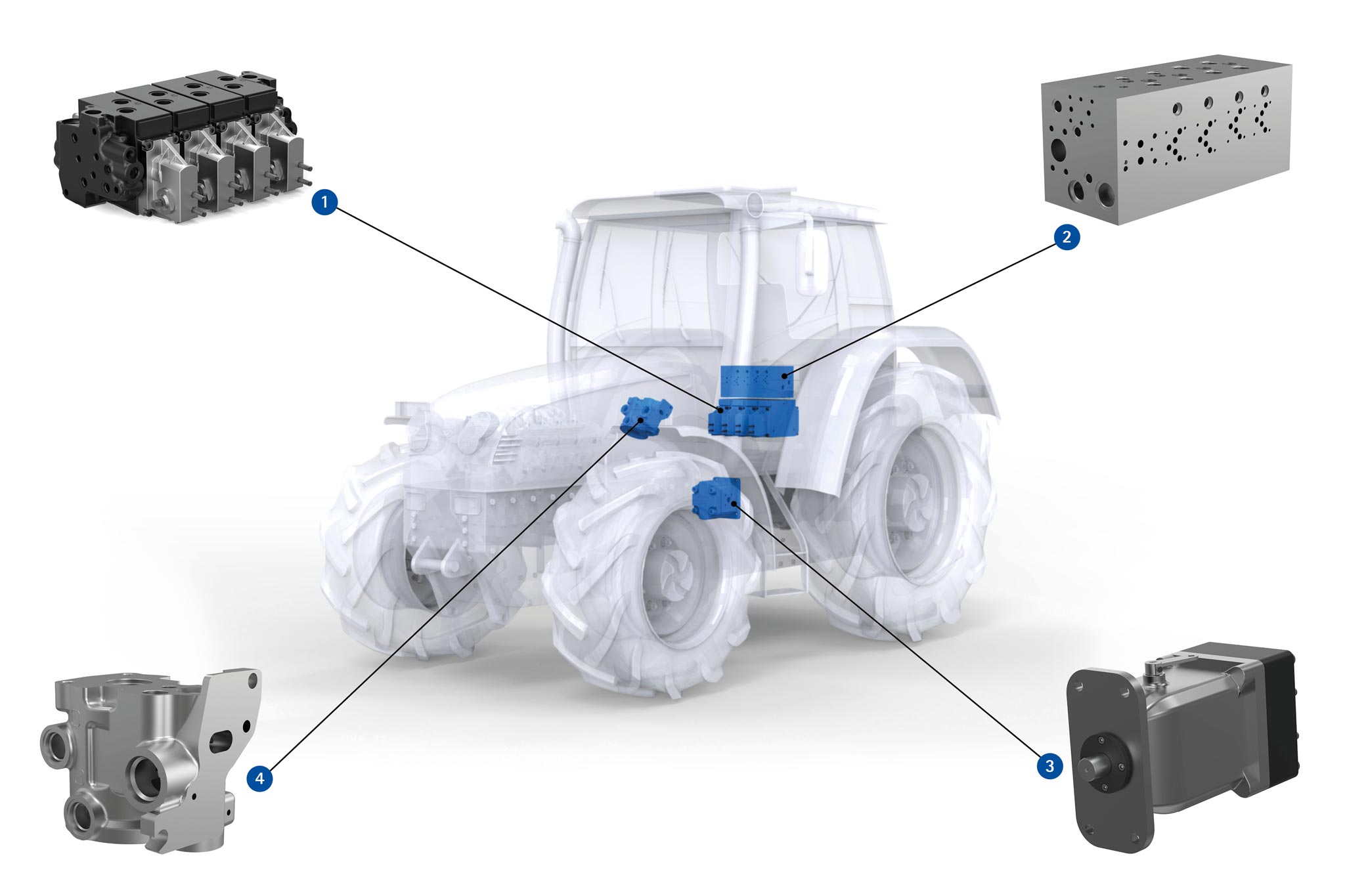

油圧

マパールは、移動式の油圧作業およびステアリング回路に機能的に関連する部品に対して完全な専用加工プロセスを提供します。さらに、革新的で価値あるプロセスソリューションは、定置型油圧機器の部品の製造においても高い評価を得ています。

