CaseStudies

-

02.12.2025

Large tool package for Mangner Zerspanungstechnik

MAPAL has equipped Mangner GmbH with a comprehensive tool package for drilling operations.

-

30.10.2025

MAPAL Indonesia provides a unique service for automotive supplier

MAPAL Indonesia enables green manufacturing with minimum quantity lubrication tools at a local automotive supplier.

-

29.07.2025

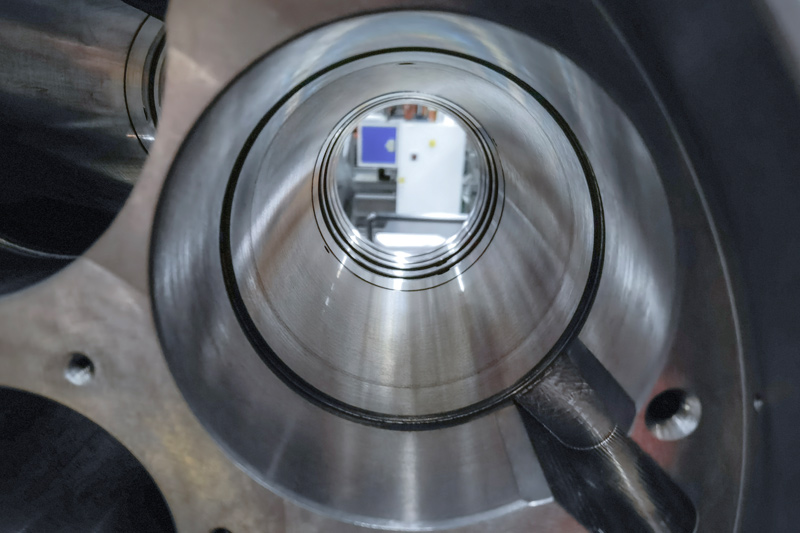

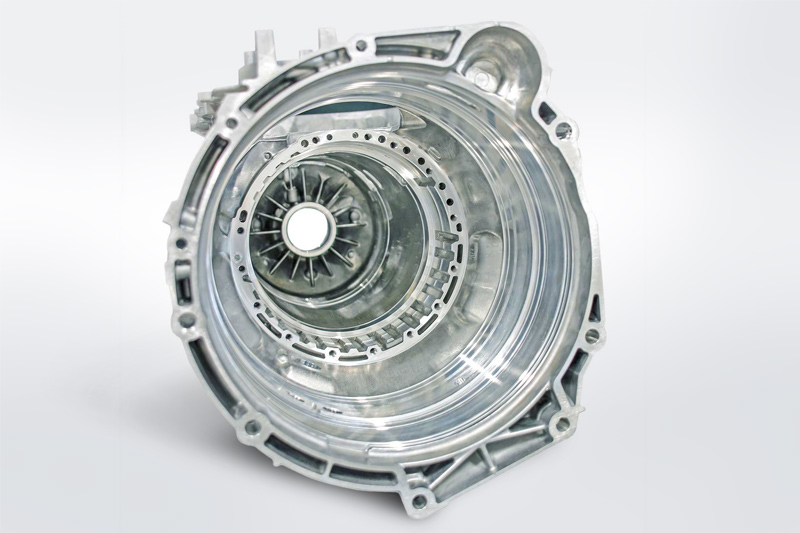

NILES-SIMMONS and MAPAL are setting standards in stator housings

The process developed by NILES-SIMMONS and MAPAL for the complete machining of stator housings for electric vehicle motors is ready for series production.

-

06.06.2025

MAPAL at Schabmüller with tool management and aluminium expertise

At the automotive supplier Schabmüller, MAPAL has already been responsible for tool management. Now, the tool manufacturer from Aalen has also taken over the CAD/CAM programming of the components, including simulation.

-

02.06.2025

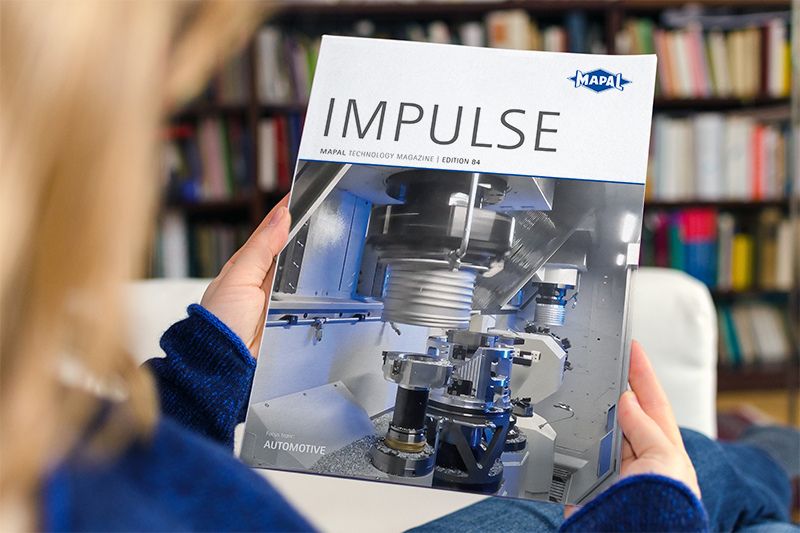

IMPULSE 84 has been published

The automotive industry is the focus of issue 84 of the technology magazine IMPULSE

