テクノロジー

-

03.02.2026

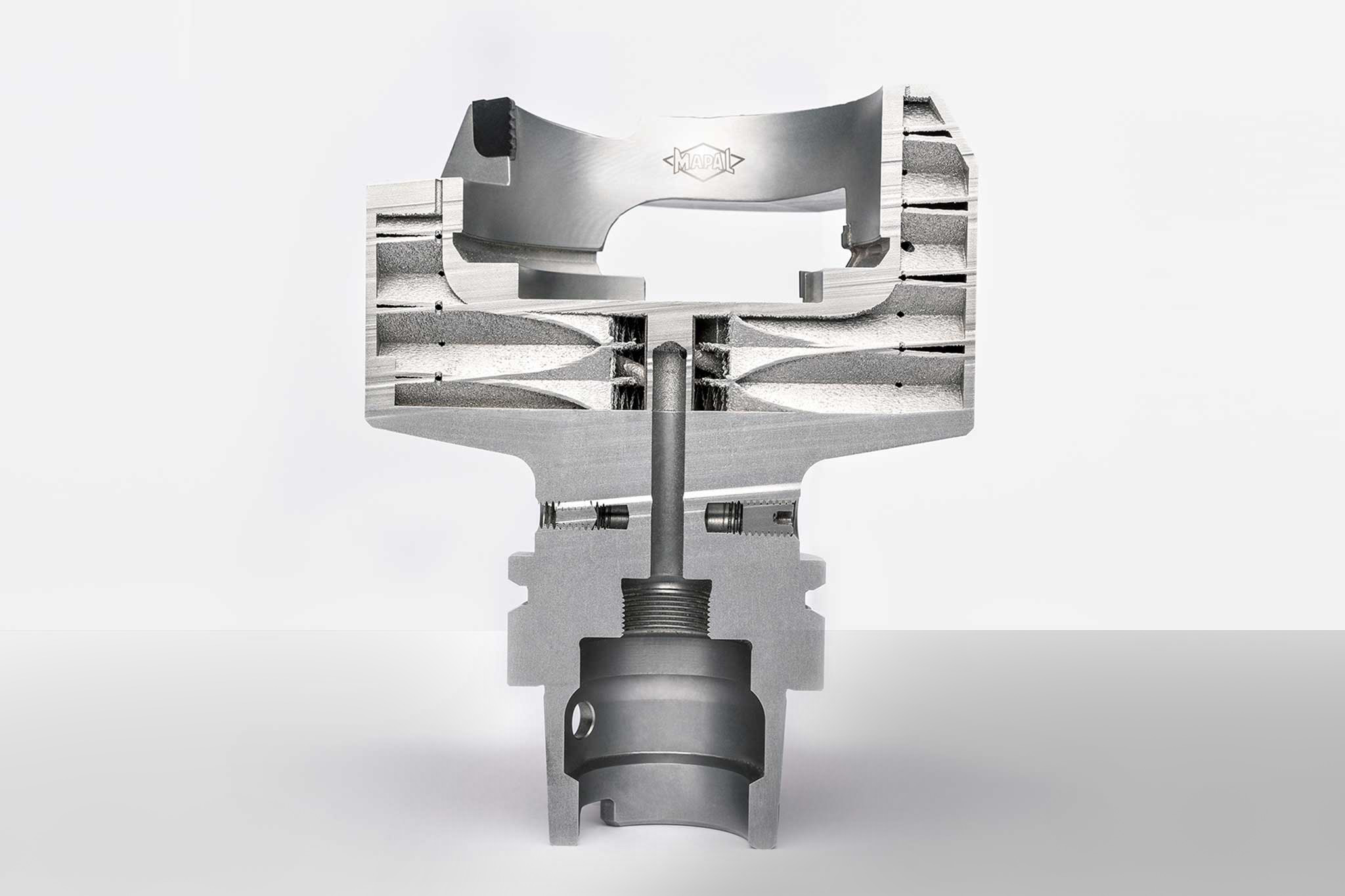

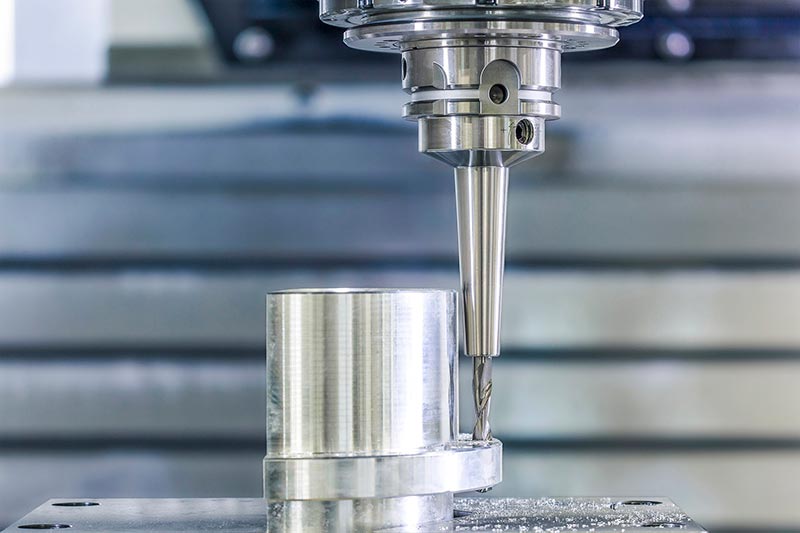

New presetting device for fine boring tools with large diameters

With the new UNISET V basic plus tool presetting device, MAPAL closes the gap between simple mechanical and high end CNC presetting devices.

-

27.01.2026

New process plant technology brochure for pumps, compressors, and valves

A new MAPAL brochure presents procress plant technology solutions for the three key component areas of pumps, compressors, and valves.

