展开式控制专家

展开式刀具在切削加工中具有最大的合理化和优化潜能。因此,为了满足对完整的刀 具产品的要求,从上世纪九十年代初期开始,也把创新型展开式刀具、钻杆和车端面 刀头都纳入了 MAPAL 的产品行列。无论是用于特殊机床,还是用于进行完整加工的灵 活的加工中心,只要涉及的是在箱体类零件上进行复杂轮廓、非圆柱孔、车端面或者 切槽加工,MAPAL 都能提供最佳的刀具解决方案。

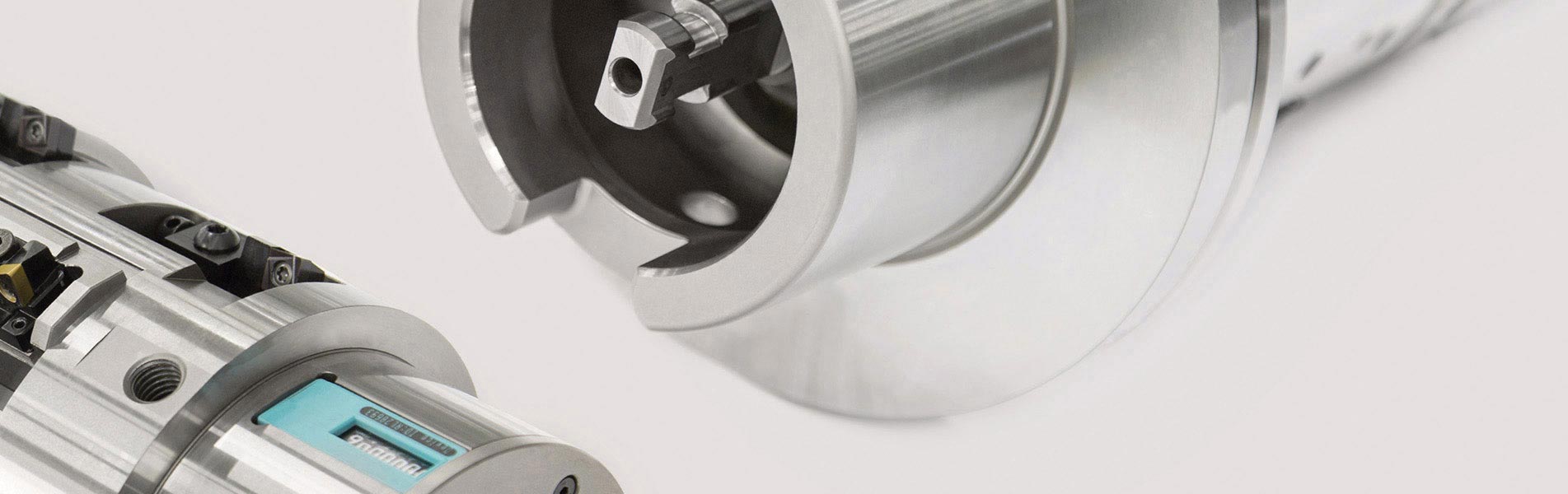

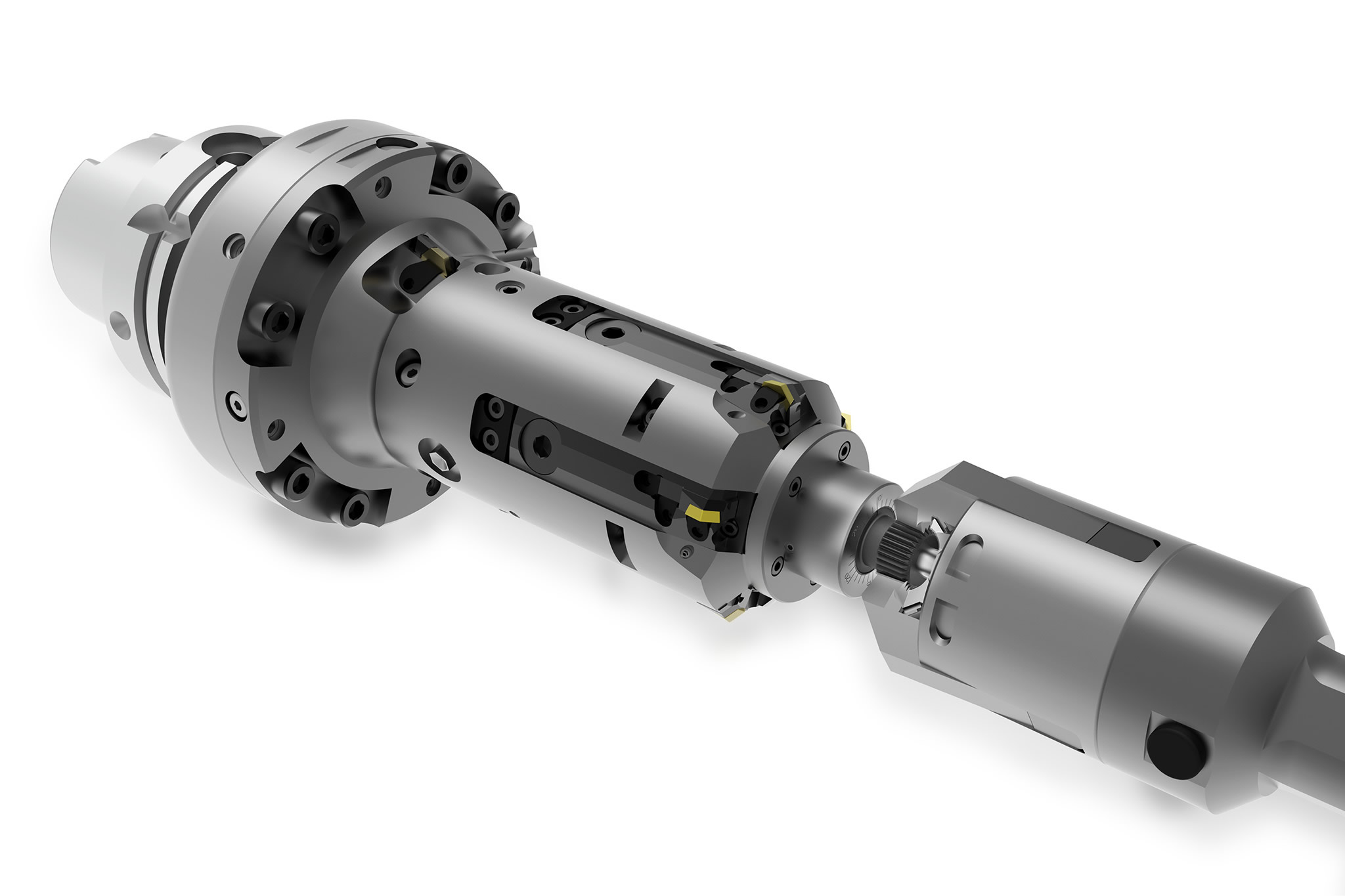

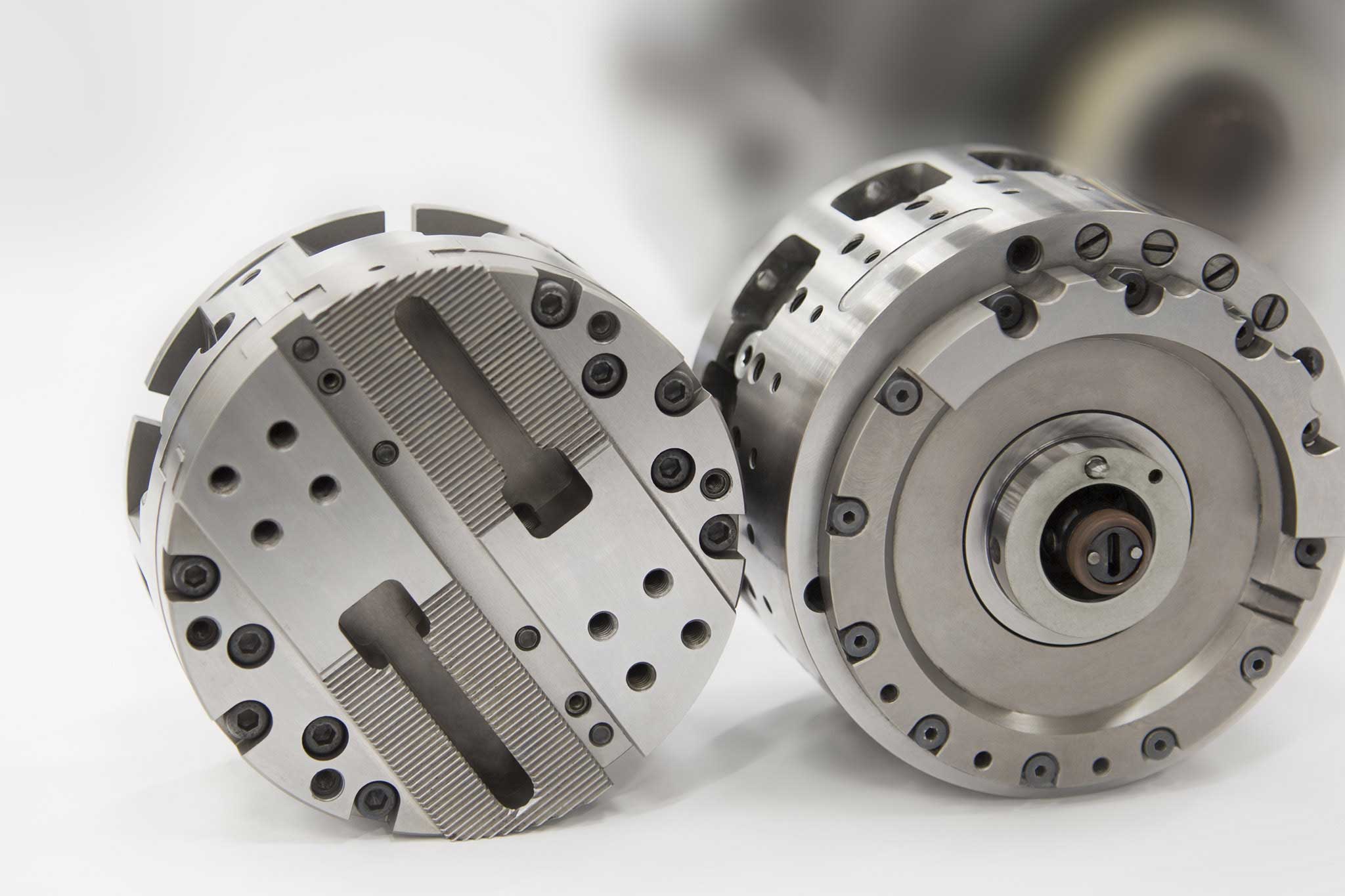