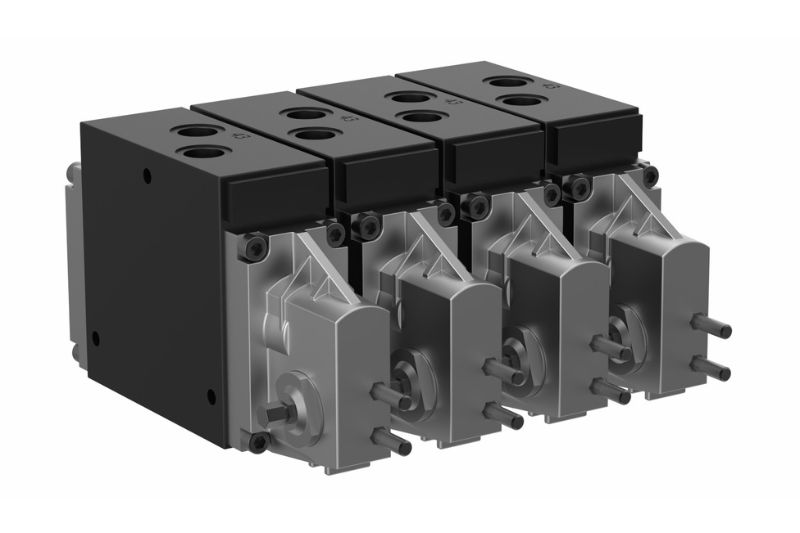

- (1) 油圧バルブハウジング

-

油圧バルブハウジングの加工ソリューション

すべてはメイン穴の加工品質に依存します。流体技術部品の加工において、バルブケースの製造は、最も高い精度が要求される分野です。ここでは長年にわたってマパールのスプール穴加工に関する技術ノウハウが必要とされてきました。スプールとスプール穴のギャップは、加工穴の精度に左右され、作動油は一定の方向にしか流れないようになっています。

最近の油圧バルブ穴は、加工公差の幅が非常に狭くなっています。そのため、加工穴の真円度、真直度、円筒度、仕上げ面精度はきわめて重要になっています。基本手順 - 加工工程の分析

