Industries

-

15.10.2025

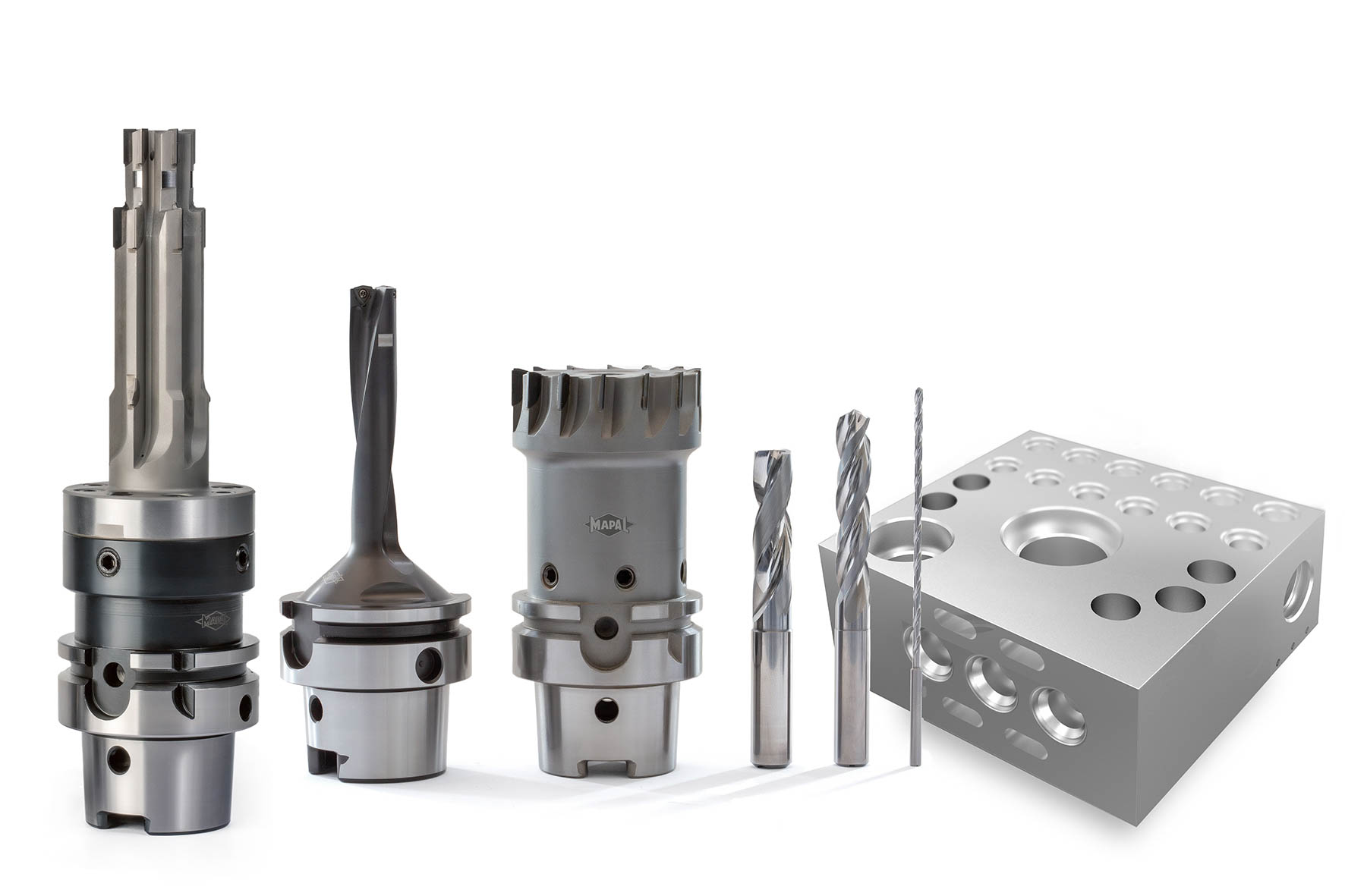

Successful tooling solutions from MAPAL increase productivity for customers.

Increasing customer productivity is at the heart of MAPAL’s standard processes for the industrial manufacturing of strategic components.

-

06.10.2025

Innovations and solutions of MAPAL

MAPAL presents its 2026 innovations and solutions in a comprehensive brochure.

