15.12.2021

Optimisation in mould making

Flexibility and productivity with solid carbide tools

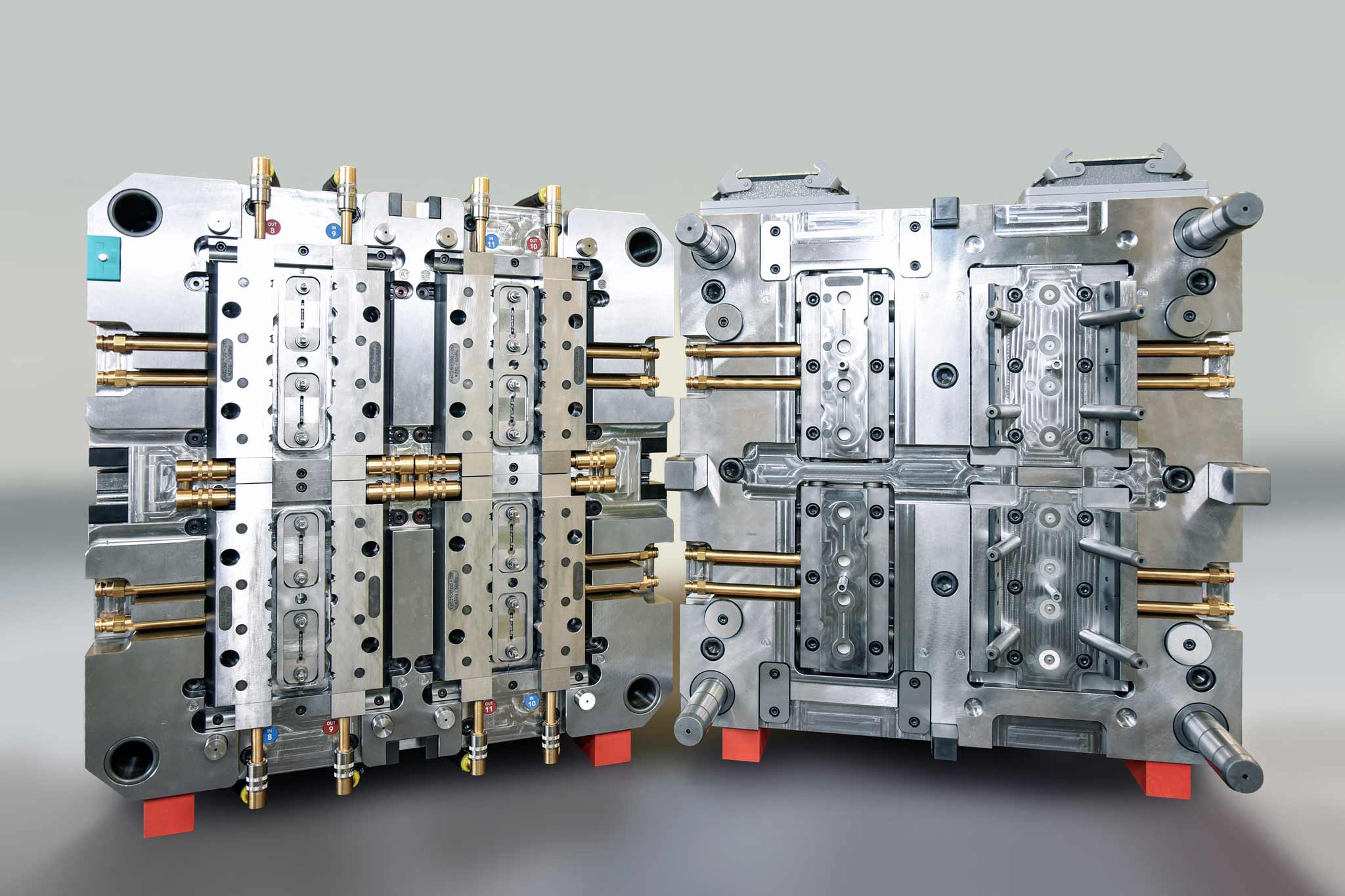

In the space of six years, Marco Schülken has thoroughly transformed the Thuringian toolmaking company he took over in 2015. With his 30 employees, he was able to attract customers in various sectors and enter new markets, including the ones abroad. MAPAL came into play when looking at optimising production processes.

The predecessor company Ralf Grübel Werkzeugbau GmbH was a third-generation owner-managed company from Walterhausen in Thuringia, which Marco Schülken was able to take over as part of a regulated succession. By changing the company name to Schülken Form GmbH, the new owner made it clear that the new brand would also bring a breath of fresh air to this long-established die and mould making company.

