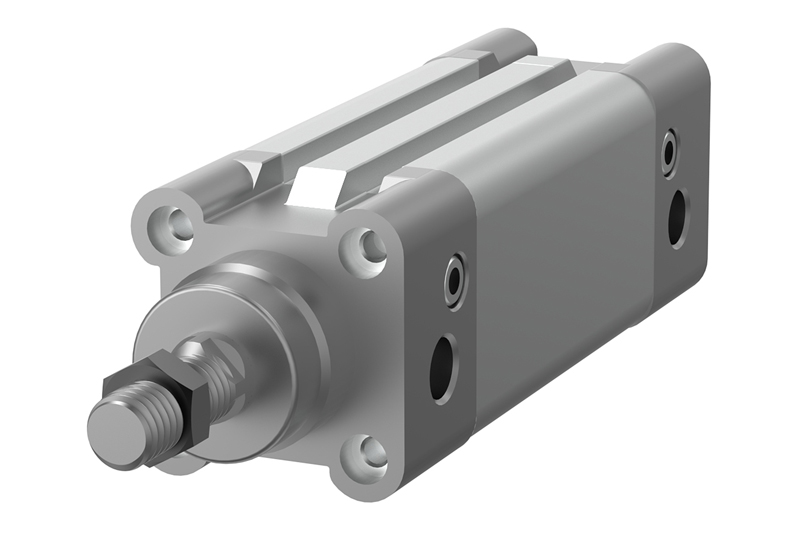

空圧

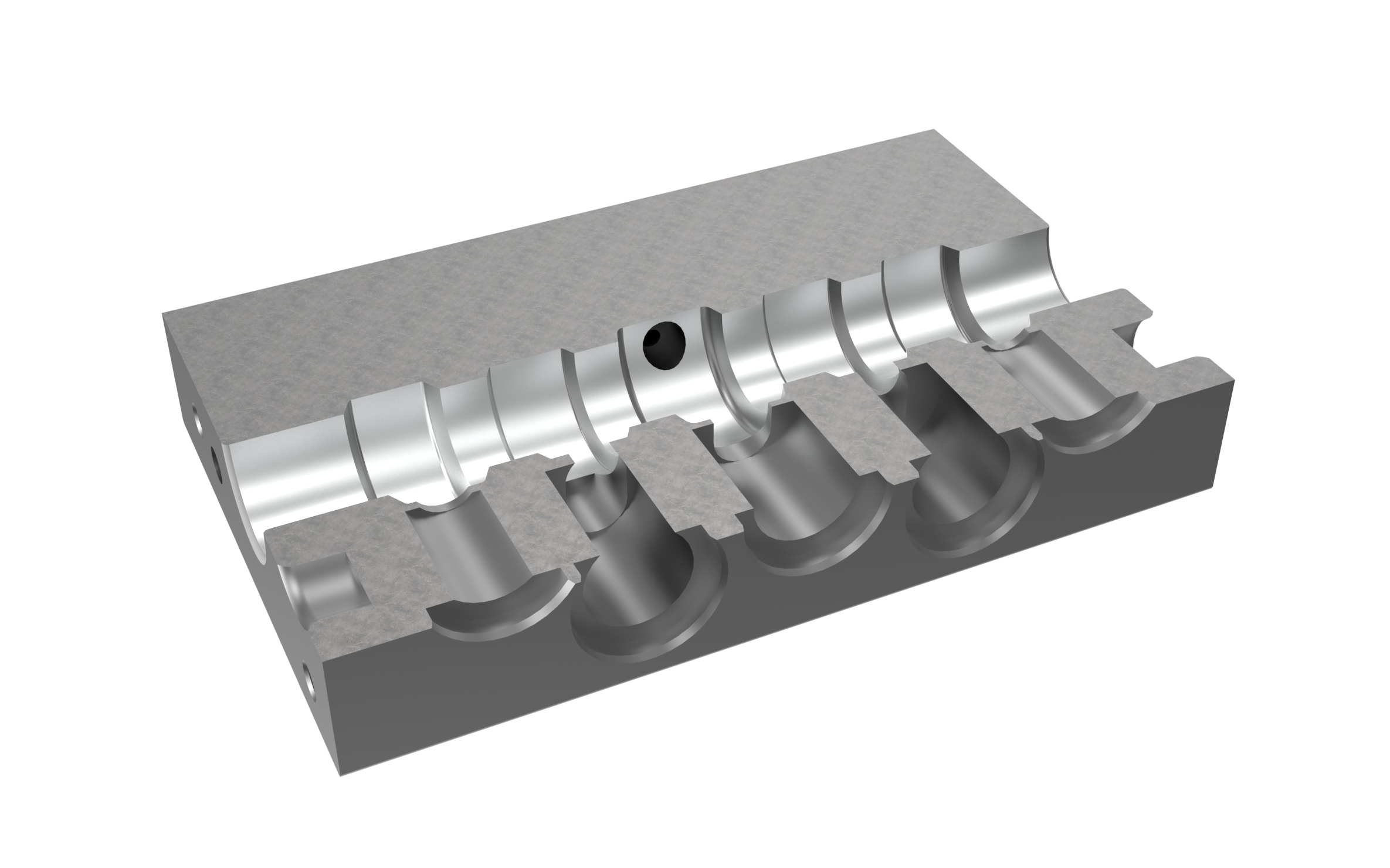

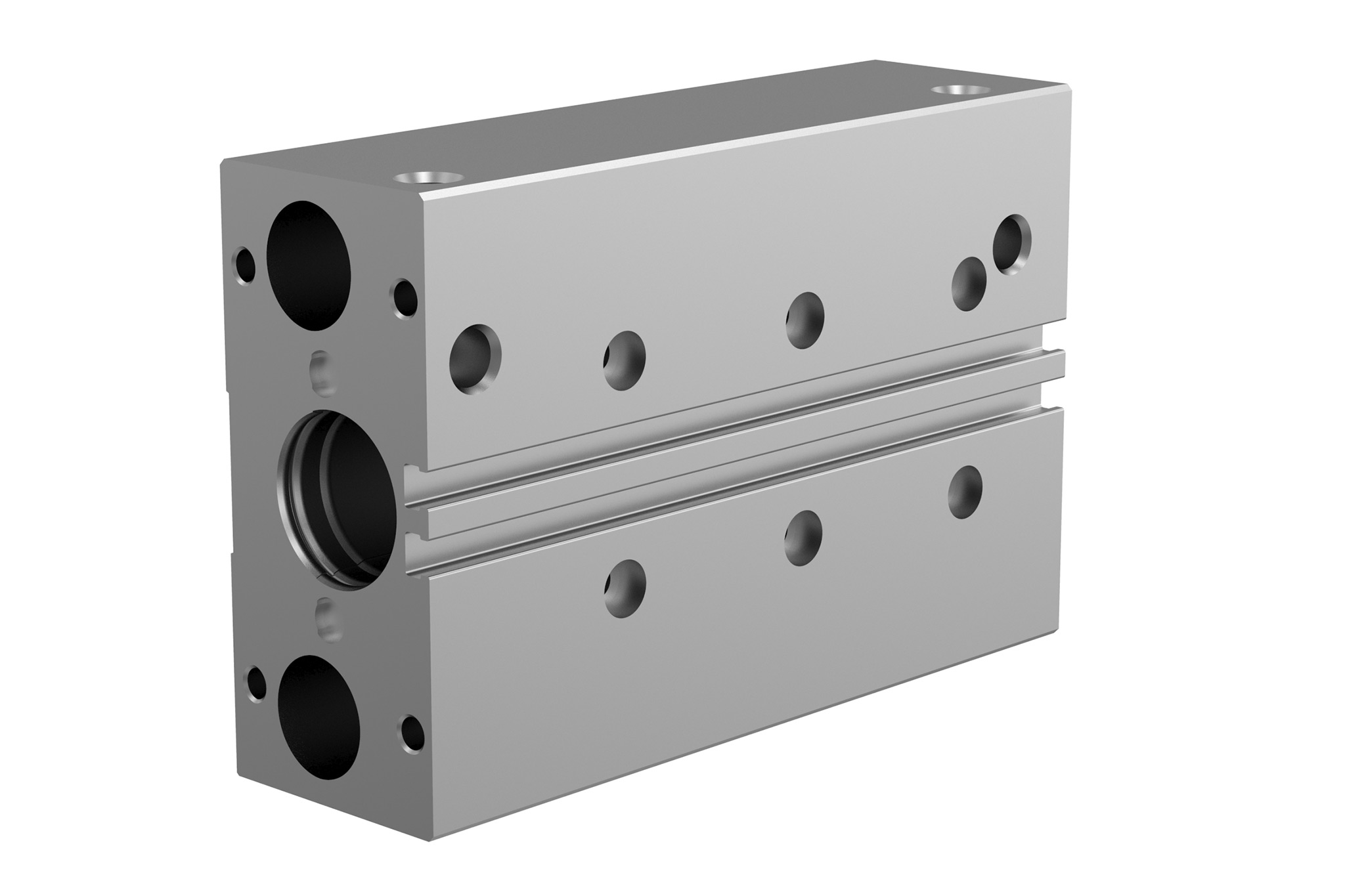

