油圧

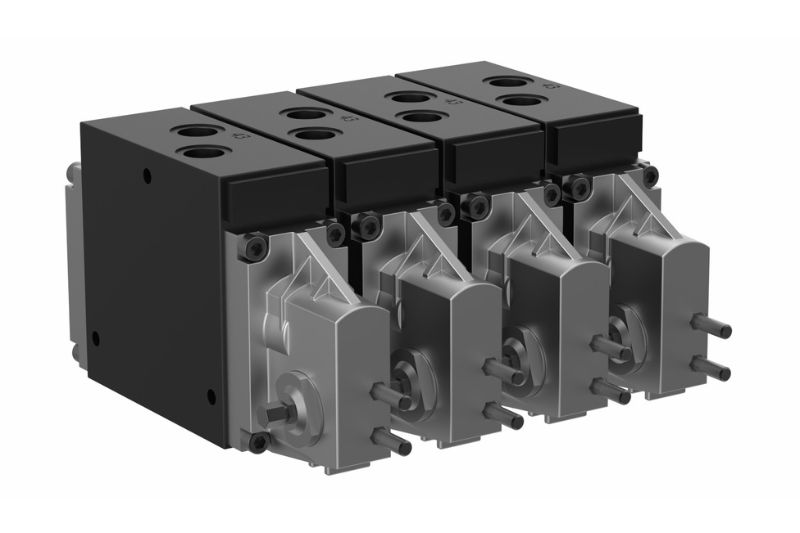

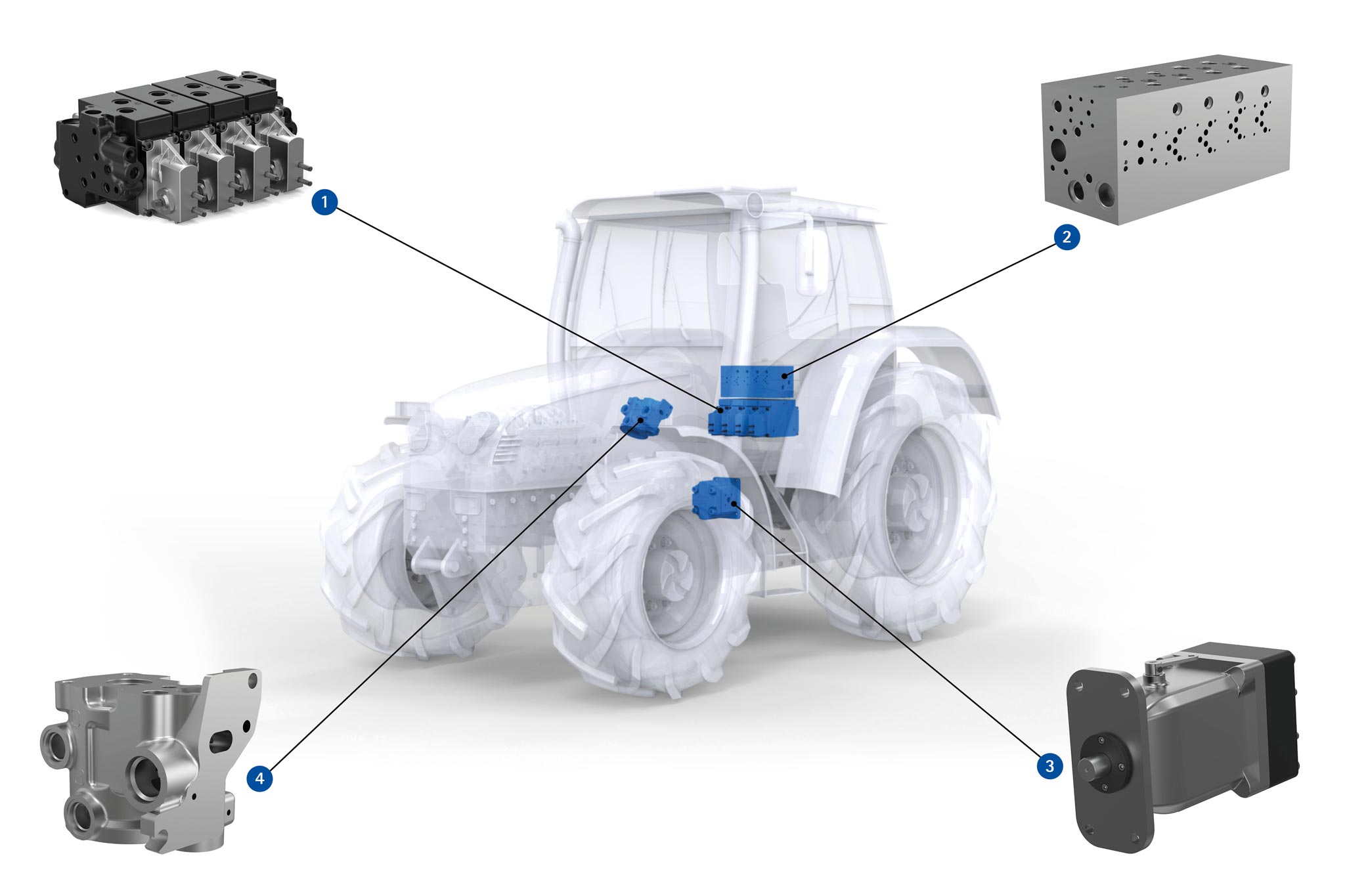

- (1) 油圧バルブハウジング

-

油圧バルブハウジングの加工ソリューション

すべてはメイン穴の加工品質に依存します。流体技術部品の加工において、バルブケースの製造は、最も高い精度が要求される分野です。ここでは長年にわたってマパールのスプール穴加工に関する技術ノウハウが必要とされてきました。スプールとスプール穴のギャップは、加工穴の精度に左右され、作動油は一定の方向にしか流れないようになっています。

最近の油圧バルブ穴は、加工公差の幅が非常に狭くなっています。そのため、加工穴の真円度、真直度、円筒度、仕上げ面精度はきわめて重要になっています。基本手順 - 加工工程の分析