In the past, Grübel supplied more than 90 percent of its products to the automotive industry. Marco Schülken has successfully abandoned this lopsided focus. The automotive share is currently less than 25 percent. Today, Schülken Form‘s main clients are companies in medical technology and packaging industries. In the medical sector, the Thuringians boast a strong position in the area of injection moulds for pipettes and blood lancets. Lancets are lancing aids for diabetics. However, now they are also being used for coronavirus tests.

Putting everything to the test

In addition to the focus on new markets, Schülken Form also underwent extensive internal restructuring. “We’ve looked at almost every machine and every process in the company and have invested a lot in this”, the Managing Director reports. Manufacturing Manager Marcus Vogt was involved in this restructuring process from the very beginning, and he is constantly asking himself how the company’s performance can be further improved. While there are always new developments in wire eroding or die-sinking eroding, milling is the fastest-moving machining technology. “You have to be constantly searching for ways to change and improve things”, says Vogt.

The Grübel company had already realised the importance of good machines and used only Hermle machining centres for milling. However, this classic tool shop still operated more like a craftsman’s establishment. The employees created their programmes directly on the machines themselves. Vogt saw an urgent need for action here: “Before we tackled the milling tools, we revised the entire process chain. We set up programming workstations and switched the whole manufacturing process to a new system.”

Hard milling adds flexibility

The next step was to approach the actual technology with the key question of how the parts could best be machined. “The classic way in toolmaking is, after all, either pre-milling, hardening and subsequent grinding or die-sinking EDM”, says Vogt, describing the initial situation. In order to make production more flexible depending on the manufacturing workload, Schülken has added hard milling. Although parts are still manufactured using the traditional method in Waltershausen, starting the milling process immediately after hardening no longer poses a problem, especially when things have to move quickly. “Today, we’ve reached the point where we can choose a lot of machining operations according to the workload of the individual departments,” Marcus Vogt enthuses.

This was not the end of the optimisation measures, though. When Schülken Form was looking for new milling tools for high-feed roughing, it was around the time that MAPAL began to enter the Die & Mould sector. Similar to Schülken, the precision tool manufacturer from Aalen had set itself the goal of reducing its dependence on the automotive industry by exploring other sectors.

Toolmaking in transition

Unlike the automotive industry where MAPAL has been very successful for many years, particularly with custom tools for large quantities, the requirements of the Die & Mould sector initially appear to be quite different. The focus here is always on individual pieces or small batches, which need to be machined with standard tools as far as possible, so that the companies can process a wide range of orders with these. However, a change has also begun in classic toolmaking, and this is already clearly visible at Schülken Form.

“The trend is towards industrial toolmaking”, Marcus Vogt sums it up. “In the past, all we cared about was releasing a decent part. Nowadays, we also have to look at the times.” Digitalisation and automation are also filtering into the Die & Mould sector. Vogt schedules the manufacture of all parts for each department with a specific time in advance. It may not be a matter of seconds, but it is still a matter of minutes. Process reliability plays an increasingly important role when it comes to achieving the specified times.

The materials that have to be machined are becoming more and more challenging. Today, stainless steels with a chromium content of 13 percent are common, resulting in increased tool wear. The ductility of new powder-metallurgical steels also imposes a challenge. Here, dimensional accuracy and surface finish are important aspects.

