13.01.2022

Performance boost with NeoMill face milling cutter

MAPAL tools are convincing in standard applications

The family-owned company BOGE Kompressoren with its headquarters in Bielefeld, Germany, is a world-renowned technology and market leader in units for generating compressed air. Apart from the performance, quality and cost-effectiveness of the products, one of the most important declared goals is the increase of efficiency and safety in the manufacturing process. When producing screw compressors, MAPAL‘s high-performance tools achieve convincing results.

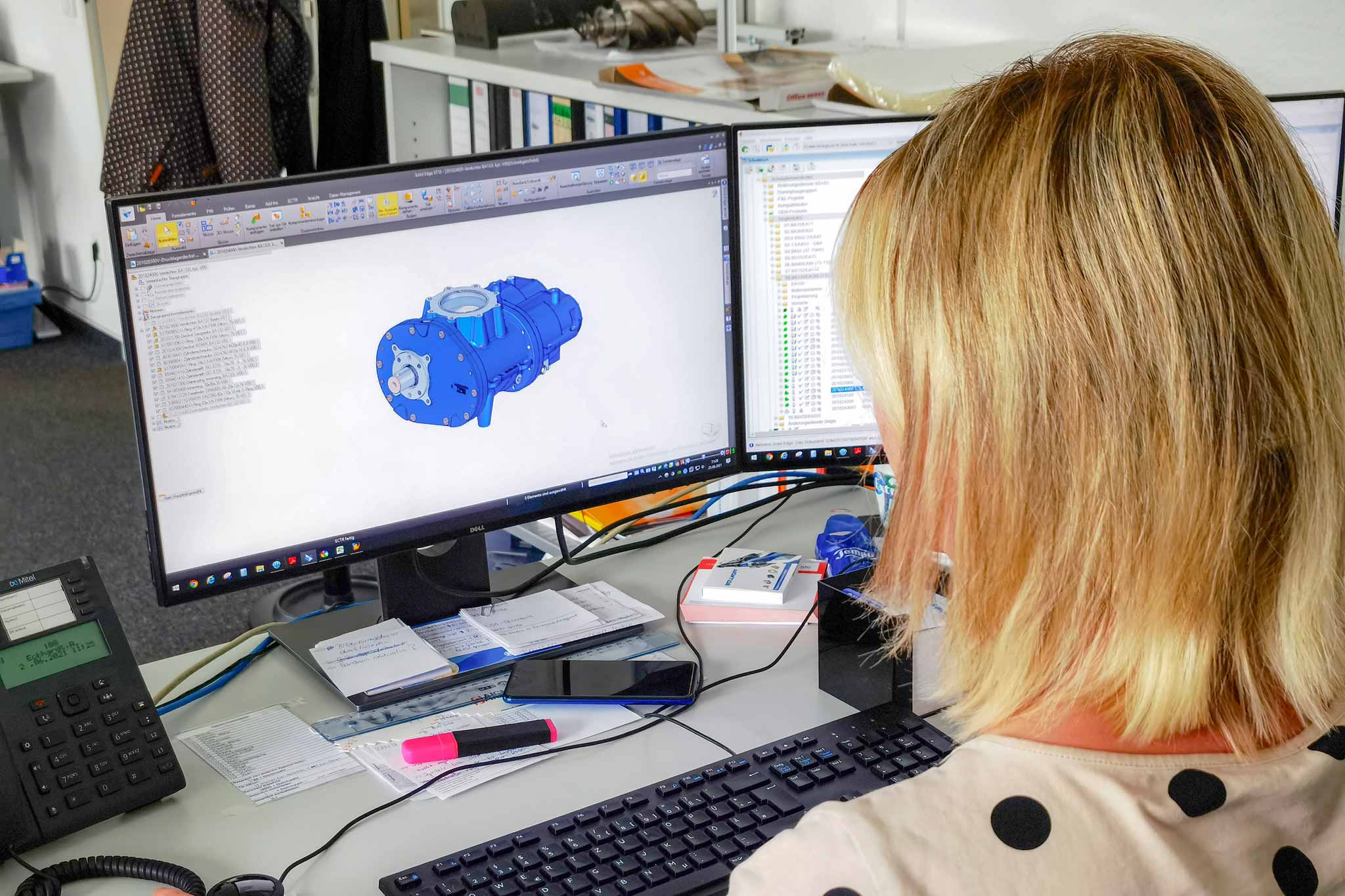

From design to optimised process

The long-standing development partnership with MAPAL…

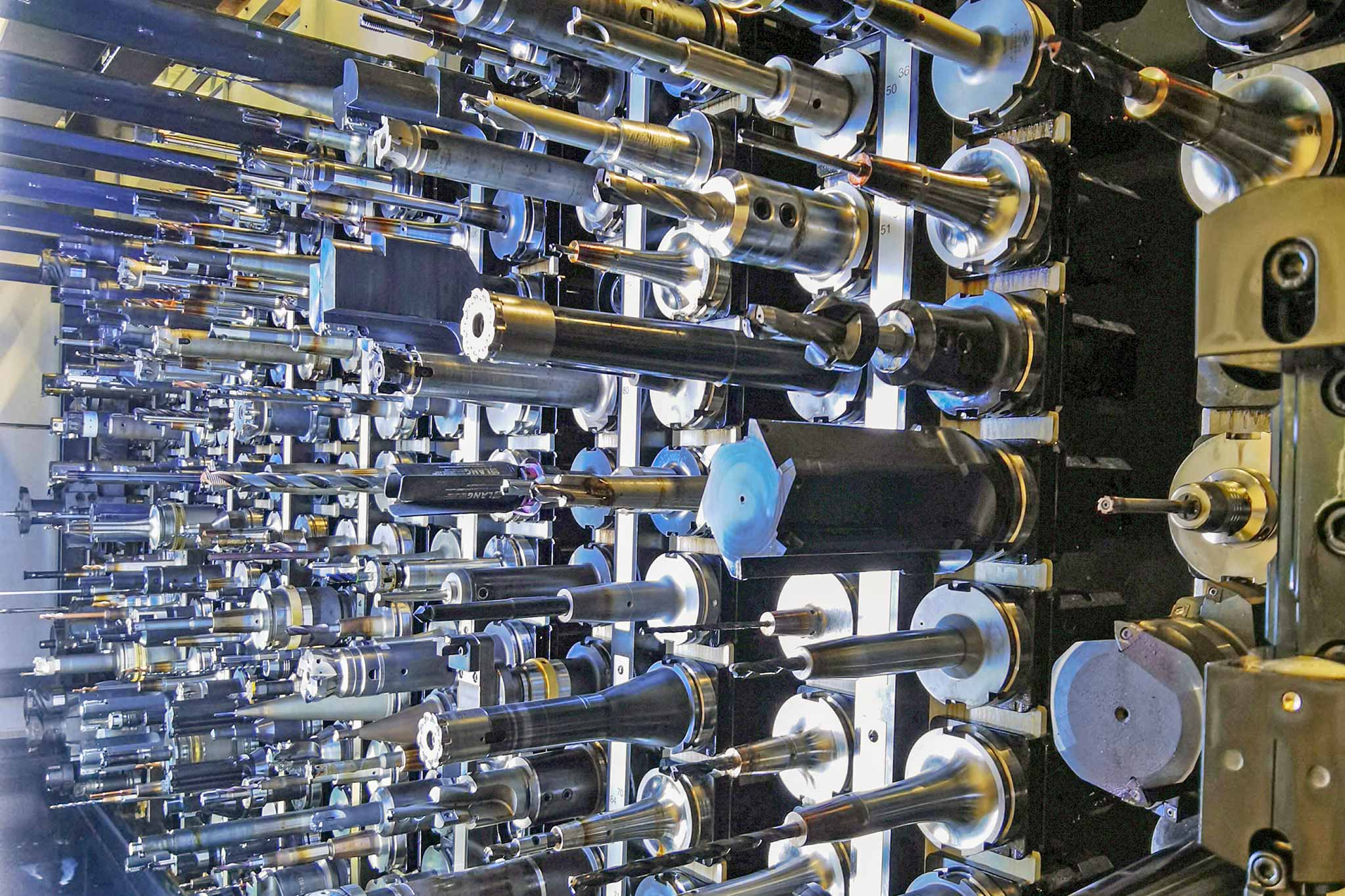

“There are many critical machining processes for housings, e.g. position bores or the bearing areas in rotors,” knows MAPAL’s application engineer Heiko Süss. Often, strict IT6 or IT7 precision requirements have to be met. This is where fine boring tools from MAPAL, designed exactly for these tasks, come into play. Not only is maximum precision important here – machining times must also be as short as possible. Well-designed multi-stage tools often result in low material removal rates that are sufficient to carry out several machining steps. Moreover, the custom tools achieve considerably closer tolerances and better surface qualities while maintaining the same high process reliability. In this area, BOGE and MAPAL have had a close partnership in development cooperation for a long time.

In the early phase of new projects, Heiko Süss already receives an inquiry from BOGE regarding the tool concept to be used for optimal machining of the new components. The machining solution suggested by MAPAL is then elaborated on within the team and validated in tests.

