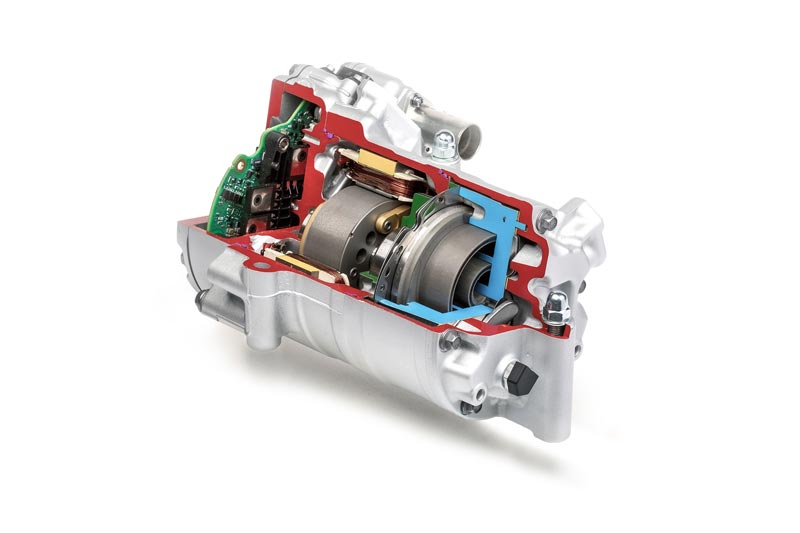

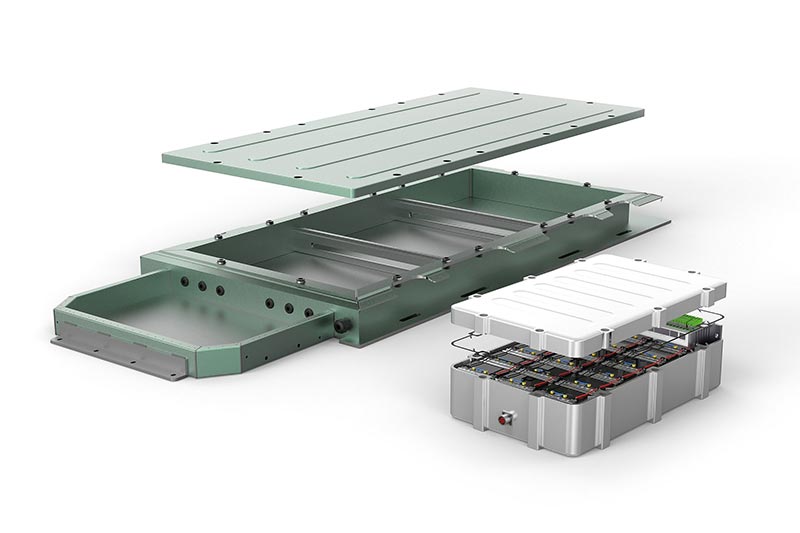

电机壳体解决方案

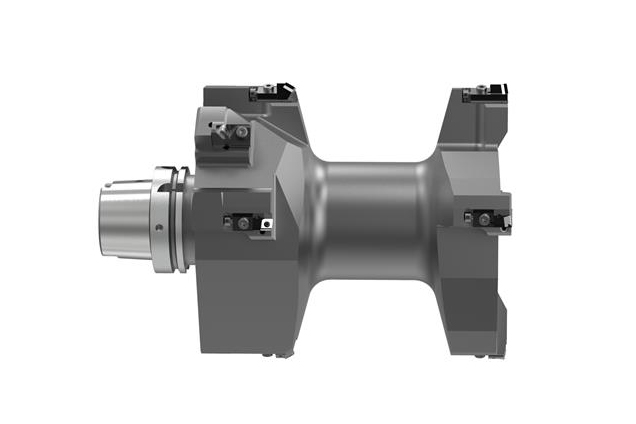

HSK-100 解决方案

大直径孔高效解决方案

- 三步加工〈粗加工、半精加工、精加工〉

- 直径可>220 mm

- 最高性能和精度

- 大批量、低节拍有效加工

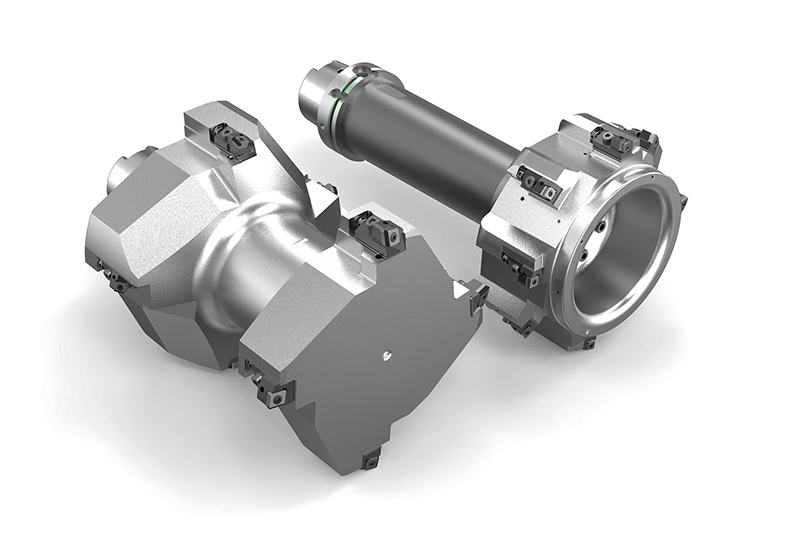

1 粗加工

商姓的租加工,大余量去除

ISO 锺刀铝合金刀体设计

- ø 250 / 258 mm

- PCD可转位刀片

- ISO刀夹

- 单台阶或复合台阶

- 重量2 最大21 kg