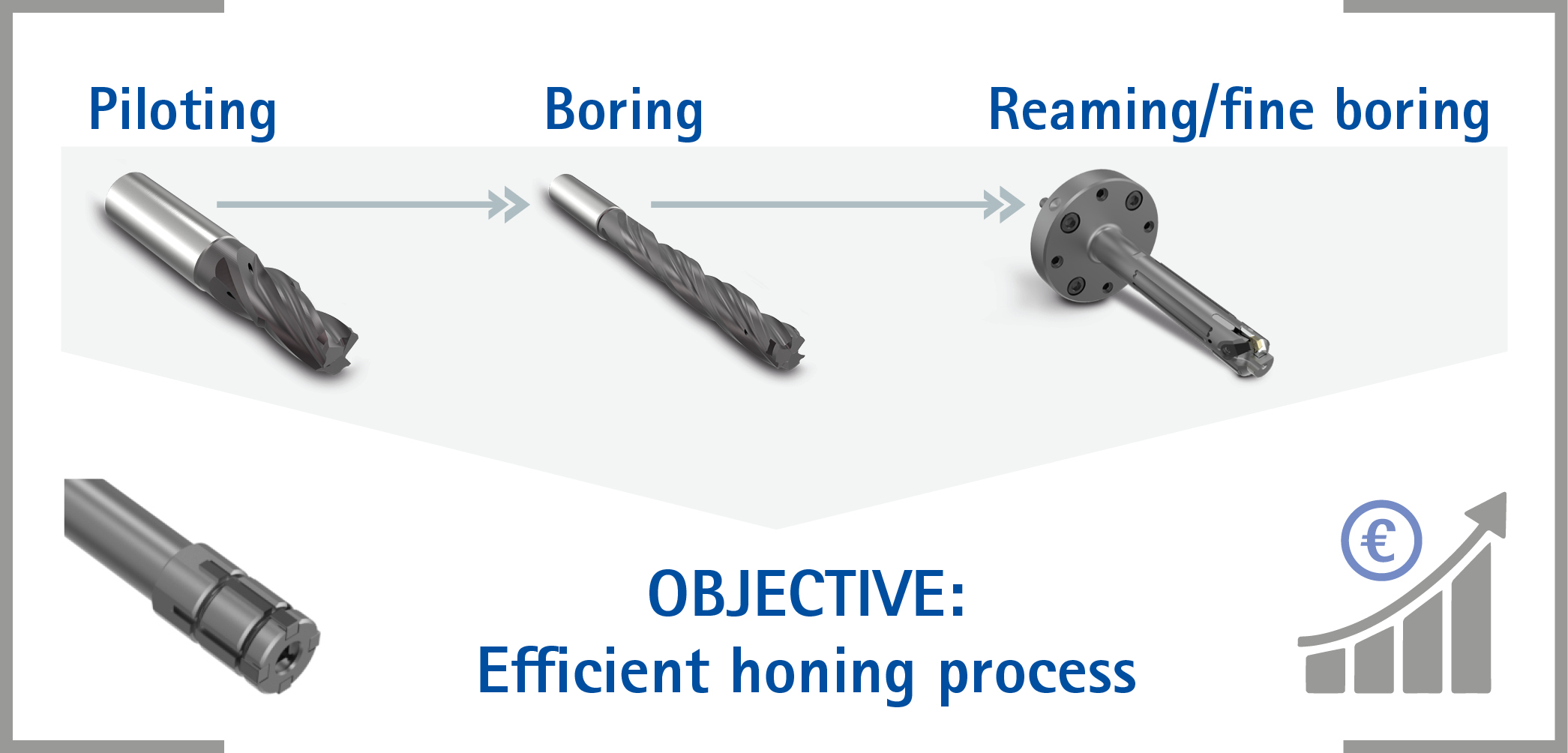

マパールは技術パートナーとして、プロセス設計全般においてお客様をサポートします。その際、エキスパートは機能に重要な穴加工によく見られるコスト要因に特に注意を払います。 ホーニング、加工ワークの要求項目、バッチサイズに基づき、マパールはお客様との対話の中で最適な加工戦略を設計します。1つの目標がすべての活動を結び付けます: パイロット穴加工から始まり、ボーリング、中仕上げ加工を経て、効率的なホーニング加工に到るまで、経済的なプロセスを設計します。 - (2) コントロールブロック