产品目录包括通过机器侧拉压杆驱动或 U 轴系统驱动的机械式展开式刀具,以 及 NC 控制的刀具,例如,用于不带附 加进给单元的机床、特别灵活的机电一 体化刀具系统 TOOLTRONIC。具有丰富经 验且极为专业化的 MAPAL 工艺规划团队 与客户密切合作,协调一致地设计出用 于客户切削加工任务的最佳解决方案。在 每个加工步骤中,都要求展开式刀具内部的极为复杂的和非常准确的机械机构和大 量不同的零件具有极高的精确性和极为精 密的运动。为了保证刀具达到最高的精密 性,MAPAL 刀具全部采用手工安装。为 了能够快速和高效地在客户处完成刀具的 调试工作,对复杂的展开式刀具都事先在 极端负载和真实的工作条件下进行了大量 的试验。之后,由 MAPAL 的切削加工专 家在客户处完成刀具的调试工作。

产品目录包括通过机器侧拉压杆驱动或 U 轴系统驱动的机械式展开式刀具,以 及 NC 控制的刀具,例如,用于不带附 加进给单元的机床、特别灵活的机电一 体化刀具系统 TOOLTRONIC。具有丰富经 验且极为专业化的 MAPAL 工艺规划团队 与客户密切合作,协调一致地设计出用 于客户切削加工任务的最佳解决方案。在 每个加工步骤中,都要求展开式刀具内部的极为复杂的和非常准确的机械机构和大 量不同的零件具有极高的精确性和极为精 密的运动。为了保证刀具达到最高的精密 性,MAPAL 刀具全部采用手工安装。为 了能够快速和高效地在客户处完成刀具的 调试工作,对复杂的展开式刀具都事先在 极端负载和真实的工作条件下进行了大量 的试验。之后,由 MAPAL 的切削加工专 家在客户处完成刀具的调试工作。