-

12.03.2025

Customer Productivity: MAPAL works closely with the companies Zimmermann and Blum

Tool manufacturer MAPAL is consortium leader of a cooperation with machine manufacturer F. Zimmernann and measuring technology specialist Blum

-

04.03.2025

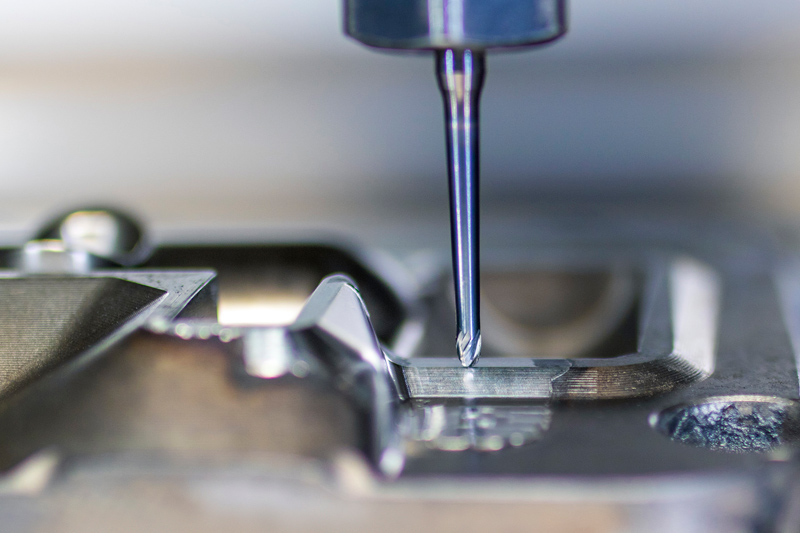

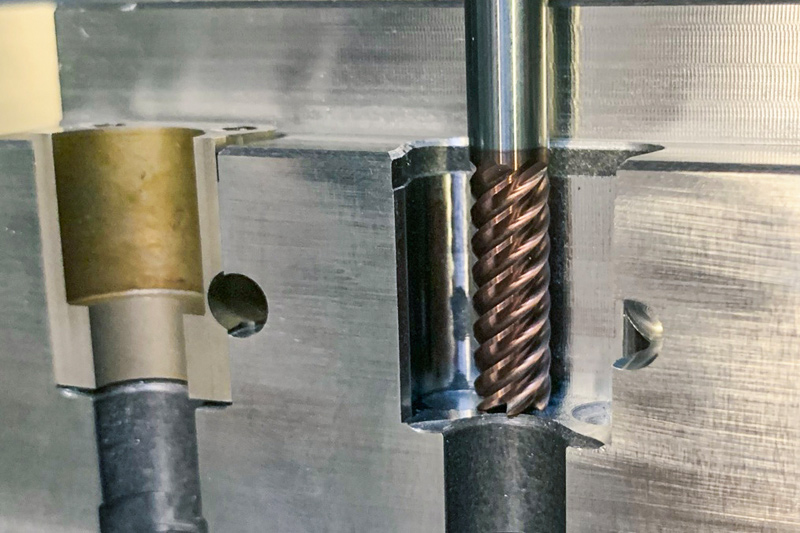

CORMOL relies on milling cutters such as the OptiMill-3D-HF from MAPAL for tool making

CORMOL from Portugal manufactures stamping tools, for which it has been working closely with MAPAL since 2022. With the OptiMill-3D-HF, CORMOL has found a reliable and economical tool solution.

-

16.01.2025

Tool management from MAPAL completed for DEUTZ in record time

MAPAL completed the entire engineering including tool design, cycle time study and cost calculation for the engine manufacturer Deutz in the Spanish plant in Zafra within a very short time.

-

19.12.2024

IMPULSE 83 has been published

Innovations and strategic focus areas are in the spotlight of issue 83 of the technology magazine IMPULSE

-

25.06.2024

Efficient production in die and mould making: Krämer+Grebe and MAPAL

The mouldmaking company Krämer+Grebe optimises production with MAPAL reamers and milling cutters and ensures process reliability in international competition.

-

08.04.2024

IMPULSE 82 has been published

Developments, solutions and applications for the aerospace industry are the focus of issue 82 of the MAPAL technology magazine IMPULSE.