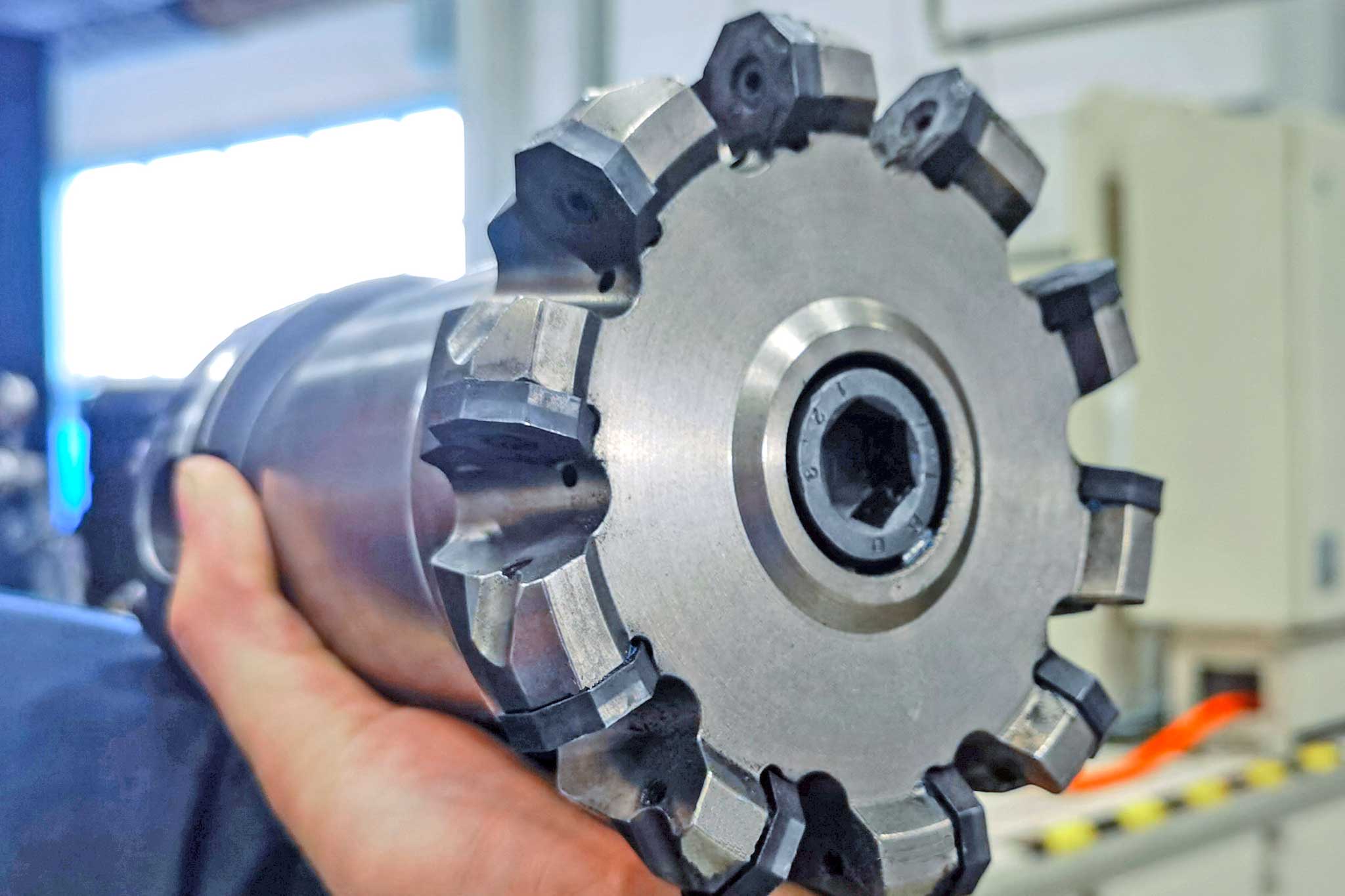

...is now also proving to be effective for milling cutters with indexable inserts

A sweeping success

“With these new tools, we were able to achieve really impressive success,” Mario Birkner is pleased to say. The material removal rate, increased from two to four millimetres, already made it possible to reduce the required machining time by half. Furthermore, it was possible to double the feed due to the softer cut and thus lower power consumption of the machine, so that the machining time decreased by more than 60 percent.