-

07.01.2026

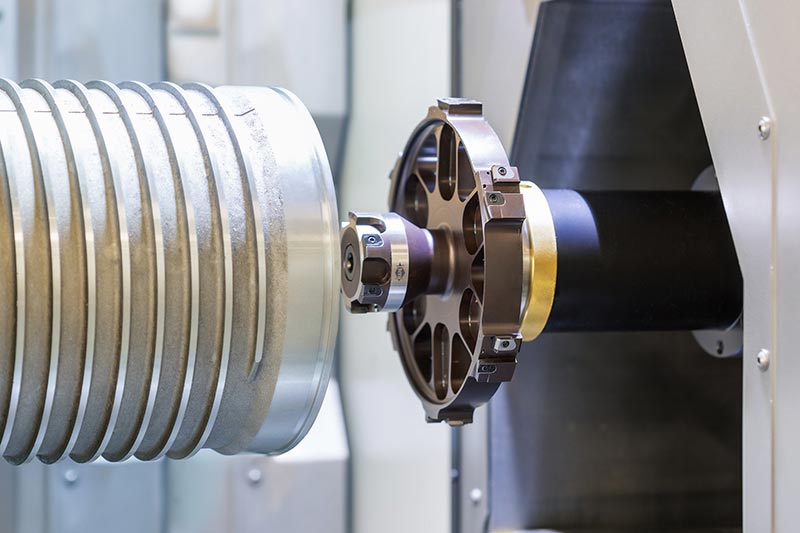

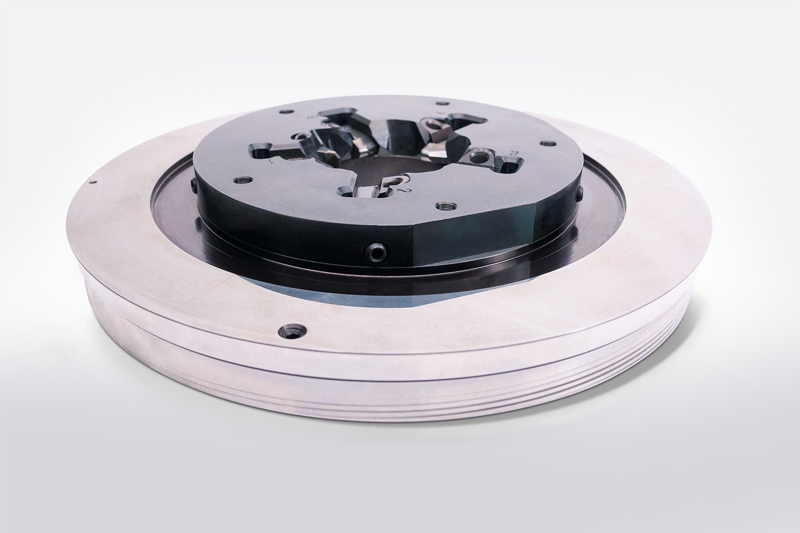

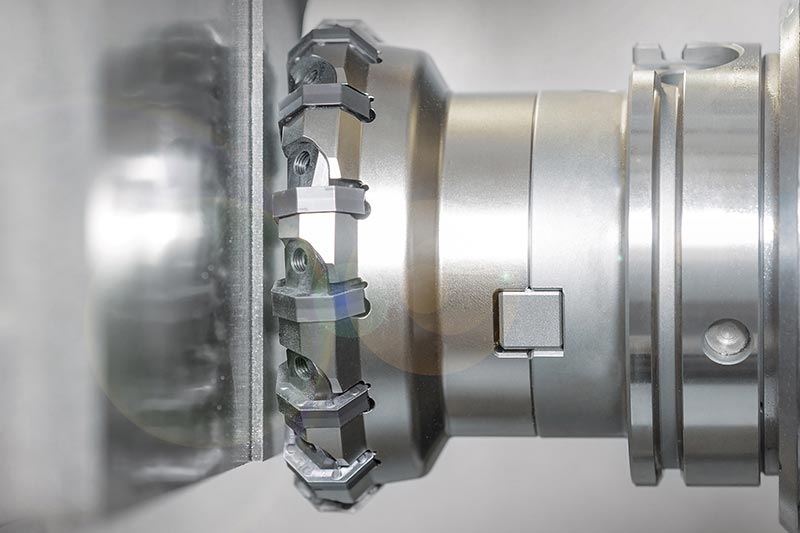

New solutions for boosting productivity with HPR400 and HPR400 plus

With HPR400 and HPR400 plus for highly productive reaming of large diameters, MAPAL meets the highest demands in fine machining.

-

16.12.2025

New milling tool solutions for maximum efficiency

MAPAL offers new solutions for semi-finishing and finishing operations with NeoMill-16-Finish and NeoMill-16-Face.

-

09.12.2025

MAPAL positions itself as a productivity provider with a complete range of services

Services such as tool design and tool management were already standard at MAPAL. Now the tool manufacturer offers complete turnkey solutions.

-

25.11.2025

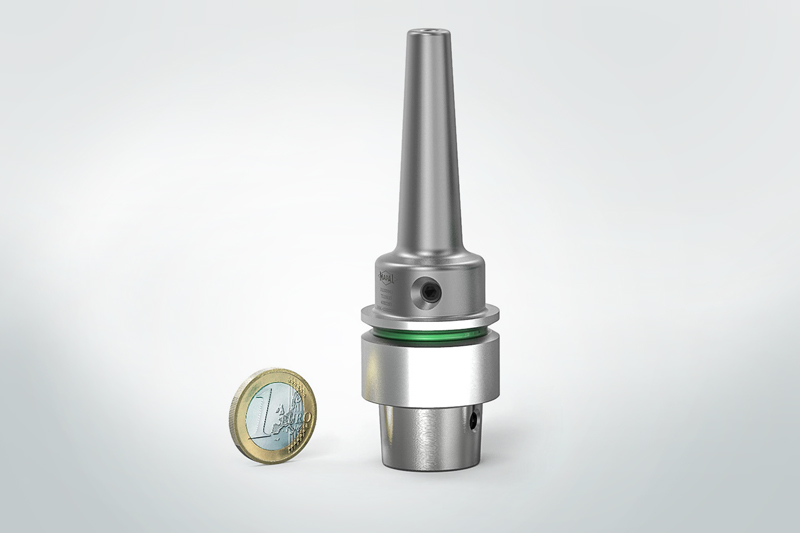

UNIQ hydraulic expansion chuck enhanced with DirectCool cooling channel

MAPAL expands the UNIQ hydraulic expansion chucks with DirectCool, delivering maximum efficiency, consistent machining quality, and economic benefits.

-

06.11.2025

New standardised chip breaker geometries for fine boring cutting edges

MAPAL has developed a standardised chip breaker geometry for fine boring cutting edges used in machining long-chipping steel materials.