-

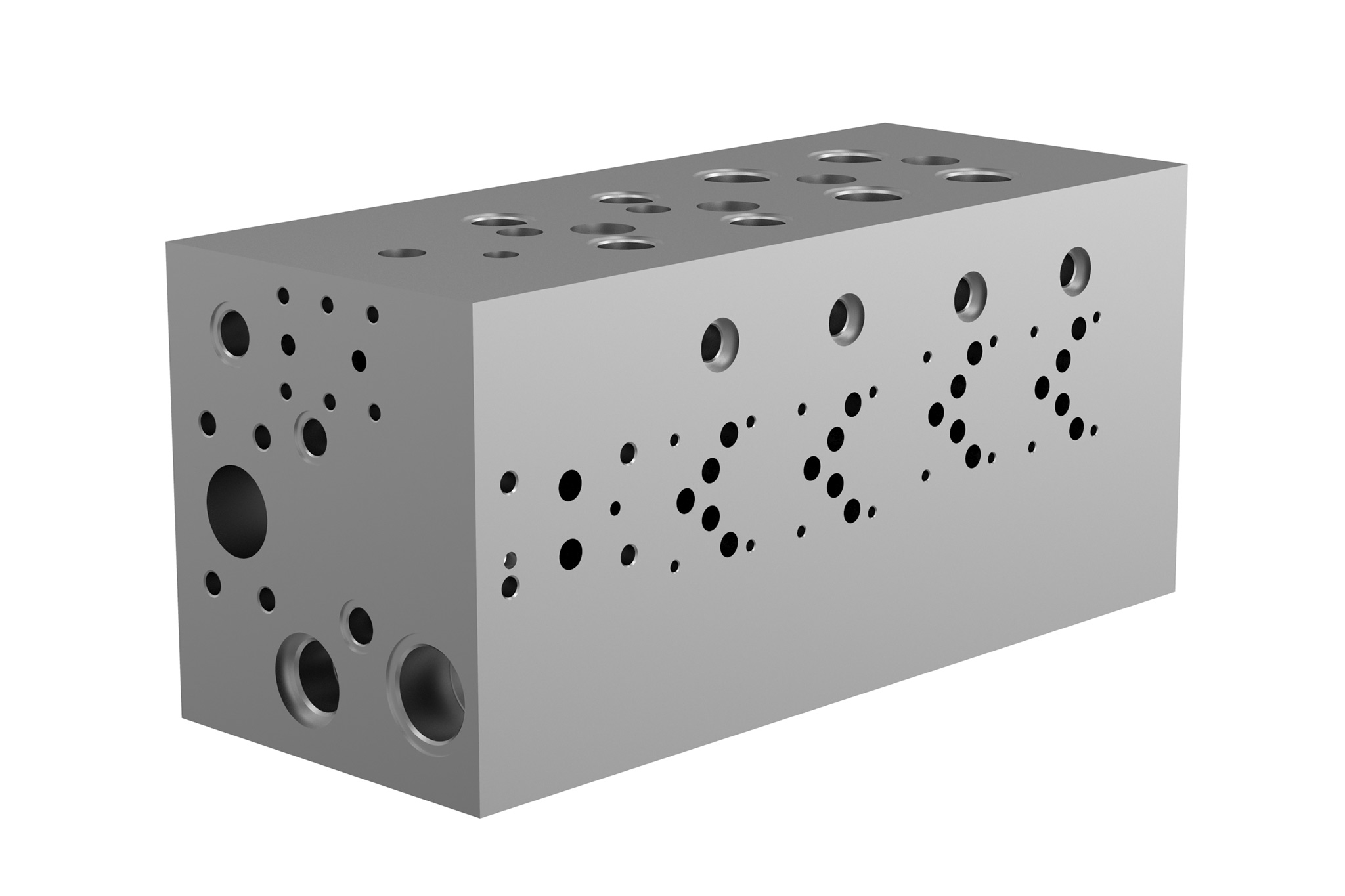

基本手順 - 加工工程の分析

マパールは技術パートナーとして、プロセス設計全般においてお客様をサポートします。その際、エキスパートは機能に重要な穴加工によく見られるコスト要因に特に注意を払います。 ホーニング、加工ワークの要求項目、バッチサイズに基づき、マパールはお客様との対話の中で最適な加工戦略を設計します。

1つの目標がすべての活動を結び付けます: パイロット穴加工から始まり、ボーリング、中仕上げ加工を経て、効率的なホーニング加工に到るまで、経済的なプロセスを設計します

- (3) アキシャルピストンマシン

-

Axial piston pump

アキシャルピストンマシンとは、アキシャルピストンポンプとモーターを指します。アキシャルピストンポンプは、機械エネルギーを油圧エネルギーに変換し、アキシャルピストンモーターは油圧エネルギーを機械エネルギーに変換します。

