CaseStudies

-

02.12.2025

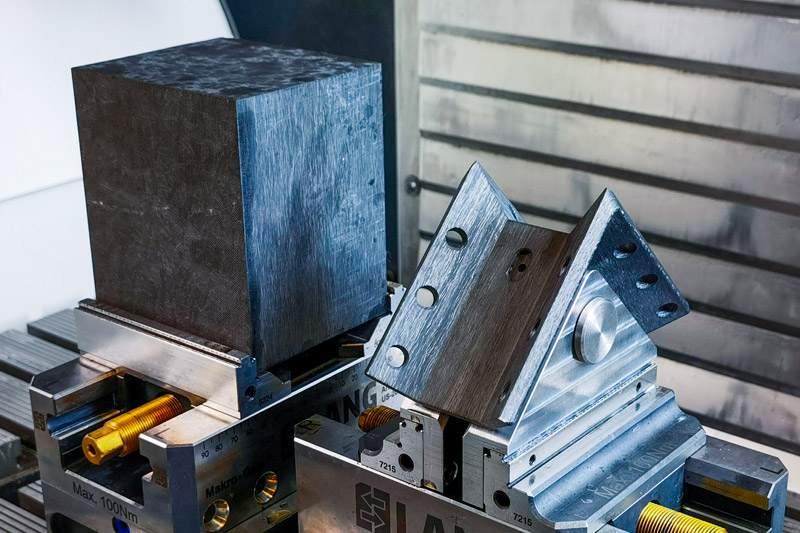

Large tool package for Mangner Zerspanungstechnik

MAPAL has equipped Mangner GmbH with a comprehensive tool package for drilling operations.

-

30.10.2025

MAPAL Indonesia provides a unique service for automotive supplier

MAPAL Indonesia enables green manufacturing with minimum quantity lubrication tools at a local automotive supplier.

-

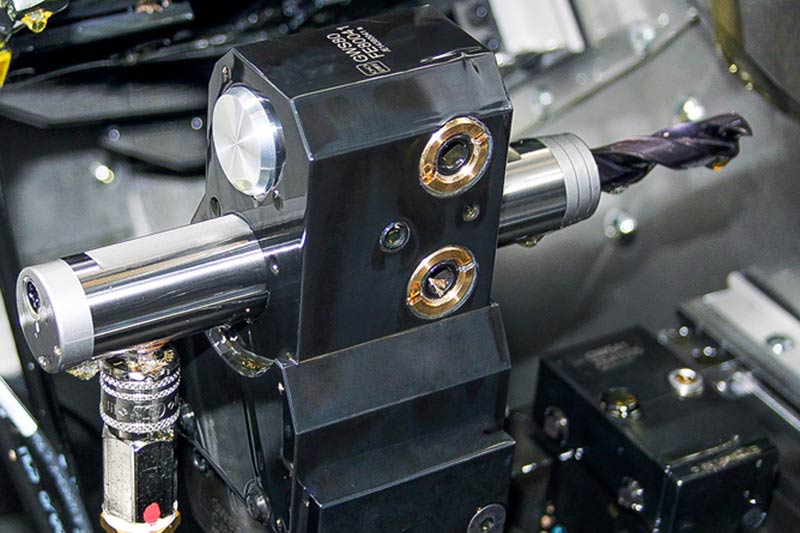

29.07.2025

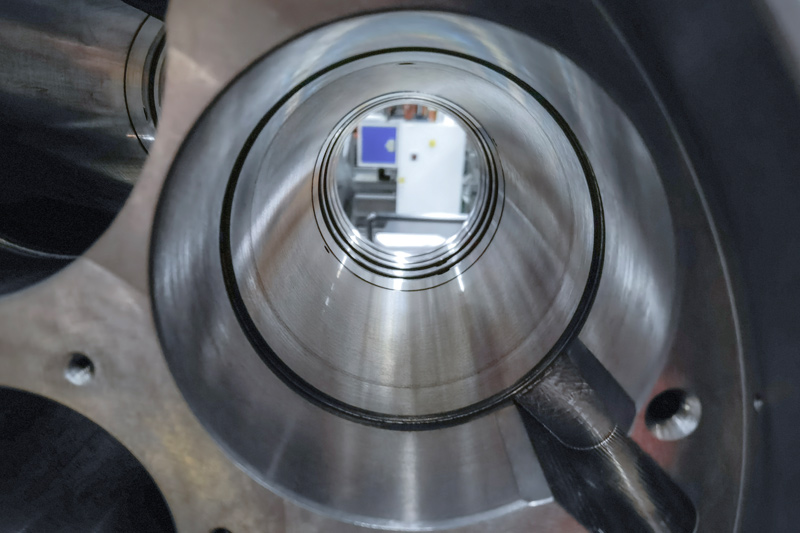

NILES-SIMMONS and MAPAL are setting standards in stator housings

The process developed by NILES-SIMMONS and MAPAL for the complete machining of stator housings for electric vehicle motors is ready for series production.

-

06.06.2025

MAPAL bei Schabmüller mit Toolmanagement und Aluminium-Kompetenz

Beim Automobilzulieferer Schabmüller verantwortet MAPAL bereits das Toolmanagement. Nun hat der Aalener Werkzeughersteller auch die CAD/CAM-Programmierung der Bauteile inklusive Simulation übernommen.

