01.02.2024

More transparency one step at a time

c-Com at thyssenkrupp Presta AG Schönebeck GmbH

As an automotive supplier, thyssenkrupp is one of the world’s leading suppliers of steering systems. At its Schönebeck site near Magdeburg, 1.5 million parts are produced every year. In order to keep track of the tools involved, the manufacturer is using Lifecycle Management from c-Com.

The company’s headquarters are located in Eschen/Liechtenstein, where the company was established as a pressing and stamping plant in 1941, producing small parts at first. At the beginning of the 60s, the company entered the automotive supplier business and has developed into a producer of steering columns, steering gears and complete electro-mechanical steering systems over the years. Presta AG has belonged to the thyssenkrupp company group since 1991.

The company accompanies the trends in the rapidly changing automotive industry towards electric mobility as well as automated and, in the next level, autonomous driving with its technology competence. A worldwide ultramodern production network set up in recent years caters to the vehicle platforms of almost all internationally renowned OEMs. However, the product portfolio of the steering division is not dependent on a vehicle’s drive type. The division has been able to more than double its turnover over the last ten years by expanding its product portfolio and through new customer projects.

The site of thyssenkrupp Presta in Schönebeck manufactures components for the company’s global network. Parts are produced here for various types of steering, such as ball-type linear drives and input shafts, as well as new types of steering for electric cars. As there are many variants for all types of steering, the variety of parts is increasing accordingly. Individual parts such as pinions and input shafts as well as preassembled parts are sent from Schönebeck for final assembly to different sites, above all in China, Europe, USA and Mexico. The steering systems are then assembled there and sent to car manufacturers.

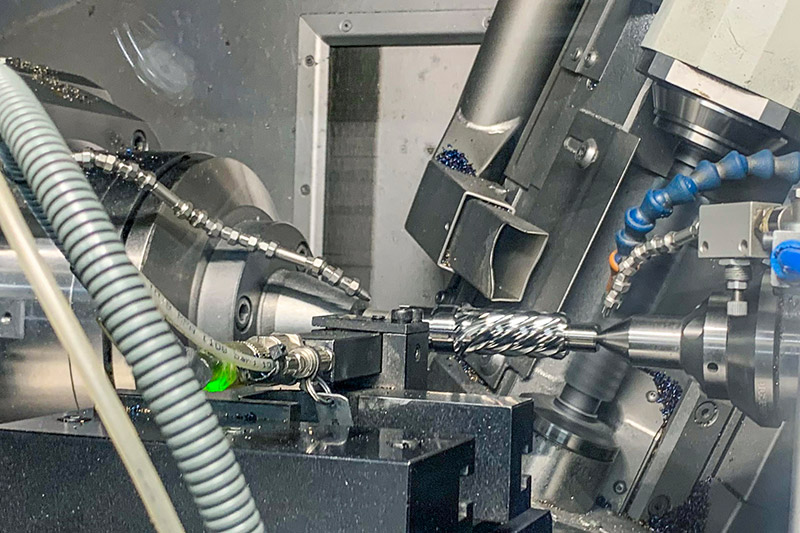

A wide variety of machinery is available to the 800 employees in Schönebeck. This includes forging machines used to produce pinions. Grinding machines, lathes and milling centres are used for mechanical machining. The assembly area for constructing the ball-type linear drive and input shafts has a particularly high degree of automation.

4,500 different tools

“We call on almost the entire tool portfolio available on the market to manufacture our parts”, reports Heiko S., Tool Management Head at thyssenkrupp Presta Schönebeck GmbH. Around 4,500 different tools are deployed in total. Almost half of them are cutting tools. Already today, it is a challenge to maintain an overview of the tools used during production. Due to the envisioned increase of production figures, not least because of new major customer from the electric mobility sector, the purchase of 48 new machines is planned. Even more tools will be involved in manufacturing as a result.

