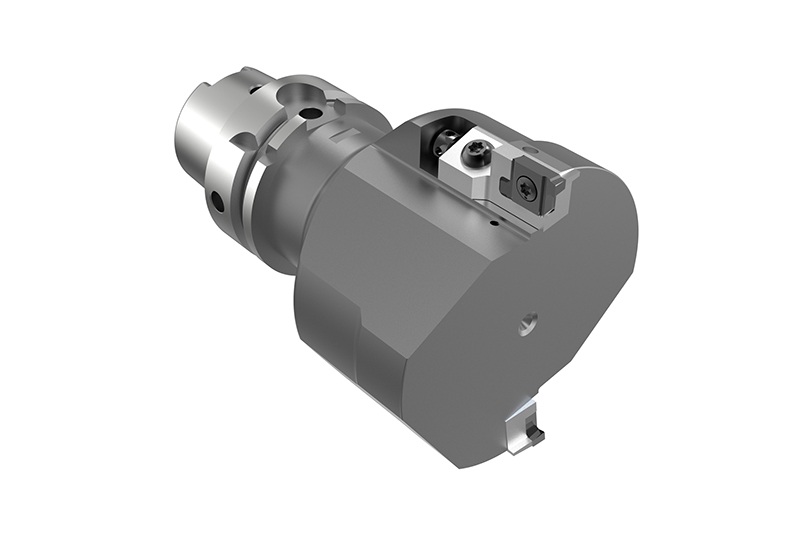

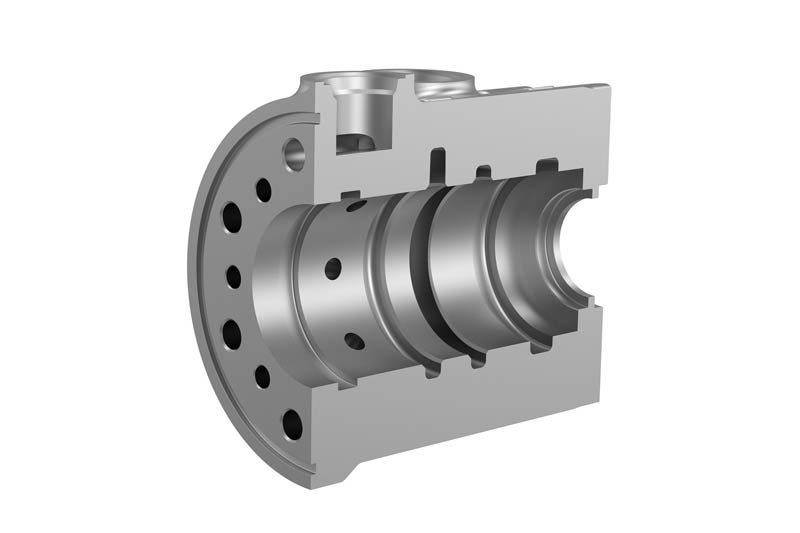

Orbitrol de direction

Orbitrol de direction boîtier GG25

Situation initiale du client

- Petites à moyennes quantités de pièces

- Coûts d’outils élevés

- Coûts élevés pour les pierrages suivants

Particularités de la solution

- Outils combinés étagés → Changement d'outils et donc des coûts de processus et une durée d'usinage réduits

- Renouvellement rapide des arêtes de coupe par remplacement simple des plaquettes amovibles

- Différents matériaux pouvant être usinés avec un seul corps d'outil → Solutions de plaquettes amovibles permettant une flexibilité maximale pour les petits lots

Alésage de tiroir

Alésage de raccordement

Rainure de joints toriques

![ANNUAL TOOL COSTS SPOOL BORE [€]*](/medias/sys_master/root/hc4/h36/9175133356062/Grafiken__EN4/Grafiken-EN4.jpg)

Avantages

- Processus de pierrage coûteux dans l'alésage de tiroir grâce à une ébauche idéale

- Coûts d'outillage des composants de grandes dimensions considérablement réduits

- Les solutions d'outils peuvent être utilisées sans difficulté dans d'autres composants de l'unité de direction lorsque les pièces varient beaucoup

![MANUFACTURING COSTS PER SPOOL BORE [€]*](/medias/sys_master/root/h83/h3a/9175133487134/Grafiken__EN5/Grafiken-EN5.jpg)