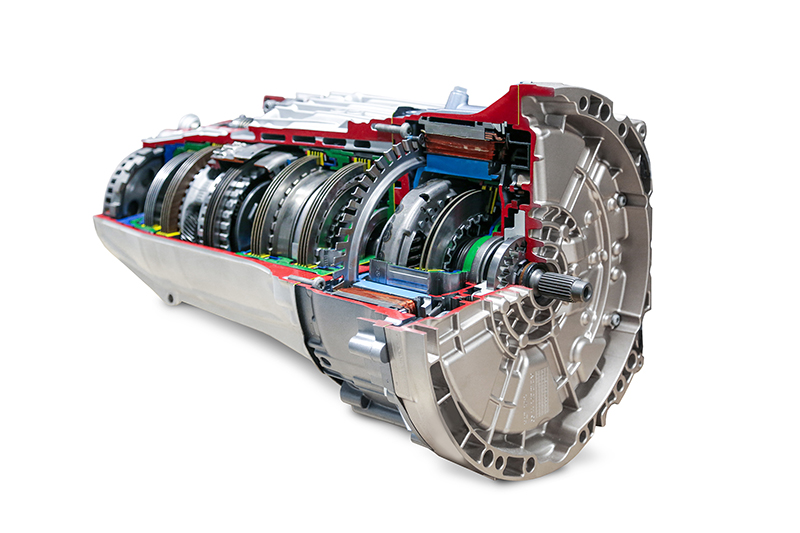

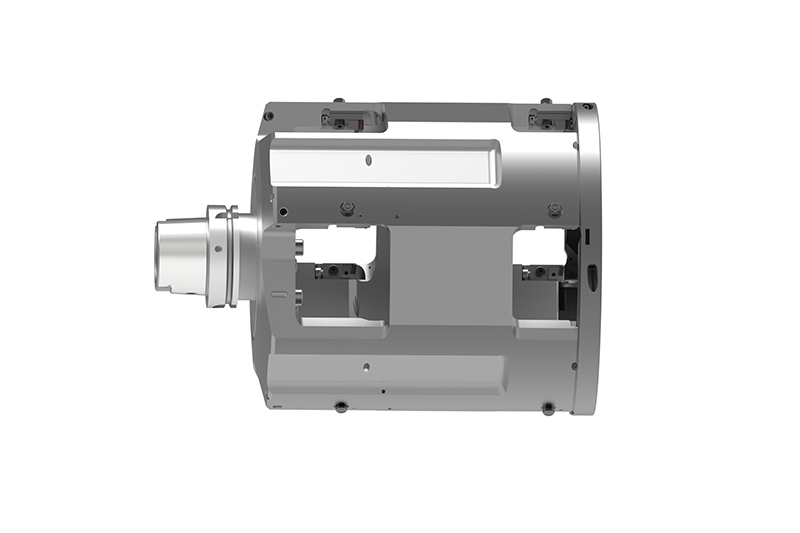

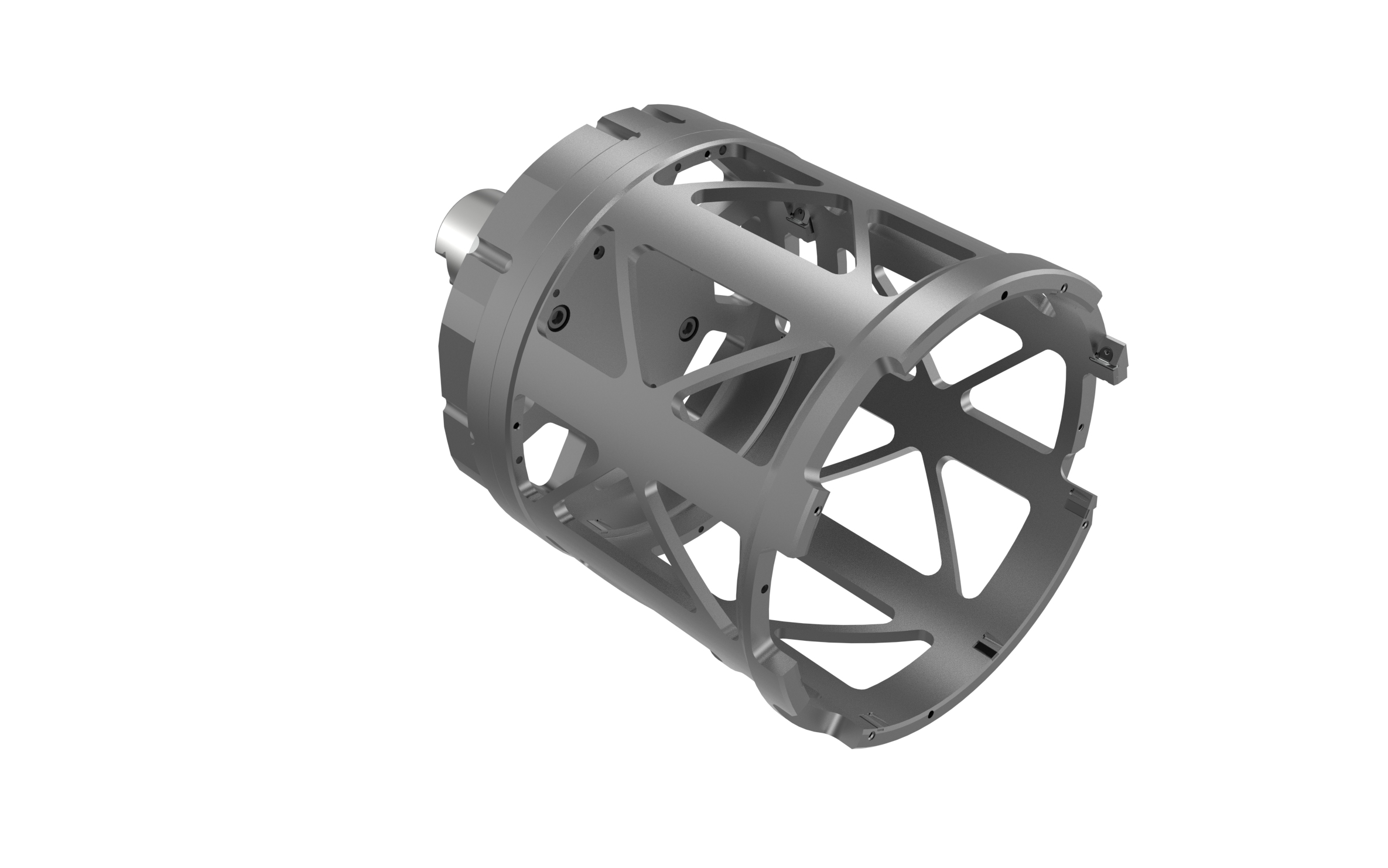

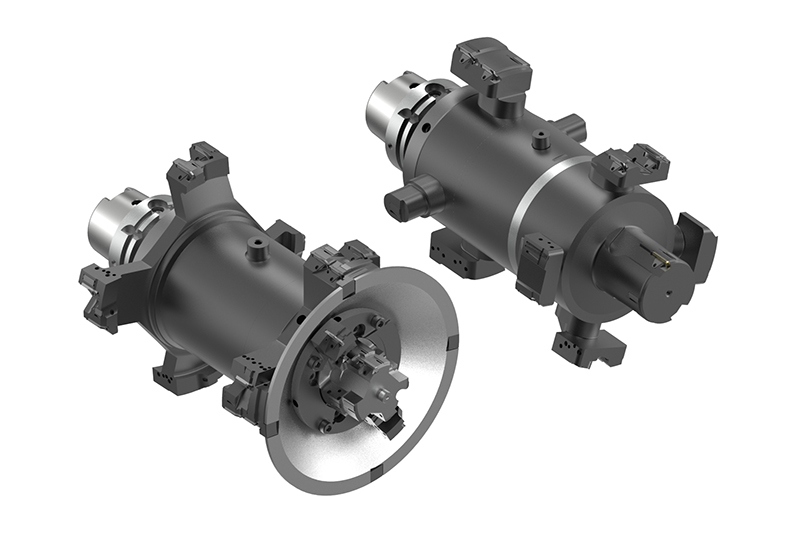

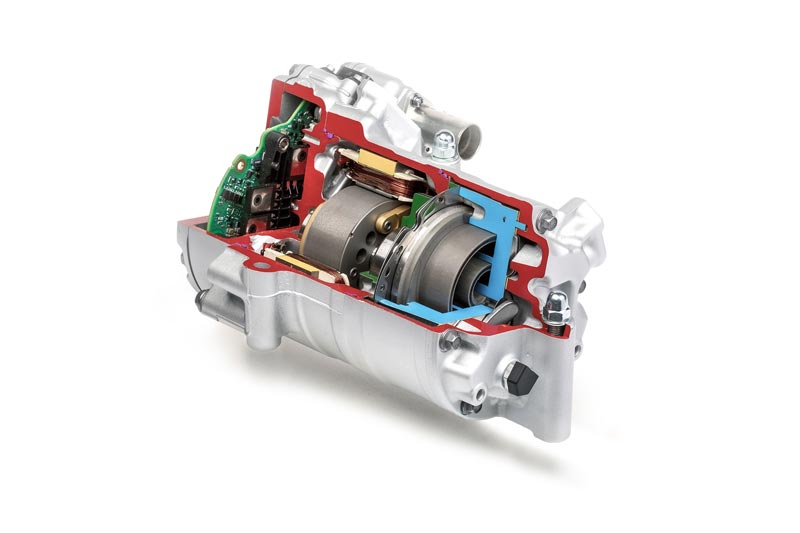

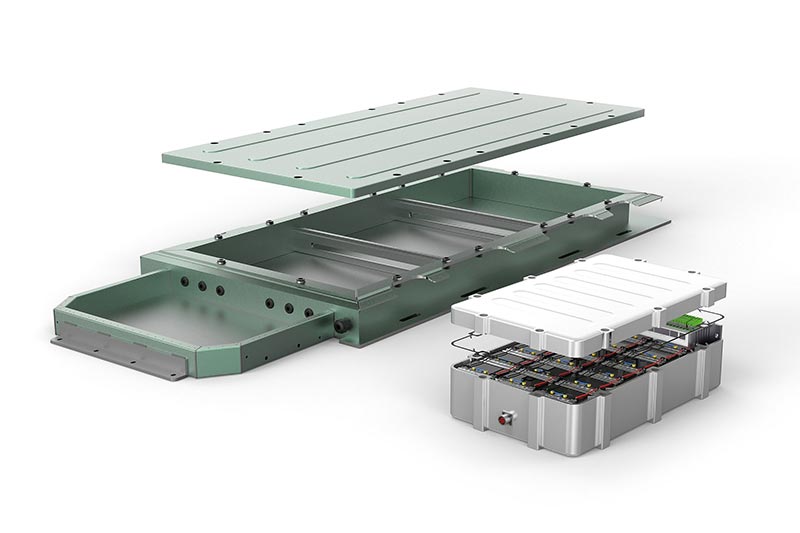

