リーマ加工とファインボーリング加工

-

07.01.2026

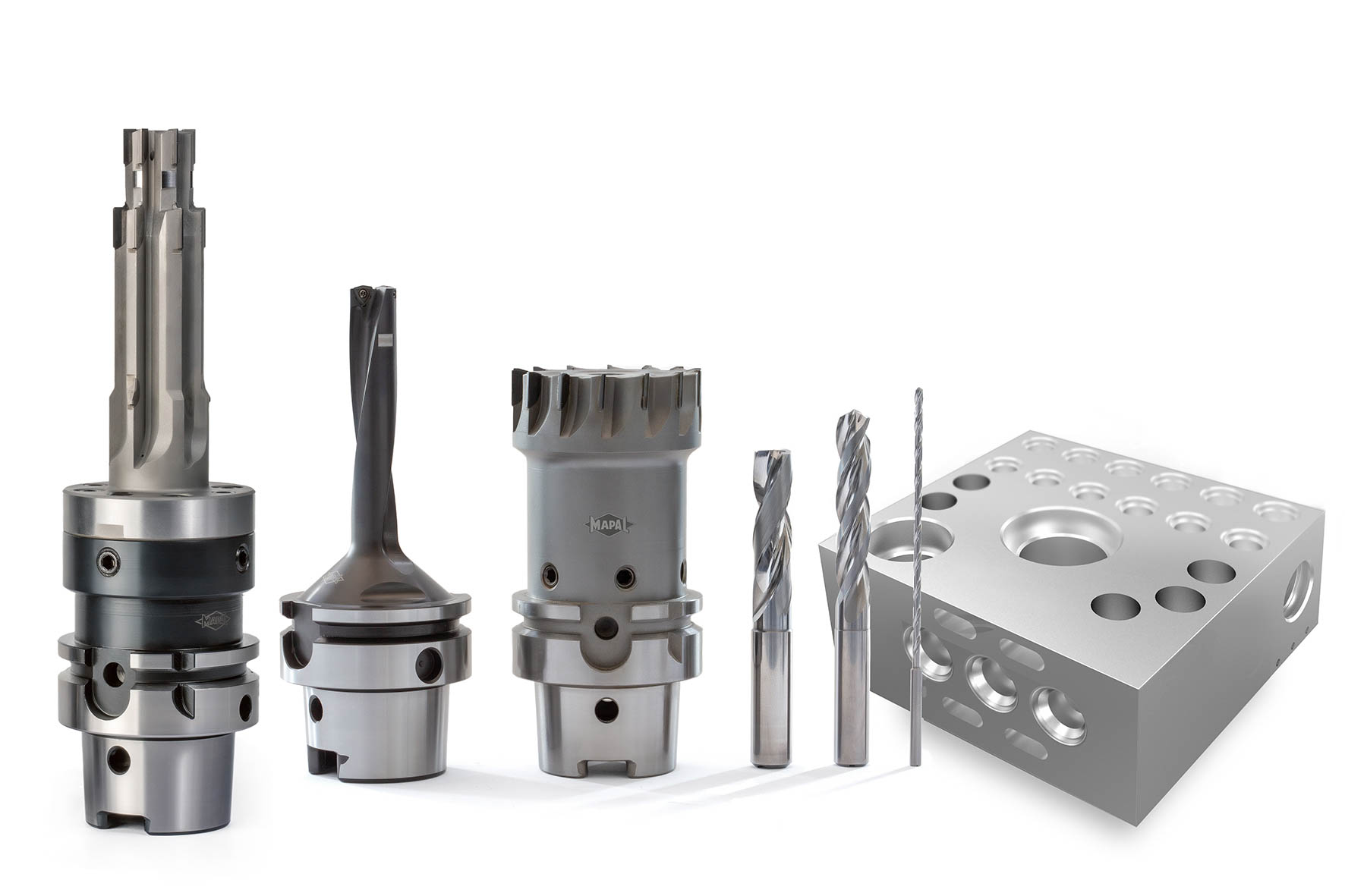

New solutions for boosting productivity with HPR400 and HPR400 plus

With HPR400 and HPR400 plus for highly productive reaming of large diameters, MAPAL meets the highest demands in fine machining.

