不同外壳体类型的切削加工要求和特征

-

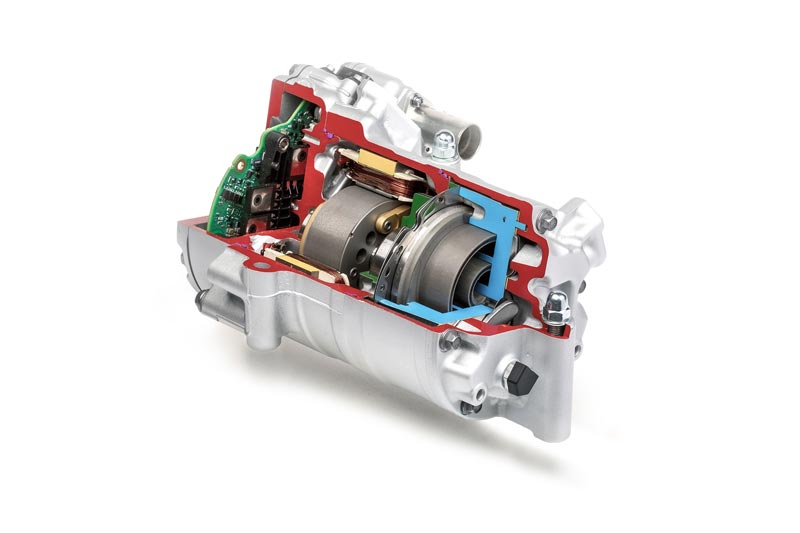

高度集成的外壳

-

高度集成的电驱发动机外壳体

描述:高度集成的复杂外壳,具有定子安装座、变速箱安装座和电源电子设备的接口。高度的功能集成,使得安装成本大大节省。紧凑的结构设计。因而使得铸件外壳体非常复杂。

特征

- 定子直接装在壳体中或者经过定子支承座/冷却外壳承接

- 定子孔借助台阶及端面作为功能表面。

- 转子的轴承孔和定子孔在壳体中被同轴集成在一起

- 通过定位销或配合面进行第二轴承盖的定位;第二轴承孔必须同轴。

- 齿轮分级的轴承孔被集成在外壳体中;要求具有很高的同心度和位置精度

- 冷却通道局部集成在外壳中

- 复杂的铸铝外壳体

切削加工要求

- 具有多个直径分级的复杂轮廓序列 (→ 大切削力和大切削去除率)

- 混合加工(→ 切屑分离/排出)

- 中断式切口(→ 触点接触、冷却回路)

- 15°-30°扁平的导入倒角(→ 流变构成和较高的径向力)

