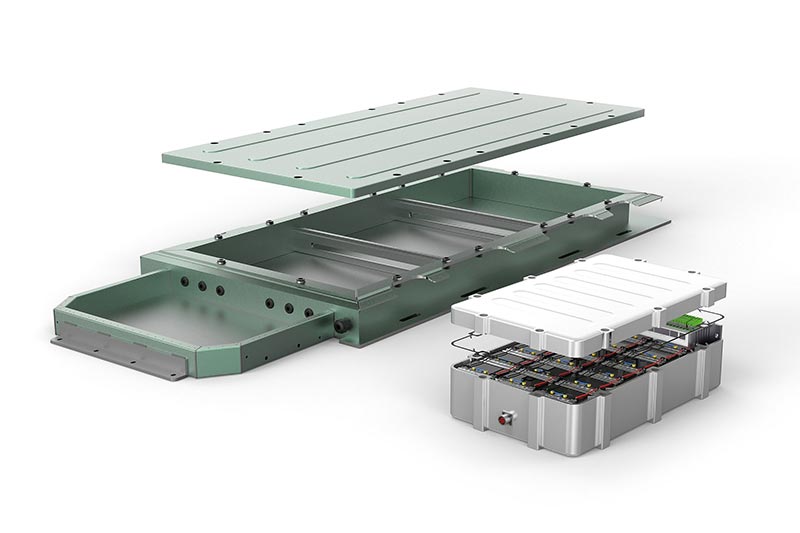

パワーサプライ用ハウジング

バッテリーシステムやパワーエレクトロニクスなどの電子部品を外部環境の影響から保護したり、車の運転中に車室内に固定するために、さまざまなハウジングが使用されています。ハウジングに求められる要件は、電子システムや駆動コンセプトによって異なります。現在、さまざまな素材や製造プロセスが使用されています。

特性

- 不安定な薄肉部品(振動の影響を受けやすい)

- キャストタンクまたは中空プロファイルで作られたフレーム構造としての組立

- 部分的に低粘度のアルミニウム

- 大面積 (2 x 3 m)

- 主にドリル加工やミーリング加工やねじ切り

- ケーブルブッシュや冷却接続部の精度および表面要求

-

押出成形プロファイル

-

バッテリーの大型化に伴い、さまざまな性能レベルやレンジに対応するモジュールコンセプトが採用されています。アルミニウム製の押出成形品を溶接してハウジングを形成します。