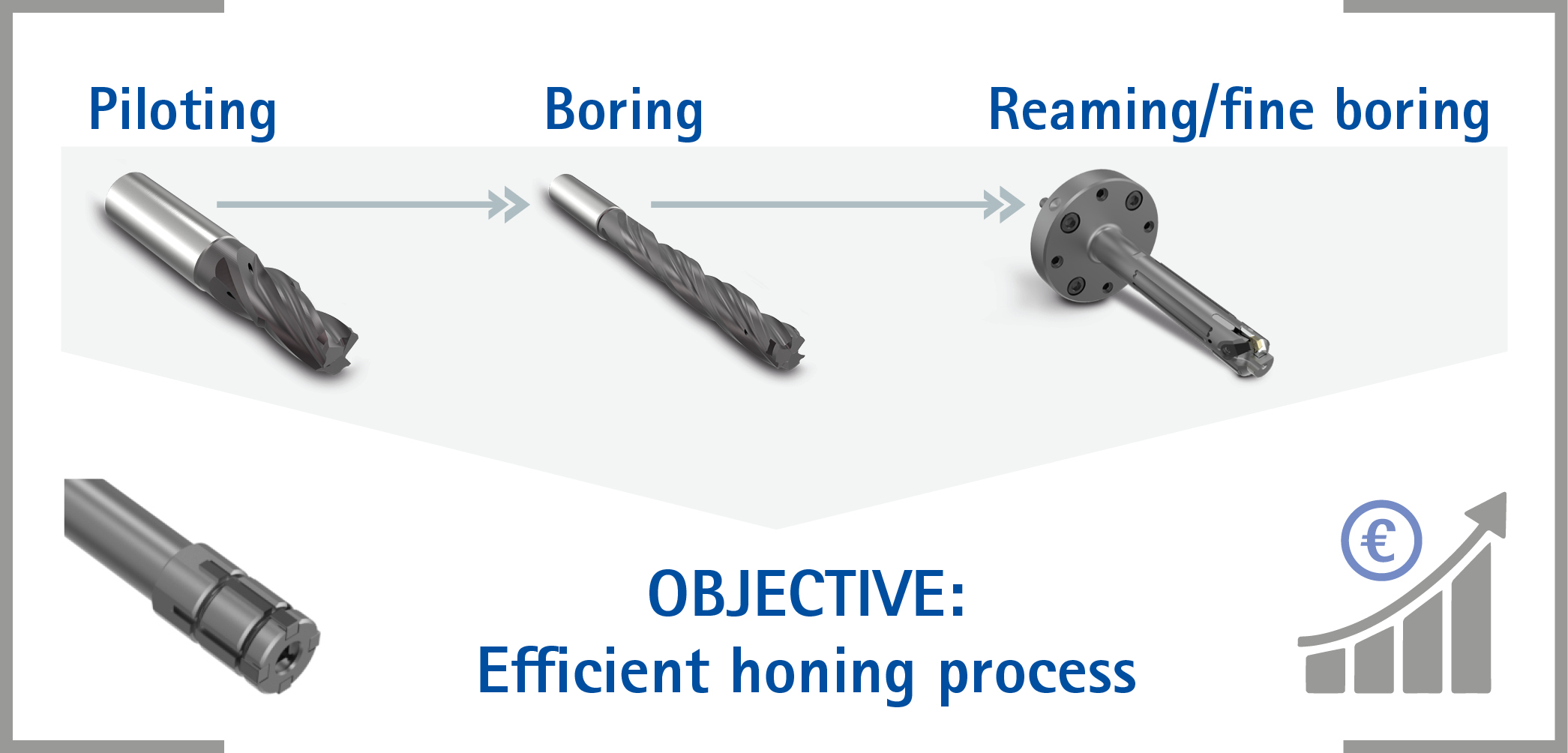

マパールは技術パートナーとして、プロセス設計全般においてお客様をサポートします。その際、エキスパートは機能に重要な穴加工によく見られるコスト要因に特に注意を払います。 ホーニング、加工ワークの要求項目、バッチサイズに基づき、マパールはお客様との対話の中で最適な加工戦略を設計します。1つの目標がすべての活動を結び付けます: パイロット穴加工から始まり、ボーリング、中仕上げ加工を経て、効率的なホーニング加工に到るまで、経済的なプロセスを設計します。 - (2) コントロールブロック