-

24.09.2025

IMPULSE 85 has been published

Innovations and solutions of the year 2026 are in the focus of issue 85 of the technology magazine IMPULSE

-

26.08.2025

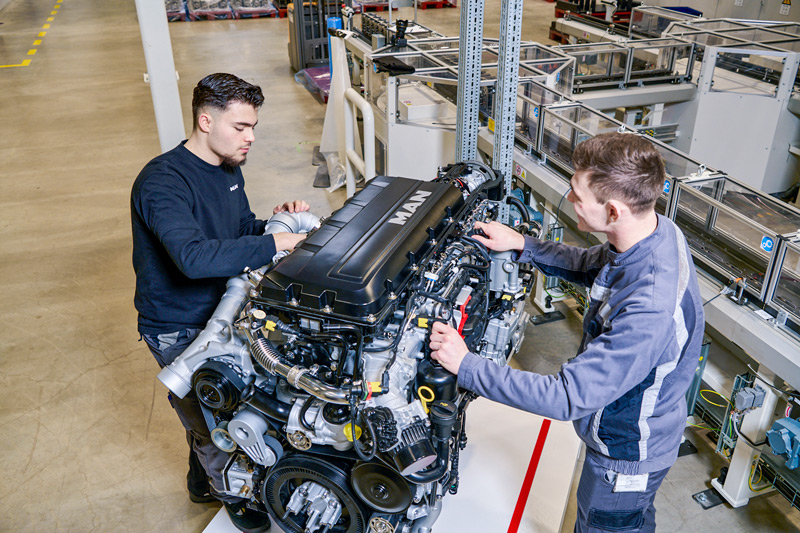

MAN uses MAPAL fine boring tools for machining cylinder heads

At MAN engines, fine boring tools from MAPAL are used to machine the valve guide and valve seat counterbores of cylinder heads."

-

12.08.2025

Matthias Winter on key focus areas in the automotive segment

The technological transformation driven by electrification and autonomous driving is placing new demands on the automotive segment. Matthias Winter discusses the key focus areas.

-

29.07.2025

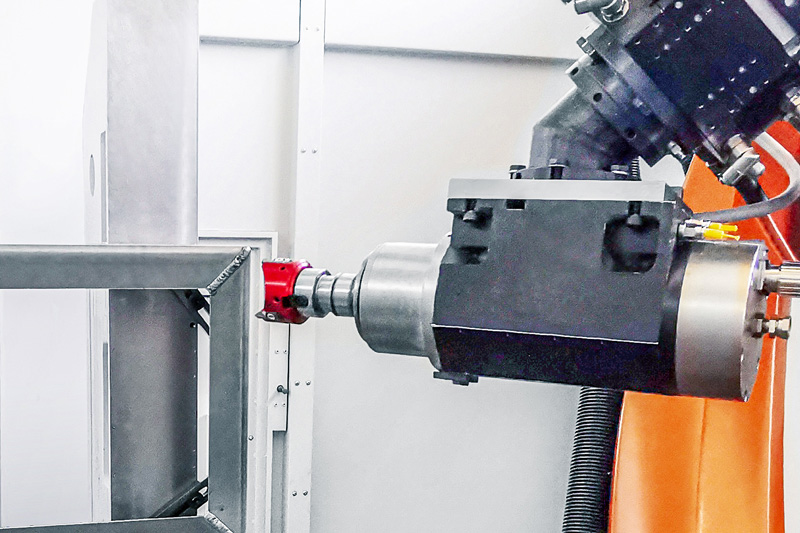

NILES-SIMMONS and MAPAL are setting standards in stator housings

The process developed by NILES-SIMMONS and MAPAL for the complete machining of stator housings for electric vehicle motors is ready for series production.

-

22.07.2025

Crankshaft and valve seat machining: MAPAL sets standards

Optimised machining of crankshafts and valve seats: MAPAL offers innovative tool solutions for modern combustion and hybrid engines.

-

06.06.2025

MAPAL at Schabmüller with tool management and aluminium expertise

At the automotive supplier Schabmüller, MAPAL has already been responsible for tool management. Now, the tool manufacturer from Aalen has also taken over the CAD/CAM programming of the components, including simulation.

