Drilling

-

03.02.2026

New presetting device for fine boring tools with large diameters

With the new UNISET V basic plus tool presetting device, MAPAL closes the gap between simple mechanical and high end CNC presetting devices.

-

02.12.2025

Large tool package for Mangner Zerspanungstechnik

MAPAL has equipped Mangner GmbH with a comprehensive tool package for drilling operations.

-

06.10.2025

Innovations and solutions of MAPAL

MAPAL presents its 2026 innovations and solutions in a comprehensive brochure.

-

22.07.2025

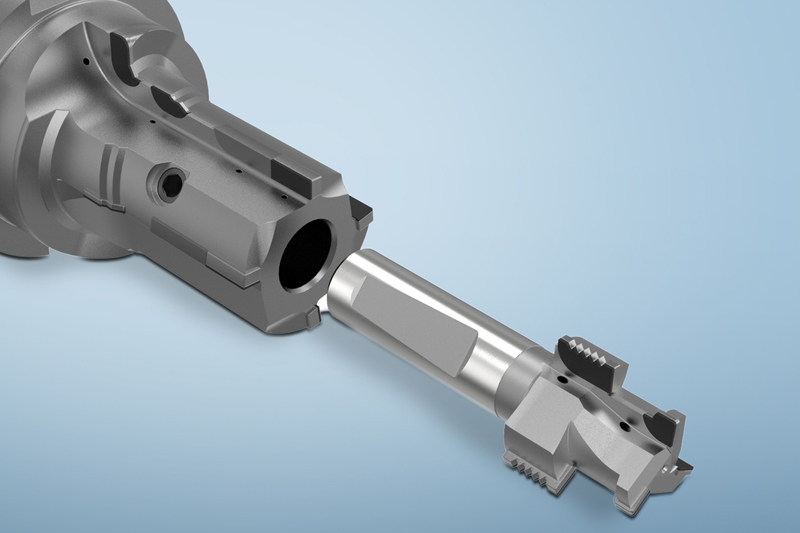

Crankshaft and valve seat machining: MAPAL sets standards

Optimised machining of crankshafts and valve seats: MAPAL offers innovative tool solutions for modern combustion and hybrid engines.

-

05.10.2023

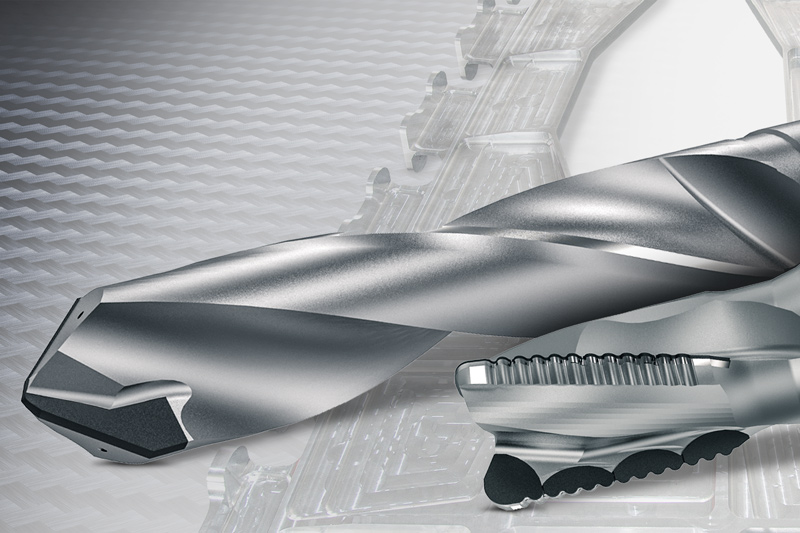

Tip for depth

With the MEGA-Deep-Drill-Steel, MAPAL is presenting the new standard for deep drilling, which has been specially designed for machining steel and cast iron.

-

19.06.2023

PCDで最適な深穴加工

The automotive supplier Schlote converted the deep drilling of oil channels in clutch housings and reliably achieves five times the service life.

-

16.11.2022

Green tools protect resources

The use of minimum quantity lubrication is a lever for saving resources in production. MAPAL offers almost all tools in variants for MQL.