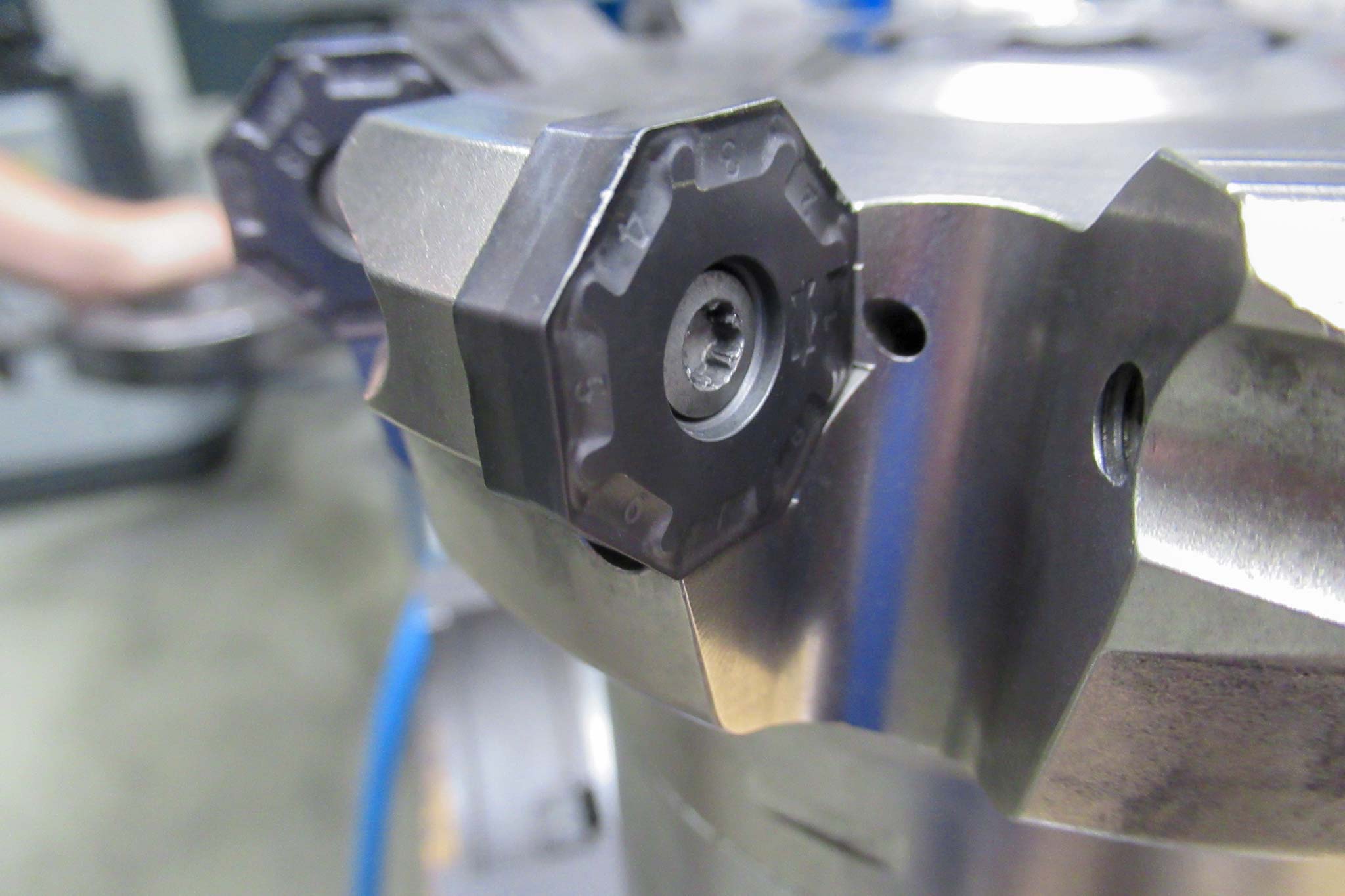

The tool life per cutting edge of the indexable inserts resulted in further time and cost advantages: 60 instead of the previous 45 minutes. In addition, the costs per cutting edge were reduced as well. This is because the octagonal (ONKU) indexable inserts from MAPAL’s NeoMill range, which are now being used, have a negative basic shape, can therefore be put in on both sides and have 16 cutting edges each in total. Thus, full replacement of the insert set is only necessary after 16 hours of use instead of the previous six hours, with corresponding positive effects on expenses for changing tools as well as on handling costs. In direct comparison with the previously used milling cutter, 45 machining hours can be saved when machining 1,200 parts.

However, these advantages could only be used to their full potential within the framework of a machine software optimisation: previously, an adaptive feed regulation automatically reduced the feed rates specified by the NC programme according to certain parameters. This automatic system proved to be too slow for the rapid machining of the NeoMill milling cutter. MAPAL’s face milling cutter was only able to realise its full performance potential after this function was deactivated. According to Mario Birkner, MAPAL will also be contacted for further machining processes in future projects.

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342