アキシャルピストンマシンは、高い安定性と優れた内部シーリングを特徴としており、高圧を可能にします。基本手順 - 加工工程の分析

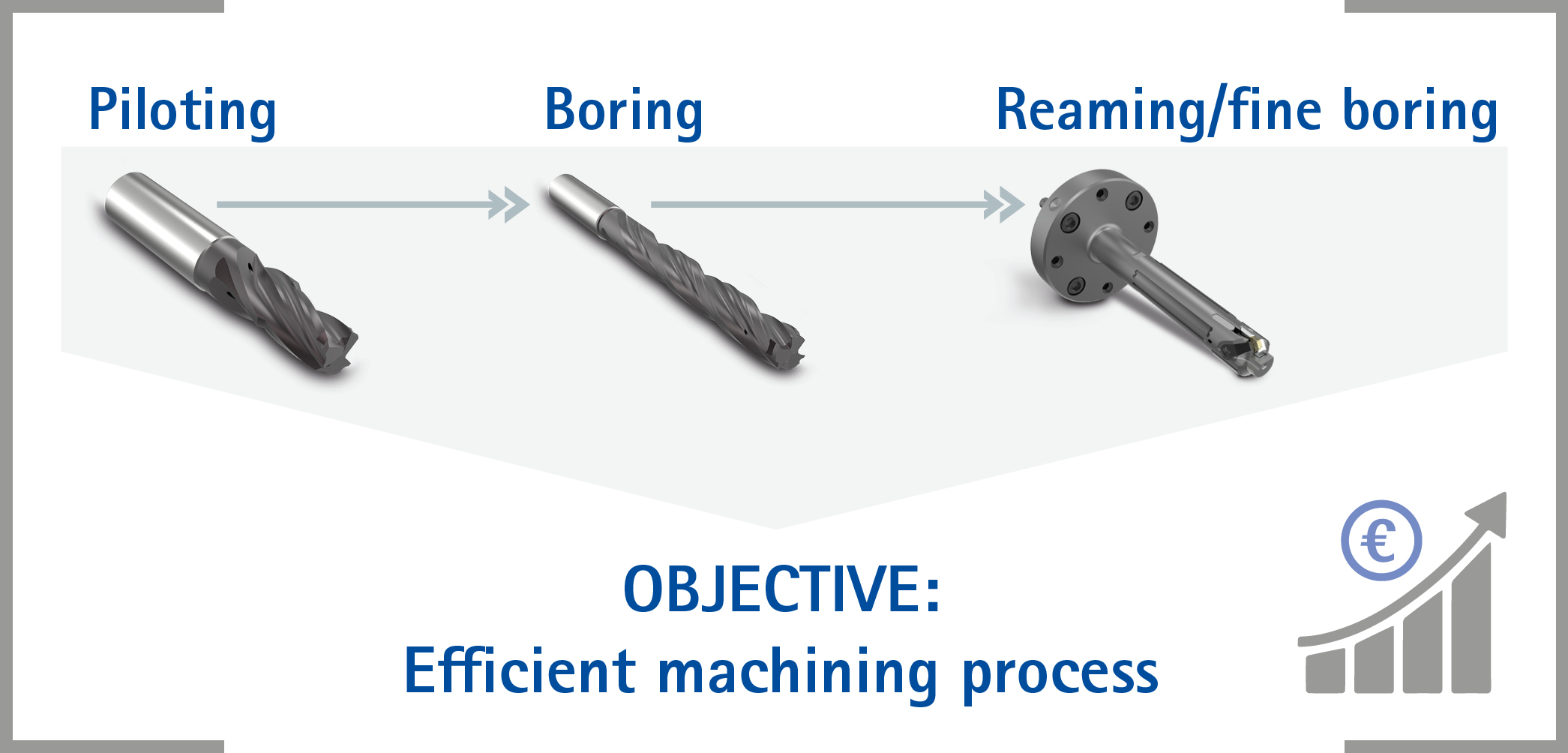

マパールは技術パートナーとして、プロセス設計全般においてお客様をサポートします。その際、エキスパートは機能に重要な穴加工によく見られるコスト要因に特に注意を払います。 ホーニング、加工ワークの要求項目、バッチサイズに基づき、マパールはお客様との対話の中で最適な加工戦略を設計します。

1つの目標がすべての活動を結び付けます: パイロット穴加工から始まり、ボーリング、中仕上げ加工を経て、効率的なホーニング加工に到るまで、経済的なプロセスを設計します

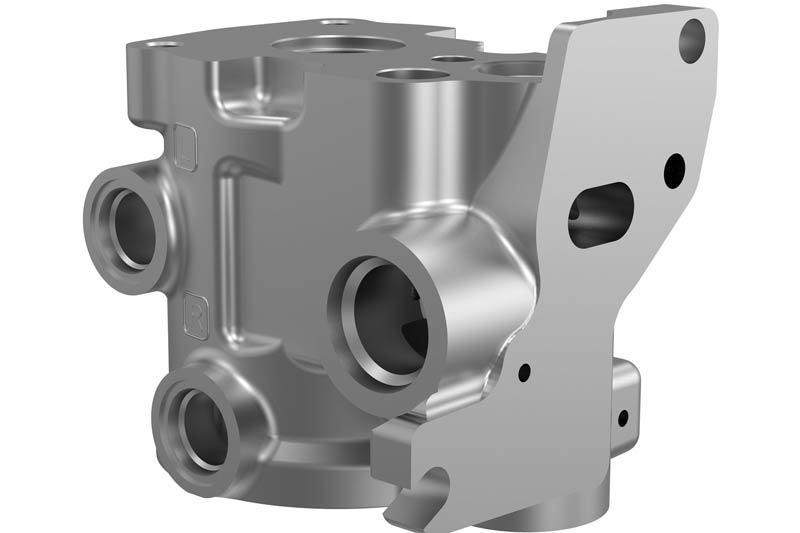

- (4) 油圧オービトロールステアリング

-

油圧オービトロールステアリング

油圧オービトロールステアリングは、油圧式ステアリングの中央制御エレメントです。油圧ポンプから送られる流量は、ステアリングホイールの動きに応じて油圧シリンダーの作動室に送られ、ステアリングナックルを作動させます。ステアリングシステムが永続的に機能するように、プライオリティバルブが使用されます。基本手順 - 加工工程の分析

マパールは技術パートナーとして、プロセス設計全般においてお客様をサポートします。その際、エキスパートは機能に重要な穴加工によく見られるコスト要因に特に注意を払います。 ホーニング、加工ワークの要求項目、バッチサイズに基づき、マパールはお客様との対話の中で最適な加工戦略を設計します。1つの目標がすべての活動を結び付けます: パイロット穴加工から始まり、ボーリング、中仕上げ加工を経て、効率的なホーニング加工に到るまで、経済的なプロセスを設計します。