-

06.11.2025

New standardised chip breaker geometries for fine boring cutting edges

MAPAL has developed a standardised chip breaker geometry for fine boring cutting edges used in machining long-chipping steel materials.

-

15.10.2025

Successful tooling solutions from MAPAL increase productivity for customers.

Increasing customer productivity is at the heart of MAPAL’s standard processes for the industrial manufacturing of strategic components.

-

06.10.2025

Innovations and solutions of MAPAL

MAPAL presents its 2026 innovations and solutions in a comprehensive brochure.

-

26.08.2025

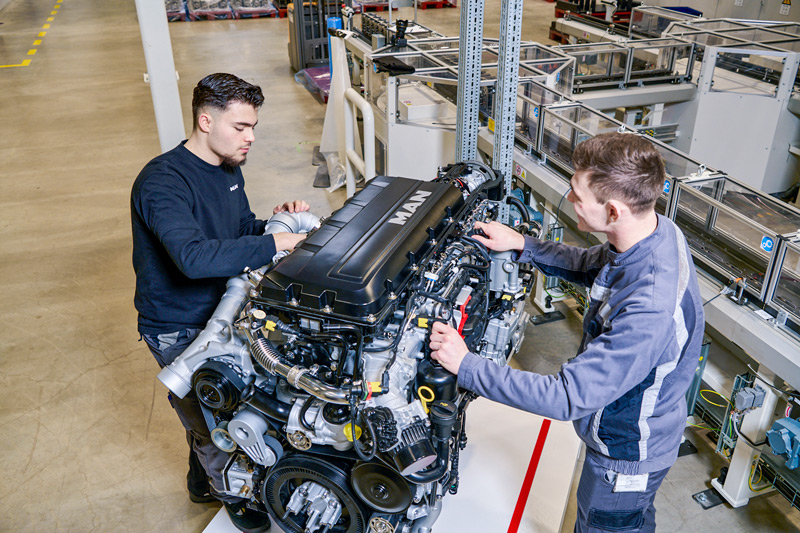

MAN uses MAPAL fine boring tools for machining cylinder heads

At MAN engines, fine boring tools from MAPAL are used to machine the valve guide and valve seat counterbores of cylinder heads."

-

22.07.2025

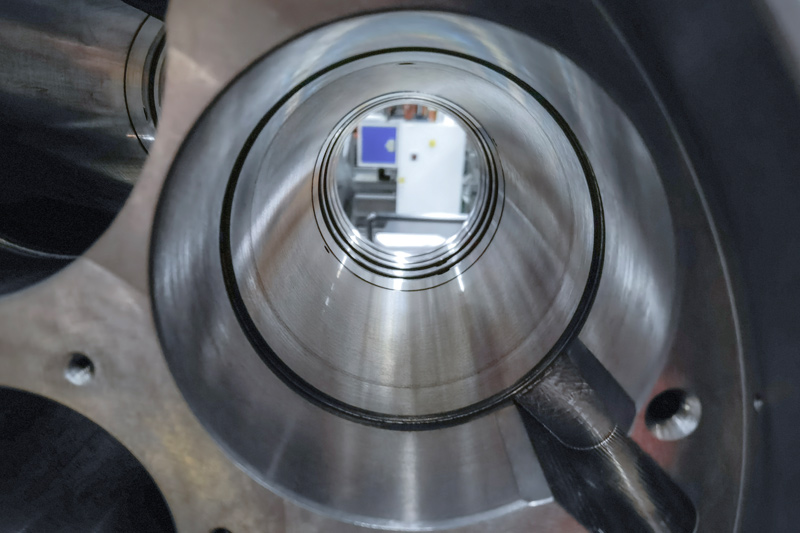

Crankshaft and valve seat machining: MAPAL sets standards

Optimised machining of crankshafts and valve seats: MAPAL offers innovative tool solutions for modern combustion and hybrid engines.

-

28.03.2025

Suitable tools for combined brake housings

Combined brake housings unite the brake master cylinder, brake booster and ABS/ESP in one component and pave the way to autonomous driving. MAPAL offers solutions for machining complex aluminum workpieces.