-

25.03.2024

Collaborative partnership in the end machining of steel

GABO STAHL relies on an automated special machine from Mössner and tool technology from MAPAL for the end machining of round steel.

-

01.02.2024

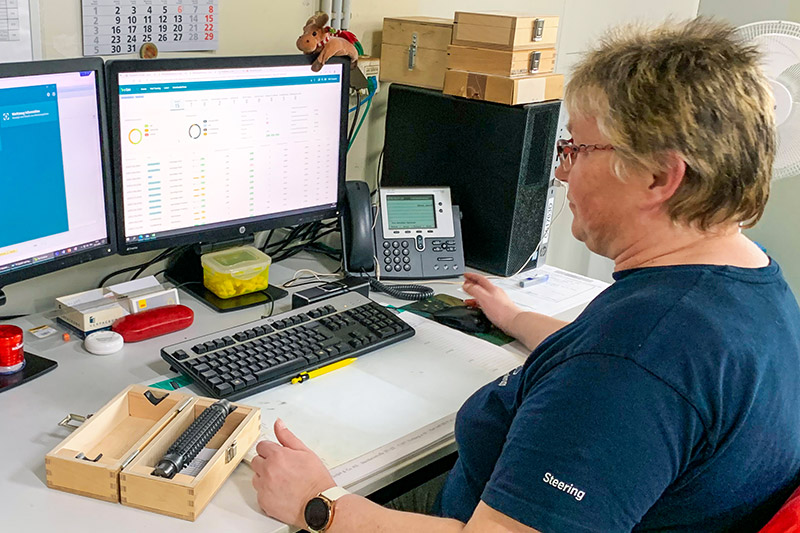

Lifecycle Management from c-Com increases transparency at thyssenkrupp Presta Schönebeck

The automotive supplier thyssenkrupp Presta uses c-Com's Lifecycle Management at its Schönebeck site and achieves transparency and considerable savings.

-

04.12.2023

Aluminium machining in new dimensions

Impressive material removal rates - bavius cuts over 20 liters per minute with aluminum high-volume milling cutters from the tool manufacturer MAPAL.

-

09.11.2023

Twice as fast to the titanium component with MAPAL

Aircraft supplier SME Aerospace Malaysia optimises its titanium component machining together with MAPAL and saves 3 hours per component.

-

28.09.2023

Structural parts in record time

Wenzler and MAPAL combine their expertise and provide answers to the question: How can aluminium components be manufactured quickly and precisely?

-

02.08.2023

Well positioned for e-mobility

The die-casting foundry 2A is ready for the transition to electric mobility. MAPAL is at 2A's side as an experienced tool partner.

-

17.07.2023

IMPULSE 81 has been published

Solutions and applications in fluid power technology as well as sustainability are the focus of issue 81 of the MAPAL technology magazine IMPULSE.

-

19.06.2023

The best deep bores with PCD

The automotive supplier Schlote converted the deep drilling of oil channels in clutch housings and reliably achieves five times the service life.

-

23.03.2023

The production must go on

Digital tool management with more than 750 tools from MAPAL ensures smooth large-scale production at Schabmüller Automobiltechnik.

-

02.03.2023

The overall process makes the difference

In direct comparison to the previous machining process, the MAPAL solution brings clear advantages. The consideration of the overall process is decisive here.

-

01.02.2023

Major progress in external reaming of turning workpieces

The Swiss manufacturer W.E. Schultz finishes turned parts with external reamers from MAPAL and reduces cutting costs to 25 and set-up costs to 10 percent.

-

07.12.2022

Learning to connect

Gewerbliche Schule Göppingen taps into MAPAL’s digitalisation know-how

-

03.11.2022

Efficient deburring with robots

The FlyCutter from MAPAL is ideally suited for deburring battery trays. Robot manufacturer KADIA is enthusiastic about the PCD-tipped milling tool.