-

顶部形状外壳

-

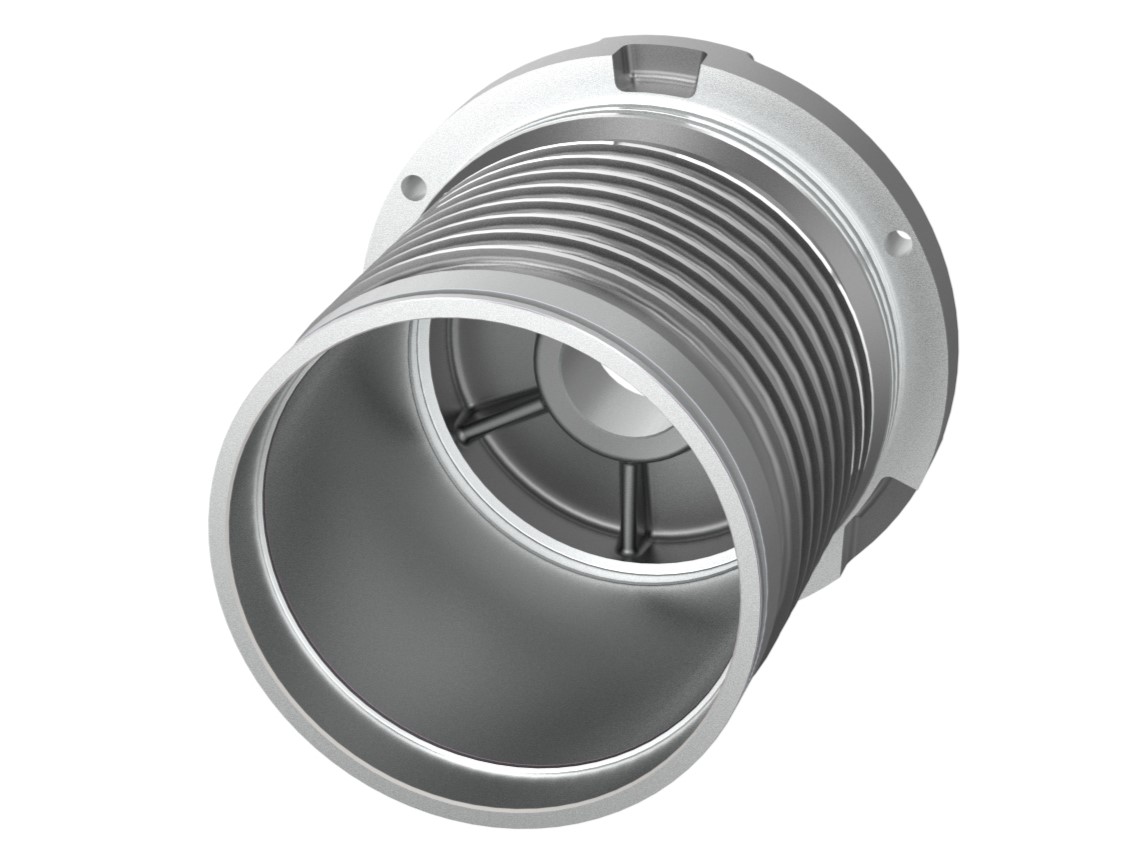

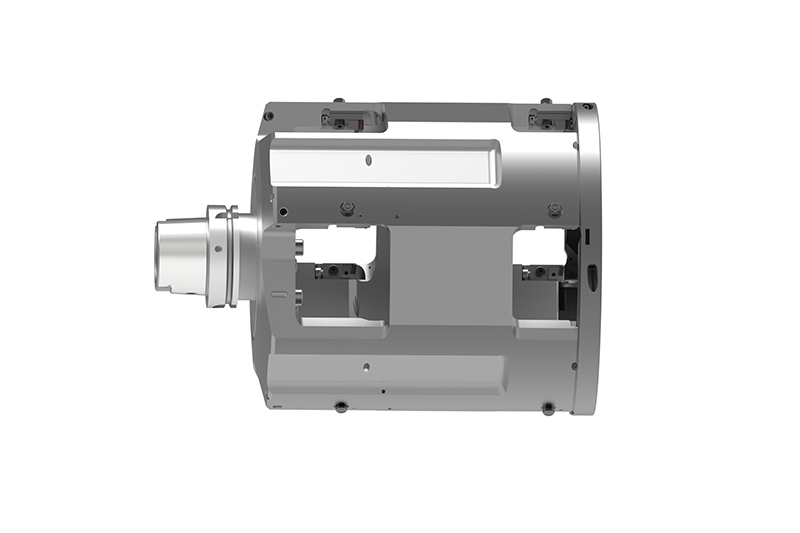

罐形电驱发动机外壳体

描述: 为了降低结构的复杂性,特别是为了实现更简单的冷却外壳体结构设计,选用罐形或者钟形外壳体或者定子支承座。

特征

- 属于集成在整个系统中的中间壳体

- 定子孔借助台阶及端面作为功能表面。

- 转子的一个轴承孔针对定子孔同轴地集成到壳体中

- 通过配合表面在外表面上进行定位

- 冷却通道作为处于外部的筋条敷设

- 其特性是壁薄、易引发振动

- 张紧通常也是个问题

切削加工要求

- 异常薄壁的结构组件(→ 相当于壁厚)

- 必须加工外部冷却筋条

- 罐形或者钟形(→ 有利于抗振动,特别设计的夹紧方案和减振器)

- 15°-30°扁平的导入倒角(→ 流变构成和较高的径向力)