-

02.06.2025

IMPULSE 84 ist erschienen

Entwicklungen, Lösungen und Anwendungen für die Automobilindustrie stehen im Mittelpunkt der Ausgabe 84 des MAPAL Technologie-Magazins IMPULSE.

-

12.03.2025

Customer Productivity: MAPAL arbeitet eng mit den Firmen Zimmermann und Blum zusammen

Werkzeughersteller MAPAL ist Konsortialführer einer Zusammenarbeit mit dem Maschinenbauer F. Zimmernann und dem Messtechnikspezialisten Blum

-

04.03.2025

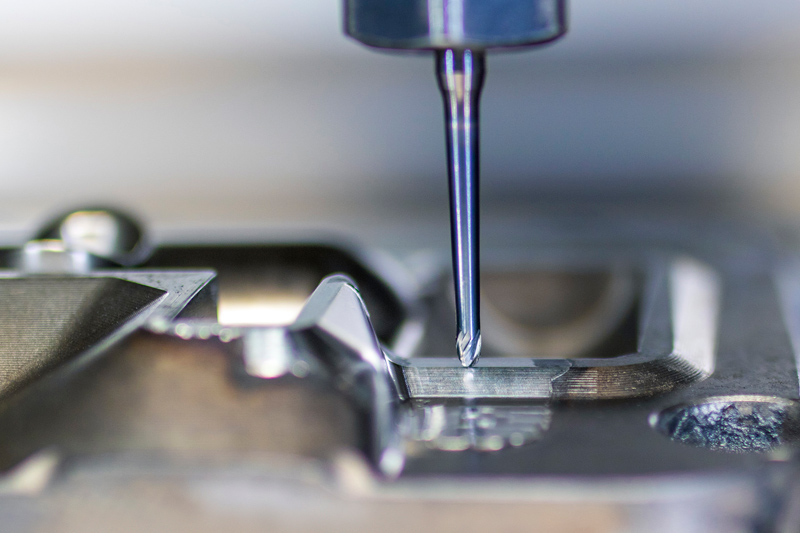

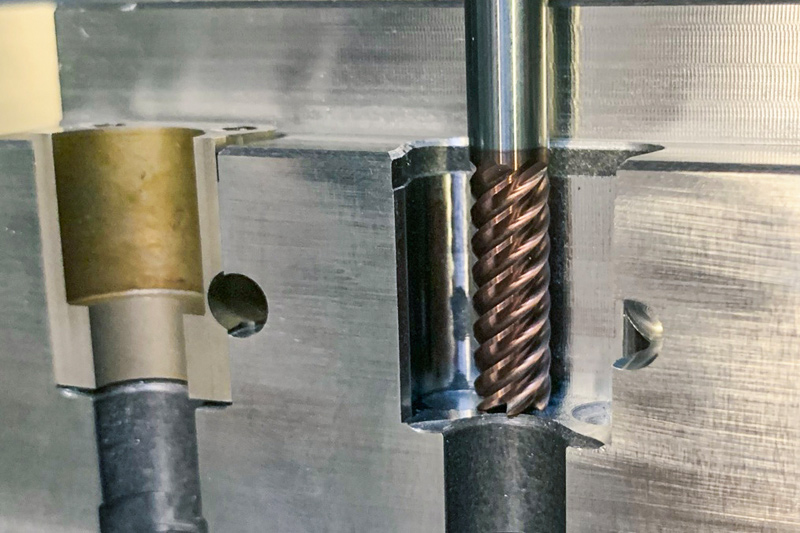

MAPAL liefert Fräser OptiMill-3D-HF für Formenbauer CORMOL

CORMOL aus Portugal stellt Stanzwerkzeuge her, für die man seit 2022 eng mit MAPAL zusammenarbeitet. Mit dem OptiMill-3D-HF hat CORMOL eine zuverlässige und wirtschaftliche Werkzeuglösung im Einsatz.

-

16.01.2025

Toolmanagement von MAPAL für DEUTZ in Rekordzeit erledigt

Für ein neues Projekt des Motorenherstellers DEUTZ in Zafra hat MAPAL das komplette Engineering inklusive Werkzeugauslegung, Taktzeitstudie und Kostenkalkulation binnen zwei Wochen auf die Beine gestellt.

-

19.12.2024

IMPULSE 83 ist erschienen

Innovationen und Schwerpunkte für das Jahr 2025 stehen im Mittelpunkt der Ausgabe 83 des MAPAL Technologie-Magazins IMPULSE.

-

25.06.2024

Effiziente Produktion im Werkzeug- und Formenbau: Krämer+Grebe und MAPAL

Das Werkzeugbauunternehmen Krämer+Grebe optimiert mit MAPAL Reibahlen und Fräsern die Produktion und sichert Prozesssicherheit im internationalen Wettbewerb.

-

08.04.2024

IMPULSE 82 ist erschienen

Entwicklungen, Lösungen und Anwendungen für die Luftfahrtindustrie stehen im Mittelpunkt der Ausgabe 82 des MAPAL Technologie-Magazins IMPULSE.