-

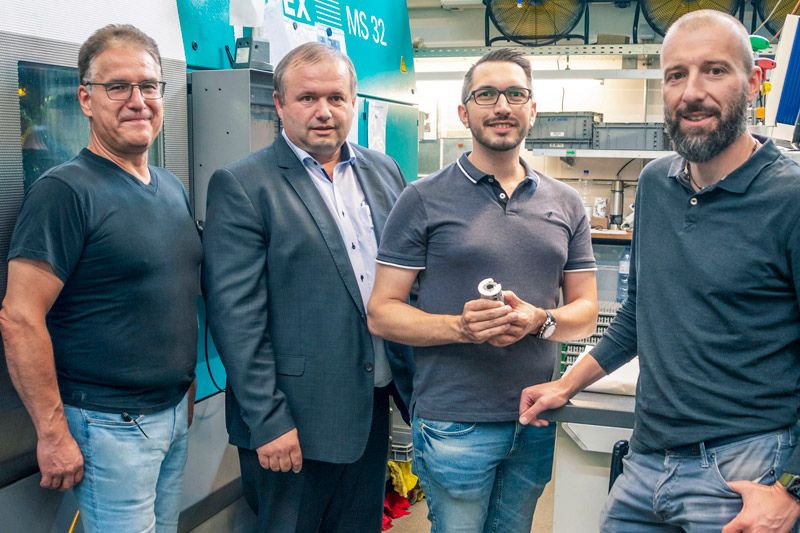

28.09.2022

Adapted hydraulic chuck as a problem solver

Simple, fast, safe and reliable – how the Swiss lathe manufacturer TORNOS is optimising the application performance of its multi-spindle lathe with the help of MAPAL hydraulic chucks.

-

22.08.2022

A new turn for e-mobility

Innovative machining process from NILES-SIMMONS and MAPAL with simultaneous internal and external machining and a combination of turning and boring/fine boring.

-

28.07.2022

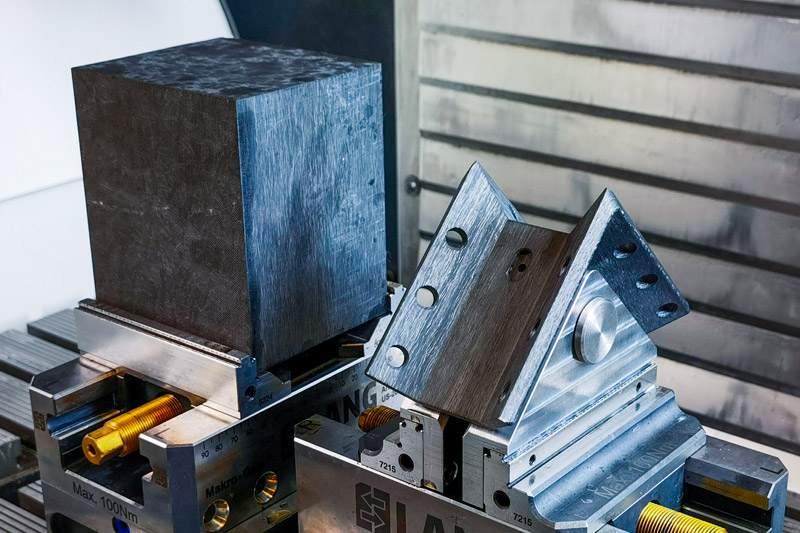

Strategic partnership in mould making

Röders GmbH and MAPAL jointly develop the machining strategy for a generic component. The approach is convincing - both in the CAM simulation and on the machine.

-

02.06.2022

3D milling of CFRP prototypes from batch sizes of one

MAPAL supports ERIKS Deutschland GmbH with process expertise and an extensive range of tools for turnkey CFRP machining.

-

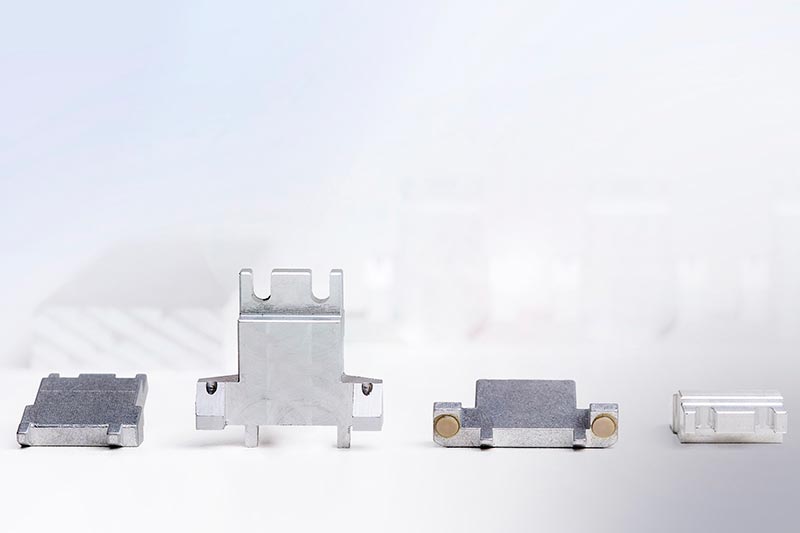

05.05.2022

Problem solver even for tricky cases

MAPAL tools demonstrate their performance potential in several problematic applications at the mould making company HaGeForm Sachsen.

-

28.04.2022

Automotive technology for aeroplanes

Machine manufacturer F. Zimmermann GmbH and MAPAL jointly set standards in the project implementation and machining of an aerospace component.

-

13.04.2022

A multi-stage fine boring tool for the highest precision

Multi-stage fine boring tool from MAPAL machines component made of GGG40 with six bores, each with three merging cylindrical areas.