-

16.01.2025

Tool management from MAPAL completed for DEUTZ in record time

MAPAL completed the entire engineering including tool design, cycle time study and cost calculation for the engine manufacturer Deutz in the Spanish plant in Zafra within a very short time.

-

25.06.2024

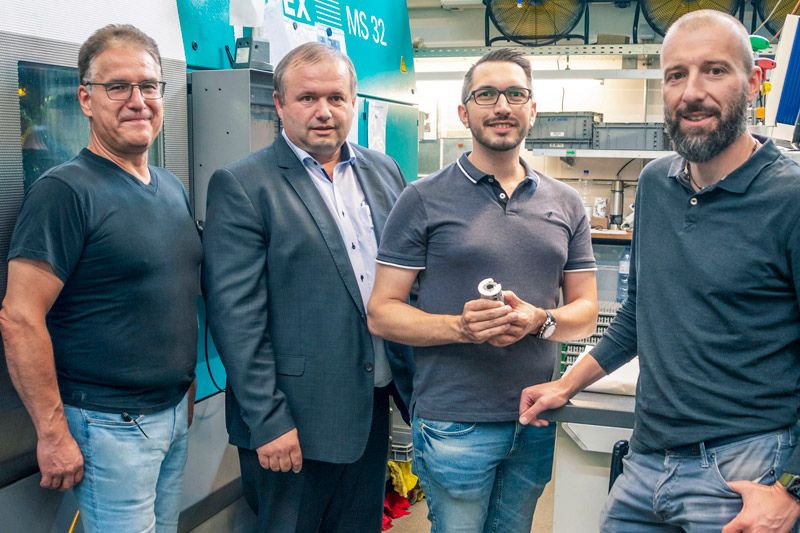

Efficient production in die and mould making: Krämer+Grebe and MAPAL

The mouldmaking company Krämer+Grebe optimises production with MAPAL reamers and milling cutters and ensures process reliability in international competition.

-

31.01.2024

Reamer with nine lives

With the FixReam 700, MAPAL launched a cylindrical shank reamer with brazed cutting edges that is particularly sustainable with nine lives.

-

04.05.2023

リーマ加工とファインボーリング加工部門からのニュース

New cutting materials are available for reaming high-alloy and stainless steels, cast steel and hardened steel. MN reamers are available within ten working days.

-

01.02.2023

Major progress in external reaming of turning workpieces

The Swiss manufacturer W.E. Schultz finishes turned parts with external reamers from MAPAL and reduces cutting costs to 25 and set-up costs to 10 percent.

-

12.01.2023

Basic–Performance–Expert

MAPAL clusters its machining solutions for electromobility components into solution stages, depending on the precision requirements and production volume.

-

16.11.2022

Green tools protect resources

The use of minimum quantity lubrication is a lever for saving resources in production. MAPAL offers almost all tools in variants for MQL.

-

22.08.2022

A new turn for e-mobility

Innovative machining process from NILES-SIMMONS and MAPAL with simultaneous internal and external machining and a combination of turning and boring/fine boring.

-

11.08.2022

MAPAL at the AMB 2022

At AMB 2022 in Stuttgart, MAPAL will be presenting innovations for the focus industries and options for increasing sustainability in Hall 1, Stand D10.

-

28.04.2022

Automotive technology for aeroplanes

Machine manufacturer F. Zimmermann GmbH and MAPAL jointly set standards in the project implementation and machining of an aerospace component.

