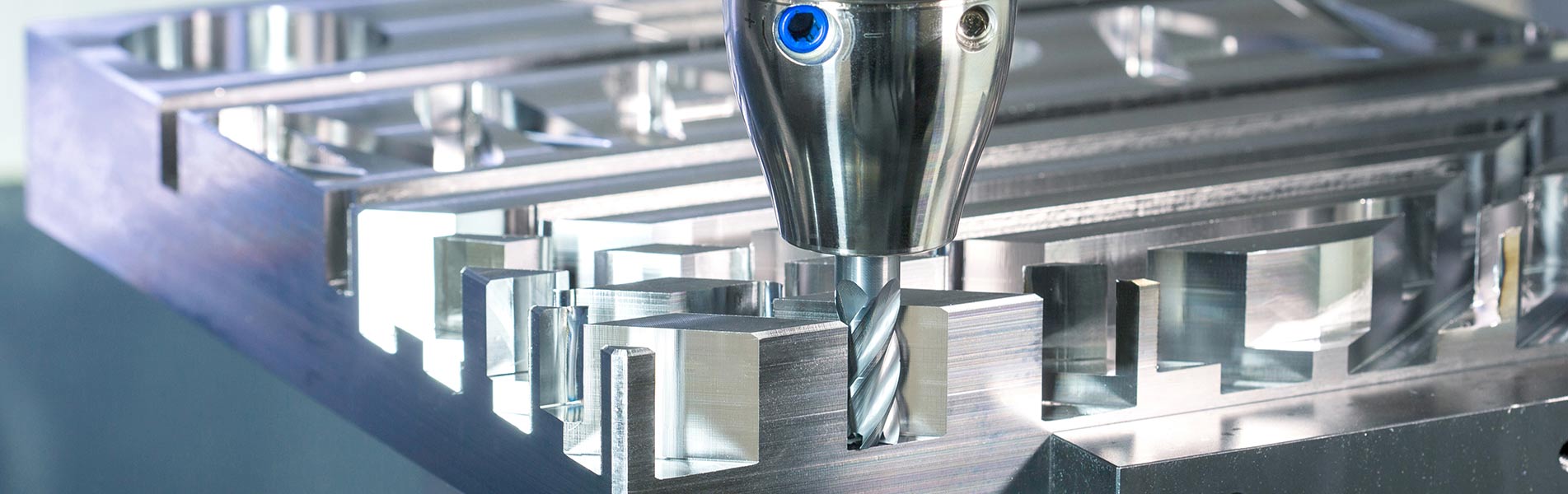

OptiMill®-Uni-HPC

Nova geração para a máxima confiabilidade do processo

A MAPAL apresenta a terceira geração da fresa de metal duro integral OptiMill-Uni-HPC – otimizada para produção automatizada e alto desempenho de corte.

A nova OptiMill-Uni-HPC para usinagem de aço, aço inoxidável e ferro fundido foi especialmente desenvolvida para processos automatizados e cumpre os mais elevados requisitos em termos de confiabilidade do processo, estabilidade e resistência ao desgaste.

O material de corte recentemente desenvolvido tem uma elevada dureza, o que reduz o risco de quebra da ferramenta. Em combinação com um revestimento resistente ao desgaste e uma geometria optimizada, o resultado é uma ferramenta altamente confiável, mesmo para operações de usinagem dinâmicas.

Uma novidade no programa da OptiMill-Uni- -HPC é uma variante com quebra dos cavacos integrado. Ela produz cavacos curtos e fáceis de remover, o que traz vantagens claras em termos de resfriamento a ar e alto rendimento de cavacos, além de permitir altas taxas de avanços.

O resultado: Maior tempo de funcionamento das máquinas, menor esforço de monitoramento e maior estabilidade do processo – ideal para turnos sem pessoal e processos automatizados.

A partir de setembro de 2025, a fresa estará disponível em três versões:

- Curta sem quebra dos cavacos (ø 3 a 20 mm)

- Longa sem quebra dos cavacos (ø 3 a 25 mm)

- Longa com quebra dos cavacos (ø 6 a 25 mm)

Com isso, a MAPAL aposta no desenvolvimento específico de um conceito comprovado para maior eficiência, confiabilidade do processo e versatilidade na usinagem moderna.