航空宇宙

高強度でありながら軽量な素材は、航空機において中心的な重要性を持っています。新しい材料の組み合わせにより、重量をさらに減らし、強度と耐食性を高め、統合的な製造デザインによって組み立てを簡素化できます。アルミニウム、チタン、または高強度鋼で作られた構造部品は、マシニングセンターや門型マシンで加工されますが、最終的な組み立ては、ハンドガイドマシン、ドリルフィードユニット、またはロボットによって行われます。

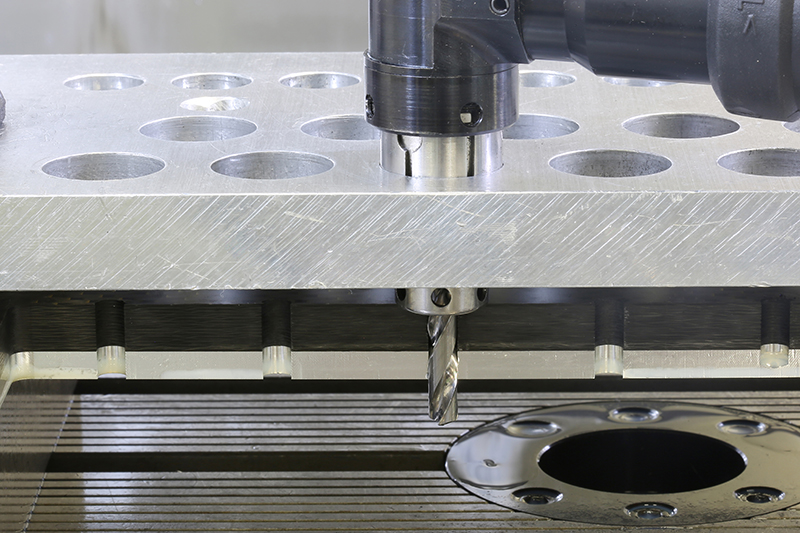

部品製造

部品製造では、部品は定置工程で加工されます。つまり、部品はマシンでワンチャック以上で加工されます。小型から中型のキュービック(箱型)部品はマシニングセンターで加工できますが、大型の部品は特別な門型マシンが必要になります。

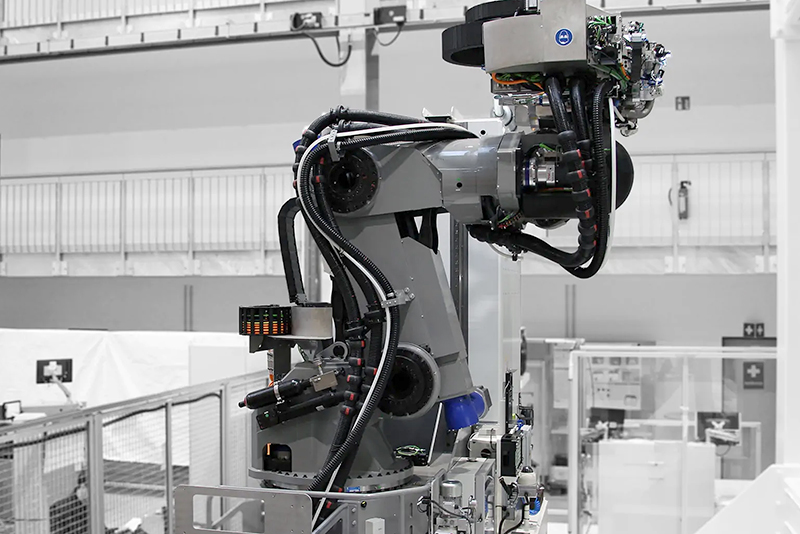

最終組立

航空機の最終組立では、対象物の大きさにより、今日でもハンドガイドマシンが使用されています。いわゆる最終組立ライン(FAL)では、例えば航空機の胴体の外皮にリベット穴を開けます。ツールは特別なガイドエレメントで設計されています。

Latest news in the aerospace sector

-

24.10.2025

Portrait: MAPAL Centre of Competence PCD tools

With the Centre of Competence for PCD tools, MAPAL sets standards in customer service, technology, efficiency and sustainability.

-

15.10.2025

Successful tooling solutions from MAPAL increase productivity for customers.

Increasing customer productivity is at the heart of MAPAL’s standard processes for the industrial manufacturing of strategic components.

-

06.10.2025

Innovations and solutions of MAPAL

MAPAL presents its 2026 innovations and solutions in a comprehensive brochure.