2. 半精加工

预留余量到最终轮廓只寸

精密锺刀

- ø 272 / 278 mm

- PCD可转位刀片

- 焊接式刀休戚铝合金刀体

- .量2 簸大 17,3 kg

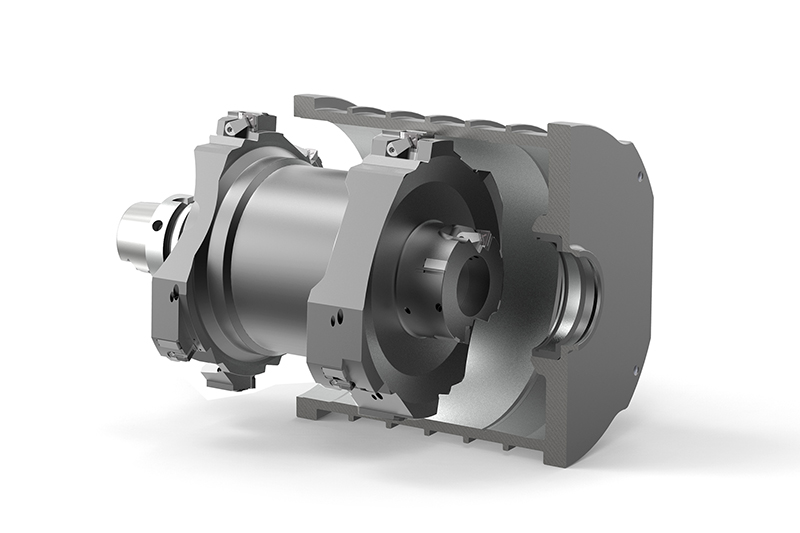

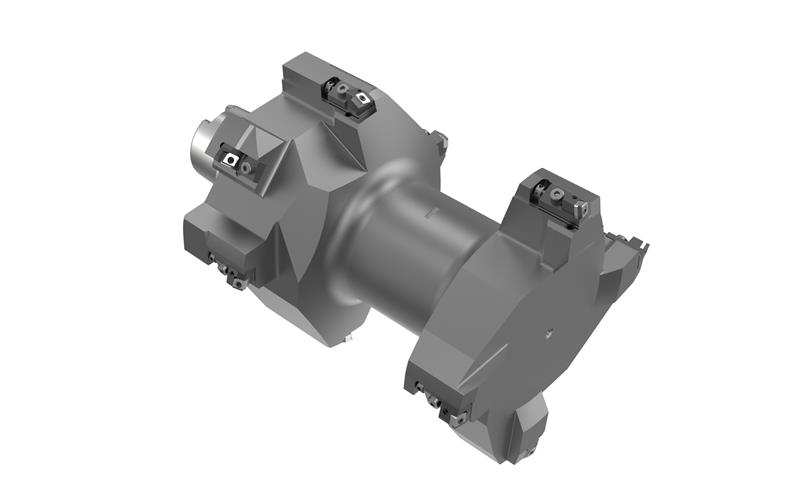

3.1 Finish machining

Innovation for the highest precision

Fine boring tool in lightweight construction made of steel with protection shield for mixed machining of the bearing bore