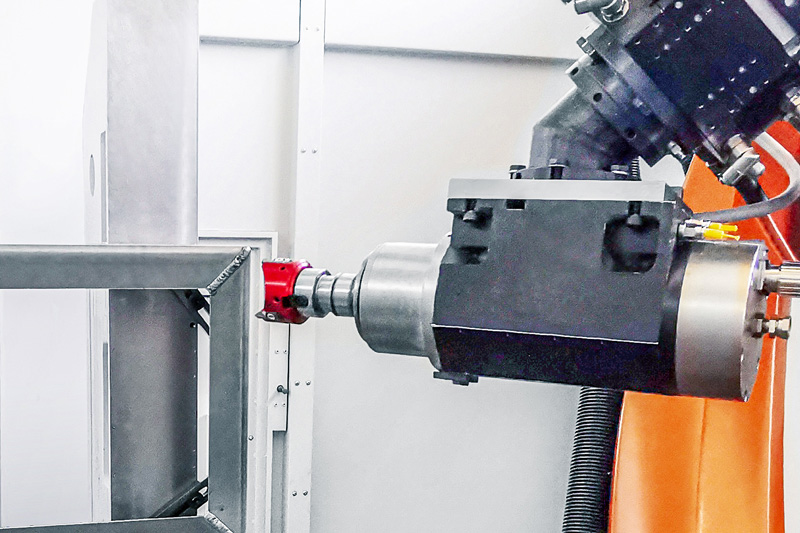

機械加工条件

- 多層構造の薄い素材

- ドリル加工: 振動およびバリの形成。ツールでのリング形成 → バリの発生やリングを防止するヘリカル加工 / 軌道穴あけ

- ミーリング加工: 振動しやすい薄い素材 → 最適化された切削形状による低振動

-

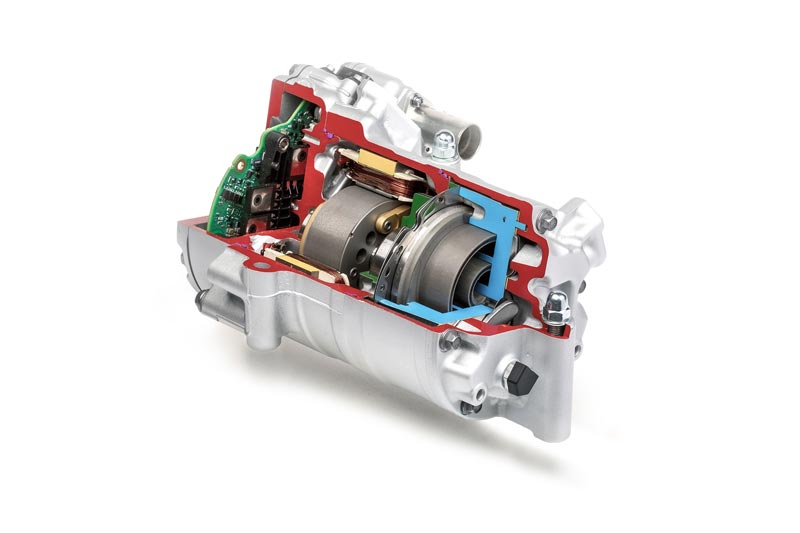

ダイキャストハウジング

-

アルミダイキャスト製のダイキャストハウジングは、パワーエレクトロニクスやハイブリッド車用の小型バッテリーシステムなどに使用されます。複雑なハウジング構造は、クーラント穴が統合された仕様です。

機械加工条件

- シール面のミーリング加工(部分的に特殊な表面要求)

- 長い工具突き出しでの電子機器やバッテリーセルの取付面のミーリング加工

- タッピングドリル穴の加工ドリル加工 (1部品あたり50穴以上)

ツール概要

-

1 / 9

アルミニウム製構造部品の加工用標準プログラム

-

-

3 / 9

OptiMill-SPM

- Ideal para la fabricación de brechas o bolsillos

- Ejecución completa en metal duro o con cuchillas de PCD soldadas

-

4 / 9

OptiMill-SPM-Finish

- Acabado de grandes profundidades en una sola pasada

- Potente rendimiento con grandes enlazados

-

5 / 9

Tritan-Drill-Alu

- Fabricación de orificios lisos para roscar

- Tres insertos para velocidades de avance máximas

- Máxima precisión de posicionamiento mediante cuchilla transversal con autocentrado

-

6 / 9

MEGA-Drill-Alu

- Broca de metal duro (VHM)

- Taladrado con tiempos de ciclo reducidos

- Formación óptima de las virutas

- Procesos de taladrado eficaces con mayor número de diámetros iguales

-

7 / 9

FaceMill-Diamond-ES

- Fresa plana de PCD

- Desbaste y acabado de superficies frontales

- Mecanizado de superficies frontales con diferentes cotas a remover con una sola herramienta

- Posibilidad de operaciones de desbaste y acabado

-

8 / 9

OptiMill-Diamond-SPM

- Fresa PCD

- Operaciones de fresado circular de diversos diámetros y superficies

- Reducción de los cambios de herramienta gracias al uso flexible de la herramienta

-

9 / 9

OptiMill-Alu-HPC-Pocket

- Fresas de corte en esquina

- Fresado de cavidades en materiales de aluminio

- Eliminación óptima de las virutas

- Estabilidad óptima

-

-

-

-

-

-

-

-

-

-

1 / 5

Fresa PCD para requisitos de mecanizado especiales

-

2 / 5

Fresa PCD con cuchillas dispuestas de forma alterna

- Bajas fuerzas de corte en toda la profundidad de mecanizado

-

3 / 5

Fresa PCD con forma espiral

- Acabado de estructuras de paredes finas

-

4 / 5

Fresas helicoidales de PCD

- Recorte con gran profundidad de corte

-

5 / 5

Fresa plana de PCD

- Fresado plano con profundidades de corte de hasta 10 mm

- Creación de perfiles superficiales definidos para superficies de contacto y apoyo

-

-

-

-

-

Case studies from the energy supply sector

-

-

-

12.07.2023

ドリル加工の代わりのフライス加工

Why milling instead of drilling can be a sensible alternative? MAPAL shows how higher process reliability and shorter machining times can be achieved.

#企業

#産業

#製品

#フライス加工

#航空宇宙産業