-

25.03.2024

Partnerschaftliche Zusammenarbeit bei der Endenbearbeitung von Stahl

Für die Endenbearbeitung von Rundstahl setzt GABO STAHL auf eine automatisierte Sondermaschine von Mössner und Werkzeugtechnik von MAPAL.

-

01.02.2024

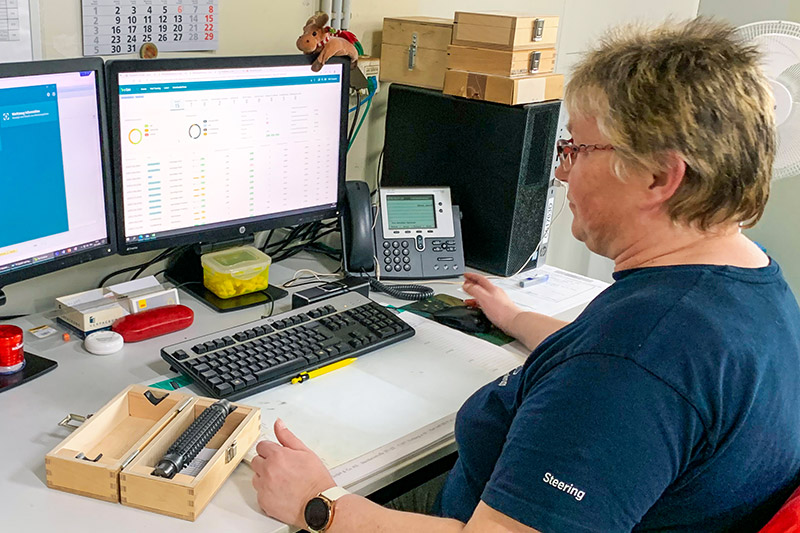

Lifecycle Management von c-Com erhöht Transparenz bei thyssenkrupp Presta Schönebeck

Der Automobilzulieferer thyssenkrupp Presta nutzt am Standort Schönebeck das Lifecycle Management von c-Com und erreicht Transparenz und beträchtliche Einsparungen.

-

04.12.2023

Aluminiumzerspanung in neuen Dimensionen

Beeindruckende Zeitspanvolumina - bavius zerspant mit Aluminium-Hochvolumenfräsern des Werkzeugherstellers MAPAL über 20 Litern pro Minute.

-

09.11.2023

Mit MAPAL doppelt so schnell zum Titanbauteil

Flugzeugzulieferer SME Aerospace Malaysia optimiert gemeinsam mit MAPAL seine Titanbauteil-Bearbeitung und spart 3 Stunden pro Bauteil ein.

-

28.09.2023

In Bestzeit zum Strukturbauteil

Wenzler und MAPAL bündeln ihr Fachwissen und geben Antwort auf die Frage: Wie lassen sich Aluminiumbauteile schnell und präzise fertigen?

-

02.08.2023

Gut aufgestellt für die E-Mobilität

Die Druckgießerei 2A ist den Übergang zur Elektromobilität gerüstet. MAPAL steht 2A dabei als erfahrener Werkzeugpartner zur Seite.

-

17.07.2023

IMPULSE 81 ist erschienen

Lösungen und Anwendungen in der Fluidtechnik sowie die Nachhaltigkeit stehen im Mittelpunkt der Ausgabe 81 des MAPAL Technologie-Magazins IMPULSE.

-

19.06.2023

Tiefe Bohrungen mit PKD optimiert

Der Automobilzulieferer Schlote stellt das Tiefbohren von Ölkanälen in Kupplungsgehäusen um und erreicht prozesssicher die fünffache Standzeit.

-

23.03.2023

Die Produktion muss laufen

Ein digitales Toolmanagement mit mehr als 750 Werkzeugen von MAPAL sorgt für eine reibungslose Großserienproduktion bei Schabmüller Automobiltechnik.

-

02.03.2023

Der Gesamtprozess macht den Unterschied

Im direkten Vergleich zum bisherigen Bearbeitungsprozess bringt die MAPAL Lösung deutliche Vorteile. Dabei ist die Betrachtung des Gesamtprozesses entscheidend.

-

01.02.2023

Wesentliche Fortschritte beim Außenreiben von Drehteilen

Der Schweizer Hersteller W.E. Schultz bearbeitet Drehteile mit Außenreibahle von MAPAL fertig und reduziert Schnittkosten auf 25 und Rüstkosten auf 10 Prozent.

-

07.12.2022

Vernetzen macht Schule

Die Gewerbliche Schule Göppingen setzt auf Digitalisierungs-Know-how von MAPAL

-

03.11.2022

Wirtschaftliches Bearbeiten mit Robotern

Der dreischneidige FlyCutter von MAPAL ist optimal geeignet zum Entgraten von Batteriewannen. Roboterhersteller KADIA ist begeistert von dem PKD-bestückten Fräser.