- ø 70 / 156 / 250 / 260 mm

- PCD-tipped indexable inserts for aluminium housing

- A = 362 mm | z = 2+4

- Cermet indexable inserts for machining of steel bearing bushes

- Finely adjustable and temperature stable

- Guide pad technology

- Weight: max. 21 kg

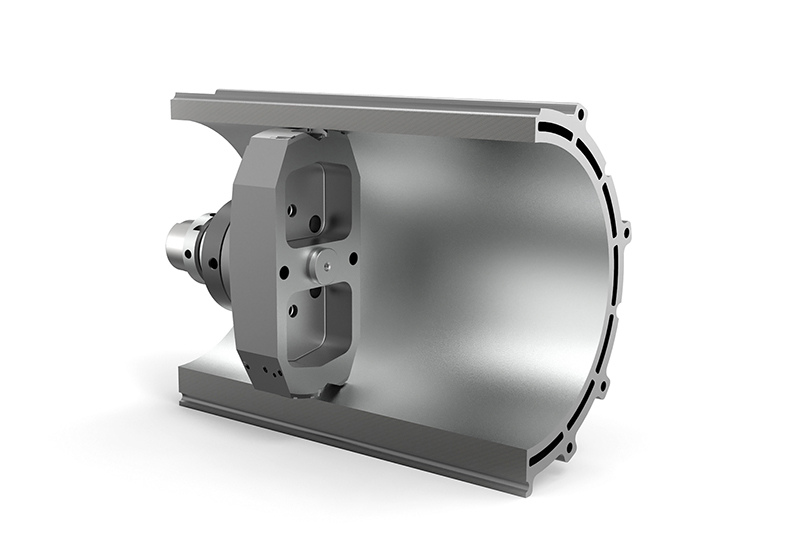

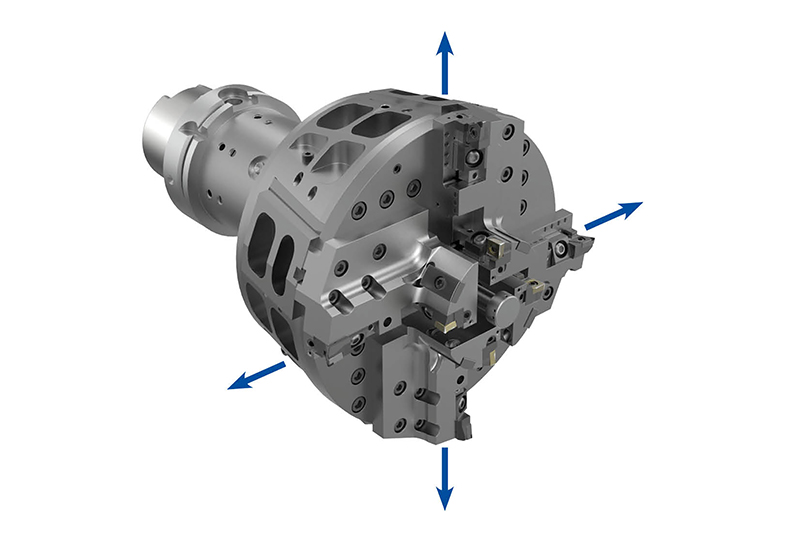

3.2 Finish machining

Flexible machining of the inner contour

Actuating tool for U-axis systems

- ø 80 / 220 mm

- Suitable for machining of housing variants

- To compensate for cutter edge wear

- Weight: max. 23 kg

Your direct contact

Contact person

Michael Kucher Component Manager E-Mobility michael.kucher@mapal.com +49 7361 585 3557