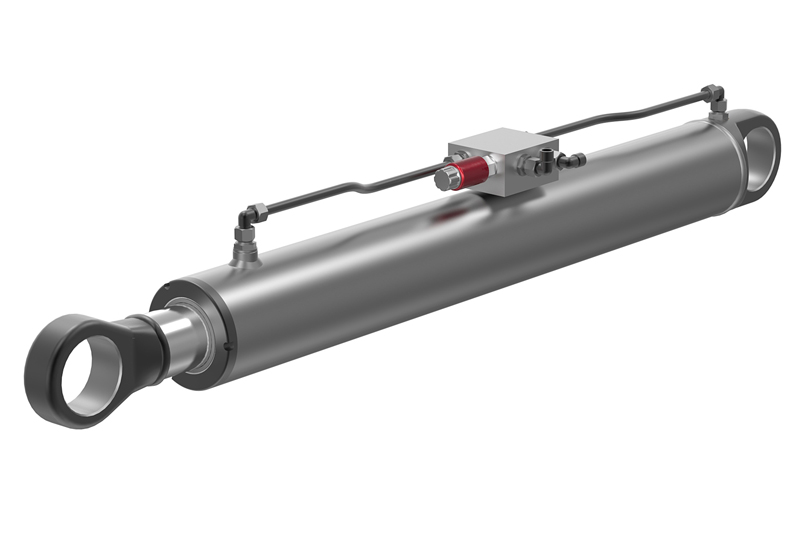

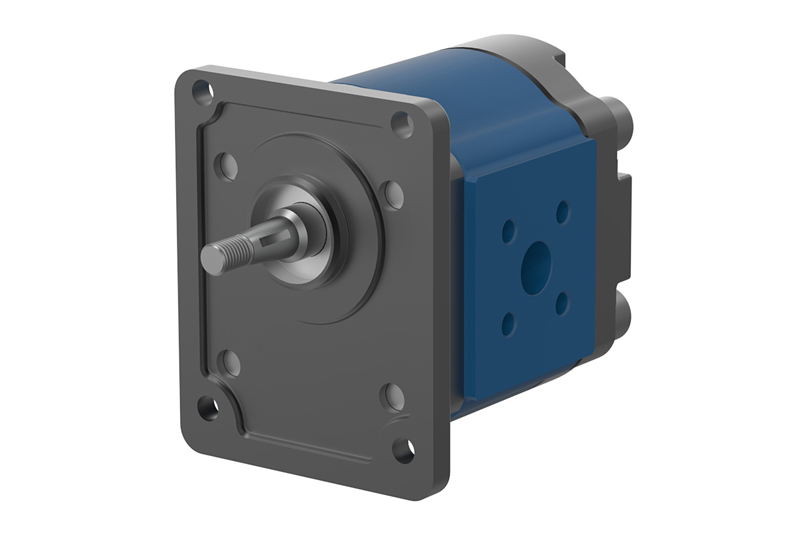

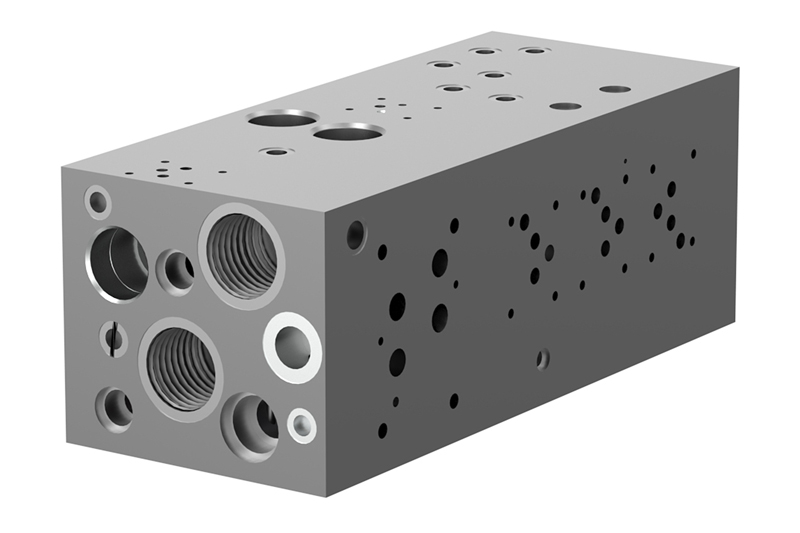

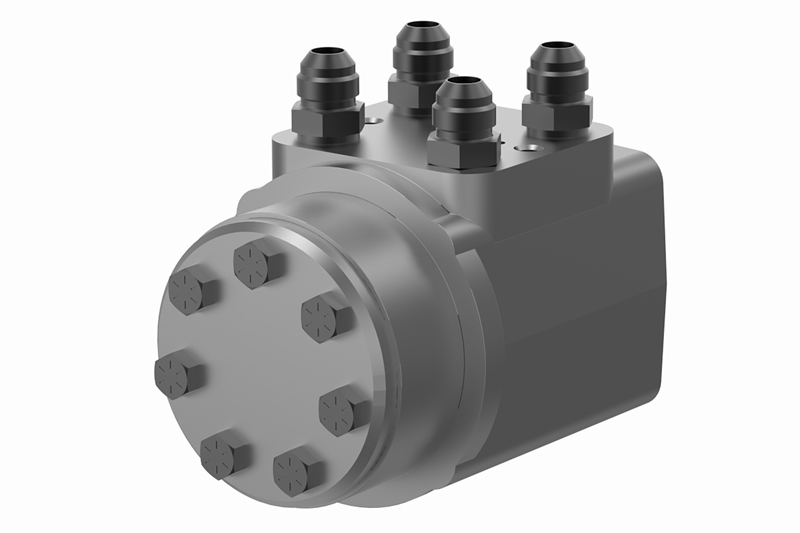

