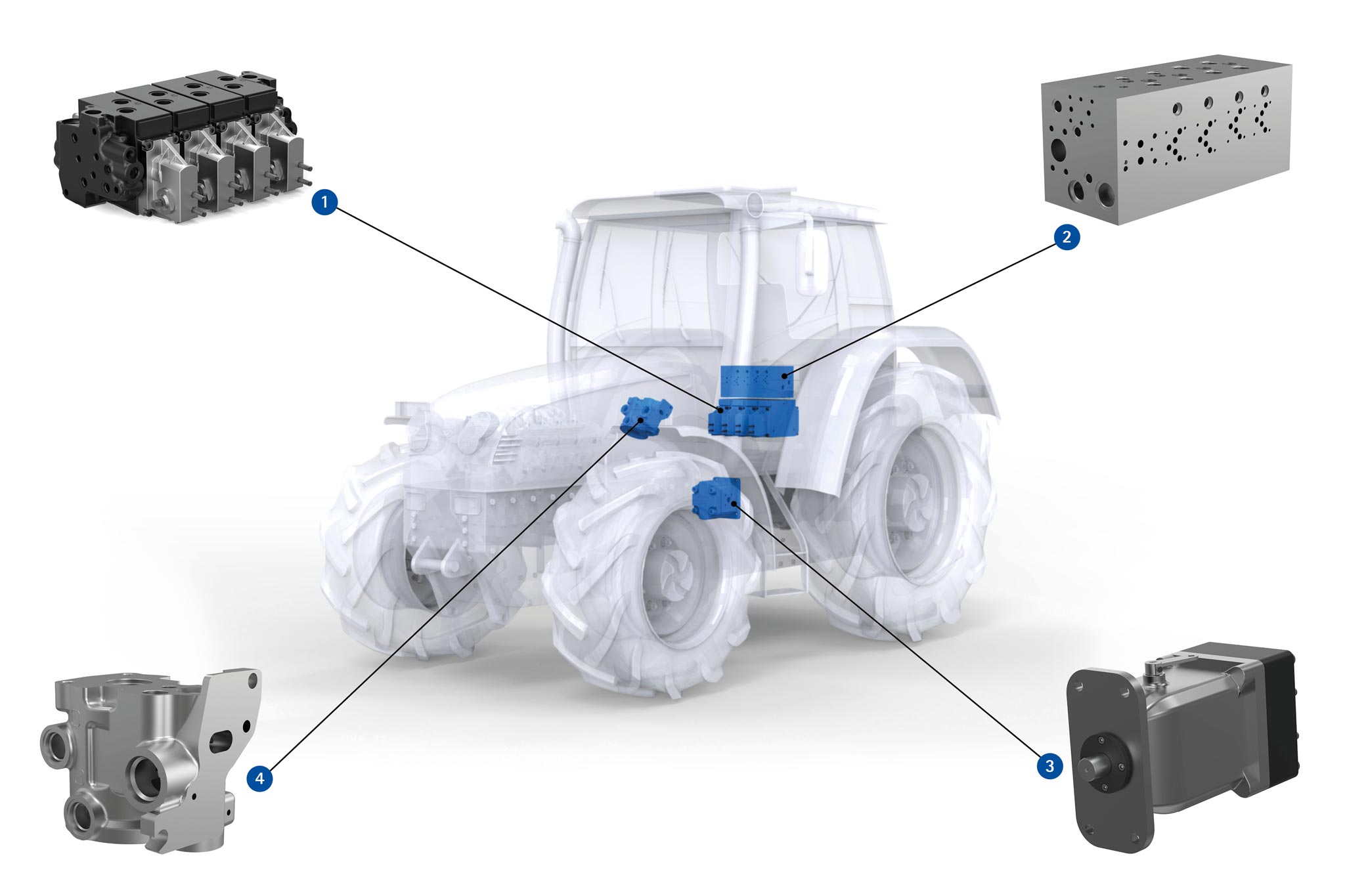

液压系统

MAPAL可以针对移动式液压系统-和转向回路中的相关功能部件提供量身定制的完整配套加工工艺。此外,具有创新和增值优势的工艺解决方案,对于固定式液压组件的加工也非常受欢迎。

作为技术合作伙伴,MAPAL公司为客户提供完整的工艺设计支持。此时,专家特别关注在功能相关的孔中经常发现的成本动因。根据各自的珩磨工艺、部件要求和批量大小,MAPAL公司与客户进行对话,设计出完美的加工策略。

一个目标统一了所有活动:设计最经济的工艺,从打导向孔到镗孔和半精加工再到高效珩磨流程

作为技术合作伙伴,MAPAL公司为客户提供完整的工艺设计支持。此时,专家特别关注在功能相关的孔中经常发现的成本动因。根据各自的珩磨工艺、部件要求和批量大小,MAPAL公司与客户进行对话,设计出完美的加工策略。

一个目标统一了所有活动:设计最经济的工艺,从打导向孔到镗孔和半精加工再到高效珩磨流程