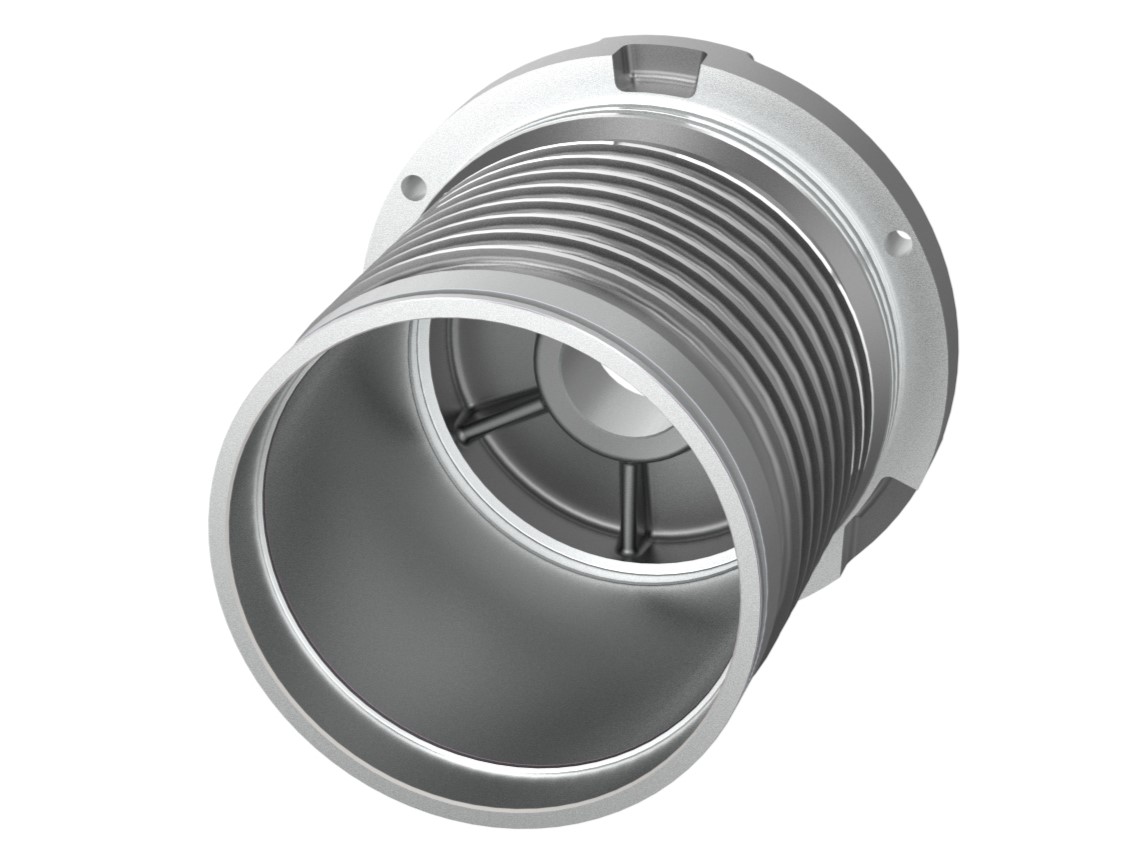

Les constructeurs et fournisseurs automobiles sont confrontés à de nouveaux défis concernant les composants pour moteurs électriques. Le boîtier d'un moteur électrique constitue un exemple de la complexité de ces défis : par rapport à un carter de boîte de vitesses, celui-ci doit être fabriqué dans des tolérances beaucoup plus restreintes, car la précision a une influence décisive sur le rendement du moteur électrique.