-

30.10.2025

MAPAL Indonesia provides a unique service for automotive supplier

MAPAL Indonesia enables green manufacturing with minimum quantity lubrication tools at a local automotive supplier.

-

24.10.2025

Portrait: MAPAL Centre of Competence PCD tools

With the Centre of Competence for PCD tools, MAPAL sets standards in customer service, technology, efficiency and sustainability.

-

15.10.2025

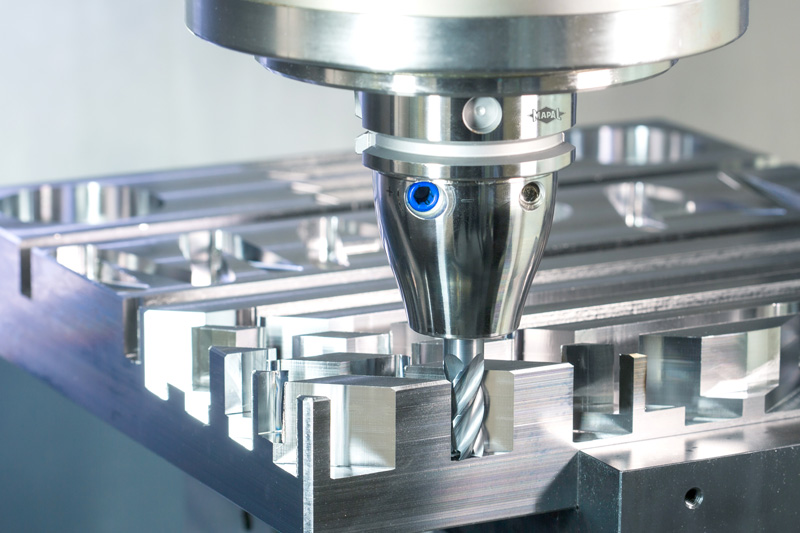

Successful tooling solutions from MAPAL increase productivity for customers.

Increasing customer productivity is at the heart of MAPAL’s standard processes for the industrial manufacturing of strategic components.

-

06.10.2025

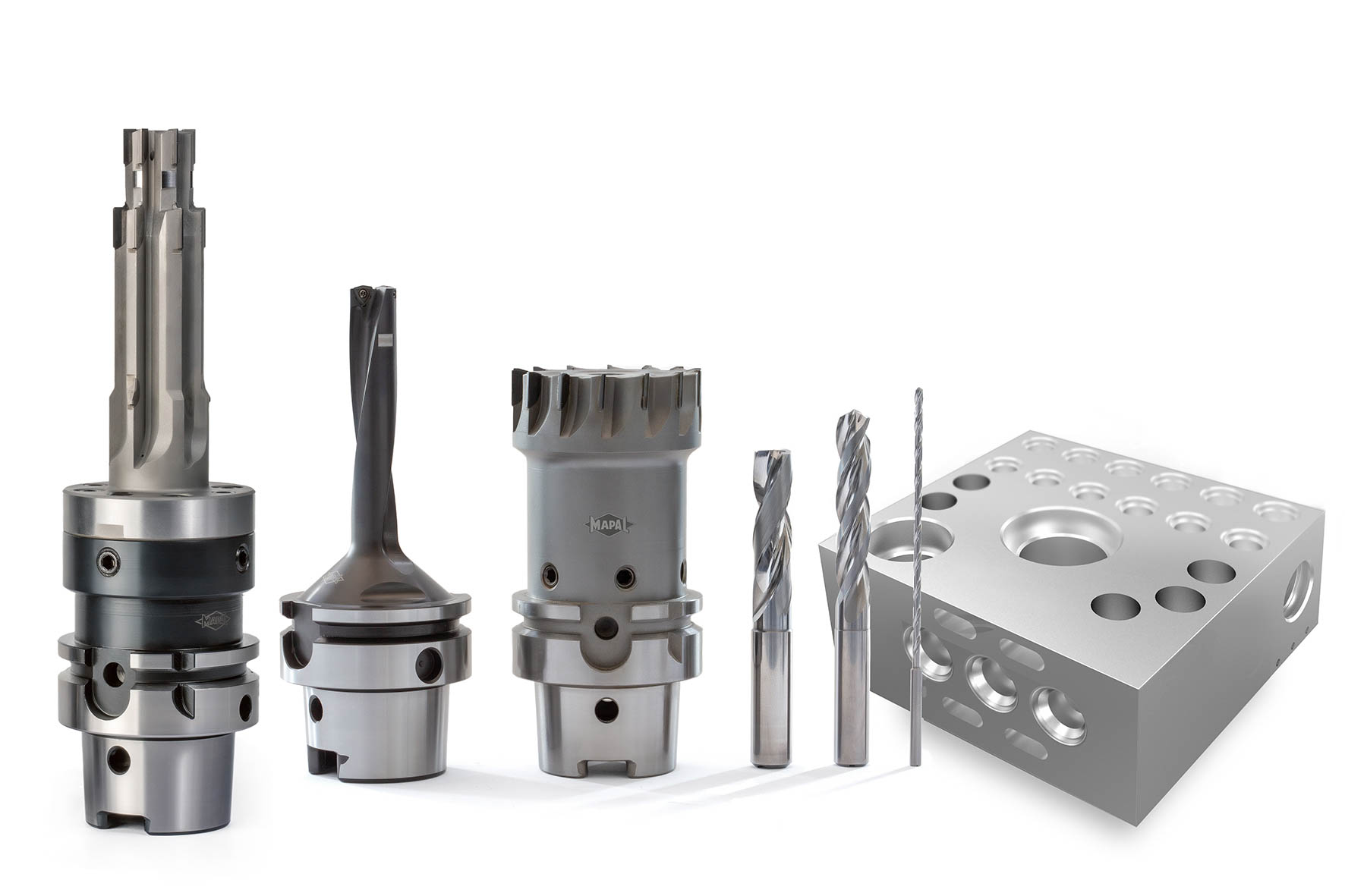

Innovations and solutions of MAPAL

MAPAL presents its 2026 innovations and solutions in a comprehensive brochure.