-

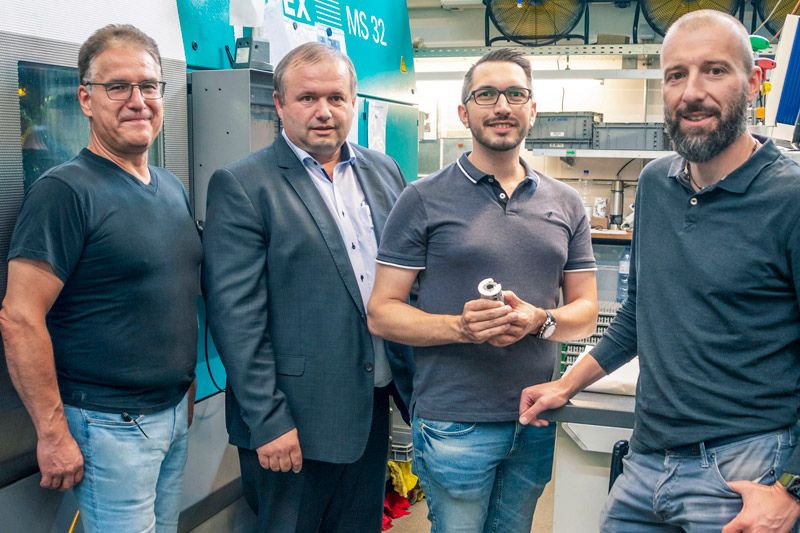

28.09.2022

Angepasste Hydrodehnspannfutter als Problemlöser

Einfach, schnell, sicher, prozesssicher: Schweizer Drehmaschinen-Hersteller TORNOS optimiert die Anwendungsperformance seiner Mehrspindel-Drehmaschinen.

-

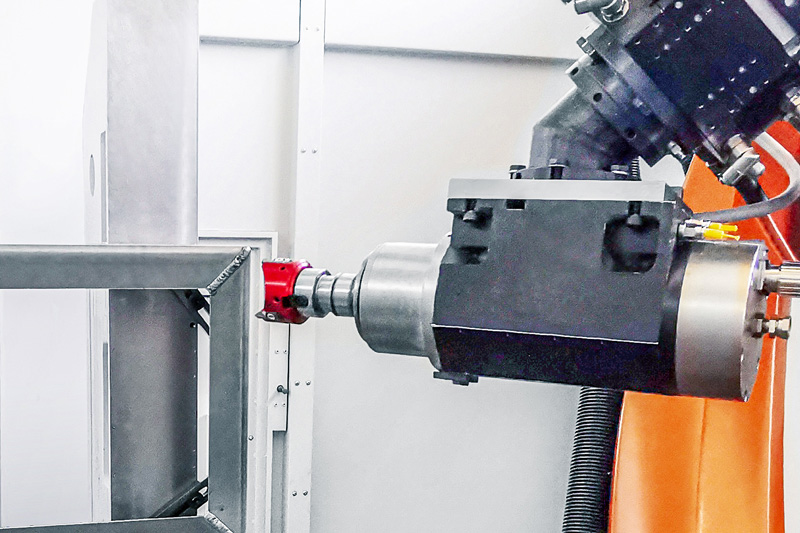

22.08.2022

Neuer Dreh für die E-Mobilität

Innovativer Bearbeitungsprozess von NILES-SIMMONS und MAPAL mit simultaner Innen- und Außenbearbeitung und einer Kombination von Drehen und Auf- & Feinbohren.

-

28.07.2022

Strategische Partnerschaft für den Formenbau

Röders GmbH und MAPAL erarbeiten gemeinsam die Bearbeitungsstrategie für ein Musterbauteil. Der Ansatz überzeugt – sowohl in der CAM-Simulation als auch auf der Maschine.

-

02.06.2022

3D-Fräsen von CFK-Prototypen ab Stückzahl Eins

MAPAL unterstützt die ERIKS Deutschland GmbH mit Prozesskompetenz und umfangreichem Werkzeugprogramm für schlüsselfertige CFK-Bearbeitungen.

-

05.05.2022

Problemlöser auch für knifflige Fälle

MAPAL Werkzeuge stellen ihr Leistungspotenzial in mehreren problematischen Anwendungen beim Formenbaubetrieb HaGeForm Sachsen unter Beweis.

-

28.04.2022

Technologie aus dem Automobilbau fürs Flugzeug

Maschinenhersteller F. Zimmermann GmbH und MAPAL setzen bei der Projektumsetzung und Bearbeitung eines Luftfahrtbauteils gemeinsam Maßstäbe.

-

13.04.2022

Ein Stufenfeinbohrwerkzeug für höchste Präzision

Ein Stufenfeinbohrwerkzeug von MAPAL bearbeitet Bauteil aus GGG40 mit sechs Bohrungen, die jeweils drei ineinander übergehende zylindrische Bereiche aufweisen.