-

13.04.2022

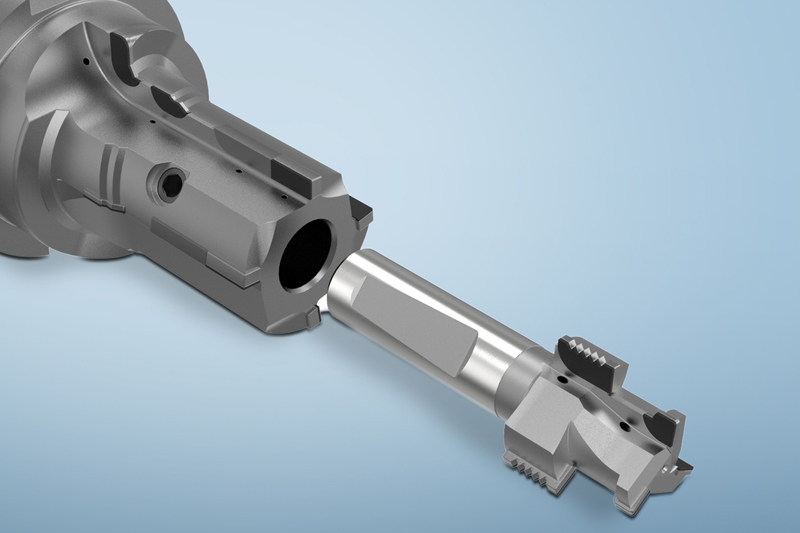

A multi-stage fine boring tool for the highest precision

Multi-stage fine boring tool from MAPAL machines component made of GGG40 with six bores, each with three merging cylindrical areas.

-

19.01.2022

When nothing is allowed to go wrong

With MAPAL tools, users can rely on the highest process reliability and precision in the final machining processes of the almost finished component.

-

13.10.2021

MAPAL Focuses on Fluid Technology

The spool bore in valve housings has particularly tight tolerances. The machining process from MAPAL fulfils the specifications reliably and with high economic efficiency.

-

14.04.2021

CVD coatings for steel and cast iron machining

Tools with innovative CVD coatings machine steel and cast materials much more economically. Examples from the fields of milling and reaming.

-

25.03.2021

One tool for reaming both through bores and blind bores

Range extension: New series can be used for through and blind bores. Tool and storage costs are reduced.

-

22.02.2021

Economical reaming in cast iron and steel in high quantities

The new, particularly economical replaceable head reamers from MAPAL, especially for the large-scale machining of cast and steel materials.

-

15.05.2020

Lowering costs with sophisticated tool solutions

Tools have an impact on the overall operating costs of machining. It pays off to focus on the overall operating costs when purchasing.

-

01.09.2019

Machining time halved, process stabilized - multi-cutting edged MAPAL fine boring tool

What role do axle swings play on crawler tracks for tractors and why maximum accuracy is required when machining them.

-

01.07.2019

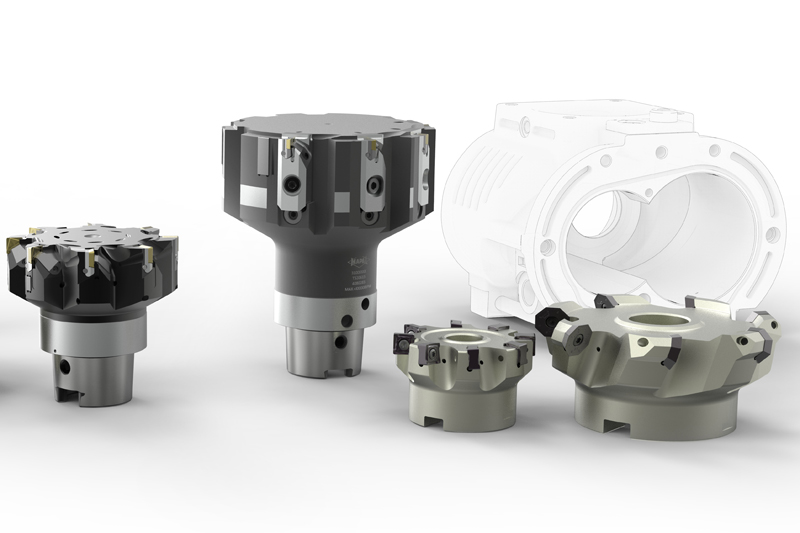

Electric motor housings reliably enter large-scale production

For the complete machining of housings for electric motors, MAPAL is offering tool solutions which are ready for series production, reliable and absolutely precise.

-

01.08.2018

External reamer ensures high-precision cylindricity

With the tool for external machining, Völlm machines pins onto planetary carriers economically and with high precision and process reliability

-

01.01.2018

Precise, efficient and easy to handle – Tools for fine machining bores from MAPAL

Interview with product manager Michael Neumann about accuracy, efficiency and handling when reaming and fine boring