-

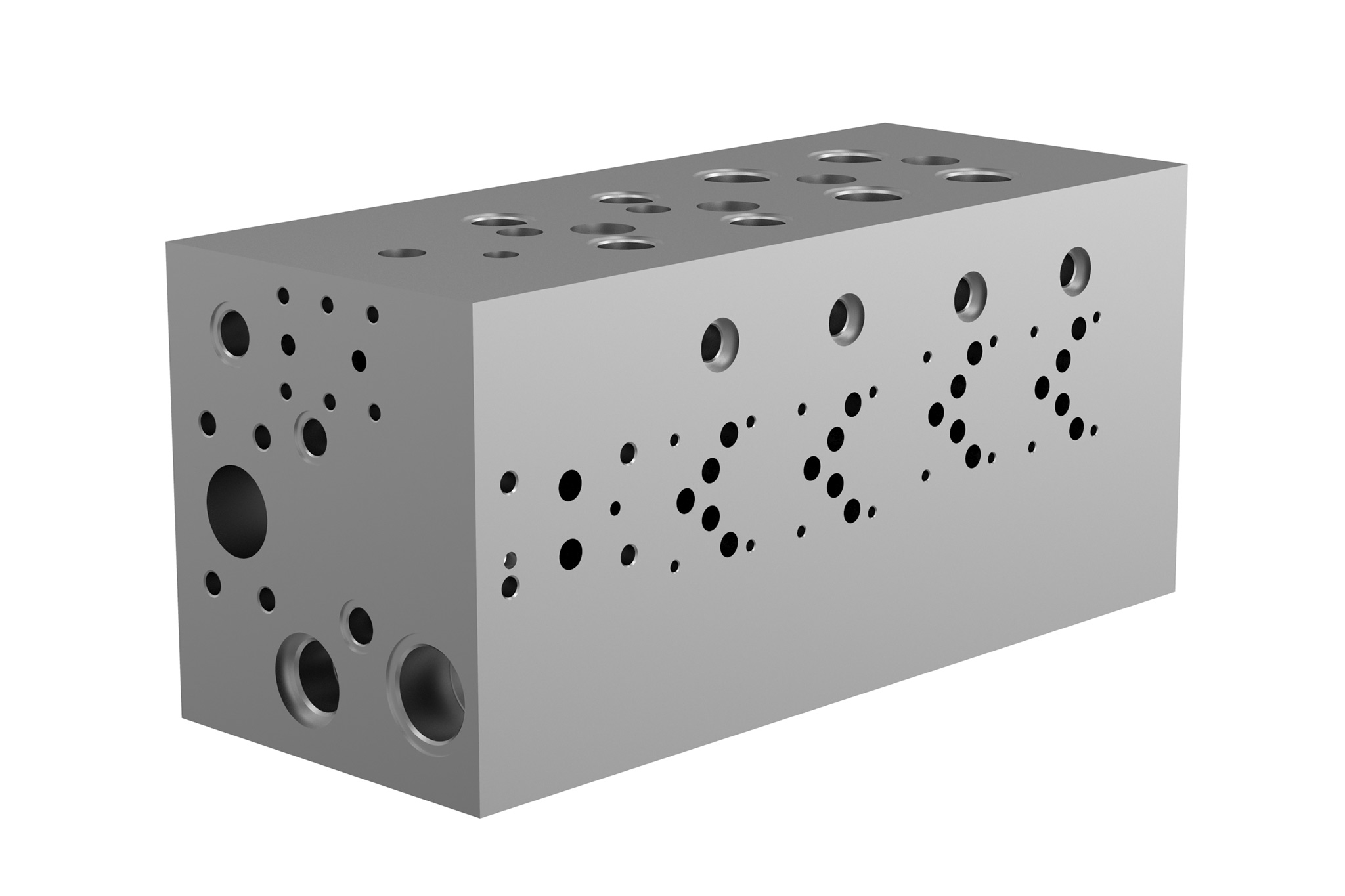

Steuerblock

Der Hydrauliksteuerblock dient als Schnittstelle für diverse Ventile und Steuerkomponenten. Diese werden ein-, oder angebaut und im Zusammenspiel dient der Steuerblock als Regel- bzw. Verteilsystem in hydraulischen Kreisläufen.

Grundlegende Vorgehensweise – Analyse des Bearbeitungsprozesses

Als Technologiepartner unterstützt MAPAL den Kunden bei der kompletten Prozessgestaltung. Dabei achten die Experten besonders auf die Kostentreiber, die oftmals in den funktionsrelevanten Bohrungen vorzufinden sind. Ausgehend vom jeweiligen Honverfahren, den Bauteilanforderungen und Losgrößen, gestaltet MAPAL im Dialog mit den Kunden, die perfekte Bearbeitungsstrategie.

Ein Ziel vereint alle Aktivitäten: den wirtschaftlichsten Prozess, beginnend beim Pilotieren über das Aufbohren und die Semi-Finish-Bearbeitung bis hin zum effizienten Honprozess auszulegen.