-

管状外壳

-

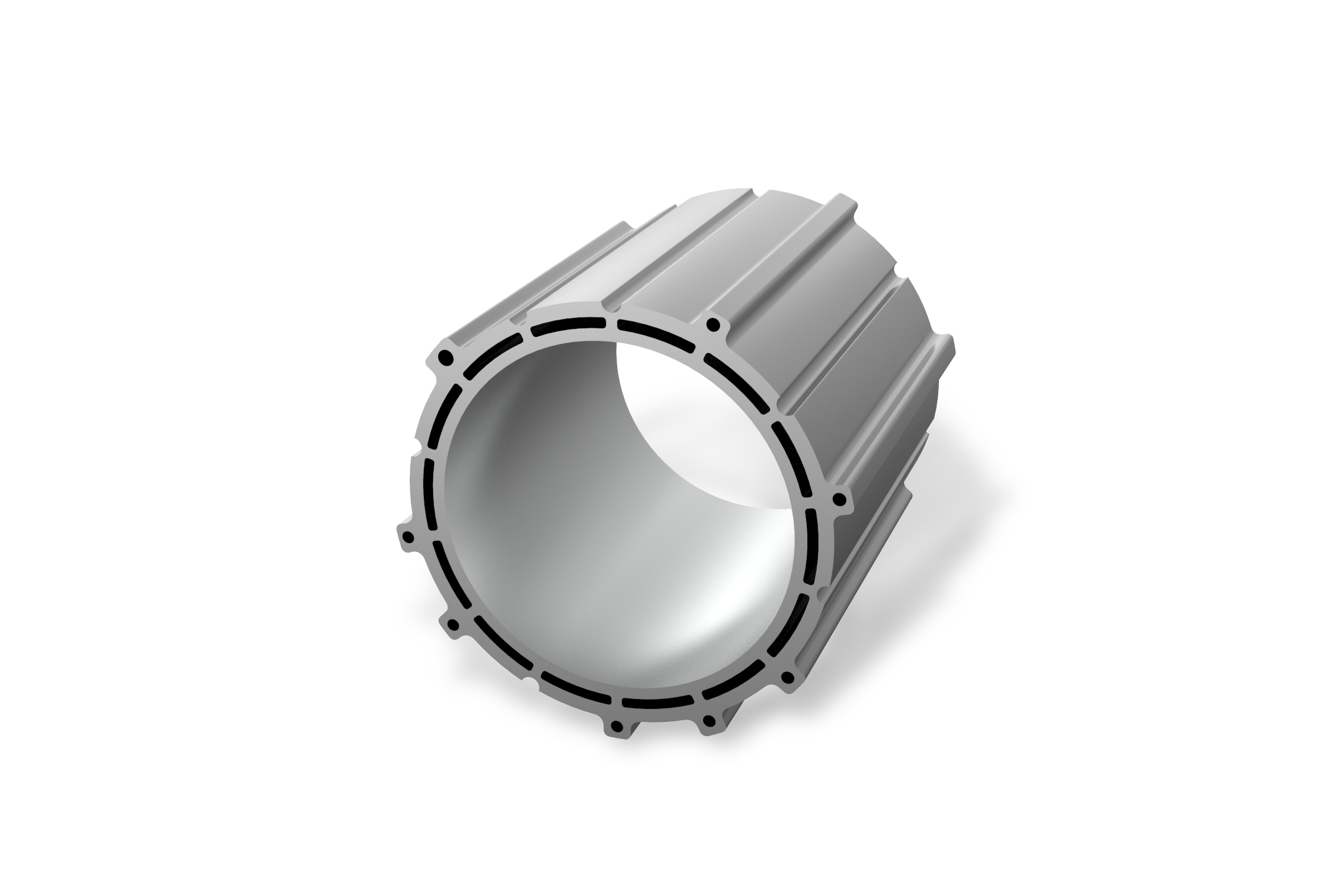

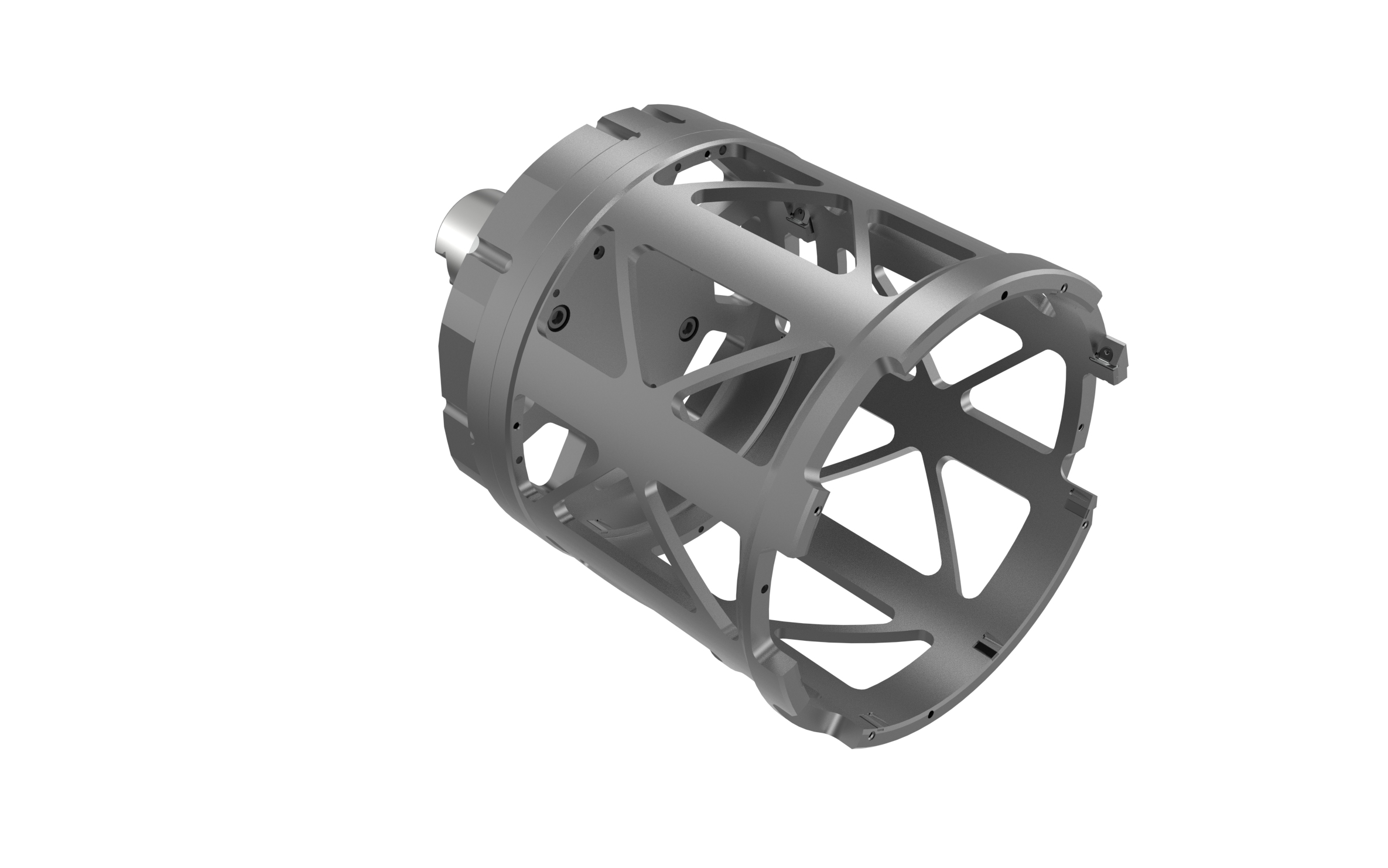

管状外形电驱发动机外壳体

描述:电动机外壳最简单的结构形式就是管状。针对不同的功率,这种外壳体的长度及其关联的电动机,都可以在规格上比较简单地进行变更。但是,由于功能集成程度低,会使安装工作量增加。

特征

- 在壳体中没有集成转子轴承孔。

- 两个轴承盖用来支撑该转子

- 两个轴承盖在安装表面上定位,以实现轴承点的同轴度

- 复杂度比较低

- 在实际运行中是旋转对称的

- 其特性是壁薄、易引发振动

- 张紧通常也是个问题

切削加工要求

- 更加稳定的结构组件,多数采用内置冷却结构

- 也可以使用挤压型材(AlSi1铝合金 → 均匀连续式切屑)

- 不带夹紧鱼尾板(→ 专用夹紧方案)

