01.09.2019

The UNISET-P in Use

Tactile measurement for less machine downtime

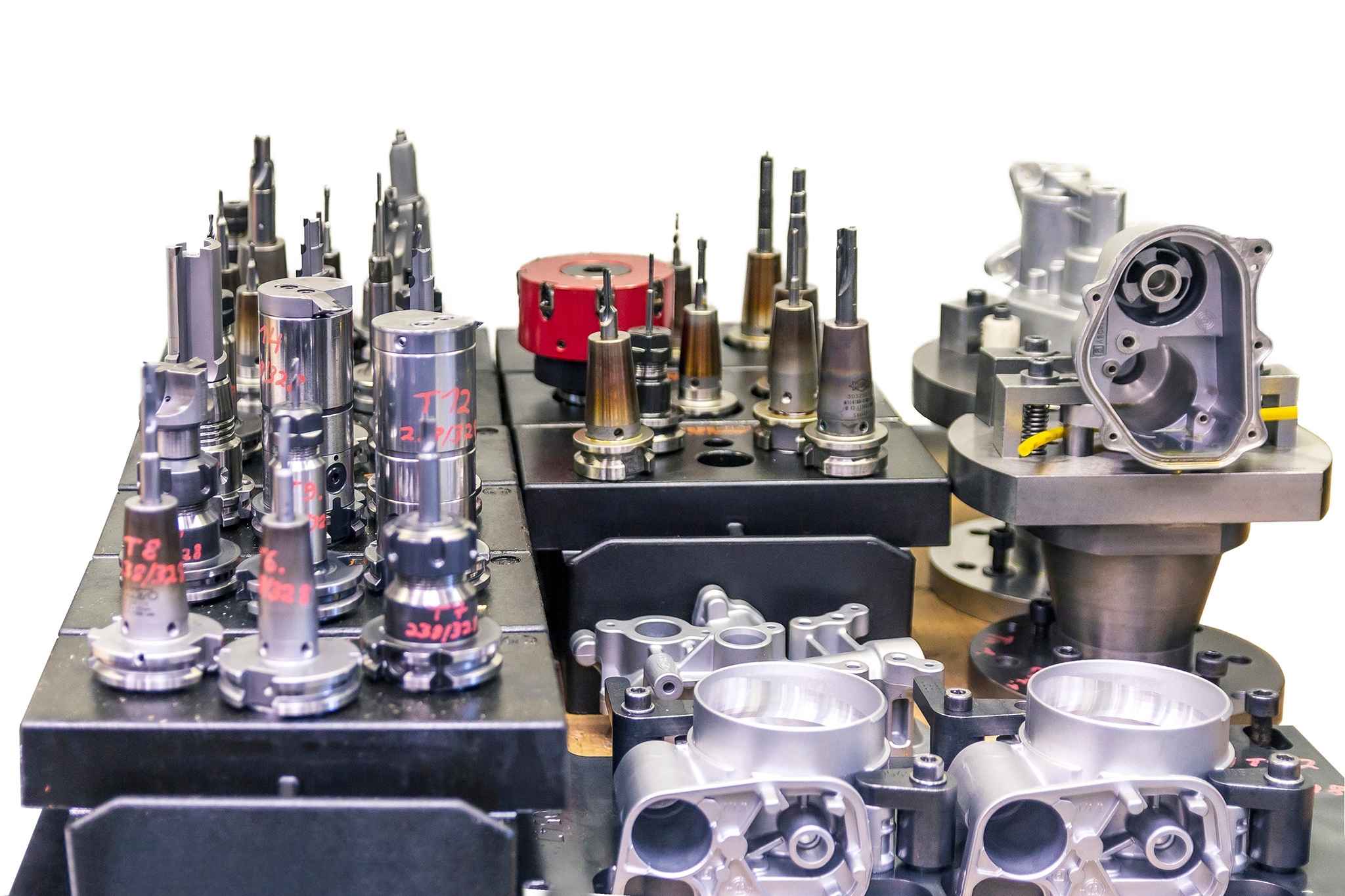

Whether housing for drive, gearbox, electric pumps or electric steering – Alupress Berlin GmbH is a specialist for the complex machining of die-cast parts. Alupress manufactures these aluminium workpieces to the µm in large-scale series production. Highly precise tools are required to achieve this goal. If these tools need to be set, Alupress relies on the new setting fixture UNISET-P from MAPAL.

75,000 parts, completely machined housings or flanges made of aluminium, leave Alupress Berlin GmbH every week. Over 80 percent of these parts are manufactured using tools from MAPAL. A reamer was the first tool from MAPAL used in the Berlin works over 20 years ago. Why? „In the area of fine machining, MAPAL‘s know-how is unique“, says Patrick Wittig, who is responsible for tool management at the works in Berlin.

The highest precision is required in many areas at Alupress. „To some extent we must manufacture bores in large-scale series production within a tolerance of 5 µm and achieve a surface roughness of Rz = 2 µm“, explains Patrick Wittig. The highest precision is therefore also fundamental for the tools.

During the machining of a flange, the required surface finish was not achieved with a tool with brazed cutting edges. „For this reason we changed to a milling cutter with adjustable PCD inserts“, recalls Burkhard Schimkat, fixture and tool technology at Alupress. However, the axial run-out on every insert on the milling cutter must be set to the µm to manufacture to the µm.

Challenge of setting to the µm

And it was exactly here that Alupress faced a challenge for a long time. „We only used an optical setting fixture“, says Patrick Wittig. „However, tactile measurement with contact with the cutting edge was indispensable in this case to manufacture to the required tolerances.“ The final accuracy had to be set directly in the machine. And that process was complex, susceptible to mistakes and time-consuming. The machine was stationary for up to two hours for this purpose.

For this reason Alupress looked for an alternative for this process. „It was only natural we approach MAPAL directly with our challenge for setting the tools“, says Patrick Wittig. After all the precision tool manufacturer has maintained a consignment store at Alupress for some time. Once a week a technical consultant from MAPAL is on site, among other things to ensure the tool stocks are correct, to check newly arrived tools or to initiate repairs. „We use the dispensing system UNIBASE-M from MAPAL for this purpose and in this context we became aware of the company‘s setting fixtures. The PCD face milling cutter that was the trigger for the search for a solution is also from MAPAL“, elaborates Patrick Wittig.

Tactile measurement with the UNISET-P

Immense time saving

Patrick Wittig is impressed: „We set, for instance, our PCD face milling cutters from MAPAL to 2 µm using the UNISET-P. The additional fine adjustment of the milling cartridges in relation to the axial run-out in the machine compartment is not required thanks to the new setting fixture.“ For Alupress this means an immense time saving.

However, this is not the only advantage that the UNISET-P offers the company. „The procedure for setting the tools can be pre-defined and saved“, explains Michael Hils. This means the operator selects the tool to be set on the monitor and receives step-by-step explanations about the values that need to be set. These values are specified once for each tool, the related measuring program prepared and saved. „The handling is very straightforward. Once a tool has been added, any of the operators can set the tool“, confirms Patrick Wittig. This increases the process reliability because only if the tools are set correctly are the required tolerances achieved during the machining. „Due to the second camera we can also very accurately document, for example the cutting edge inspection“, Patrick Wittig explains a further advantage of the UNISET-P.

Comprehensive setting not only during setting

About Alupress Berlin GmbH