何时采用展开式控制

产品总览

驱动类型和输出 端类型

TOOLTRONIC

车端面刀头

线镗杆

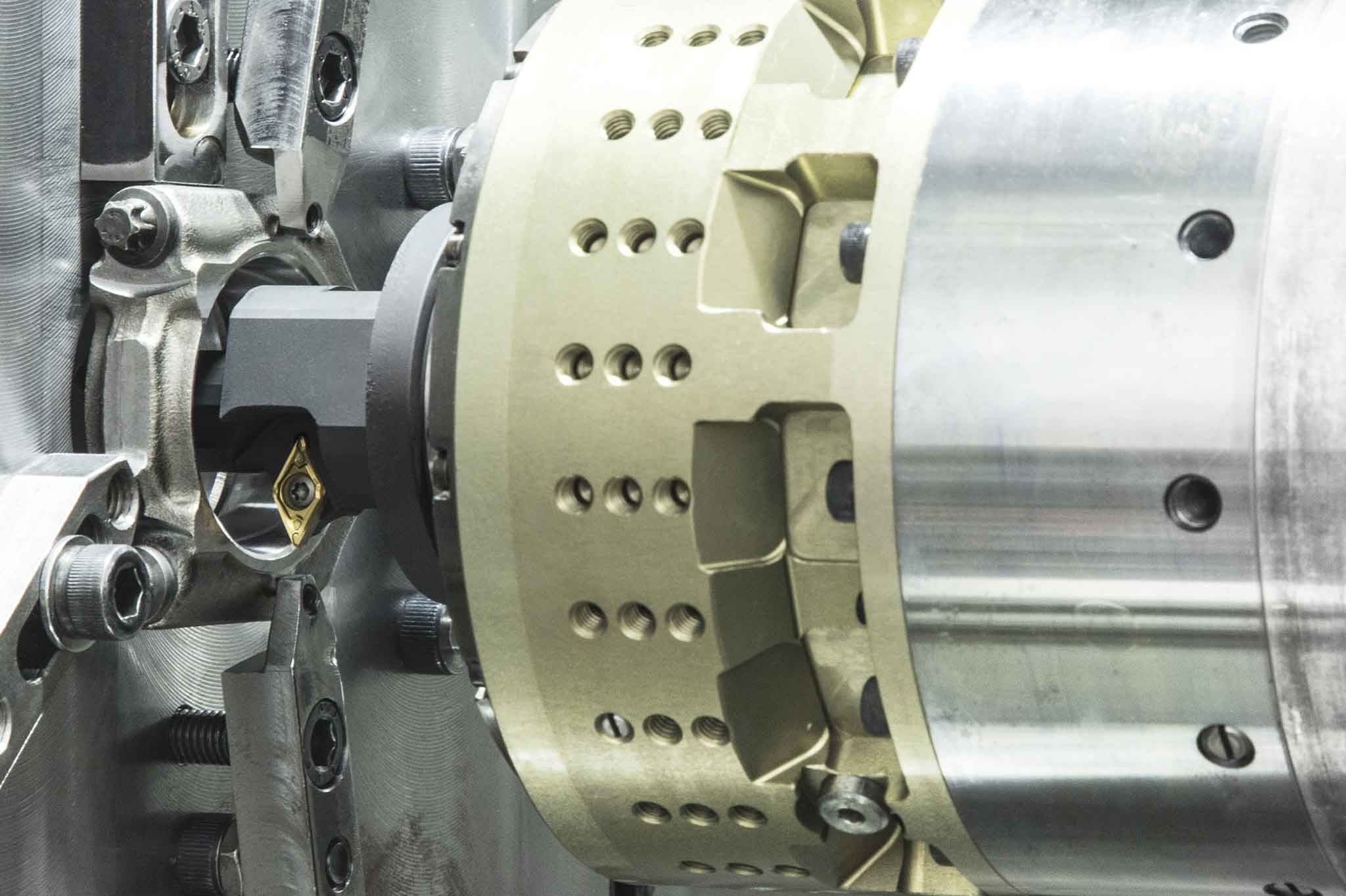

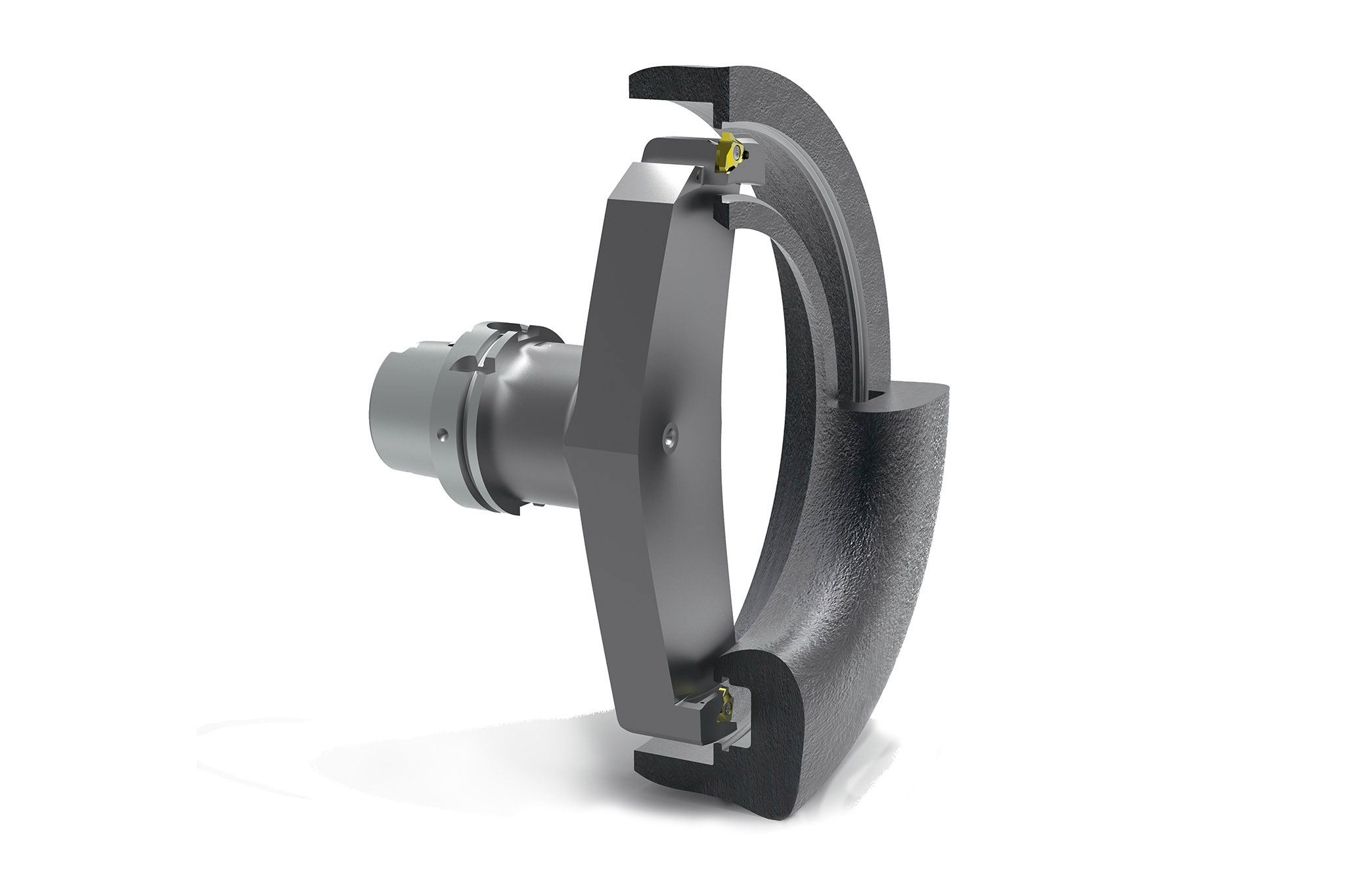

线镗杆是对箱体中的轴承轴瓦面进行 专门加工的刀具。在这里,刀具至少要 由一个在装夹设备 (工件夹具) 当中 的轴承导向。采用这种多刃刀具可以 同时对多个轴瓦面进行加工。一个选 项的拉压杆能够附加地完成对各轴瓦 面的端面加工和 / 或完成切削刃的抬 起以补偿切削刃的磨损。