- 局部带有符合IT6-公差要求的配合面

-

混合壳体

-

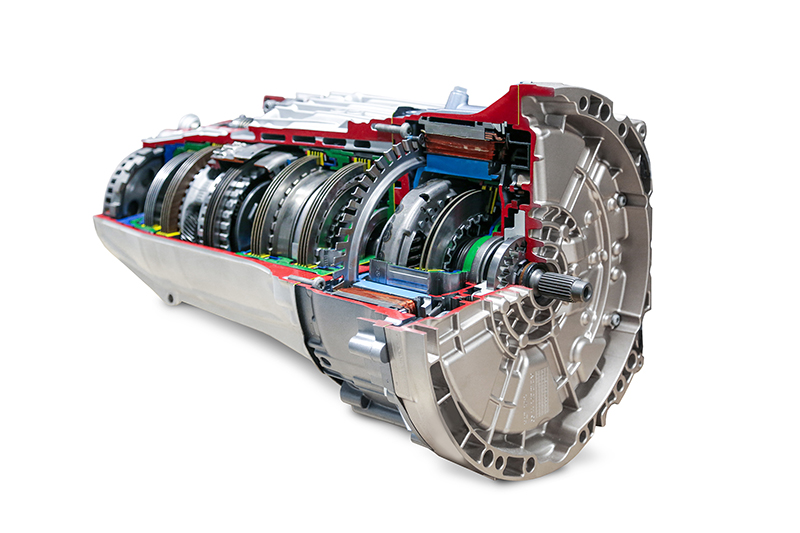

混合动力变速箱壳体和混合动力模块壳体/中间壳体

描述: 通过圆盘形混合动力模块壳体或者中间壳体,将电动机集成到现有的变速箱结构中。空间上比较适中的结构,也可以借助局部罐形壳体作为推入件来实现。

特征

混合动力模块壳体/中间壳体

- 主要是定子的支撑

- 在盘形状态下,没有转子轴承

- 在罐形状态下,集成了一个转子轴承结构

混合动力变速箱壳体

- 极端化的长度-直径-比

- 其特性是壁薄、易引发振动

- 复杂的轮廓序列

- 中断式的切口

切削加工要求

混合动力变速箱壳体

- IT6-公差标准

- 对同轴度和台阶尺寸具有很高的要求

- 最大重量和倾覆力矩受到限制

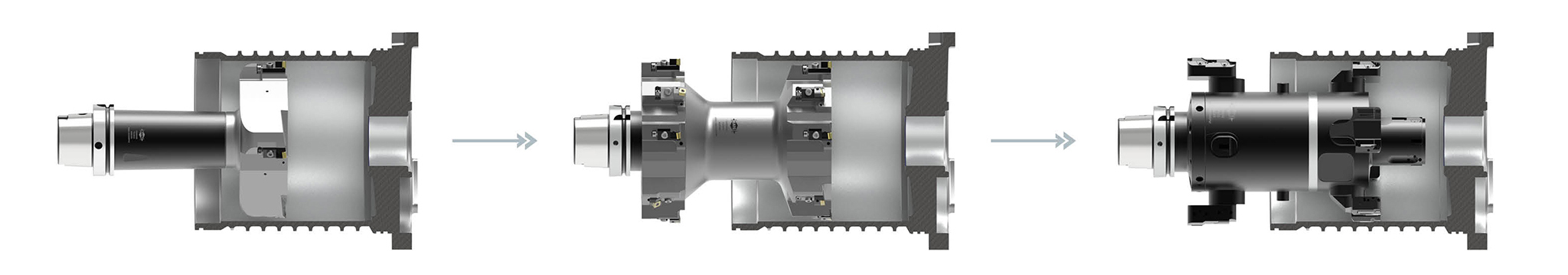

加工定子壳体的基本操作步骤

根据余量情况、机床加工区和夹紧要求,对加工流程和刀具进行个性化的单独设计。在此基础上,使得作用于部件上的切削力得以保持到尽可能的小。定子孔的加工分为三个步骤:预加工、半精加工和精加工。

-

预加工

-

ISO-镗刀特别适用于粗加工应用。通过该方式可以获得高切削速度并可实现大惯量进给,从而获得快速和经济化的材料去除。在一定条件下,例如:在使用精铸件以及相应的机床加工条件下,可以省去初始的粗加工工序。

-

半精加工

-

在半精加工过程中,将对电机外壳复杂的轮廓进行预加工。即在后续的精加工中,以所需的质量加工出带有倒棱和径向过渡的完整轮廓。这一工序可以实现壳体的最佳成型。根据具体主轴实际的功率和加工余量,可能需要将半精加工分配在两道工序中进行。

-

精加工

-

在最后一道工序中,使用带有可精密调节可转位刀片导条式精密镗刀对定子孔精密加工。

电机定子壳体的外部加工是一项艰巨的高要求加工任务。这些壳体对于电机的效率具有至关重要的作用,通常采用管状或罐形设计。在该加工工艺流程中,必须克服一系列的难度挑战。薄壁型铝制壳体上带有用于冷却循环散热的集成加强筋,基于该类别工件在直径精度、形位公差上的要求,对应的加工要求需要达到极高的精度。保证各种不同直径之间的同心度在加工中具有非常重要的意义。