-

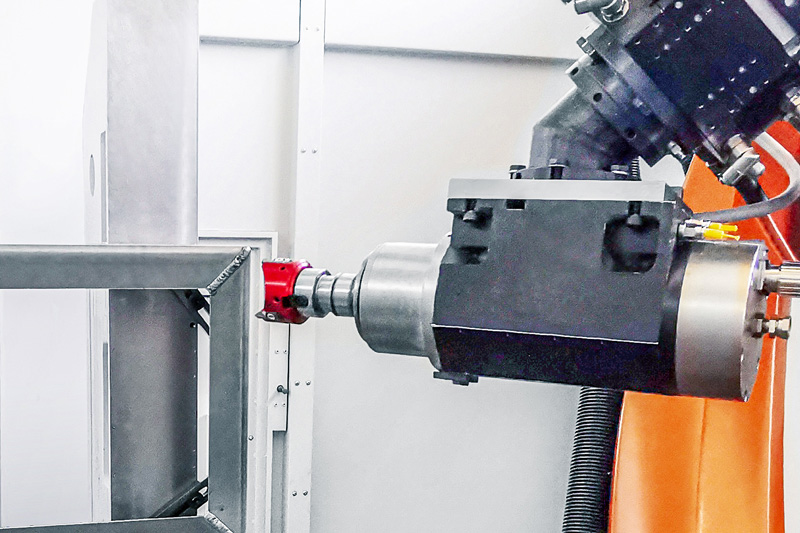

17.03.2022

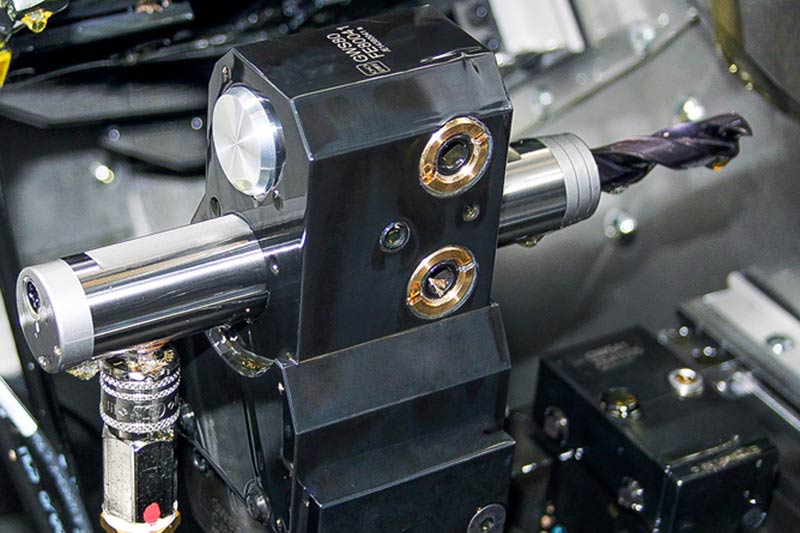

Electronic actuating tool makes milling-turning centre an all-rounder

The integration of the TOOLTRONIC mechatronic tool system into the RX18 milling turning centre from Reiden Technik AG met the customer's high requirements.

-

13.01.2022

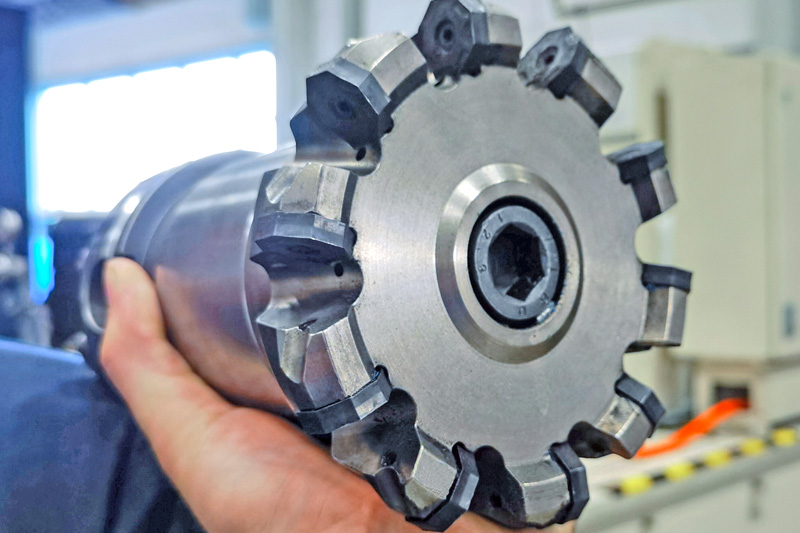

Performance boost with NeoMill face milling cutter

NeoMill face milling cutters from MAPAL cut machining times of screw compressors at BOGE Kompressoren by fifty percent.