-

17.03.2022

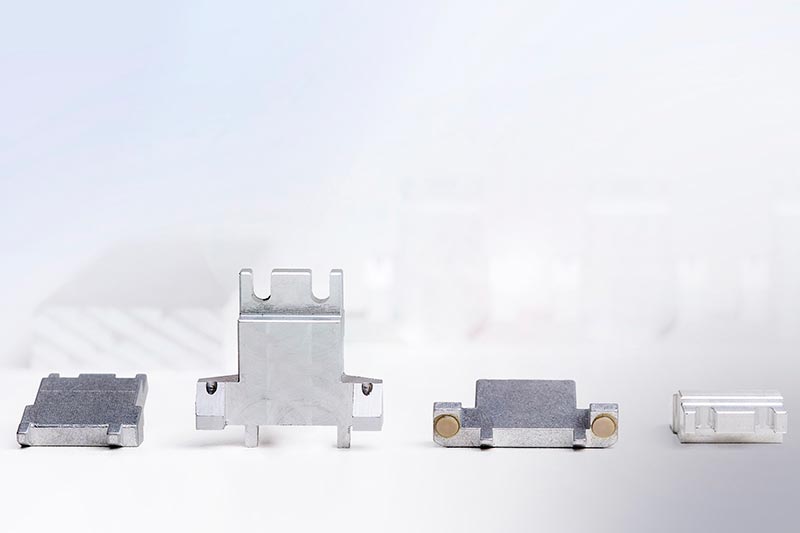

Elektronisches Aussteuerwerkzeug macht Fräs-Drehzentrum zum Alleskönner

Die Integration der MAPAL TOOLTRONIC in das Fräsdrehzentrum RX18 der Reiden Technik AG realsierte die Kundenforderung nach speziellen Innenkonturen.

-

13.01.2022

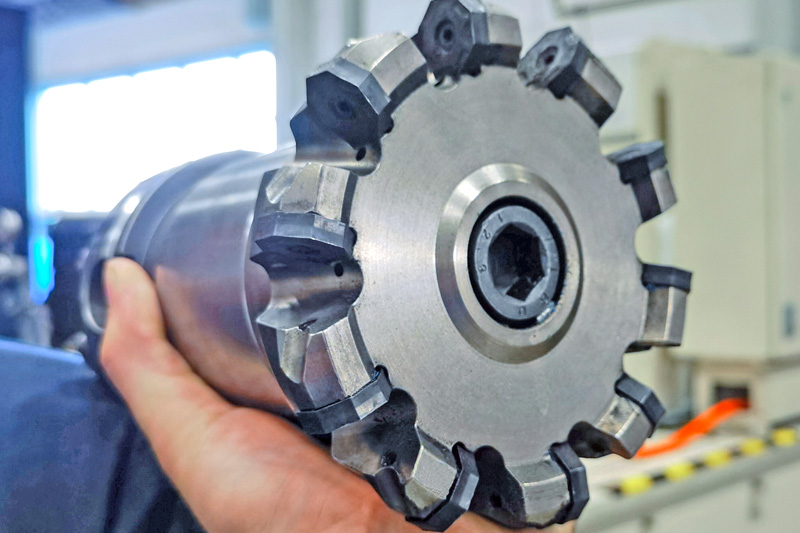

Leistungssprung mit NeoMill Planfräser

NeoMill Planfräser von MAPAL halbierten die Maschinenlaufzeit von Schraubenkompressoren bei BOGE Kompressoren in Großenhain.

-

15.12.2021

Optimierung im Formenbau

Auf dem Weg hin zum Industriewerkzeugbau optimiert Schülken Form seine Produktionsabläufe. MAPAL Werkzeuge spielen dabei eine wichtige Rolle.

-

25.10.2021

IMPULSE — Ausgabe 76 ist erschienen.

Neues zur E-Mobilität. Neue Werkzeuge zur Bearbeitung von Titan sowie Ventil- und Statorgehäusen. Ein neues Modul von c-Com.

-

16.08.2021

IMPULSE — Ausgabe 75 ist da!

Entdecken Sie smarte Lösungen sowie das Potenzial der Tooltronic und der radialen Fräswerkzeuge NeoMill von MAPAL.

-

14.07.2021

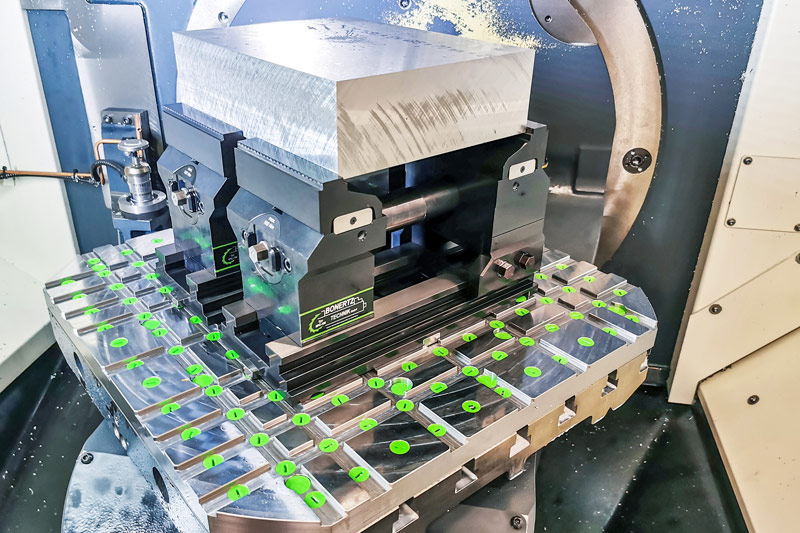

Wenn Werkzeugkompetenz und Beratungsqualität zusammenpassen

Bei der Herstellung anspruchsvoller Spannmittel für Werkzeugmaschinen setzt die Bonertz Technik GmbH auf Leistung und Prozesssicherheit von MAPAL Werkzeugen.