线镗杆应用在对曲轴轴承孔和凸轮轴 轴承孔的加工中。这是在汽缸曲轴箱 体中这种孔加工的最精确的方式。

其它应用

展开式刀具客户服务

工艺规划 - 选型设计 - 调试 - 保养

MAPAL 在展开式刀具范围提供针对全部产 品的大量的咨询服务。

在首次会谈中,由销售人员接收对加工 流程的要求,以便能够提供客户定制的 产品。

作为特殊解决方案的专家,当然也提供 采用标准部件匹配于客户专门要求的解 决方案。为了能够编排保养日期和减少服务费用, 也可以与客户签订客户定制的服务合同。

MAPAL 客户服务团队以定义的保养间隔对 刀具进行检查

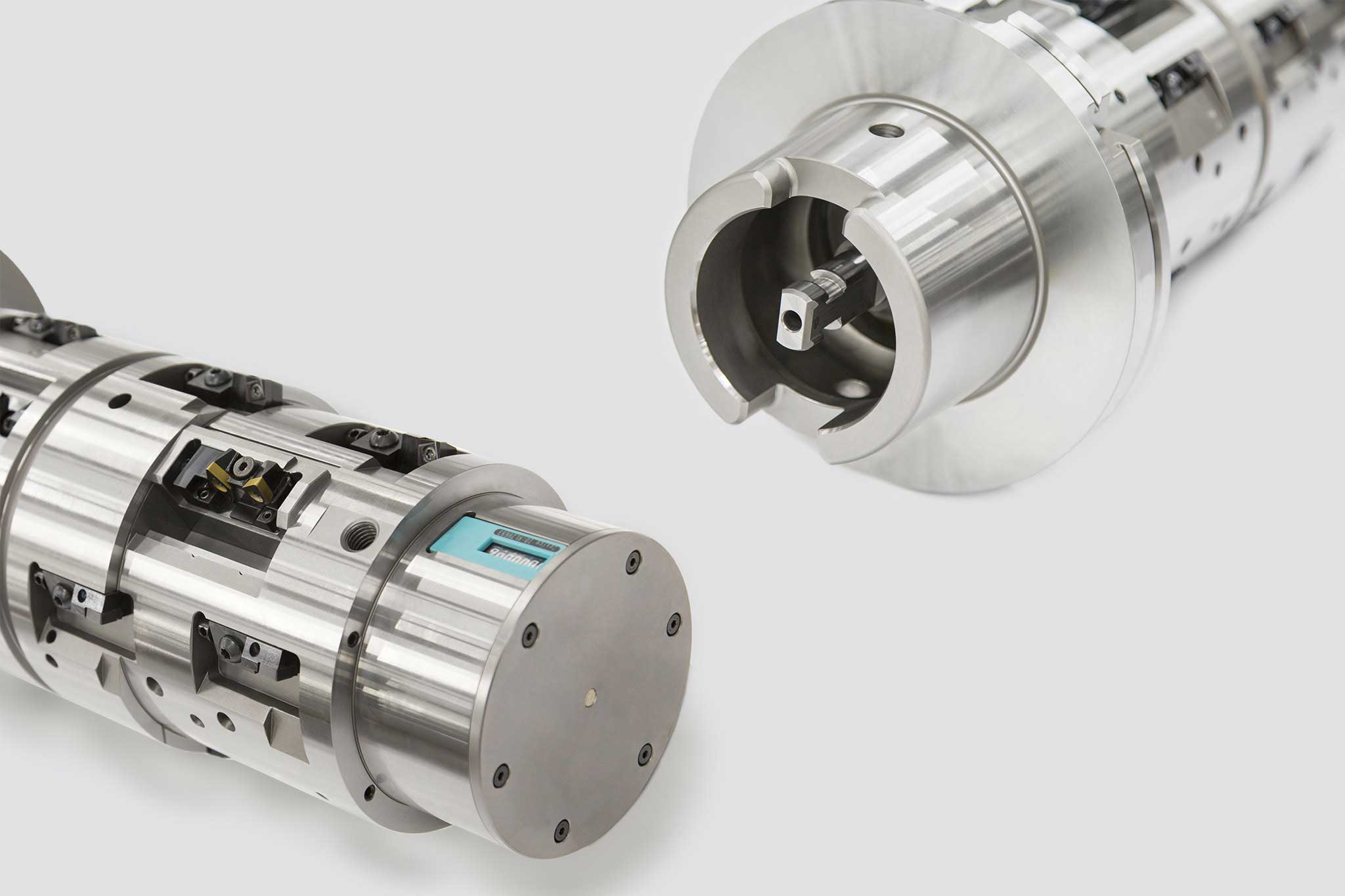

在刀具中独立的维修显示,使得预防性保养维护以及维修更加简单快捷。

MAPAL公司开发了一个特别简单快捷的系统,可针对用户在旋转刀具维修工作的时间点和频率等问题,立刻提供支持。

一个维修-芯片与LED的集成(其中一些也可进行改装),通过“灯光闪烁”可以发出一个需要进行保养维护的信号。在此过程中,将列出运行小时的数量。

一个维修-芯片与LED的集成(其中一些也可进行改装),通过“灯光闪烁”可以发出一个需要进行保养维护的信号。在此过程中,将列出运行小时的数量。