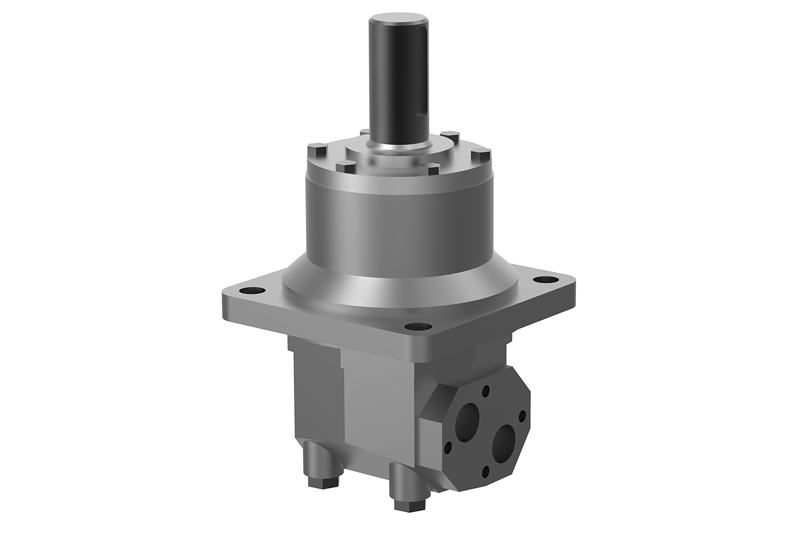

流体技術製品でよく使われる鋳鉄、スチール、ステンレス鋼および非鉄金属等の被削材に対して、マパールは穴加工とミリング加工の両方で優れた専門知識を有し、経済的なプロセスソリューションを提供します。さまざまな形状の油圧および空圧部品の厳しい要求の機械加工に関して、マパールは長年にわたりお客様から信頼を得てきました。

Weitere Werkzeughighlights

流体技术的其它解决方案

MAPAL公司支持对于几乎所有组件尺寸的其它流体技术组件进行完整加工,并为功能相关的切削加工要求提供强大的解决方案。