-

01.07.2021

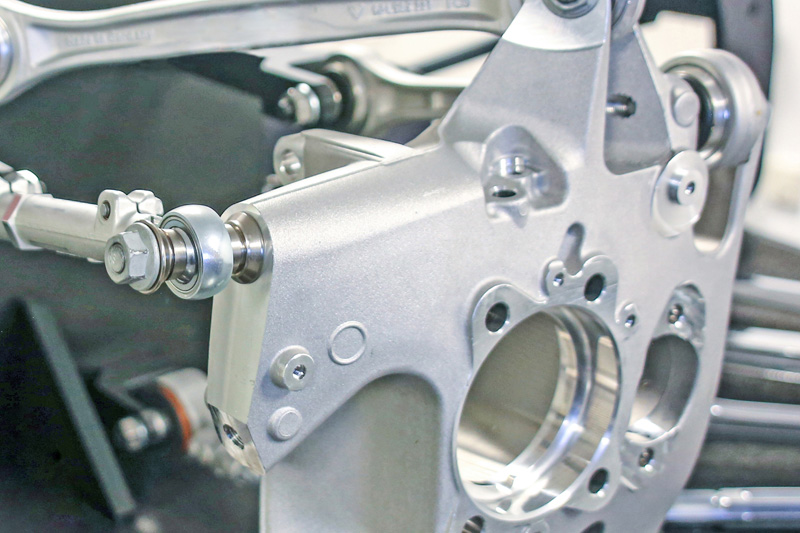

Durchdachte PKD-Werkzeugkonzepte für die Aluminiumzerspanung

Die Carl Hirschmann GmbH bearbeitet Aluminium-Schmiedeteile für Sportfahrzeuge mit mehrstufigen Kombinationswerkzeuges ihres Entwicklungspartners MAPAL.

-

11.05.2021

Höchstleistungen beim Präzisionszerspanen von Aluminium

Aluminium-Strukturbauteile für Flugzeuge werden meist aus dem Vollen zerspant. Das erfordert enorme Leistung und hohe Präzision von Maschinen und Werkzeugen.

-

07.04.2021

IMPULSE Ausgabe 74 ist da!

Die neue Ausgabe von Impulse liegt bereit. Ein Schwerpunktthema ist der Marktstart von MAPAL im Werkzeug- und Formenbau.

-

01.01.2021

Höchste Standzeiten in CFK dank Diamantbeschichtung

Warum MAPAL auf die Technik von SP3 setzt, was deren Anlagen besonders macht und wo genau das meiste Know-how beim Beschichten mit Diamant steckt …

-

08.10.2020

Standortübergreifendes Tool Management 4.0

MAPAL übernimmt Werkzeugverantwortung für die Hitachi Automotive Systems Group in Polen, Mexiko und der Türkei

-

26.06.2020

Walter Formenbau setzt auf Know-how von MAPAL

Um sein Ziel der komplett vernetzten Produktion zu erreichen, hat sich Inhaber Dr. Jens Buchert MAPAL als Komplettanbieter mit ins Boot geholt.

-

23.06.2020

Vom Prozess gedacht – Entwicklungspartnerschaft von Maschinen- und Werkzeughersteller

Zwischen ELHA und MAPAL besteht eine langjährige Entwicklungspartnerschaft. Daraus ergeben sich erhebliche Vorteile für die Kunden.

-

15.01.2020

Neue Futter für einheitliche Prozesse

Bei der Planung einer neuen Motorenfertigungslinie im Werk Kyoto setzt die Mitsubishi Motors Corporation auf das Know-how und den Service von MAPAL.

-

19.12.2019

Toolmanagement für deutlich mehr Effizienz

Für sein neues Werk hat Shakti Precicion Components MAPAL mit dem Toolmanagement betraut – mit Erfolg, wie signifikante Effizienzsteigerungen zeigen.

-

09.12.2019

Zylinderbohrungen in LKW-Motoren hochgenau bearbeiten

Hochpräzise MAPAL Aussteuerwerkzeuge sowie ein Sonder-Einstellgerät sorgen für eine präzise und wirtschaftliche Produktion bei Mercedes-Benz Mannheim.

-

01.09.2019

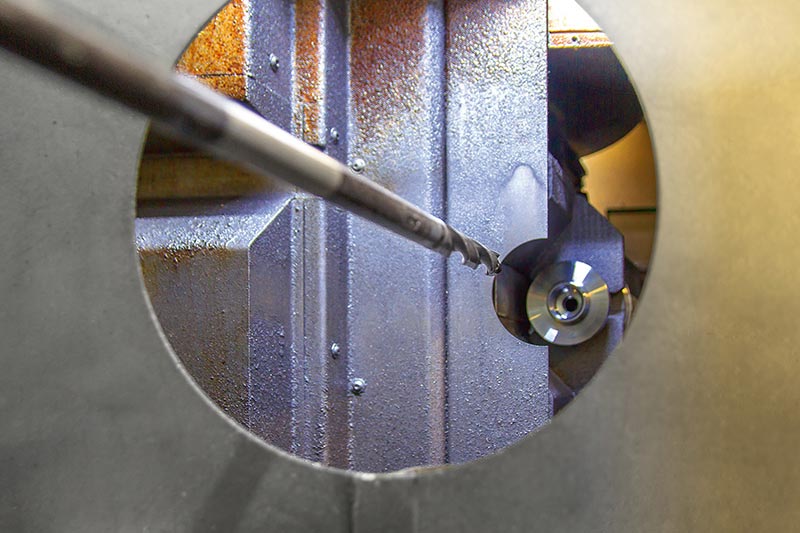

Feinbohren in Superlative - Grüner setzt auf MAPAL

Die Innenbearbeitung eines Getriebegehäuses übernimmt ein 207 Kilogramm schweres Werkzeug. Zum Werkzeug hat MAPAL das passende Messgerät entwickelt.