Comparison delivers clear results

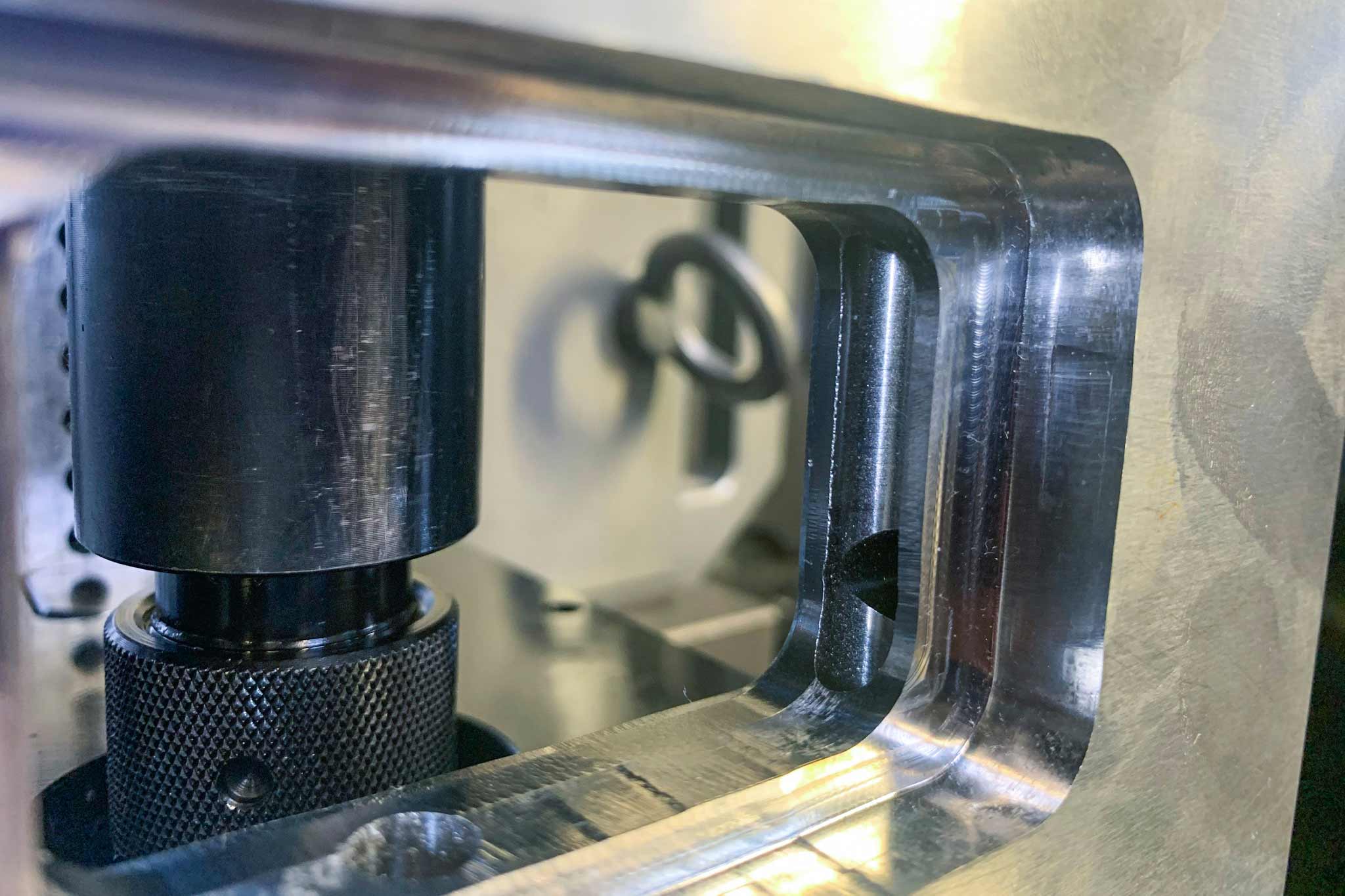

The bar was already high when Schülken tested the OptiMill-3D-HF-Hardened, the first MAPAL tool. Due to its special lens head geometry, this high-feed milling cutter made from solid carbide is suitable not just for roughing, but also for high-gloss finishing of planes in hardness up to 68 HRC. This matched Marcus Vogt’s requirements: “We don’t want a special tool for a special machining operation. I always choose tools that allow me to tackle several areas. These are exactly the kind of solid carbide tools that allow me to do both hard and soft roughing.”

The results achieved with the solid carbide high-feed milling cutter were immediately impressive, resulting in this roughing tool with its higher performance being included in Schülken’s standardised tool list instead of the previously used tool from another manufacturer. The Manufacturing Manager limits his tool set to 300 different types and claims to be able to meet all requirements with it – even though no two parts are the same. “From now on, we don’t use any other tool than MAPAL’s milling cutter for the corresponding applications,” says Vogt.

This also applies to the next tool Schülken subjected to a comparative test: the finishing milling cutter OptiMill-Hardened-Finish, which can finish up to 68 HRC surfaces with a 3xD ap material removal rate in one cut. Vogt describes how enthusiastic the machine operators are: “When it comes to finishing hardened high-alloy tool steel 1.2083, the milling cutter impressed greatly with superior surfaces and a long tool life. Among other things, small pockets are milled to fit with this tool.” After the two solid carbide milling cutters, Schülken is currently testing a high-feed milling cutter with indexable inserts: MAPAL’s NeoMill-4-HiFeed-90, whose positive cutting edges produce a soft cut.