-

30.09.2025

New OptiMill-Uni-HPC for machining steel, stainless steel and cast iron

The third generation of MAPAL’s versatile OptiMill-Uni-HPC for machining steel, stainless steel and cast iron has been further developed

-

24.09.2025

IMPULSE 85 has been published

Innovations and solutions of the year 2026 are in the focus of issue 85 of the technology magazine IMPULSE

-

26.08.2025

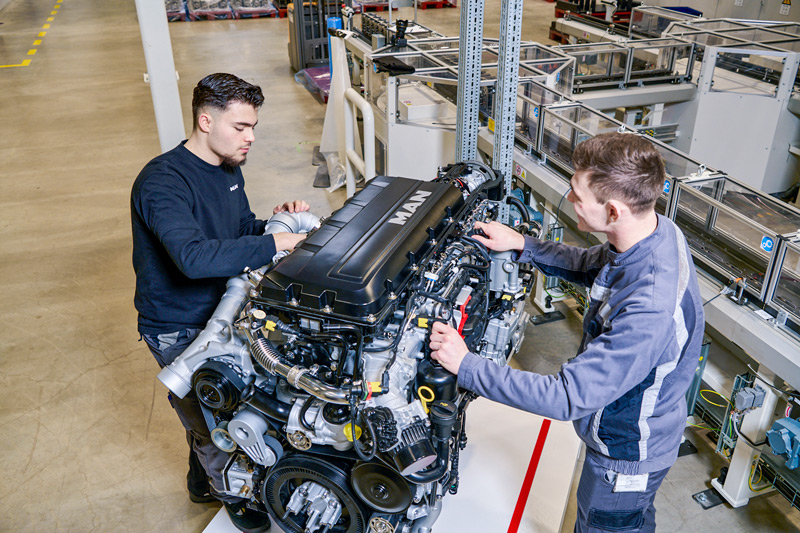

MAN uses MAPAL fine boring tools for machining cylinder heads

At MAN engines, fine boring tools from MAPAL are used to machine the valve guide and valve seat counterbores of cylinder heads."

-

29.07.2025

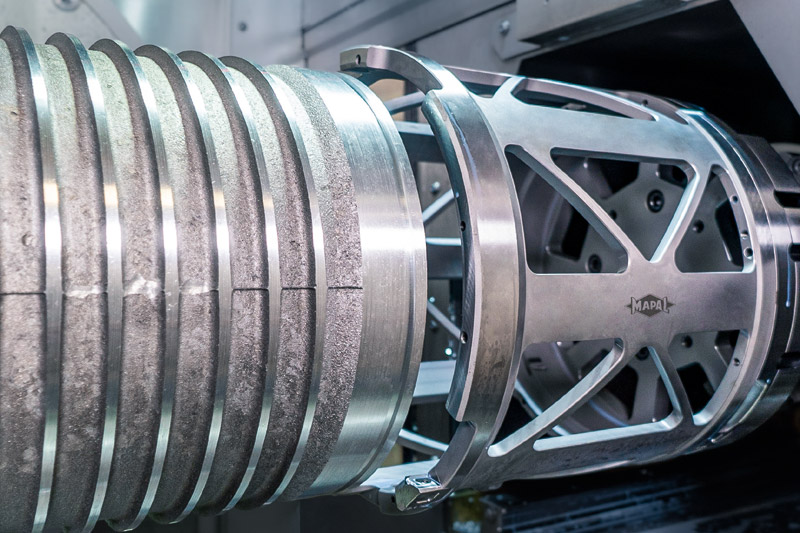

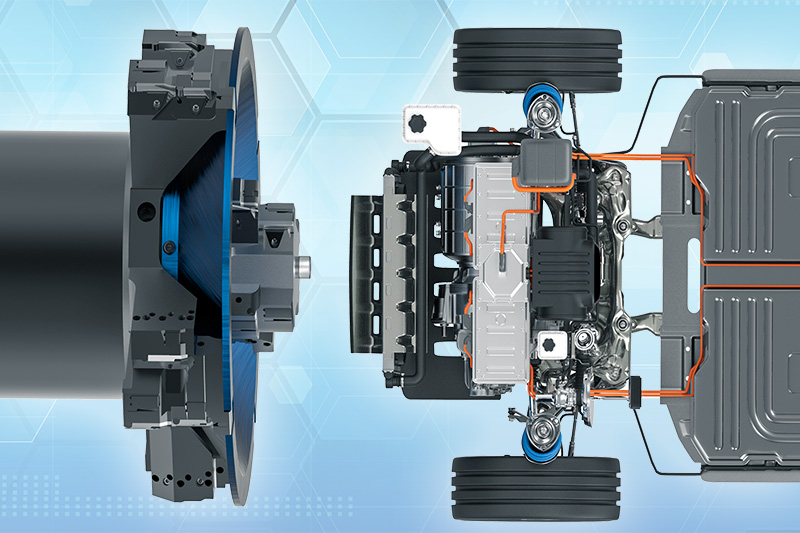

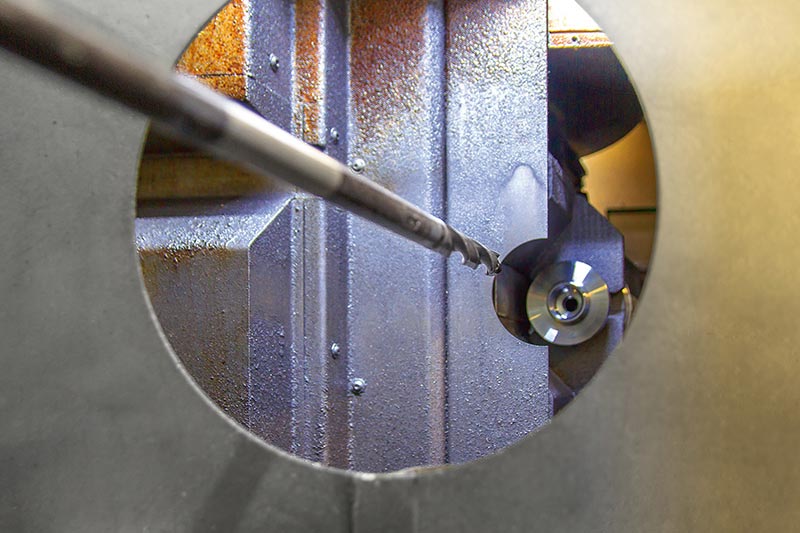

NILES-SIMMONS and MAPAL are setting standards in stator housings

The process developed by NILES-SIMMONS and MAPAL for the complete machining of stator housings for electric vehicle motors is ready for series production.