准备工作

-

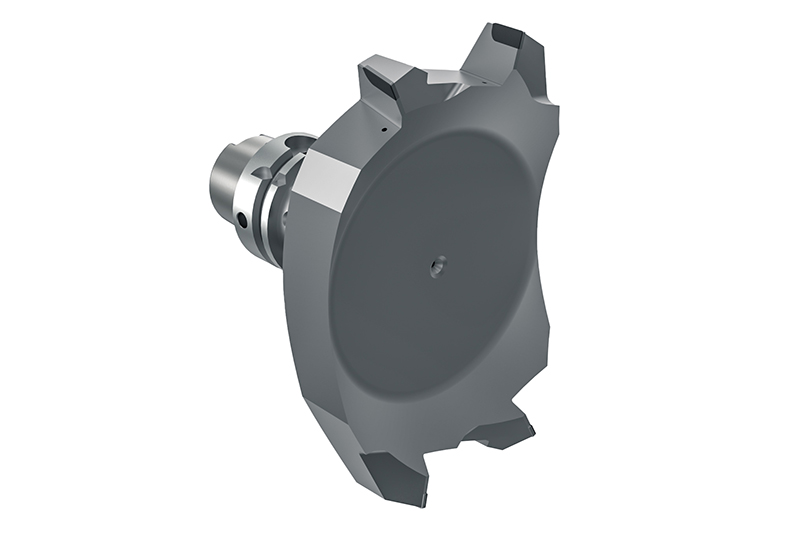

螺旋线铣刀带有 ISO标准可回转切削刀片

预加工外径和表面

- 带涂层的ISO标准-可转位切削刀片由硬质合金或者镶嵌PCD的切削刀片制成

- 减小的切削力

- 标准产品

- HSK刀柄扩展,适用于不同的加工深度

-

-

铣刀带有ISO标准可回转切削刀片

粗加工密封槽

- 有涂层硬质合金 ISO-可转为刀片

- 减振器作为选配

- 密封槽的高效粗加工

精加工

-

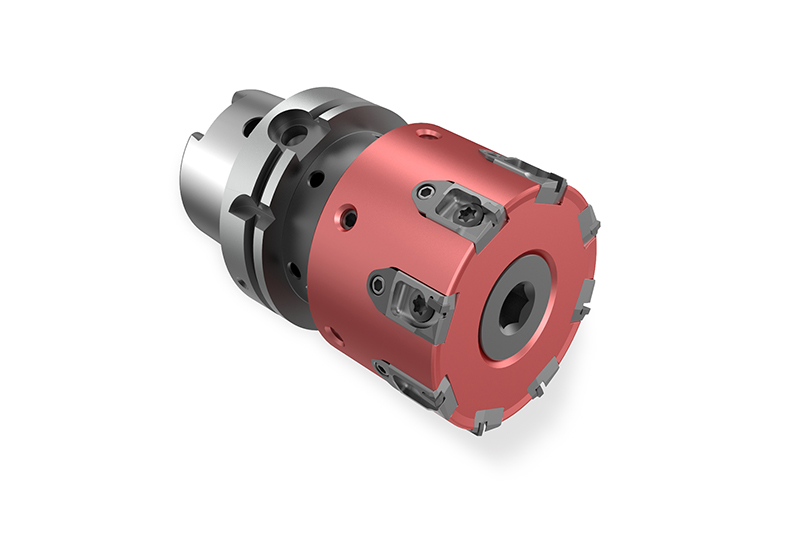

特殊轮廓PCD铣刀

密封槽的精加工

- PCD-成形切削刃

- 单切槽轮廓的最佳几何形状

- 减振器作为选配

- 一次装夹中完成所有切槽加工

-

轻型精密镗刀

外径精加工

- 可调节的PCD切削刃

- 轻型刀具基体

- 加工直径最大 Ø 260 mm

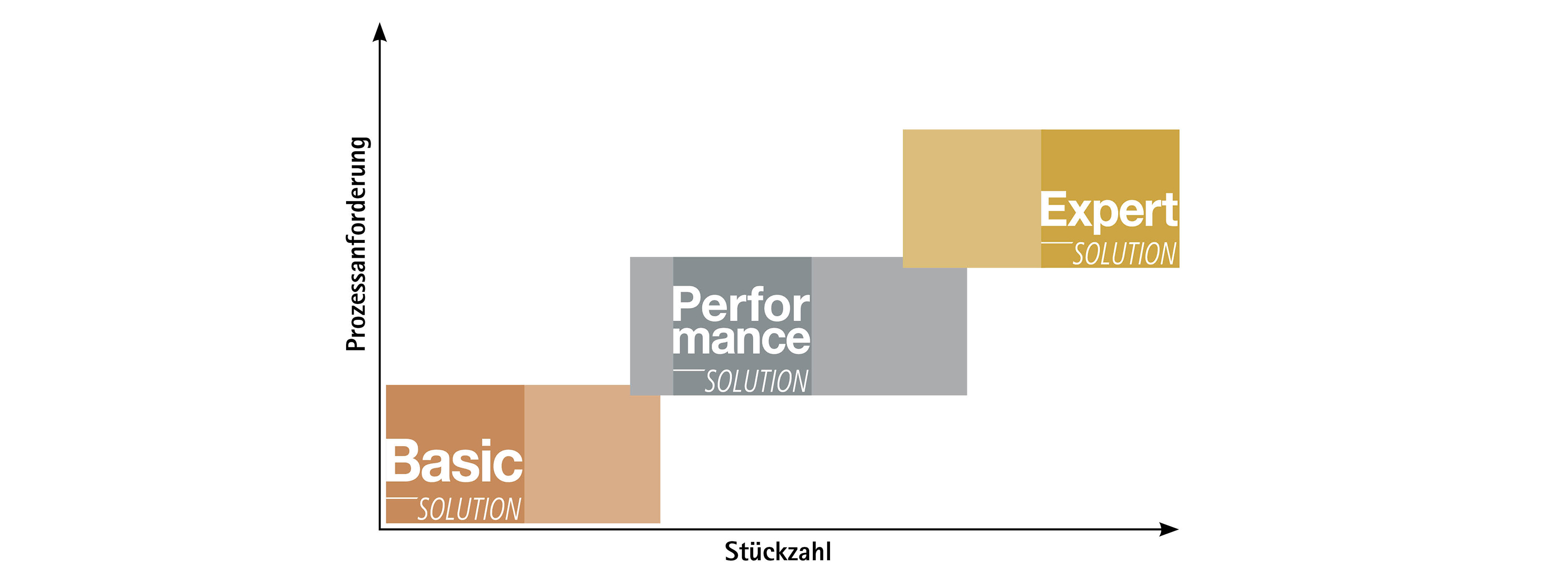

切削加工解决方案用于...