-

15.12.2021

Optimisation in mould making

On the way to industrial toolmaking, Schülken Form is optimising its production processes. MAPAL tools play an important role in this.

-

25.10.2021

IMPULSE — edition 76 is available

News on e-mobility. New tools for machining titanium as well as valve housings and pot-shaped stator housings. A new module from c-Com.

-

16.08.2021

IMPULSE — edition 75 is available

Discover smart solutions as well as the potential of MAPAL’s Tooltronic and the radial milling cutters NeoMill.

-

14.07.2021

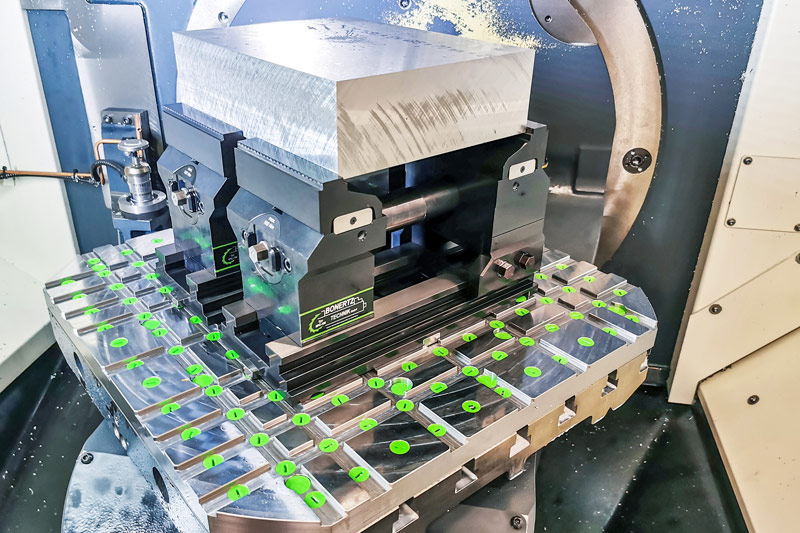

When tool expertise and consulting quality match

For the production of sophisticated clamping devices for machine tools, Bonertz Technik GmbH relies on the performance and process reliability of MAPAL tools.

-

01.07.2021

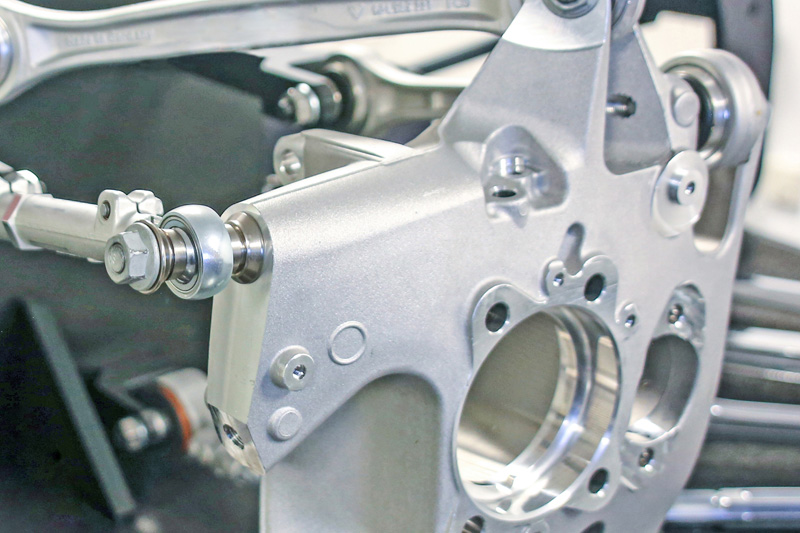

Sophisticated PCD tool concepts for machining aluminium

Carl Hirschmann GmbH processes aluminum forged parts for sports vehicles with multi-stage combination tools from its development partner MAPAL.

-

11.05.2021

High performance in precision machining of aluminium

Aluminum structural components for aircraft are mostly machined from solid. This requires enormous performance and high precision from machines and tools.

-

07.04.2021

IMPULSE edition 74 is available

The latest edition of Impulse is available. One of the main topics is the market launch of MAPAL in the die and mould sector.

-

01.01.2021

Maximum tool life in CFRP thanks to diamond coating

Why MAPAL relies on SP3 technology for the coating of solid carbide tools, what makes their machines special and where the expertise for diamond coatings comes from…

-

08.10.2020

Multi-Site Tool Management 4.0

MAPAL takes over tool management at the Hitachi Automotive Systems Group in Poland, Mexico and Turkey

-

26.06.2020

Walter Formenbau trusts in MAPAL’s expertise

In order to achieve its goal of fully networked production, owner Dr Jens Buchert brought MAPAL on board as a complete supplier.