The final frontier has been crossed

Availability of the tools makes all the difference

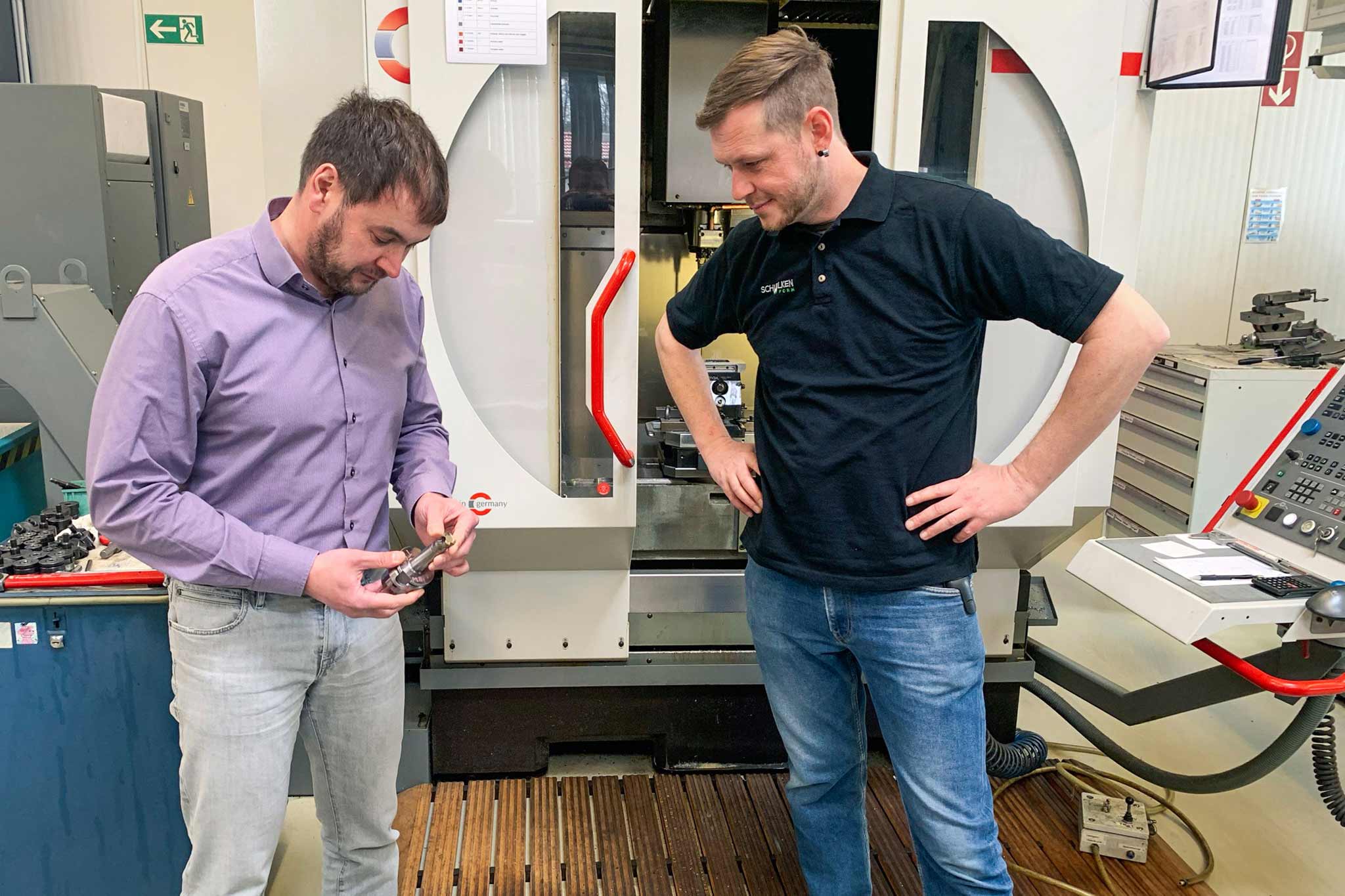

Schülken demands performance in more than just machining, as Vogt explains: “When it comes to selecting tool suppliers, we want the tools to be available immediately, and that if a problem ever arises, I want to have a contact person who knows what they’re talking about.” This contact person is Product Specialist Felix Wendler, who is responsible for the Die & Mould sector and is based at the MAPAL site in Meiningen. He considers it important to be on site with the customer, especially when testing new tools: “I like to hear how the tool sounds during machining. One can deduce a lot from that. When I see and feel surfaces, I can tell what needs to be changed to make it work better.”

MAPAL’s logistics concept ensures that the standard tools are quickly replenished. Of around 6,500 items that are in the catalogue for the Die & Mould sector, the majority are available within 24 hours. Somewhat more specialised dimensions can be delivered within five days. This is very convenient for Schülken Form, which has less and less time to produce its complex injection moulds.

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342