-

10.11.2022

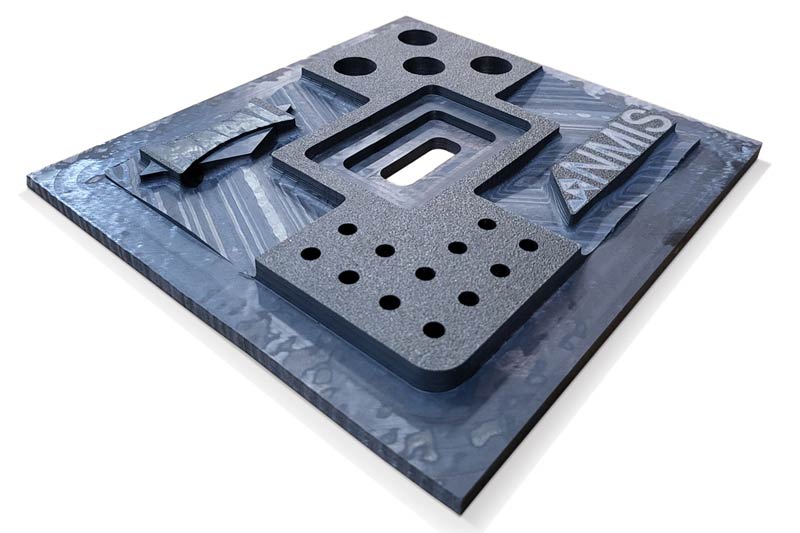

CFRP demo part for trade fairs and events

A generic component developed in collaboration with the National Manufacturing Institute Scotland demonstrates MAPAL's expertise in CFRP machining.

-

10.03.2022

Titanium Machining Takes Off

MAPAL is making drilling and milling of the ductile, high-strength workpiece material more productive, thereby reducing costs.

-

09.02.2022

MAPAL is investing in countersink manufacturing

Countersinks from MAPAL produce high quality countersinks and are fast and durable. MAPAL is investing in production at the Winterlingen site in 2022.

-

19.01.2022

When nothing is allowed to go wrong

With MAPAL tools, users can rely on the highest process reliability and precision in the final machining processes of the almost finished component.

-

01.06.2021

PCD for machining challenging aviation components

MAPAL solutions for aerospace: 60 percent longer tool life when drilling CFRP materials and long-chipping aluminum alloys with process-reliable dry roughing.

-

04.05.2021

Three-edged drilling and reaming in one step

Three cutting edges and six guide chamfers for high precision and economic efficiency: The Tritan-Drill-Reamer from MAPAL machines fitting bores in one step.

-

08.03.2021

Partner in the mining industry

Tool life and feed more than doubled, with excellent surfaces. The Rockbit-Drills from MAPAL machine the seats for bit inserts in mining tools.

-

08.02.2021

Economical and reliable machining of steel beams

The flexible use of steel beams in many areas goes hand in hand with closely defined manufacturing tolerances. How MAPAL contributes to high process reliability.

-

27.01.2021

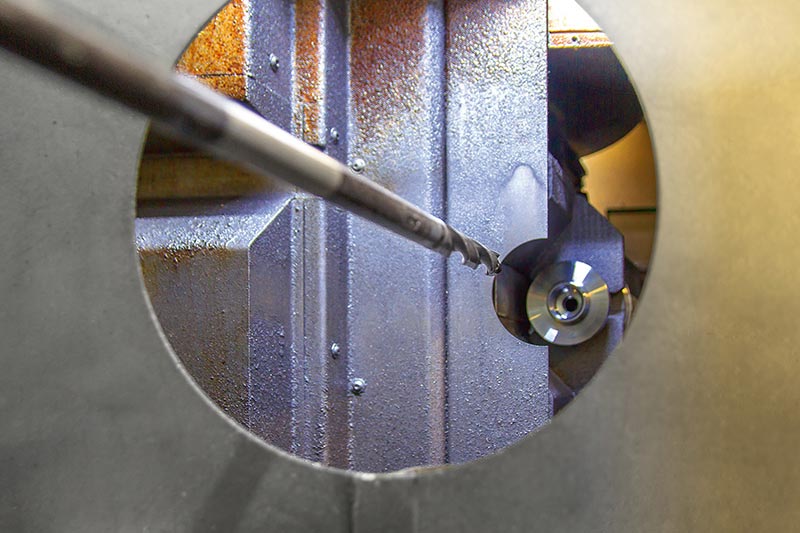

Drilling diameters from one millimeter with internal cooling

For steel machining in the micro range, MAPAL has expanded its range of solid carbide drills to include the new MICRO-Drill-Steel series for the diameter range 1.0 to 2.9 mm.

-

15.05.2020

Lowering costs with sophisticated tool solutions

Tools have an impact on the overall operating costs of machining. It pays off to focus on the overall operating costs when purchasing.

-

18.10.2019

Better, faster, more cost-effective: drilling from solid in steel

With many innovations, MAPAL increases the cost-effectiveness of solid drilling of steel. Specialists are available for different applications.

-

01.06.2018

Great potential in drilling from the solid carbide on heat exchangers with the TTD-Tritan

A higher efficiency in production is achieved through the usage of heat exchanger. Even more potential can be reached with the usage of economically made high precision tools. As a TTD-Tritan proves to reduce the cycle time by 57 percent...

-

01.05.2018

Using new solutions for a reliable process - relief bore is introduced in crancshafts

How an automobile manufacturer brings a new process safely into series production with MAPAL by its side as technology partner.

-

01.01.2018

Dry Machining of Multilayer Composites in Aircraft Construction

The final assembly of aircraft presents special challenges for tool manufacturers. MAPAL has developed special tools just for this.