Empower Your Aluminium Machining

技术设计是关键

MAPAL凭着数十年对铝加工刀具的设计、生产和应用领域的富足经验,已成为铝工件加工方面具有领先地位的技术合作伙伴。为了向客户提供最佳的切削工艺流程,MAPAL除了提供全面的产品和应用组合之外,还提供针对市场、材料以及加工等方面的专业知识。只有通过对所有影响因素的融会贯通的认识,并秉承伙伴式的合作模式,才能让我们加工工艺的全部潜力得到充分发挥——而这就是MAPAL代表的全部信念。

用户至上

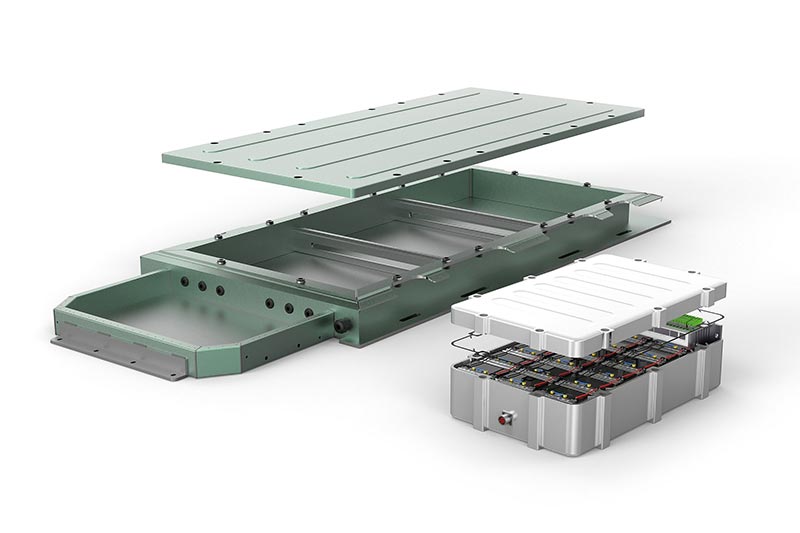

行业和结构组件

铝质材料切削的挑战

产品和应用