-

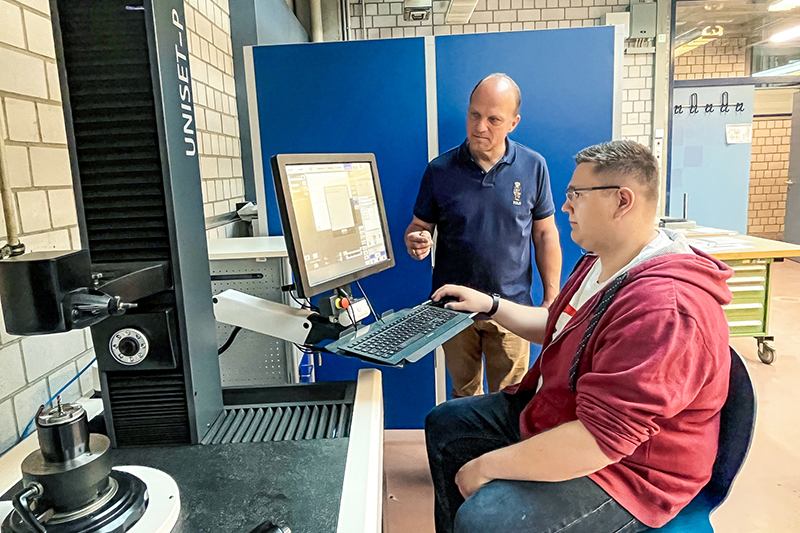

01.09.2019

Werkzeuge µm-genau einstellen – taktiles Messen für weniger Maschinenstillstand

Wie Alupress mit dem UNISET-P von MAPAL immens Zeit einspart, die Prozesssicherheit erhöht und hochpräzise arbeitet.

-

01.09.2019

Unterstützung bei jedem Projekt – CastAlum setzt auf MAPAL

Neben Werkzeugen und Spannfuttern bietet MAPAL mit seinen Services weitere Vorteile, um die wirtschaftlichsten Produktionsergebnisse zu erzielen.

-

01.09.2019

Aircraft Industries setzt auf Hochvolumenfräser von MAPAL

Hochvolumenfräser, Bohr-Senk-Kombinationswerkzeuge und Reibahlen im Einsatz in der Teilefertigung und Endmontage des Flugzeugbauers Aircraft Industries.

-

01.09.2019

Bearbeitungszeit halbiert, Prozess stabilisiert - Mehrschneidiges MAPAL Feinbohrwerkzeug

Welche Rolle Achsschwingen an Raupenlaufwerken für Traktoren spielen und wieso bei ihrer Bearbeitung höchste Genauigkeit gefragt ist.

-

01.05.2019

Digitalisiertes Nachschliffmanagement – Transparenz und Effizienz dank c-Com

Das Management der Werkzeuge ist oft der kritische Punkt im Nachschleifprozess. Wie MILLER diese Herausforderung meistert.

-

01.05.2019

Mikuni India steigert Produktivität dank PKD-Werkzeugen von MAPAL

Der Automobilzulieferer spart bei der Fertigung eines Vergasergehäuses den Einsatz eines kompletten Bearbeitungszentrums ein.