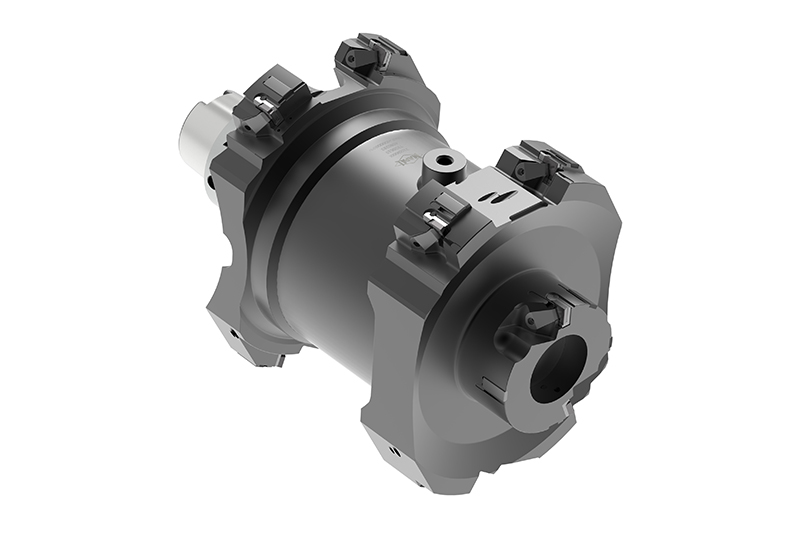

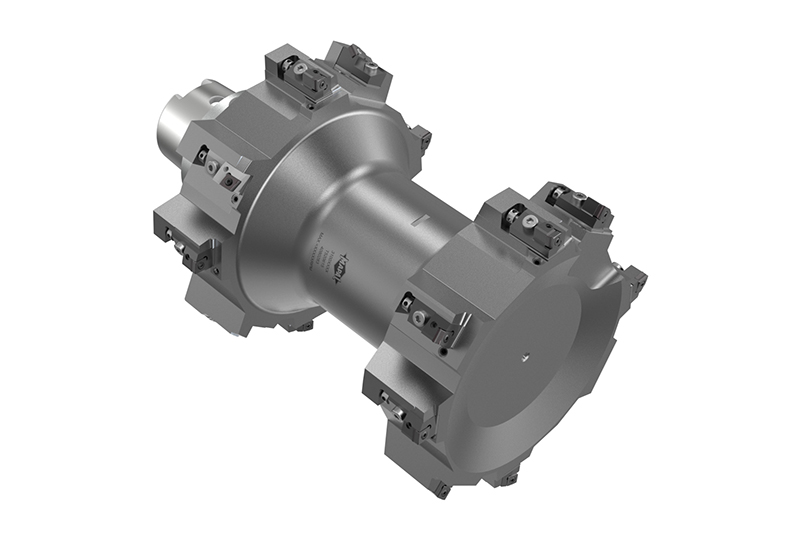

De plus, les parois d'un boîtier de moteur électrique sont généralement nettement plus minces que celles d'un carter de boîte de vitesses du fait de sa conception spécifique (canaux de refroidissement intégrés, par exemple). En outre, des coussinets de palier en acier sont pressés dans certains de ces boîtiers. Des boucliers de protection spéciaux dans l'outil empêchent les copeaux d'acier d'entrer en contact avec les surfaces en aluminium lors de l'usinage et de les endommager.