-

15.07.2025

MAPAL Dr. Kress SE & Co. KG will be taking part in EMO 2025 in Hanover

MAPAL will once again take part in EMO in Hanover this year, where the company will showcase its latest products and innovations.

-

02.06.2025

IMPULSE 84 has been published

The automotive industry is the focus of issue 84 of the technology magazine IMPULSE

-

15.05.2025

Sustainability report from MAPAL for the year 2023

MAPAL's sustainability report creates transparency regarding internal developments in areas such as the environment, product longevity, or employee relations.

-

05.05.2025

MAPAL is a partner and tool supplier for CHIRON turnkey machines

CHIRON America upgrades standard machines to turnkey machines at its plant in Charlotte. MAPAL is the tool supplier for a machine for manufacturing truck components.

-

09.04.2025

MAPAL develops two generic components for the aerospace industry

MAPAL has developed two sample components for the aerospace sector. The Generic Components, a valve housing and a torsion joint, cover all the demanding machining steps.

-

28.03.2025

Suitable tools for combined brake housings

Combined brake housings unite the brake master cylinder, brake booster and ABS/ESP in one component and pave the way to autonomous driving. MAPAL offers solutions for machining complex aluminum workpieces.

-

12.03.2025

Customer Productivity: MAPAL works closely with the companies Zimmermann and Blum

Tool manufacturer MAPAL is consortium leader of a cooperation with machine manufacturer F. Zimmernann and measuring technology specialist Blum

-

04.03.2025

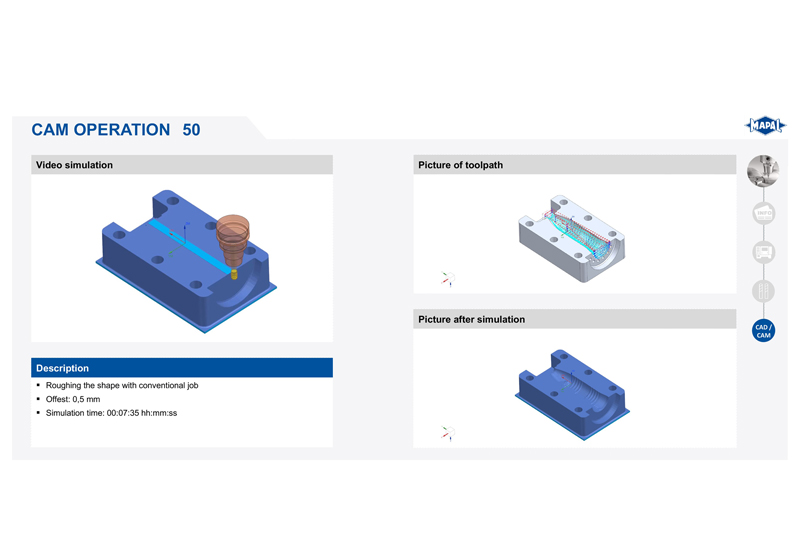

CORMOL relies on milling cutters such as the OptiMill-3D-HF from MAPAL for tool making

CORMOL from Portugal manufactures stamping tools, for which it has been working closely with MAPAL since 2022. With the OptiMill-3D-HF, CORMOL has found a reliable and economical tool solution.

-

26.02.2025

Another design award for the UNIQ hydraulic chucks from MAPAL

Following the iF Design Award and the Good Design Award, the UNIQ hydraulic chucks from MAPAL have also been honoured with the Green Design Award, which focuses on sustainability.

-

11.02.2025

MAPAL underlines its aluminum competence for pneumatics with focus components

For the machining of a pneumatic valve housing and a pneumatic cylinder, MAPAL can draw on its expertise and product portfolio for aluminum machining.

-

16.01.2025

Tool management from MAPAL completed for DEUTZ in record time

MAPAL completed the entire engineering including tool design, cycle time study and cost calculation for the engine manufacturer Deutz in the Spanish plant in Zafra within a very short time.

-

19.12.2024

IMPULSE 83 has been published

Innovations and strategic focus areas are in the spotlight of issue 83 of the technology magazine IMPULSE

-

15.11.2024

Easy handling, rigid connection, optimal cooling: new BFS connection for replaceable head milling systems

MAPAL has introduced a new bayonet-like separation point for interchangeable head milling systems onto the market. Users benefit from very easy handling, rigid connection and optimal cooling

-

06.11.2024

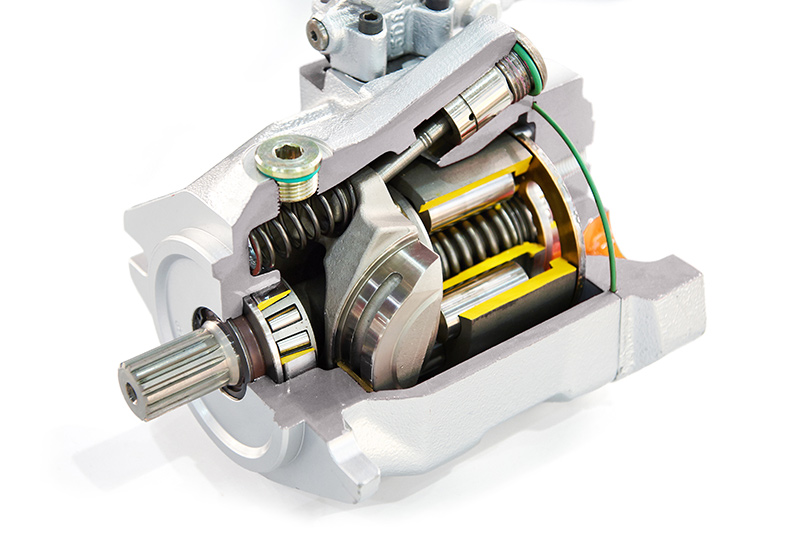

Optimum processing through component and market expertise: solutions for the scroll compressor

Machining solutions for scroll compressors: MAPAL offers precise, durable tools for electromobility. Focus on quality, efficiency and application-orientated processes.

-

10.10.2024

Sustainable machining with hydraulic chucks: High efficiency and long service life

Hydraulic chucks contribute to sustainability in machining. The clamping technology conserves resources, improves workpiece quality and reduces energy consumption.

-

07.08.2024

Empower Your Aluminium Machining

Aluminium materials are increasingly being used in various industries. MAPAL is the leading technology partner for the machining of aluminium components.