-

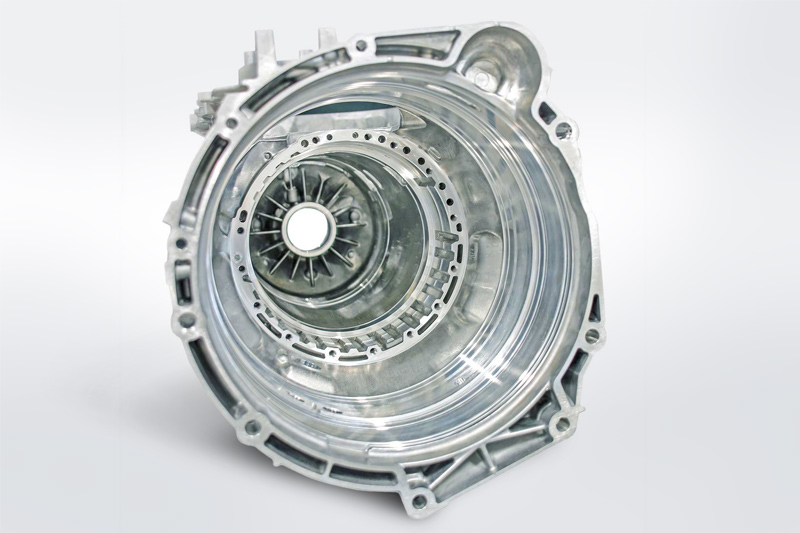

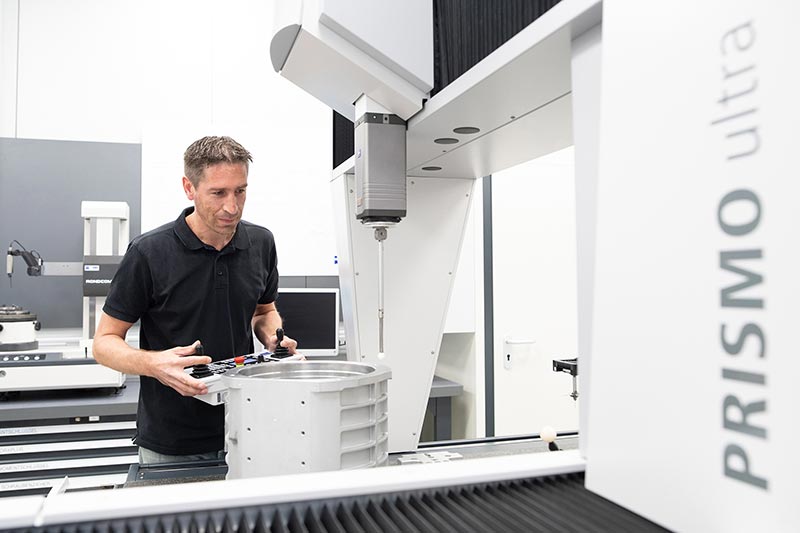

01.05.2019

Roadmap E-Mobilität

Wie MAPAL mithilfe des Koordinatenmessgeräts ZEISS PRISMO ultra die Werkzeugentwicklung beschleunigt und was das mit der Elektromobilität zu tun hat.

-

01.11.2018

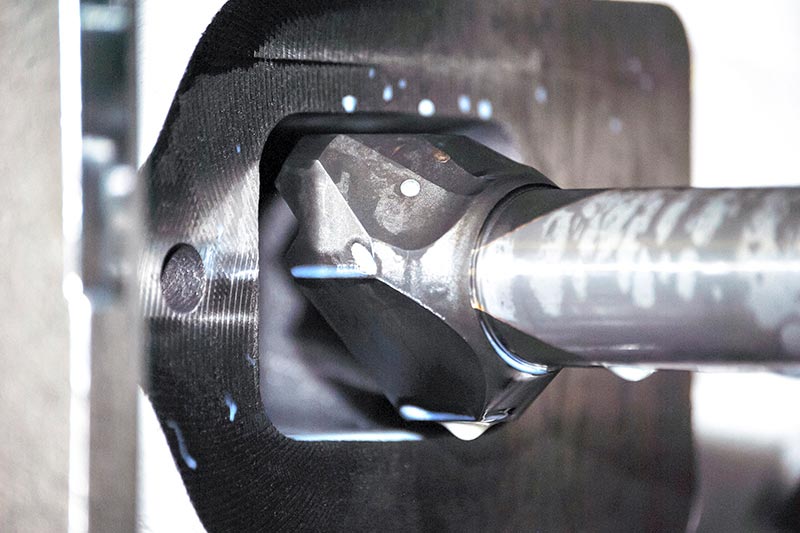

Kugelbahnfräsen an Gleichlaufgelenken für die Elektromobilität

Warum Neapco bei der Hartbearbeitung des homokinetischen Außengelenks einer Antriebswelle auf Kugelbahnfräser von MAPAL setzt.

-

01.10.2018

Hervorragendes Ergebnis dank enger, partnerschaftlicher Zusammenarbeit

MTU Friedrichshafen setzt auf kundenspezifische ISO-Planfräser von MAPAL. Die Planheit der Montageflächen erhöht sich prozesssicher um den Faktor 10.

-

01.08.2018

Außenreibahle sichert hochpräzise Zylindrizität

Für die Fertigung von Planetenträgern setzt Karl Völlm auf Präzisionswerkzeuge von MAPAL.

-

01.06.2018

Perfekte Kombi für Strukturbauteile – schneller, besser, weniger Schnittkräfte

Aluminium-Strukturbauteile optimal fräsen mit dem Horizontal-Bearbeitungszentrum FZH von Zimmermann und Hochvolumenfräsern von MAPAL.

-

01.05.2018

Mit neuen Lösungen zum sicheren Prozess – Entlastungsbohrung für die Kurbelwelle bearbeiten

Wie ein Automobilhersteller mit dem MAPAL als Technologiepartner einen neuen Prozess sicher in die Serie bringt.

-

01.02.2018

Maschinen erfolgreich umrüsten

Wie die Stefan Plätzer Maschinenbau GmbH ihre Anzahl an produzierten Bauteilen pro Stunde von vier auf 30 gesteigert hat.

-

01.02.2018

Geballte Flexibilität und Effizienz - Plandrehköpfe und Aufsatzwerkzeuge von MAPAL

An Komponenten für Strohballenpressen muss Bühring komplexe Konturen zerspanen. Wieso er sich für eine Werkzeuglösung von MAPAL entschieden hat …