-

02.06.2025

IMPULSE 84 has been published

The automotive industry is the focus of issue 84 of the technology magazine IMPULSE

-

28.03.2025

Suitable tools for combined brake housings

Combined brake housings unite the brake master cylinder, brake booster and ABS/ESP in one component and pave the way to autonomous driving. MAPAL offers solutions for machining complex aluminum workpieces.

-

16.01.2025

Tool management from MAPAL completed for DEUTZ in record time

MAPAL completed the entire engineering including tool design, cycle time study and cost calculation for the engine manufacturer Deutz in the Spanish plant in Zafra within a very short time.

-

19.12.2024

IMPULSE 83 has been published

Innovations and strategic focus areas are in the spotlight of issue 83 of the technology magazine IMPULSE

-

06.11.2024

Optimum processing through component and market expertise: solutions for the scroll compressor

Machining solutions for scroll compressors: MAPAL offers precise, durable tools for electromobility. Focus on quality, efficiency and application-orientated processes.

-

01.02.2024

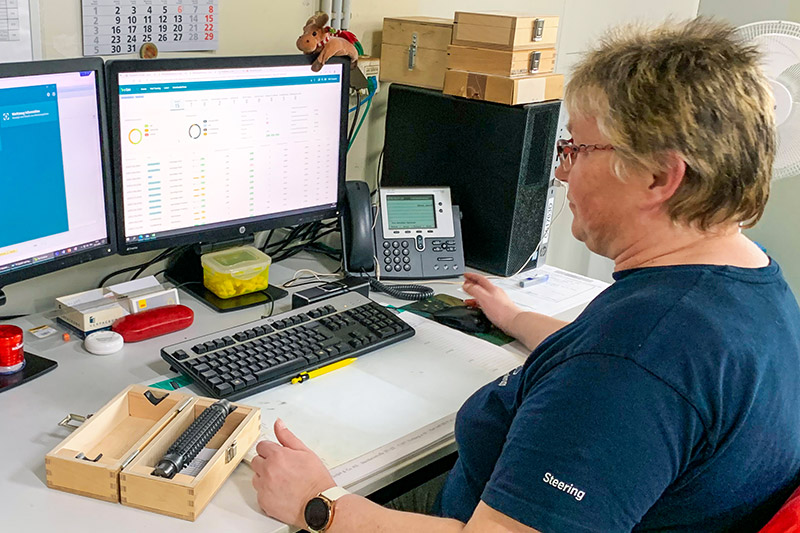

Lifecycle Management from c-Com increases transparency at thyssenkrupp Presta Schönebeck

The automotive supplier thyssenkrupp Presta uses c-Com's Lifecycle Management at its Schönebeck site and achieves transparency and considerable savings.

-

28.09.2023

Structural parts in record time

Wenzler and MAPAL combine their expertise and provide answers to the question: How can aluminium components be manufactured quickly and precisely?

-

02.08.2023

Well positioned for e-mobility

The die-casting foundry 2A is ready for the transition to electric mobility. MAPAL is at 2A's side as an experienced tool partner.

-

27.06.2023

High process reliability when milling CFRP composite materials

The OptiMill-Composite-Speed-Plus milling cutter from MAPAL stands for high process reliability due to long tool life, high breaking strength and the best cutting quality.

-

19.06.2023

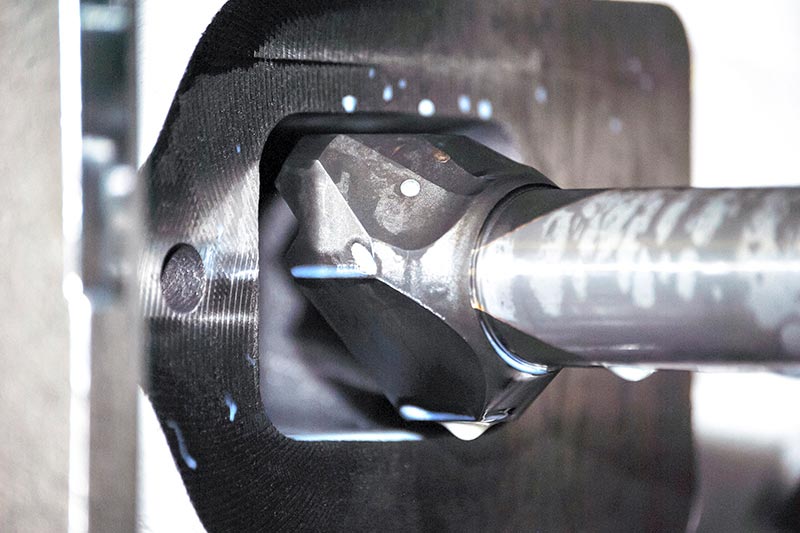

The best deep bores with PCD

The automotive supplier Schlote converted the deep drilling of oil channels in clutch housings and reliably achieves five times the service life.