-

Basic

-

采用标准刀具的原型解决方案

- 高灵活性

- 用于预加工和精加工系统

- 模块化结构

- 从Ø 87 - 1000mm 标准产品系列

- 精镗短刀具夹紧杆,可以在µm-范围内调节

- 简易的安装操作

预加工

-

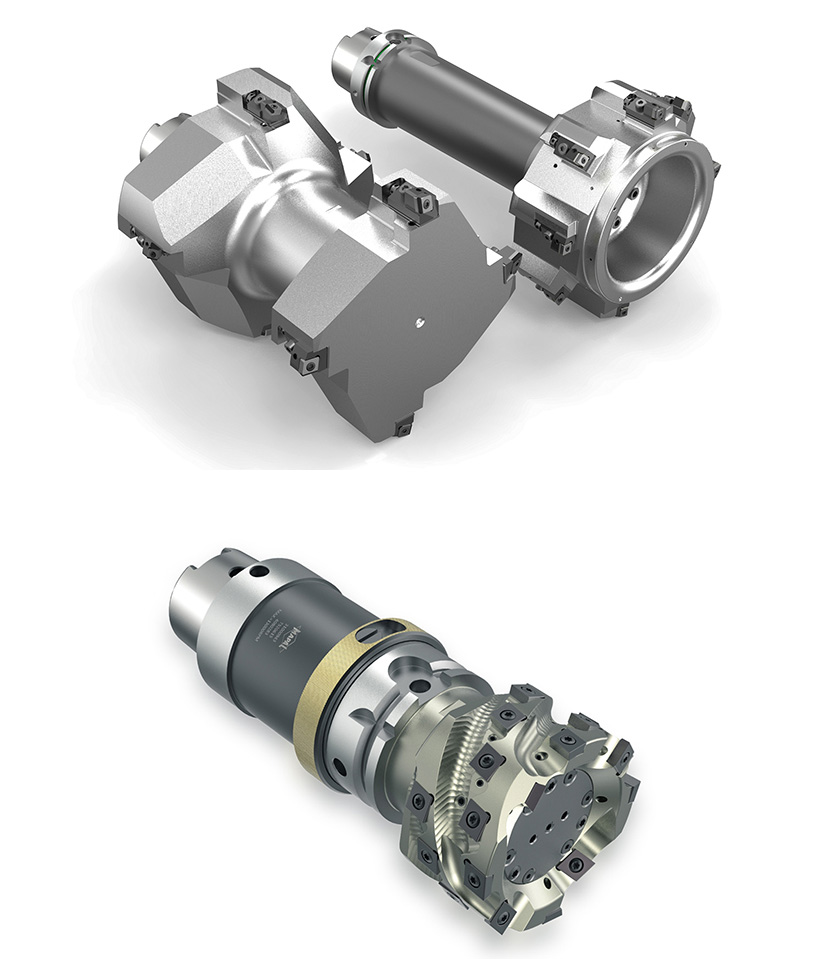

螺旋线铣刀

带有ISO标准-可转位刀片

- 带涂层的ISO标准-可转位刀片由硬质合金或者镶嵌PCD的切削刀片制成

- 减小的切削力

- 标准产品

- HSK刀柄-扩展,适用于不同的加工深度

-

预加工和精加工

-

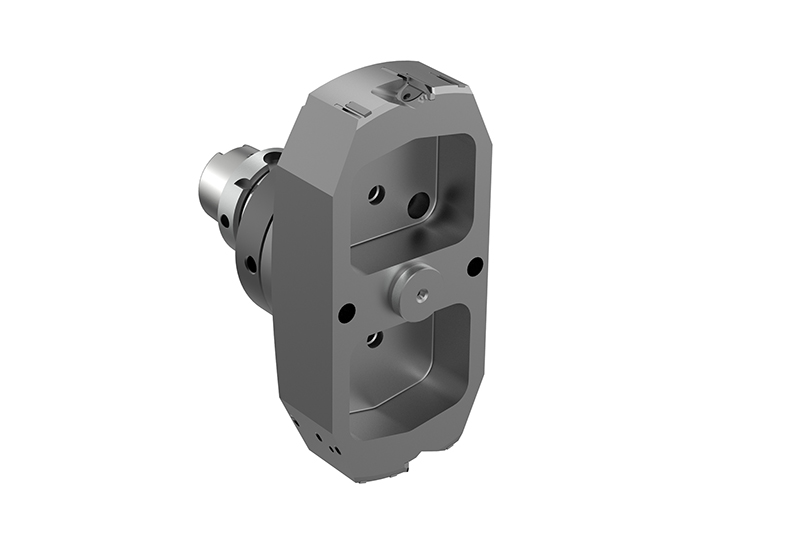

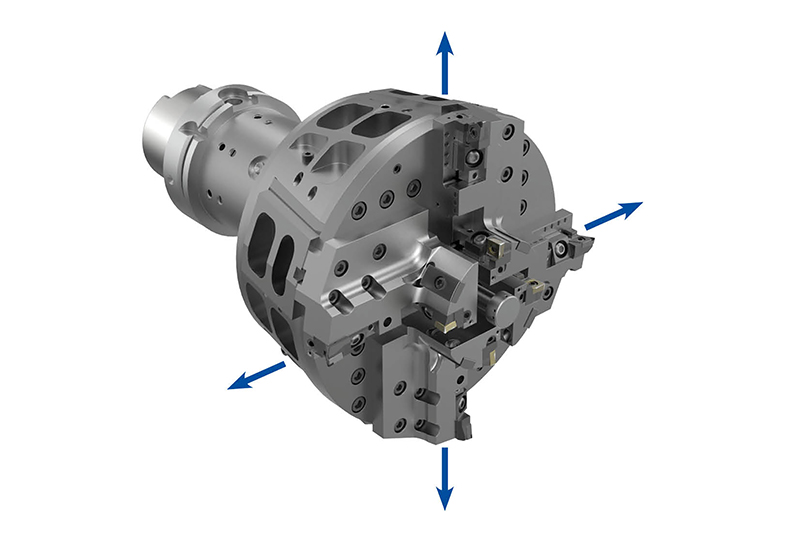

ModulBore

在镗孔和精镗过程中的高柔性化

- 用于预加工和精加工系统

- 模块化结构

- 从ø87 mm-1000 mm标准供货

- 精镗短刀具夹紧杆,可以在µm-范围内调节

- 简易的安装操作

-

Performance

-

具有HSK-63/HSK-100刀柄的批量解决方案

工艺可靠的解决方案,具有极高的适配性并可满足极宽的要求范围

- 分为三个阶段的加工流程(预加工、半精加工和精加工)

- 极轻刀具

- 紧凑型机床上的大部件

- 中小批量加工的最佳方案

预加工

-

螺旋线铣刀

带有ISO标准-可转位刀片