-

02.07.2024

Aluminium expertise in focus at the annual press conference

At the annual press conference in Aalen, the focus was on the annual report, innovations for AMB and aluminium machining.

-

29.05.2024

Machining titanium economically

For economic results in titanium machining, tool technology and process must be optimally designed. A case for MAPAL.

-

08.04.2024

IMPULSE 82 has been published

Developments, solutions and applications for the aerospace industry are the focus of issue 82 of the MAPAL technology magazine IMPULSE.

-

11.01.2024

Major process improvements in the machining of axial piston machines

MAPAL has developed profound process solutions for the economical and precise machining of axial piston machine components.

-

04.12.2023

Aluminium machining in new dimensions

Impressive material removal rates - bavius cuts over 20 liters per minute with aluminum high-volume milling cutters from the tool manufacturer MAPAL.

-

22.11.2023

Development of customised diamond coatings

MAPAL develops extremely hard and wear-resistant diamond coatings for machining materials such as CFRP, ceramics, graphite and aluminium alloys.

-

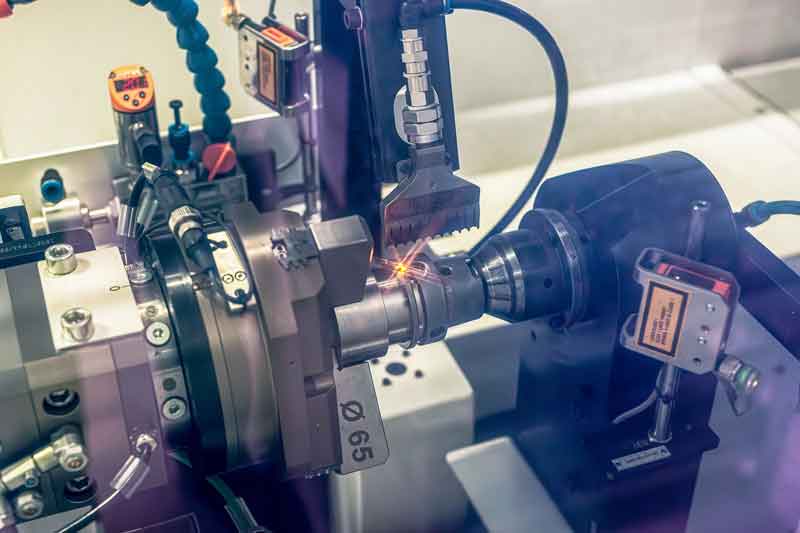

26.10.2023

Investing in health, sustainability and quality

MAPAL has commissioned a new, unique laser hardening system for series production - with significant added value.

-

19.10.2023

"MAPAL's focus has always been and will always be on the customer."

CTO Jacek Kruszynski on structures, development priorities and plans in the area of digitalisation.

-

07.08.2023

MAPAL at the EMO 2023

MAPAL will be presenting itself in Hall 4, Stand A18 with the focus industries, Innovations 2024, the Online Shop and new developments on the subject of sustainability.

-

25.01.2023

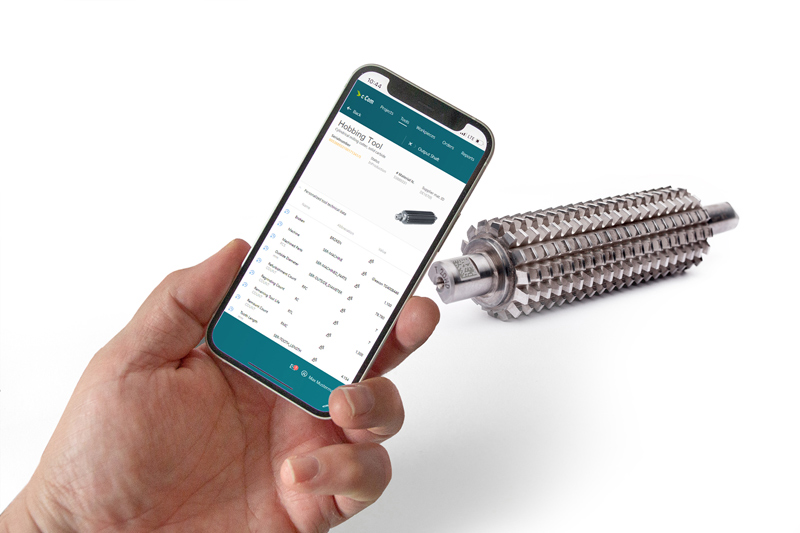

Gnutti Carlo Group relies on c-Com digital tool management

The Gnutti Carlo Group implements a digital tool management solution from c-Com for its worldwide locations.

-

12.01.2023

Basic–Performance–Expert

MAPAL clusters its machining solutions for electromobility components into solution stages, depending on the precision requirements and production volume.

-

16.11.2022

Green tools protect resources

The use of minimum quantity lubrication is a lever for saving resources in production. MAPAL offers almost all tools in variants for MQL.

-

10.11.2022

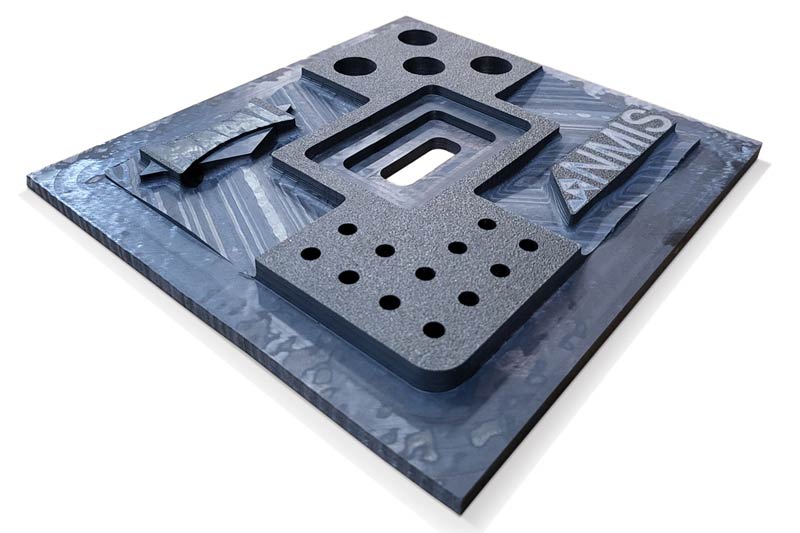

CFRP demo part for trade fairs and events

A generic component developed in collaboration with the National Manufacturing Institute Scotland demonstrates MAPAL's expertise in CFRP machining.