-

11.05.2023

A strategy for battery frames

MAPAL’s electric mobility experts have designed a generic component that encompasses the main machining operations of a battery frame.

-

23.03.2023

The production must go on

Digital tool management with more than 750 tools from MAPAL ensures smooth large-scale production at Schabmüller Automobiltechnik.

-

25.01.2023

Gnutti Carlo Group relies on c-Com digital tool management

The Gnutti Carlo Group implements a digital tool management solution from c-Com for its worldwide locations.

-

03.11.2022

Efficient deburring with robots

The FlyCutter from MAPAL is ideally suited for deburring battery trays. Robot manufacturer KADIA is enthusiastic about the PCD-tipped milling tool.

-

30.06.2022

Even more cost-effective turbochargers

How the complete machining of turbochargers becomes even more productive with indexable insert milling cutters from the NeoMill range.

-

10.03.2022

Titanium Machining Takes Off

MAPAL is making drilling and milling of the ductile, high-strength workpiece material more productive, thereby reducing costs.

-

01.07.2021

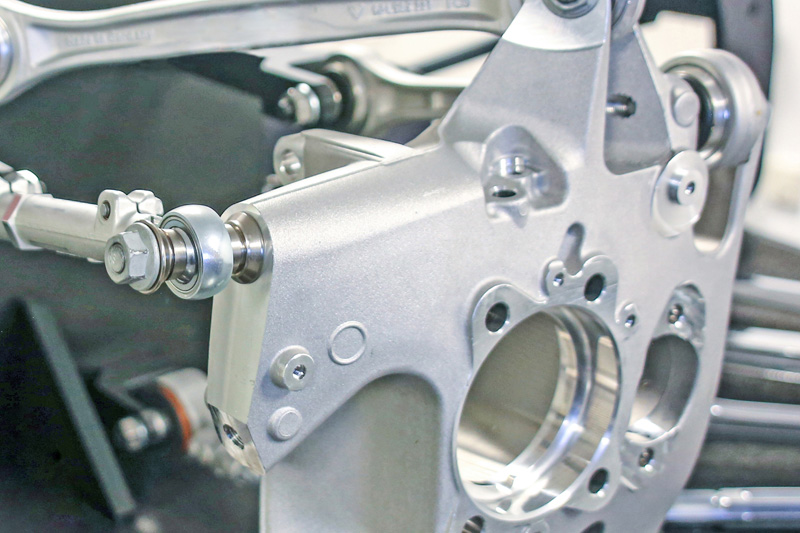

Sophisticated PCD tool concepts for machining aluminium

Carl Hirschmann GmbH processes aluminum forged parts for sports vehicles with multi-stage combination tools from its development partner MAPAL.

-

15.01.2020

New chucks for standardized Processes

Mitsubishi Motors Corporation relies on the expertise and service of MAPAL when planning a new engine production line at its Kyoto plant.

-

09.12.2019

Highly precise machining of truck engine cylinder bores

High-precision MAPAL actuating tools and a special setting fixture ensure precise and economical production at Mercedes-Benz in Mannheim.

-

08.11.2019

Reliable and Cost-effective Manufacture of Turbochargers in Series

Manufacturers of turbochargers face challenges in machining. How MAPAL makes the entire process cost-effective and efficient.

-

01.07.2019

Electric motor housings reliably enter large-scale production

For the complete machining of housings for electric motors, MAPAL is offering tool solutions which are ready for series production, reliable and absolutely precise.

-

01.11.2018

Constant velocity joints for electro mobility

Why Neapco relies on ball nose milling cutters from MAPAL for hard machining the homokinetic outer joint of a drive shaft.

-

01.10.2018

Excellent result thanks to close, partnership-based cooperation

MTU Friedrichshafen converts finish machining to minimally invasive face milling. They also achieve evenness improved by a factor of 10 with milling cutters from MAPAL.