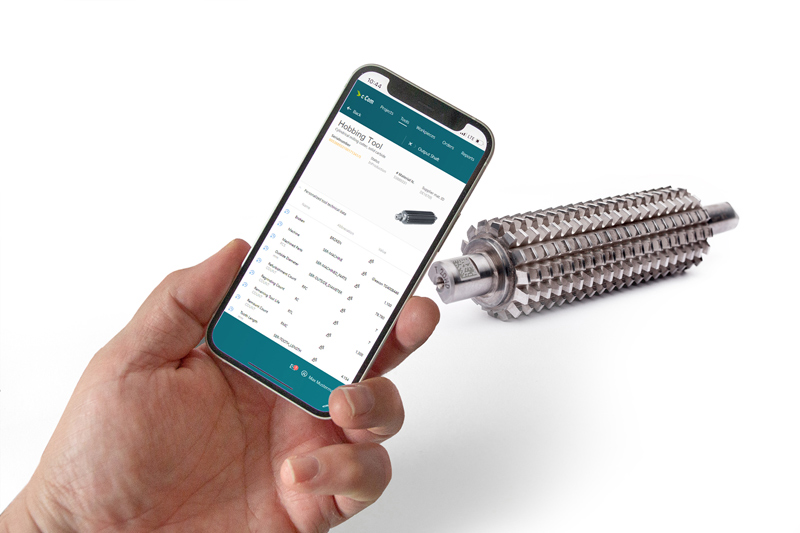

As the administrative effort to manually track tools was extremely high and prone to error, the company sought professional support in data management for its inhouse tool management. A comparison of different systems showed that few could deal with thyssenkrupp Presta Schönebeck’s large portfolio of various tools. About two years ago, the Lifecycle Management from c-Com was introduced in a pilot project in order to keep track of the hobbing tools deployed in manufacturing and to perform an inventory range analysis. “Lifecycle Management offers a central platform for orchestrating the tool processes across company boundaries”, explains Markus Deininger, Project Manager at c-Com. “With the help of the digital twin, all relevant tool and process data are made available and continuously updated for all authorised process participants. In this way, we ensure that tool data is updated comprehensively without interruption. The customer has a detailed and up-to-date overview of the inventory at their disposal whenever needed.” An important aspect influencing thyssenkrupp Presta Schönebeck’s decision was the fact that the c-Com platform can be expanded with other products like the Digital Tool Management.

Are there enough tools?

c-Com improved this significantly. Hobbing tools are so-called serialised tool. Deininger explains what this means: “A serialised tool is uniquely identifiable due to the material number assigned only to it. Through the serialisation, we can attach all technical data to the tool’s digital twin in our platform. You thus know the tool’s condition and exactly where it is. This is useful for key tools that are very important for the process chain.”

Heiko S. can now follow every single tool in Lifecycle Management and sees how much longer the worker can use it, when it has to be reground and when the hob has to be reordered. The Tool Assistant app makes it easy for the employees to assign a tool to a specific task. When the tool is no longer fit for production, the employee removes it from the system. The condition has to be selected and recorded – i.e., was the tool removed because it was broken or worn out? Only very few entries must be made in the app for this. The tool is then automatically prepared for shipment to be reground.

The regrinding partner also has access to c-Com and the pertinent information, so they know which tool to expect and how many parts it has machined. Upon return delivery, a note is made as to what tooth length has been ground and how often the tool can still be used. Many parts of the system are automated to provide the customer with the best data quality possible.

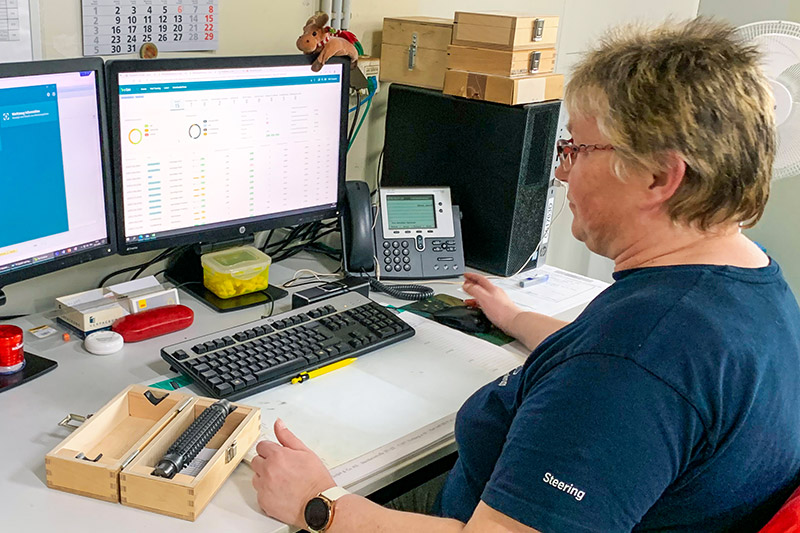

Jana S. is an employee in the big tool warehouse and works with c-Com every day to book goods movements internally as well as for external suppliers. She enters the tools in the system and gathers all the relevant data. Shipment for regrinding used to entail handwritten lists with 20 to 30 items. Nowadays, the job is done with a few mouse clicks. She used to have to search the factory for tools, so she really appreciates the tracking capabilities: “It’s a big relief to know where every single hobbing tool is now.”

Tool expenditures made transparent

Red bars mean bottlenecks

Based on target figures for parts to be produced, the Tool Planning module presents information about how long required tool will last, taking all the possible regrinding processes into account. This inventory range analysis is meant to prevent bottlenecks even when production is ramped up. Tool Planning is a big help for Heiko S.: “I can now find all the information I need for my job at a glance. Red bars show me areas I have to examine because there could be a disparity between inventory and need for the products we are manufacturing.” The dashboard also shows the tool costs and consumption on particular machines.

The pilot project with the hobbing tools was a big success for Lars B.. “The investment in c-Com has definitely paid off”, the Technical Head assures. “The warehouse was intransparent in some places. The reduction of inventory brings us enormous benefits because storage costs are ultimately losses.”

In the next step, c-Com is to be employed for the non-serialised tools. The company is unable to allocate them to particular machining operations for the simple reason that worn-out indexable inserts and drills are often just thrown out without recording their tool life. Whenever a tool is checked out in c-Com, a record is made regarding the machine and part the tool is used for. It is also possible to see in retrospect how many parts the tool produced. When procuring new machines, thyssenkrupp Presta Schönebeck wants to ensure that they already have the software to exchange information with c-Com via an interface.

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342