Exigences d'usinage et caractéristiques des différents types de boîtier

Procédure de base pour l'usinage de boîtiers de stator

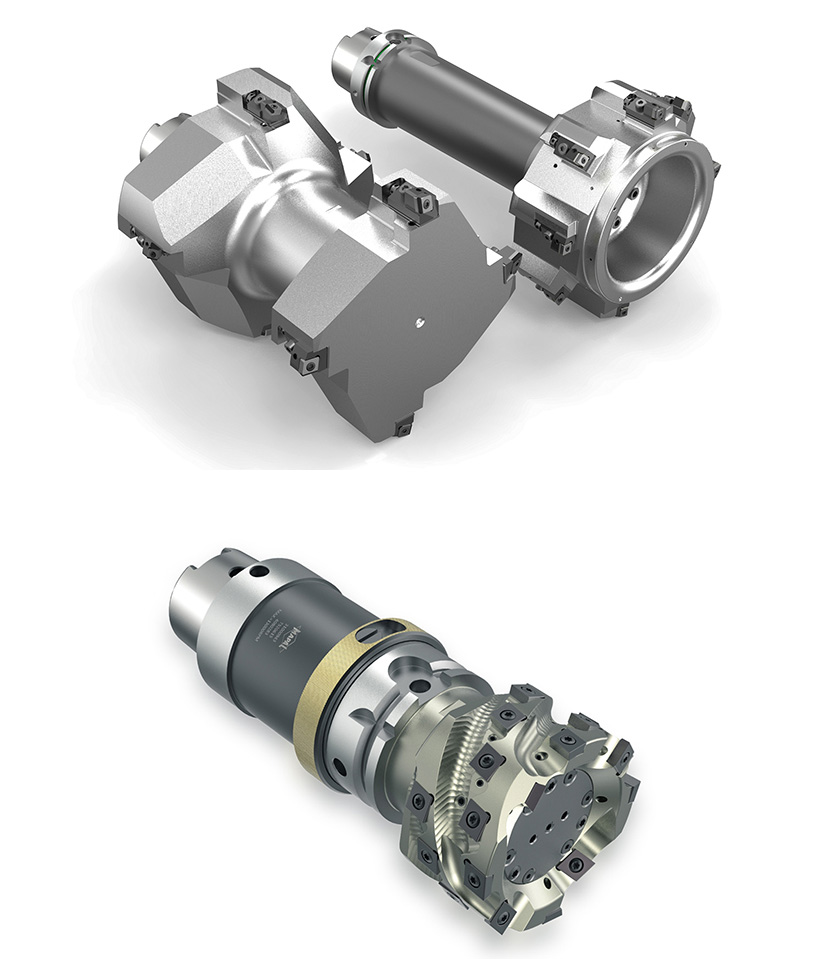

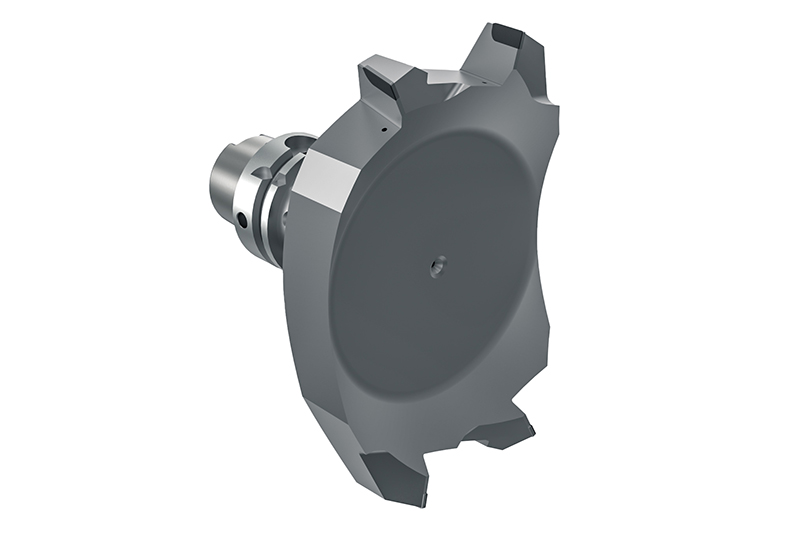

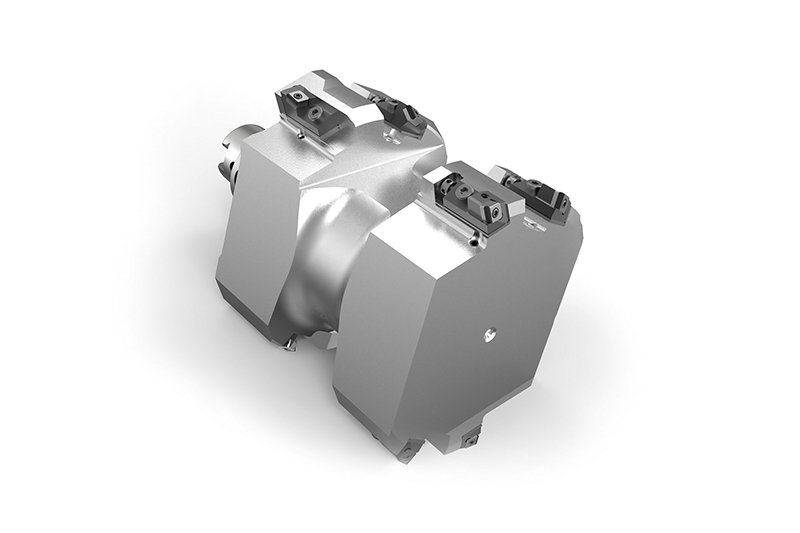

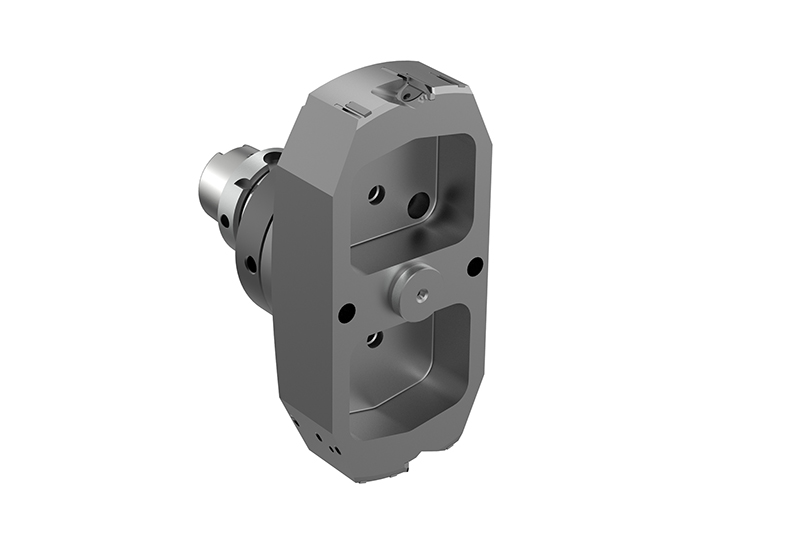