-

23.06.2020

Conceived from the process – a development partnership between a machine manufacturer and a tool manufacturer

MAPAL and ELHA share a long lasting business association therefore the customers gain huge advantages.

-

15.01.2020

New chucks for standardized Processes

Mitsubishi Motors Corporation relies on the expertise and service of MAPAL when planning a new engine production line at its Kyoto plant.

-

19.12.2019

Increasing efficiency with tool management

Shakti Precision Components has entrusted MAPAL with tool management for its new factory – with success, as significant increases in efficiency are demonstrated.

-

09.12.2019

Highly precise machining of truck engine cylinder bores

High-precision MAPAL actuating tools and a special setting fixture ensure precise and economical production at Mercedes-Benz in Mannheim.

-

01.09.2019

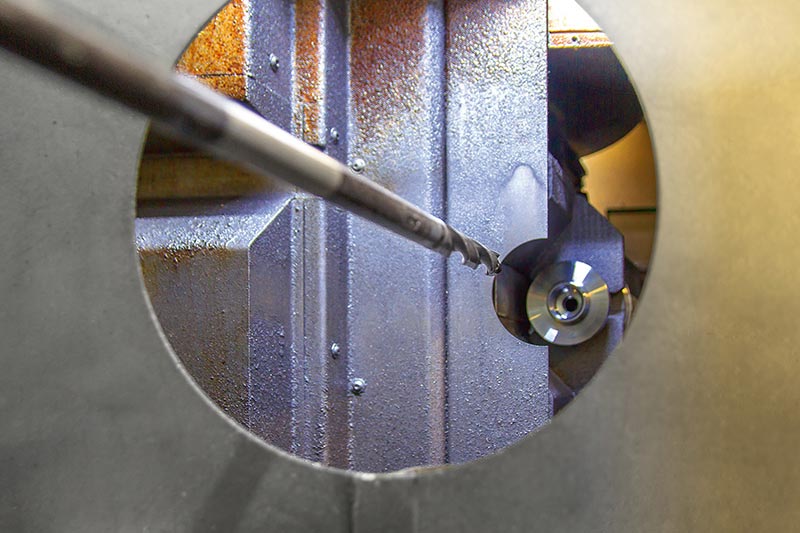

Superlative Fine Boring – Grüner Relies on MAPAL

A tool weighing 207 kilograms performs the internal machining of a transmission housing. MAPAL has developed the appropriate measuring device for the tool.

-

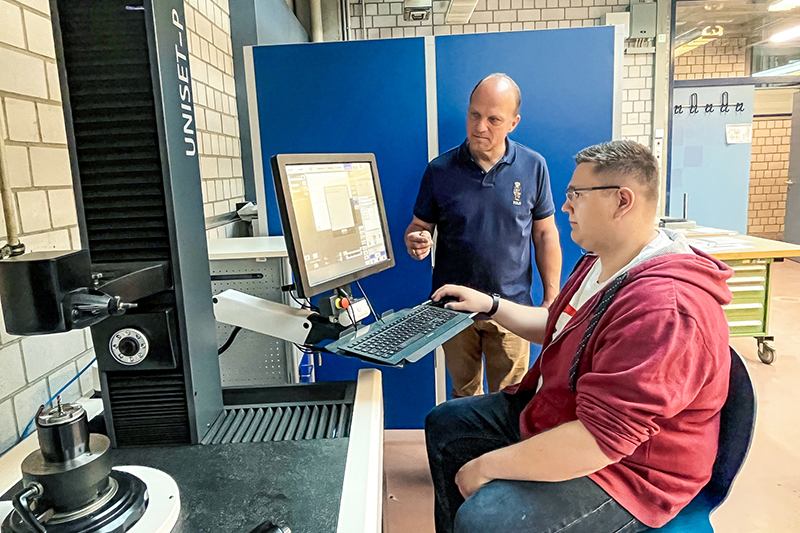

01.09.2019

Challenge of setting to the µm - tactile measurement for less machine downtime

How Alupress saves a lot of time, increases process reliability and works with high precision with the UNISET-P from MAPAL.

-

01.09.2019

Support for every project - CastAlum Ltd Relies on Service from MAPAL

In addition to tools and chucks, MAPAL offers CastAlum Ltd further advantages with its services to achieve the most economical production results.

-

01.09.2019

Aircraft Industries depends on milling cutters for high-volume machining from MAPAL

High volume milling cutters, drilling/countersinking combination tools and reamers in use in the parts production and final assembly of aircraft manufacturer Aircraft Industries.

-

01.09.2019

Machining time halved, process stabilized - multi-cutting edged MAPAL fine boring tool

What role do axle swings play on crawler tracks for tractors and why maximum accuracy is required when machining them.