-

19.10.2022

ハイドロチャックがよりサステナビリティな理由

Service life, energy balance, handling: Why hydraulic expansion chucks have clear advantages over shrink chucks in terms of sustainability.

-

12.09.2022

Customer needs as an impetus for innovation

At the AMB in Stuttgart, MAPAL will be presenting new products and innovative machining solutions for the focus industries, thereby increasing the competitiveness of customers.

-

-

22.03.2022

The Digital Twin is Showing its Teeth

Quality assurance and error detection in production through real-time data analysis is promised by the Machining Analytics Solutions module from c-Com.

-

10.03.2022

Titanium Machining Takes Off

MAPAL is making drilling and milling of the ductile, high-strength workpiece material more productive, thereby reducing costs.

-

25.10.2021

IMPULSE — edition 76 is available

News on e-mobility. New tools for machining titanium as well as valve housings and pot-shaped stator housings. A new module from c-Com.

-

04.10.2021

Continuous process for electromobility

Topfförmige Statorgehäuse für Elektromotoren sind aufgrund ihrer Dünnwandigkeit und engen Toleranzen anspruchsvoll zu bearbeiten. MAPAL liefert den kompletten Prozess.

-

04.10.2021

MAPAL receives state funding for digital project

Umwelt- und ressourcenschonende Zerspanung – MAPAL forscht mit renommierten Partnern. Kern des Projekts ist die genaue Analyse von Daten.

-

16.08.2021

IMPULSE — edition 75 is available

Discover smart solutions as well as the potential of MAPAL’s Tooltronic and the radial milling cutters NeoMill.

-

07.04.2021

IMPULSE edition 74 is available

The latest edition of Impulse is available. One of the main topics is the market launch of MAPAL in the die and mould sector.

-

01.04.2021

E-Mobility: New Catalogue

Electrified components, their structure, their requirements and MAPAL's machining concepts –useful tips and detailed illustrations.

-

08.02.2021

Economical and reliable machining of steel beams

The flexible use of steel beams in many areas goes hand in hand with closely defined manufacturing tolerances. How MAPAL contributes to high process reliability.

-

01.01.2021

Maximum tool life in CFRP thanks to diamond coating

Why MAPAL relies on SP3 technology for the coating of solid carbide tools, what makes their machines special and where the expertise for diamond coatings comes from…

-

04.12.2020

Electrified Mobility

Reliable machining of small housings for electric motors made of magnesium and aluminium

-

23.06.2020

Conceived from the process – a development partnership between a machine manufacturer and a tool manufacturer

MAPAL and ELHA share a long lasting business association therefore the customers gain huge advantages.

-

15.05.2020

Lowering costs with sophisticated tool solutions

Tools have an impact on the overall operating costs of machining. It pays off to focus on the overall operating costs when purchasing.

-

01.05.2020

For Short Machining Times – Try Whirling Instead of Grinding

Why whirling is worthwhile for ball screw threads, what this has to do with ball nose milling cutters and what role additive manufacturing plays in this.

-

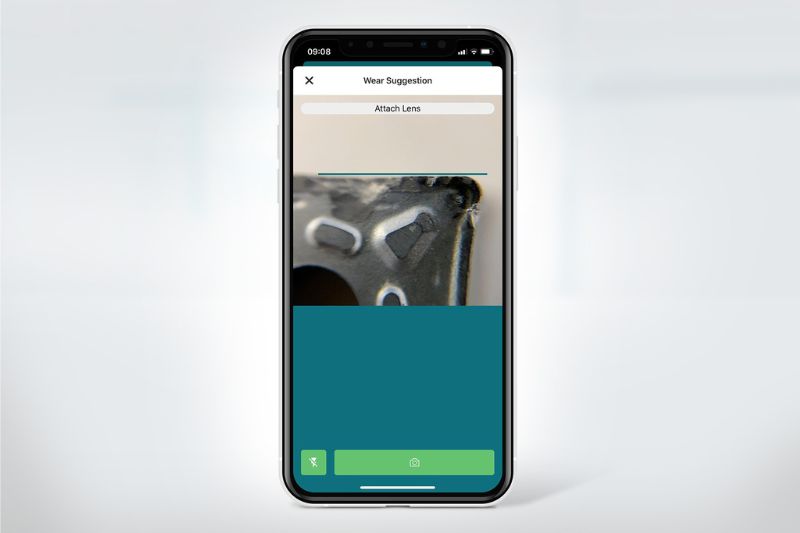

09.03.2020

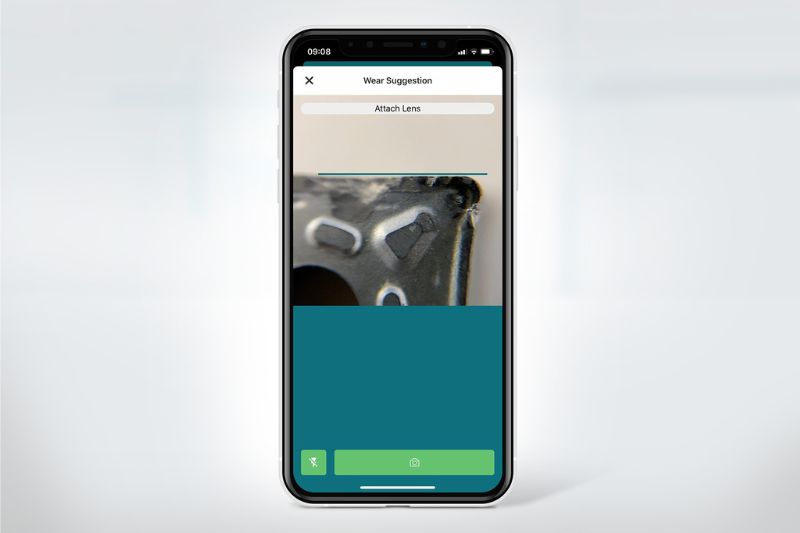

The c-Com wear detection app: a technical advisor in your pocket

Worn cutting edges raise questions about their nature, cause and future prevention. Luckily, c-Com has the answers.

