Empower Your Aluminium Machining

技术设计是关键

MAPAL凭着数十年对铝加工刀具的设计、生产和应用领域的富足经验,已成为铝工件加工方面具有领先地位的技术合作伙伴。为了向客户提供最佳的切削工艺流程,MAPAL除了提供全面的产品和应用组合之外,还提供针对市场、材料以及加工等方面的专业知识。只有通过对所有影响因素的融会贯通的认识,并秉承伙伴式的合作模式,才能让我们加工工艺的全部潜力得到充分发挥——而这就是MAPAL代表的全部信念。

用户至上

産業および部品

Herausforderungen der Aluminiumzerspanung

Produkte und Anwendungen

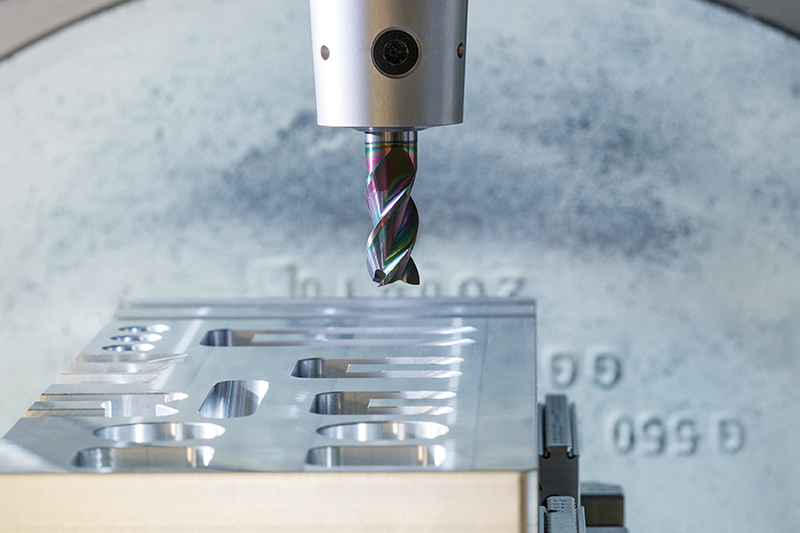

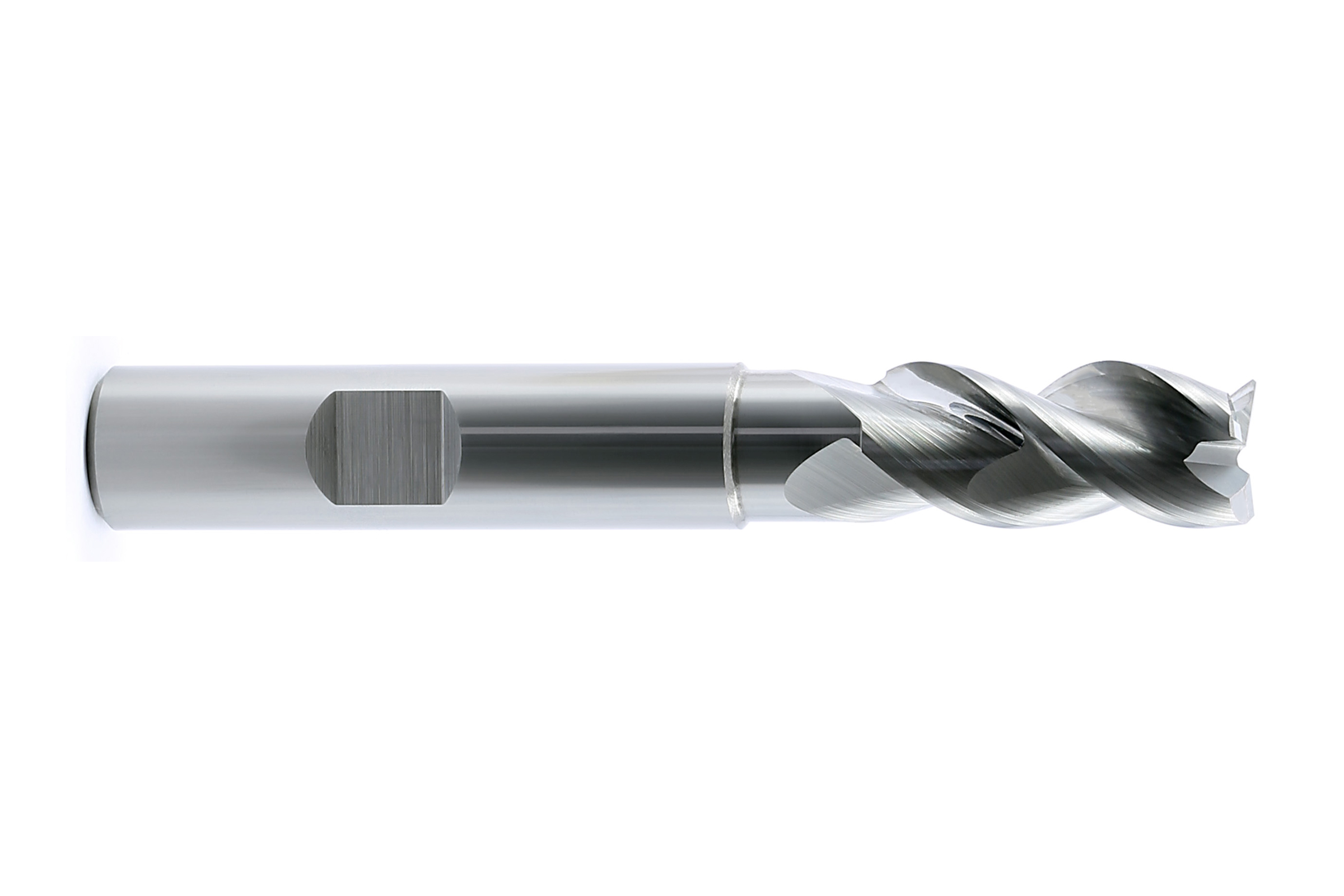

Fräsen mit Vollhartmetall

Fräsen mit PKD

Fräsen mit Wendeschneidplatten

Bohren

Reiben

Fixação

Exemplos da prática

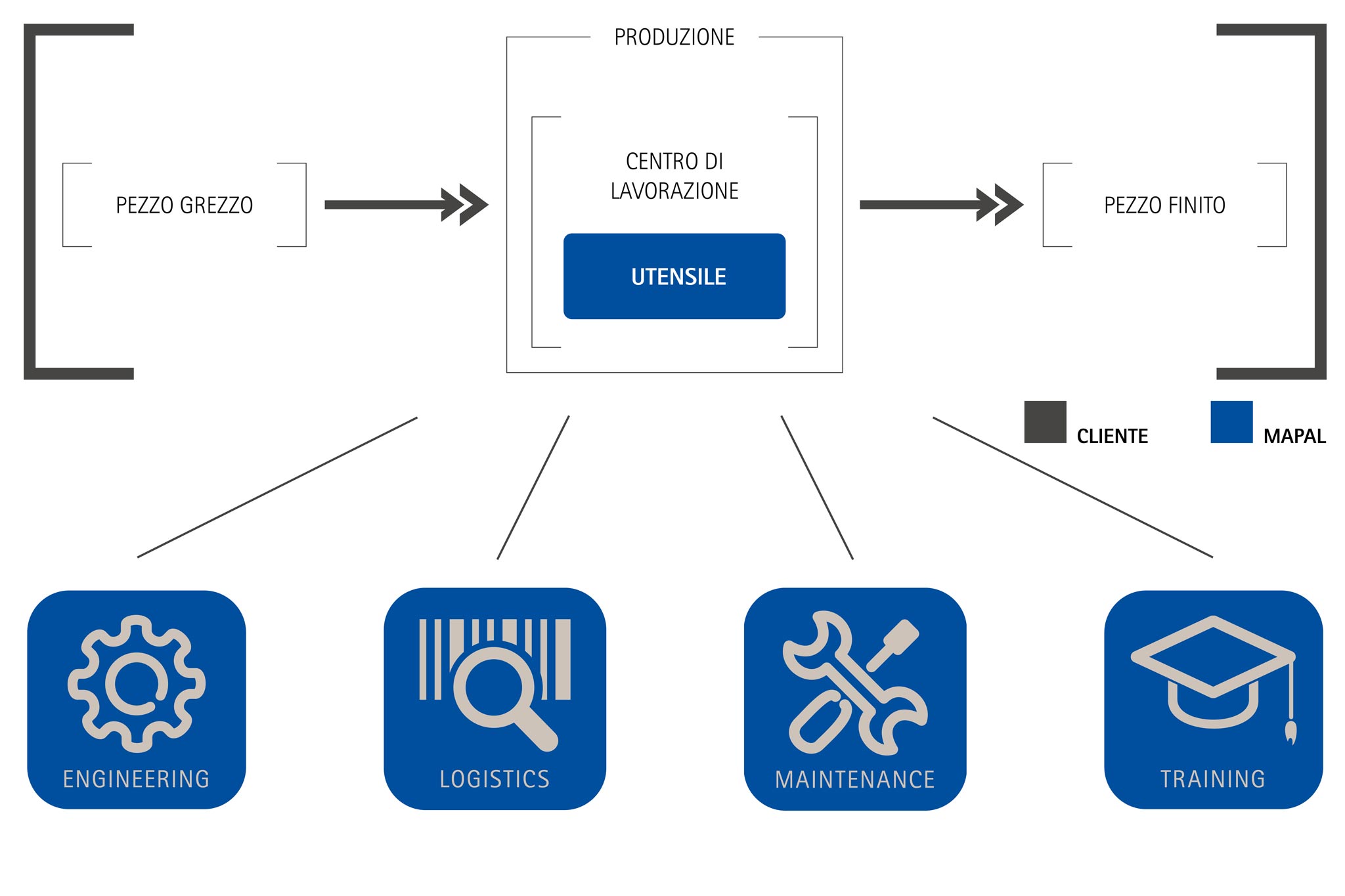

Servizi MAPAL

Grazie al servizio di engineering, MAPAL garantisce una produzione rapida, precisa e affidabile. Un ulteriore potenziale di risparmio può essere sfruttato nell’area della logistica e della manutenzione. E nel campo della formazione, MAPAL assicura che il know-how specialistico accumulato sia a disposizione del cliente in modo trasparente e completo, offrendogli un vantaggio decisivo sulla concorrenza.

In tutte le offerte di servizio MAPAL, l’ottimizzazione dei processi e un’assistenza completa sono al centro della transizione verso l’Industria 4.0. Sempre con l’obiettivo di contribuire in modo significativo a una produzione regolare, produttiva e conveniente per il cliente.

Vantaggi:

- Soluzioni per pezzi completi, compresi utensili, attrezzature, programma NC e messa in servizio

- Progettazione e implementazione completa del processo per un servizio chiavi in mano

- Assistenza rapida e flessibile sul posto in tutto il mondo

- Tecnologia utensile efficiente e ottimizzata dal punto di vista dei costi

- Coordinamento ottimale di utensile, pezzo, attrezzatura e macchina

- Massima qualità del prodotto, sicurezza dei processi ed efficienza fin dall’inizio

- Svolgimento rapido dalla pianificazione alla realizzazione nel rispetto dei tempi

/-P3A1692-1-.jpg)