-

01.05.2019

Digitalisation for regrinding of tools – Transparency and efficiency courtesy of c-Com

Tool management is often the critical point in the regrinding process. How MILLER overcomes this challenge.

-

01.05.2019

Mikuni India steigert Produktivität dank PKD-Werkzeugen von MAPAL

The automotive supplier needs one machining centre less for the process when manufacturing a carburetor housing.

-

01.05.2019

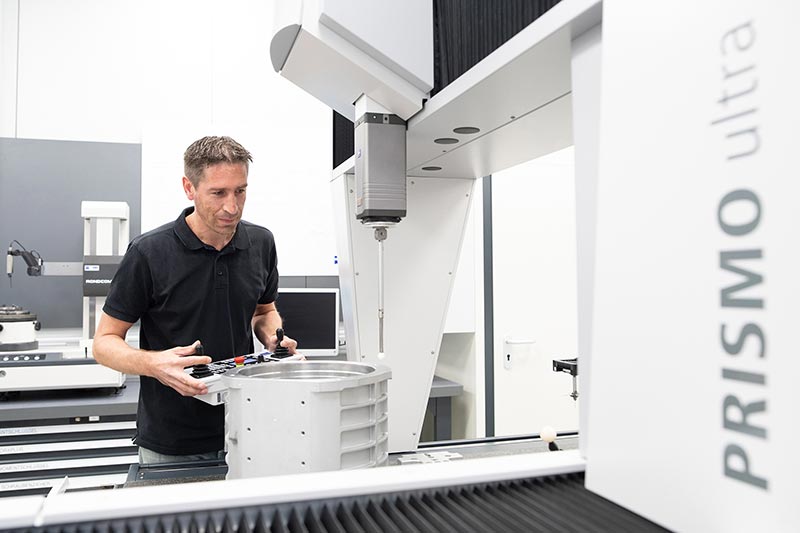

Roadmap E-mobility

How MAPAL uses the ZEISS PRISMO ultra coordinate measuring machine to accelerate tool development and what this has to do with electric mobility.

-

01.11.2018

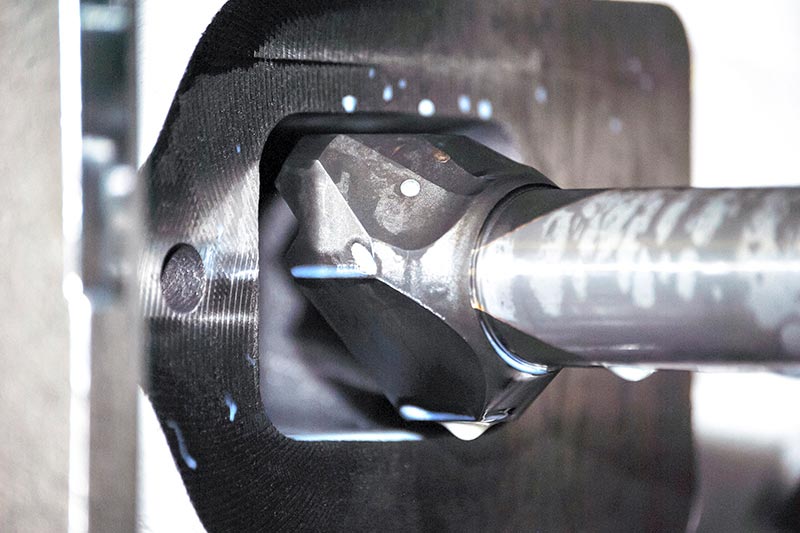

Constant velocity joints for electro mobility

Why Neapco relies on ball nose milling cutters from MAPAL for hard machining the homokinetic outer joint of a drive shaft.

-

01.10.2018

Excellent result thanks to close, partnership-based cooperation

MTU Friedrichshafen converts finish machining to minimally invasive face milling. They also achieve evenness improved by a factor of 10 with milling cutters from MAPAL.

-

01.08.2018

External reamer ensures high-precision cylindricity

With the tool for external machining, Völlm machines pins onto planetary carriers economically and with high precision and process reliability

-

01.06.2018

Perfect combination for structural parts – faster, better, lower cutting forces

F. Zimmerman GmbH relies on high volume milling cutters from MAPAL in combination with their machining centre FZH, which therefore raises performance to a whole new level.

-

01.05.2018

Using new solutions for a reliable process - relief bore is introduced in crancshafts

How an automobile manufacturer brings a new process safely into series production with MAPAL by its side as technology partner.

-

01.02.2018

Successfully Re-tooling Machines

How Stefan Plätzer Maschinenbau GmbH has increased the number of parts produced per hour from four to 30.

-

01.02.2018

Concentrated flexibility and efficiency – facing heads and mounting tools from MAPAL

Bühring is tasked with machining complex contours on components for straw balers. Why the company has decided to go for a tool solution from MAPAL