-

17.01.2020

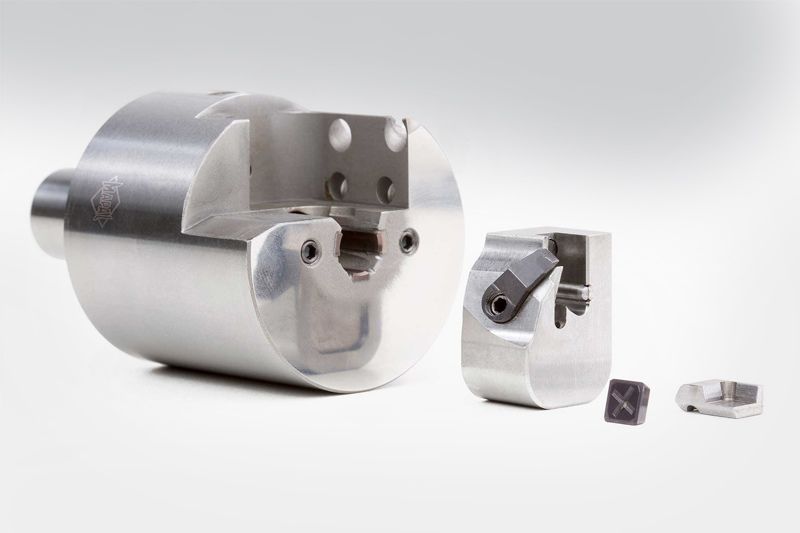

With additive manufacturing to more productivity - Bell tool for external machining from MAPAL

Lighter PKD tools usually mean significantly higher cutting data. An example of this is the new bell tool from MAPAL.

-

15.01.2020

Milling cast and steel parts more cost-effectively

MAPAL's new milling cutter programme with indexable inserts shows its potential in concrete applications.

-

01.01.2020

Partnerships, customer portals and artificial intelligence

c-Com isn’t just developing its own applications. It’s also generating added value for customers by working closely with cooperation partners.

-

01.01.2020

Complete Supplier in Tool and Mould Making

Why MAPAL has a unique selling point as a complete supplier in die and mould making and how customers benefit from this.

-

01.01.2020

The new FaceMill-Diamond: Process-reliable face milling with a long tool life

The productivity of MAPAL's PCD facemilling system Face-Mill-Diamond increased due to research and development.

-

02.12.2019

Digital coating processing – effective, sustainable and transparent

When reconditioning tools, the effort involved in order processing is often very high. Oerlikon Balzers and c-Com are therefore jointly developing an app.

-

25.11.2019

Minimized set-up time, maximum tool life – cooperation between MARPOSS and c-Com

When companies bundle their competencies, they often open up significant added value for their customers. One example of this is the collaboration between MARPOSS and c-Com.

-

08.11.2019

Reliable and Cost-effective Manufacture of Turbochargers in Series

Manufacturers of turbochargers face challenges in machining. How MAPAL makes the entire process cost-effective and efficient.

-

01.09.2019

High-performance Milling Cutter for the Machining of Structural Parts

Axel Fleischer speaks in an interview about challenges, opportunities and new potential in the aerospace industry with high-performance milling cutters from MAPAL

-

16.08.2019

Handling Made Easy for External Reaming of Small Diameters

Adjustable external reamers offer an economical alternative to the traditional grinding process in series production.

-

25.07.2019

Higher Surface Quality through Vibration Dampaning

New Milling Cutter Arbors with Vibration Damper Improve Process Reliability and Surfaces

-

01.07.2019

Electric motor housings reliably enter large-scale production

For the complete machining of housings for electric motors, MAPAL is offering tool solutions which are ready for series production, reliable and absolutely precise.

-

28.05.2019

MAPAL Expert Day highlights potential in steel and cast machining

Scientists, users and tool specialists show various ways of increasing efficiency. Participants are enthusiastic.

-

01.05.2019

Digitalisation for regrinding of tools – Transparency and efficiency courtesy of c-Com

Tool management is often the critical point in the regrinding process. How MILLER overcomes this challenge.

-

01.05.2019

MAPAL acquires majority stake in ADICO - manufacturer of PCD and PcBN blanks

ADICO and MAPAL have been working together for years. MAPAL fully integrated the company into the Group at the end of 2018.

-

27.03.2019

c-Connect – digitizing one step at a time

How machining companies manage to digitalise their manufacturing processes without seeing the need to completely modernize their machining park.

-

01.01.2019

Changing Mobility

How machine manufacturer Heller together with tool manufacturer MAPAL brought the manufacturing of a newly designed stator housing to series maturity.

-

01.09.2018

Reliable Machining of Structural Parts Susceptible to Vibration

How customers machine demanding structural parts economically and reliably with a complete solution from MAPAL.

-

01.09.2018

OptiMill-Uni-Wave Cord Roughing Cutter

Large cutting depth, optimum chip removal and high material removal rate – the new universal milling cutter from MAPAL is impressive for machining steel and stainless steel.

-

01.09.2018

Miniaturisation in clamping technology thanks to additive manufacturing

Additively manufactured hydraulic chucks in small format from MAPAL are following the trend towards miniaturisation. They meet the highest standards.

-

01.08.2018

External reamer ensures high-precision cylindricity

With the tool for external machining, Völlm machines pins onto planetary carriers economically and with high precision and process reliability

-

01.06.2018

With MAPAL for a chatterfree process

Various tool concepts reduce vibrations during machining and ensure a smooth, reliable process.

-

01.05.2018

Using new solutions for a reliable process - relief bore is introduced in crancshafts

How an automobile manufacturer brings a new process safely into series production with MAPAL by its side as technology partner.

-

01.03.2018

Smaller, more heat resistant more and more individual - application focus clamping technology from MAPAL

Interview with product manager Jochen Schmidt about the role of clamping technology in the machining process, the advantages thanks to additive manufacturing and digital services

-

01.02.2018

Concentrated flexibility and efficiency – facing heads and mounting tools from MAPAL

Bühring is tasked with machining complex contours on components for straw balers. Why the company has decided to go for a tool solution from MAPAL

-

01.01.2018

Precise, efficient and easy to handle – Tools for fine machining bores from MAPAL

Interview with product manager Michael Neumann about accuracy, efficiency and handling when reaming and fine boring

-

01.01.2018

Dry Machining of Multilayer Composites in Aircraft Construction

The final assembly of aircraft presents special challenges for tool manufacturers. MAPAL has developed special tools just for this.

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342