03.02.2026

UNISET-V basic plus – new setting fixture for fine boring tools with large diameters

MAPAL provides highly cost-effective and flexible manual setting technology

With the UNISET-V basic plus, MAPAL is filling the gap between simple mechanical and expensive CNC setting fixtures. The new tool setting fixture combines precision, robustness and practicality especially for large fine boring tools and is available in spring 2026.

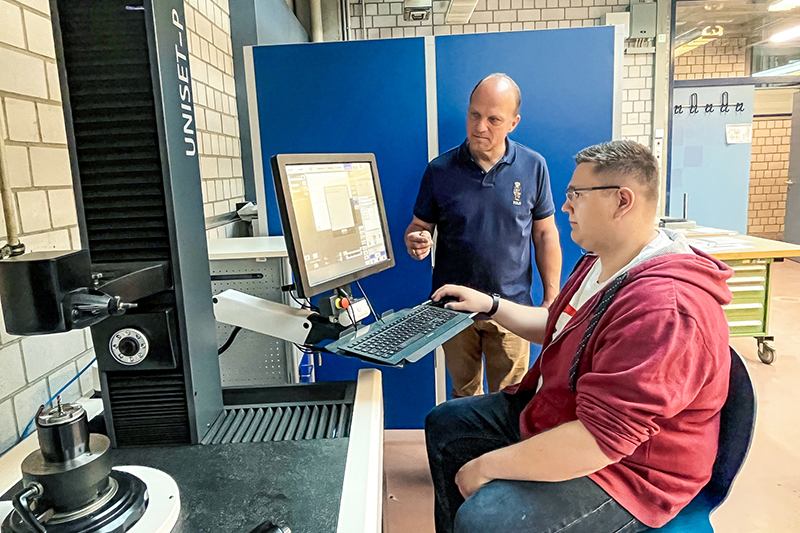

At EMO 2025, MAPAL presented a manual setting fixture tailored to the specific needs of small and medium-sized enterprises in the form of the new UNISET-V basic plus. This fills a crucial gap between simple mechanical setting solutions and CNC systems while continuing to guarantee full precision and high stability.

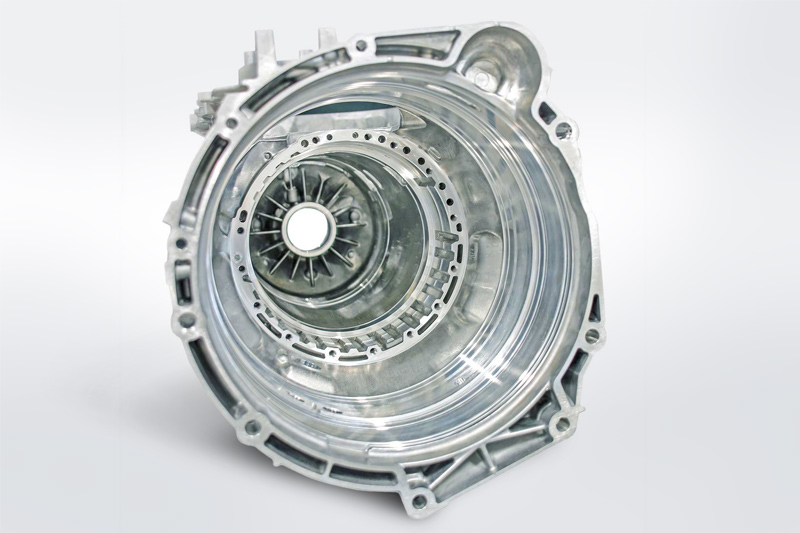

The device from MAPAL’s UNISET range was designed as a response to demand from the automotive industry. In the electromobility industry in particular, large, heavy tools are often used to machine components like stator housings. These tools require extremely sensitive setting for high-precision fine machining.

Robust design for precise setting of tools with guide pad technology

The UNISET-V basic plus is designed for setting tools with a diameter of 100 to 400 mm, a maximum measuring length of 750 mm and with spindle connections HSK63, HSK100 and SK50. Tool weights of up to 45 kg are possible. Using reducing adapters, HSK32 to HSK80 can also be mounted. As the UNISET-V basic plus housing is based on a stable welded design, high mechanical stability is guaranteed. This is a key advantage in production environments.

As a stationary bench-top device with a height of 1.3 metres and a weight of 179 kg, the UNISET-V basic plus does not necessarily need to be placed in a setting room. It can be set up anywhere it is needed on a stable surface. For instance, it can be placed next to the machine where the tools being set are applied.

The UNISET-V basic plus enables micrometre-precise setting of cutting edge overhang and back taper for reaming and fine boring tools. It is operated using a two-button principle, where the cutting edge is set via a guide pad.

The UNISET-V basic plus is primarily targeted at small and medium-sized companies that have previously done without precise setting technology. However, the UNISET-V basic plus is also the right choice for larger companies seeking process reliability and high precision when setting tools with large diameters and high weights.

Brief description

Contact

Mathias Ostertag Public Relations mathias.ostertag@mapal.com Phone: +49 7361 585 3566