- 带涂层的ISO标准-可转位刀片由硬质合金或者镶嵌PCD的切削刀片制成

- 减小的切削力

- 标准产品

- HSK刀柄-扩展,适用于不同的加工深度

-

PCD-成型铣刀

孔底面的轮廓加工

- 焊接切削刃

- 可以实现特殊轮廓加工

- 可选择采用 HSK-加长杆

半精加工

-

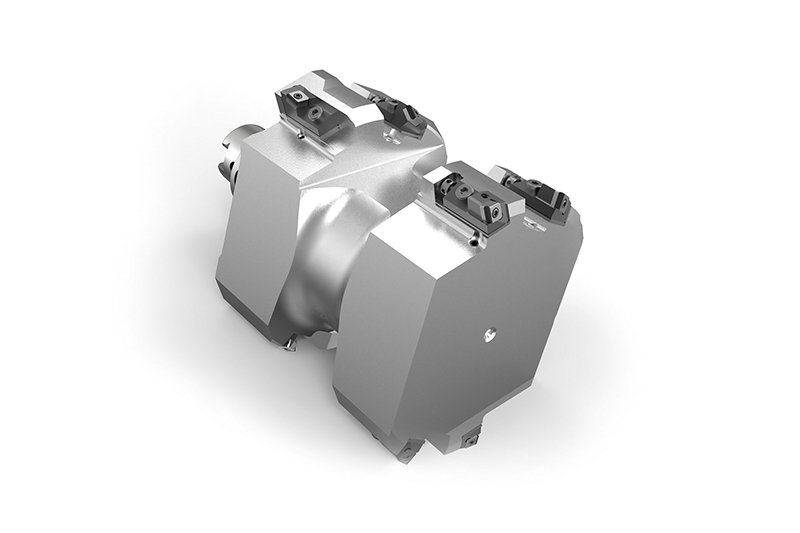

精密镗刀

带有ISO标准-可转位刀片

- 刀具形状适宜于刀库的要求

- 带涂层的ISO标准-可转位刀片由硬质合金或者镶嵌PCD的切削刀片制成

-

精密镗刀

单-或多-阶梯刀具

- ISO短刀夹

- 镶嵌PCD的ISO标准-切削刀片

- 由铝材料制成的基体

-

精密镗刀

单-或多-阶梯刀具

- ISO短刀夹

- 镶嵌PCD的ISO标准-切削刀片

- 由铝材料制成的基体

精加工

-

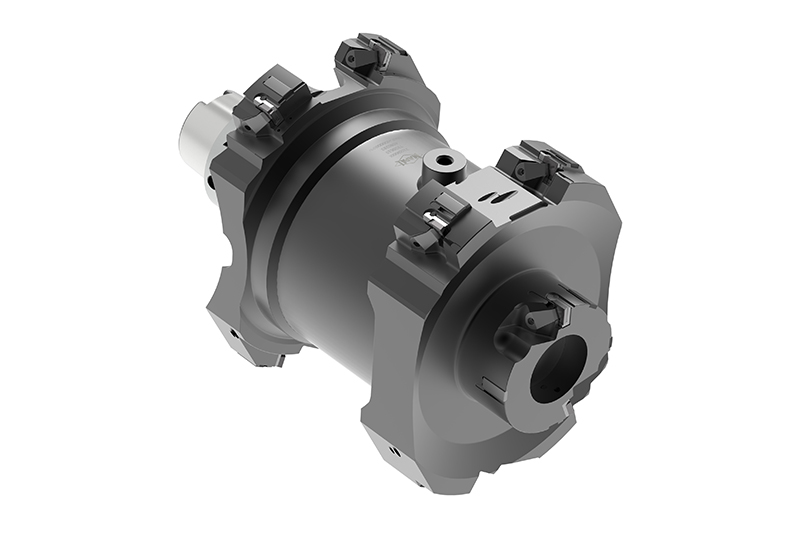

精镗刀具

带有导向板

- 镶嵌PCD的切削刀片

- 可精细调节

- 导向条由聚晶金刚石PCD制成

- 刀具形状适宜于刀库的要求

-

精镗刀具

采用钢制轻型结构

- 镶嵌PCD的切削刀片

- 金属陶瓷刀片,用于加工钢质轴承衬套

- 可以精细调节并且具有极高热稳定性

- 带EA系统的导向板技术

-

Expert

-

具有HSK100刀柄的批量解决方案

针对大直径加工提供极高生产率

- 分为三个阶段的加工流程(预加工、半-精加工和精加工)