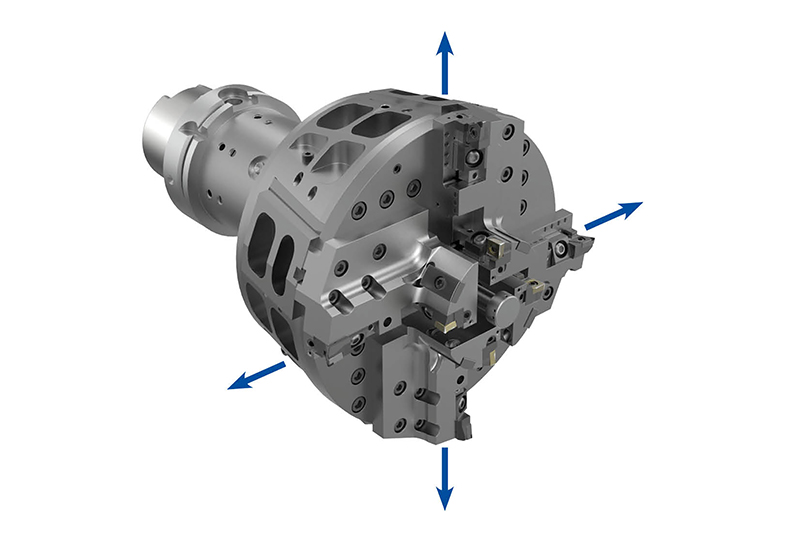

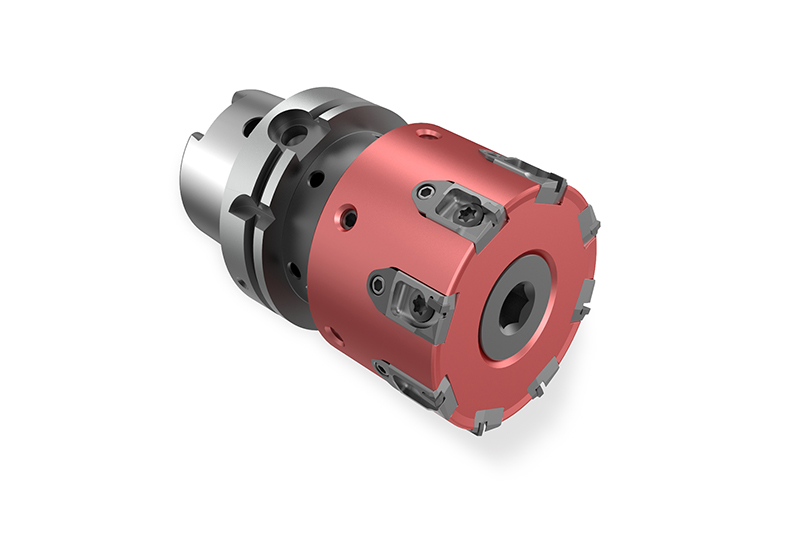

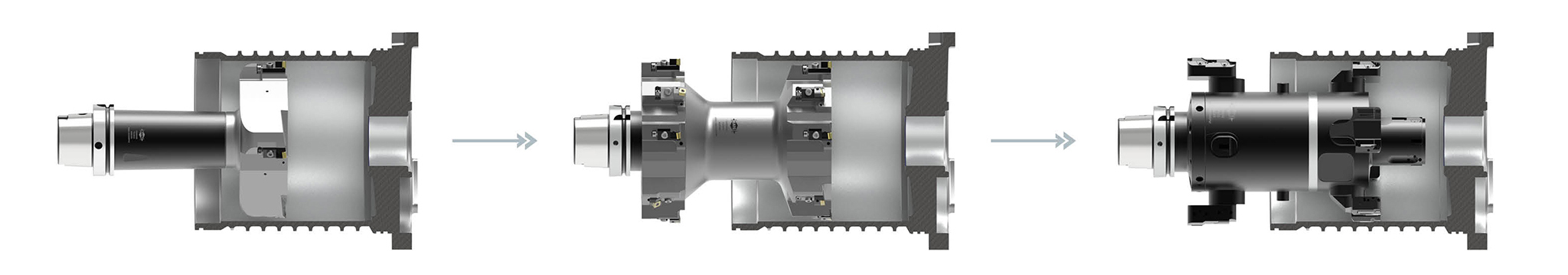

Le processus d'usinage ainsi que les outils sont conçus individuellement en fonction de la configuration dimensionnelle, du parc de machines et de la fixation d'outils. Les forces de coupe agissant sur le composant sont donc réduites au maximum. L'usinage de l'alésage du stator est divisé en trois étapes : pré-usinage, usinage de semi-finition et usinage final.

Lavorazione esterna del corpo statore

Soluzioni di asportazione truciolo per…