Motore a combustione

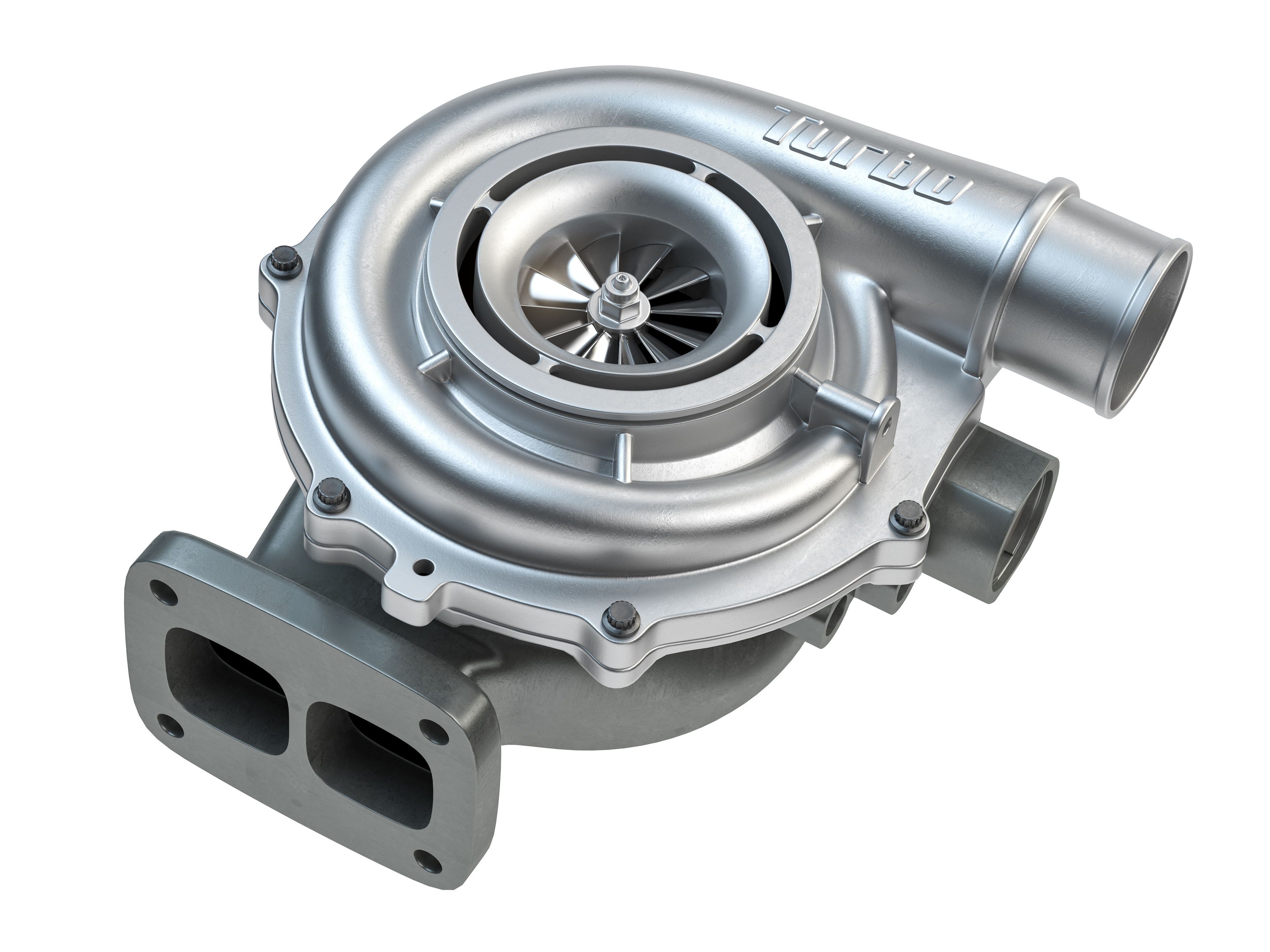

Per oltre un secolo, i motori a combustione hanno definito la mobilità. Questi continuano a trovare molte applicazioni, nonostante i severi standard sulle emissioni e l’emergere di soluzioni di propulsione alternative. Tecnologie che migliorano l’efficienza, come il downsizing e la sovralimentazione, continuano ad assicurarne la competitività, mentre i combustibili sintetici conferiscono loro un potenziale sostenibile per il futuro. Nonostante la dominanza dell’elettromobilità in alcune regioni, la tecnologia dei motori a combustione continuerà a muovere milioni di nuovi veicoli, affermandosi come un elemento imprescindibile nell’industria automobilistica globale.