- (3) Axialkolbenmaschine

-

Axialkolbenmaschine

Unter dem Begriff Axialkolbenmaschine werden Axialkolbenpumpe und –motor zusammengefasst. Die Axialkolbenpumpe setzt mechanische Energie in hydraulische Energie um während der Axialkolbenmotor hydraulische Energie in mechanische Energie umwandelt.

Axialkolbenmaschinen zeichnen sich durch große Stabilität und gute innere Abdichtung aus, wodurch hohe Drücke möglich sind.

Grundlegende Vorgehensweise – Analyse des Bearbeitungsprozesses

Als Technologiepartner unterstützt MAPAL den Kunden bei der kompletten Prozessgestaltung. Dabei achten die Experten besonders auf die Kostentreiber, die oftmals in den funktionsrelevanten Bohrungen vorzufinden sind. Ausgehend vom jeweiligen Honverfahren, den Bauteilanforderungen und Losgrößen, gestaltet MAPAL im Dialog mit den Kunden, die perfekte Bearbeitungsstrategie.

Ein Ziel vereint alle Aktivitäten: den wirtschaftlichsten Prozess, beginnend beim Pilotieren über das Aufbohren und die Semi-Finish-Bearbeitung bis hin zum effizienten Honprozess auszulegen.

- (4) Lenkorbitrol

-

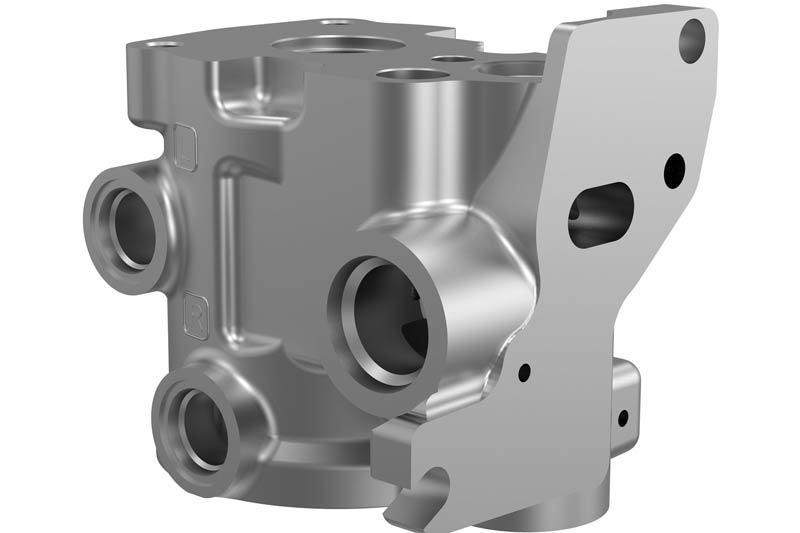

Lenkorbitrol

Das Lenkorbitrol ist das zentrale Steuerelement hydrostatischer Lenkungen. Der von einer Hydraulikpumpe geförderte Volumenstrom wird entsprechend der Bewegung am Lenkrad in die Arbeitsräume eines Hydraulikzylinders geleitet, der die Achsschenkellenkung betätigt. Für die dauerhafte Funktion der Lenkungen wird ein Prioritätsventil eingesetzt.

Grundlegende Vorgehensweise – Analyse des Bearbeitungsprozesses

Als Technologiepartner unterstützt MAPAL den Kunden bei der kompletten Prozessgestaltung. Dabei achten die Experten besonders auf die Kostentreiber, die oftmals in den funktionsrelevanten Bohrungen vorzufinden sind. Ausgehend vom jeweiligen Honverfahren, den Bauteilanforderungen und Losgrößen, gestaltet MAPAL im Dialog mit den Kunden, die perfekte Bearbeitungsstrategie.Ein Ziel vereint alle Aktivitäten: den wirtschaftlichsten Prozess, beginnend beim Pilotieren über das Aufbohren und die Semi-Finish-Bearbeitung bis hin zum effizienten Honprozess auszulegen.