- 较大的加工直径 > 220 mm

- 最高的性能和精度

- 对于大批量、短节拍加工任务的最理想加工工艺

预加工

-

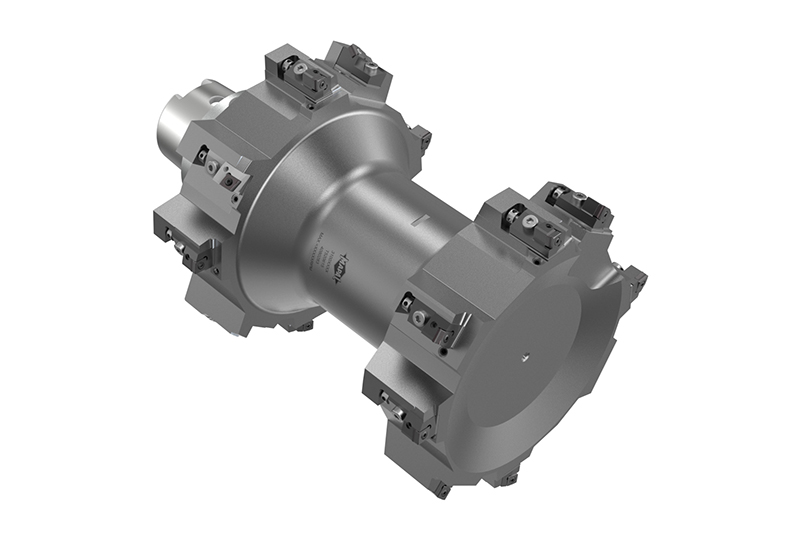

ISO标准镗刀

铝结构

- 镶嵌PCD的切削刀片

- ISO标准短刀杆

- 分一级的或者多级结构执行

半精加工

-

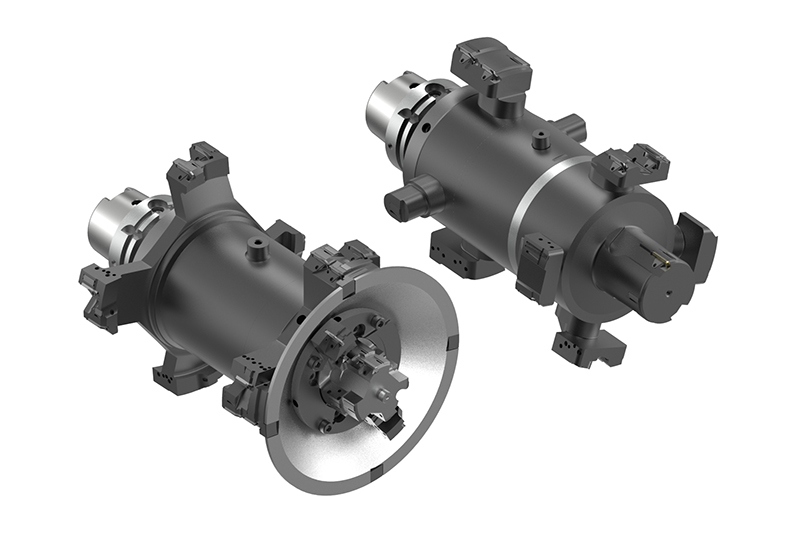

精密扩孔刀具

铝结构

- 镶嵌PCD的切削刀片

- 结构设计为焊接结构或者采用铝材质的基体

精加工

-

Outil d'alésage de précision

de construction légère

- Plaquettes de coupe à insert PCD pour boîtier alu

- Plaquettes de coupe en cermet pour l'usinage de coussinets de palier en acier

- Ajustage précis et stabilité de température

- Technologie de patins de guidage

-

Outil recessing

pour les systèmes d'axe U

- Adapté pour l'usinage de variantes de boîtier

- Pour la compensation de l'usure des arêtes de coupe

Autres solutions d'usinage

-

-

Alésoir externe avec système EA

- Usinage extérieur de l'alésage de palier

-

Fraise à planer avec inserts de fraisage en PCD

- Génération de profils de surface définis pour les surfaces d'étanchéité et de contact (p. ex., structures transversales)

- Qualité de surface Rz < 1

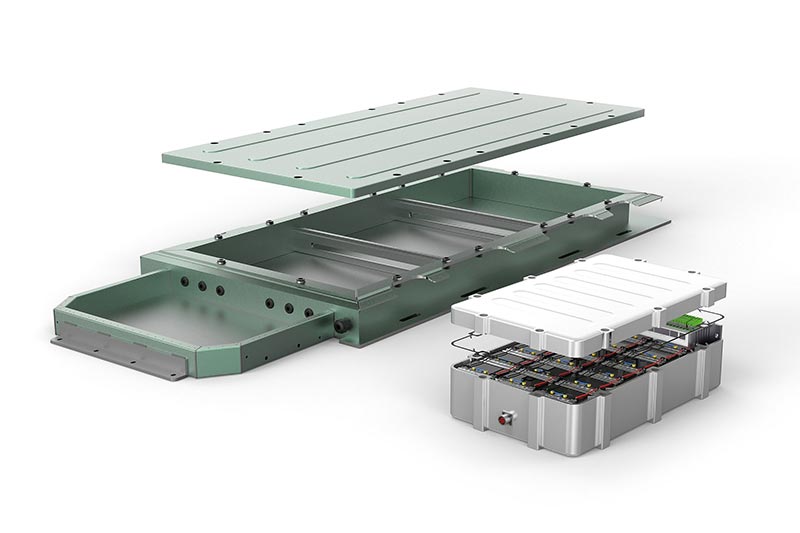

Autres composants électrifiés

-

-

-

Production d'énergie

Accumulateur, système de commande, chargement

Usinage sans vibrations de carters complexes à parois minces

-

Micromobilité

Exemple : vélo électrique

Une grande précision, même à petite échelle