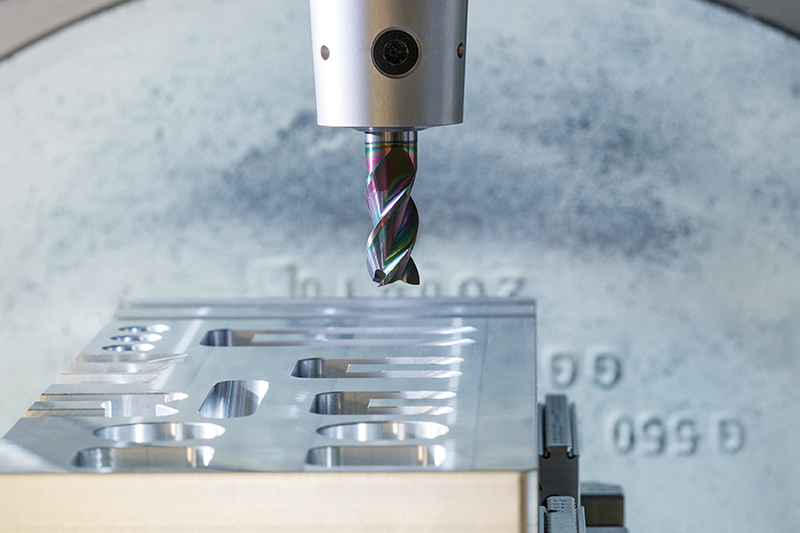

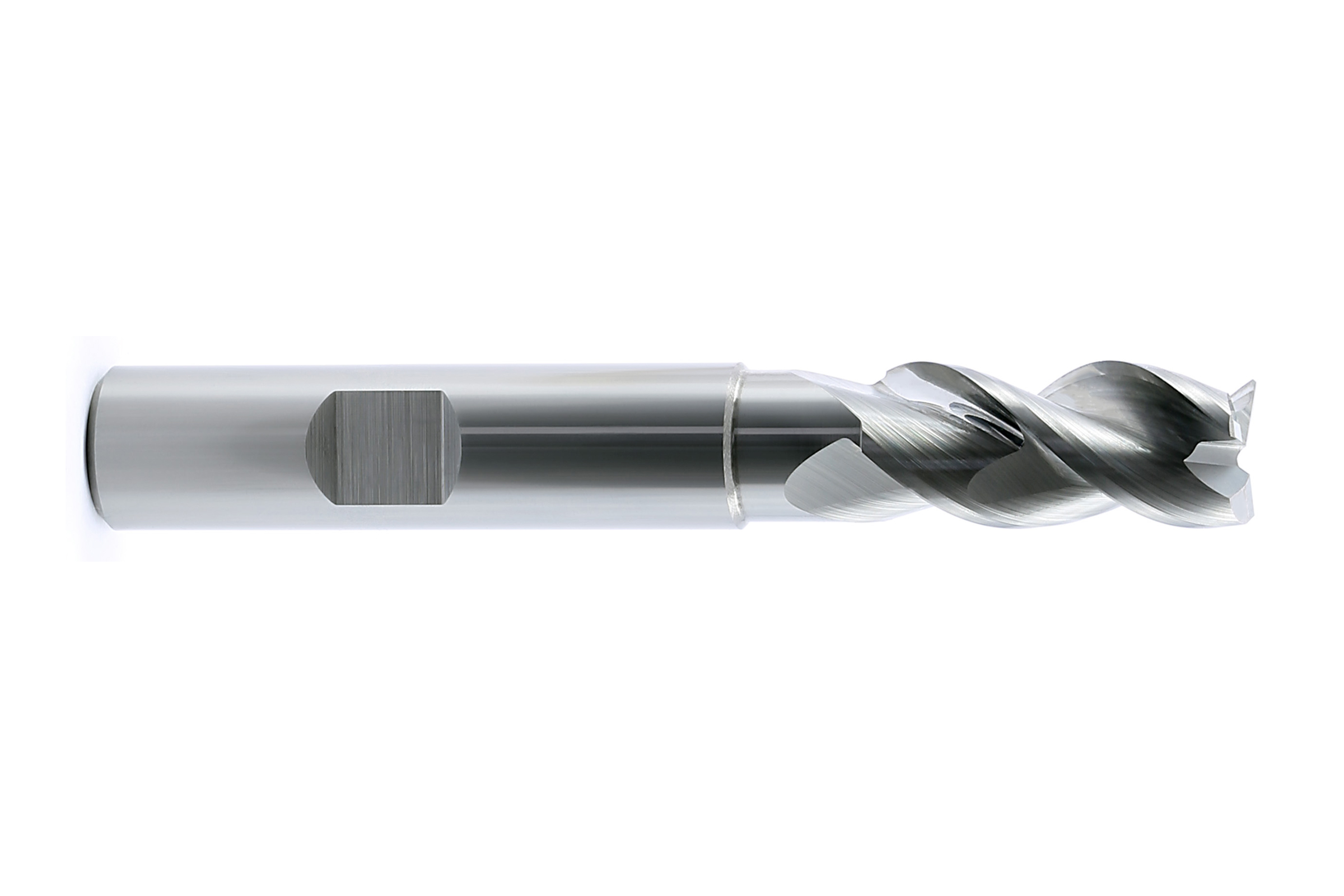

采用整体硬质合金刀具铣削

采用PCD刀具铣削

采用可转位刀片铣削

钻孔

铰孔

夹紧

具体实例

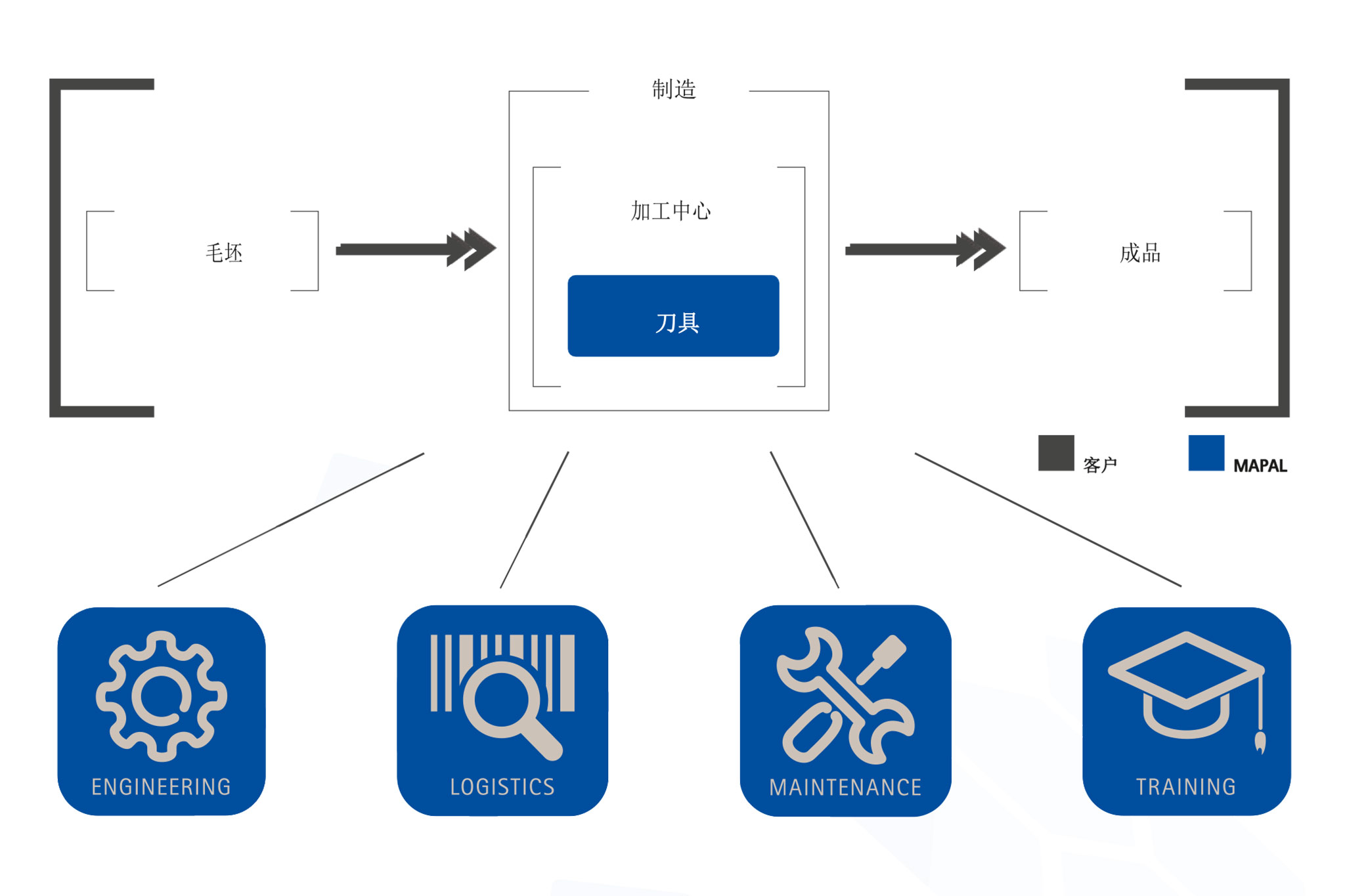

MAPAL 维护服务

通过 工程设计 服务模块,MAPAL公司可以确保为客户提供快速、精确和安全的加工。同时在 物流 和维护 领域可以为客户挖掘更多的成本节省潜力。在 培训 方面MAPAL集团基于自己的经验积淀,致力于向客户提供透明、完整的专业知识传输 — 极大帮助了客户在竞争环境中占据决定性的领先优势。

在MAPAL公司的所有 服务项目 中,始终把工作的重点置于面向工业4.0发展,提供最佳的工艺流程和全方位的支持。始终抱定一个目标:致力于为保障客户生产的平稳、高效和经济性的加工做出自己的贡献。

优点:

- 成套的工件加工解决方案,其中包括:刀具、工装夹具、NC-程序和投入运行

- 整个工艺流程的设计和执行的一站式服务

- 在全球范围内提供快速、灵活的现场支持

- 高效且切削成本优化的刀具工艺

- 刀具、工件、工装夹具和机床最佳的协调配置

- 从始至终的目标就是要实现最高的产品质量、稳定的过程可靠性并达到最好的经济效益

- 确保最高的安全性前提下,规划和实施得以更加快速开展

/-P3A1692-1-.jpg)