28.04.2022

Technologie aus dem Automobilbau fürs Flugzeug

Titanbearbeitung auf Portalfräsmaschine von F. Zimmermann GmbH

Zur Auslegung einer Turnkey-Maschine für die Fertigung von Titanteilen für die Aerospace-Industrie hat der Maschinenhersteller Zimmermann als Werkzeug- und Technologiepartner MAPAL ins Boot geholt. Dessen Line Boring-Technologie in Verbindung mit einer neuen Generation von Werkzeugen zur Titanbearbeitung ließen das Projekt trotz besonderer Herausforderungen zu einem gemeinsamen Erfolg werden.

The F. Zimmermann GmbH from the town Neuhausen auf den Fildern is known above all for its big portal milling machines. The export-oriented machine manufacturer has already delivered more than 550 systems in 37 countries worldwide. They can often be found in the R&D departments of large corporations where they support the entire product development process from drafting designs to the various stages of prototyping. “Everything which one day takes form was on one of our machines as a model”, says Steffen Nüssle, Head of Sales and Application Technology at Zimmermann.

Typical material for model making are wood, polystyrene and Ureol. Zimmermann began metalworking more than 20 years ago with aluminium. This was their door opener for the aerospace industry. Gradually, they tried their hand at machining composite material, steel and highly heat-resistant workpiece material like titanium, Waspaloy, Inconel and invar. Models and prototypes are not the focus anymore with these materials. The aerospace industry uses the portal milling machines to produce parts.

Bespoke turnkey manufacturing – focus on simultaneous engineering

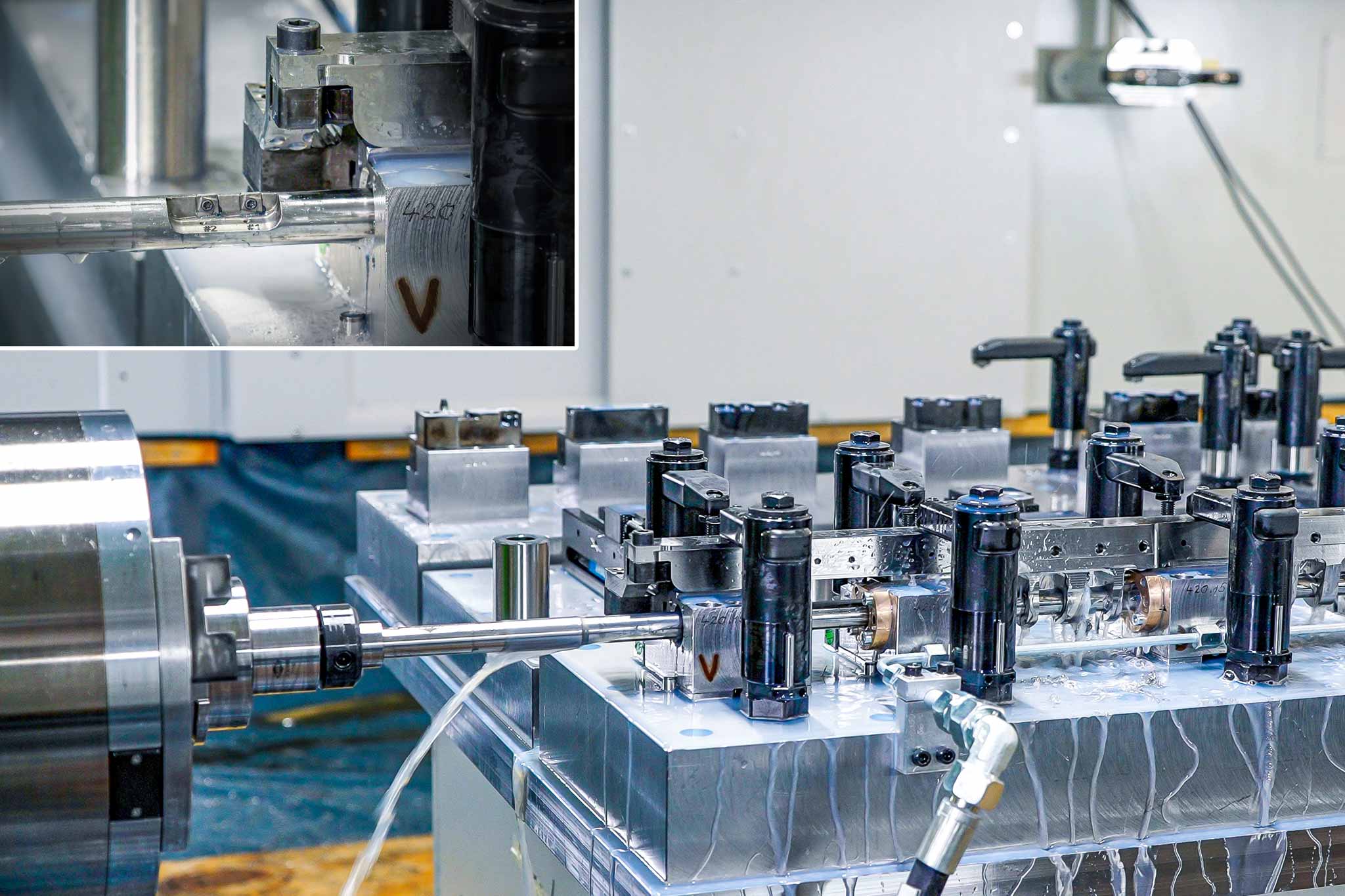

The part in question is an approximately 1.5-metre-long mount. A particular machining challenge was posed by the row of twelve bores in the lugs, which are located over a space of 990 mm on the workpiece. The customer required high precision here. A tolerance of H7 was stipulated at a bore diameter of 17 mm. Over the entire length of the part, the concentricity of the bore had to be less than 0.05 mm. The same accuracy is necessary for the perpendicularity of the bore lugs towards the part surface.

Zimmermann picked MAPAL as its tool partner for good reason. “Our application engineers don’t make any compromises for a turnkey project like this one. Only a very good system partner comes into question”, says Nüssle, who goes on to report that he had only the best experience with the tool manufacturer.

Past Zimmermann turnkey projects involved wing spars for the Airbus A350 or countersinks and deep bores on wind turbine blades made of fibreglass. While employed for another machine manufacturer, Nüssle also worked with MAPAL. This involved machining bearing seats for crankshafts and camshafts for large diesel motors using the line boring technology. MAPAL has acquired extensive knowledge about such line boring bars from the automotive industry. Now this knowledge is required for aerospace parts whose lugs are very similar to the journal bearings in the crankshaft bearing aisle of a combustion engine.

Powder-metallurgical titanium

The project partners brooded over the material for the part. The customer announced forged blanks made of the titanium alloy TA15m. “All of us have experience with aerospace titanium, so we knew what we were getting into, but even our full-fledged aerospace experts had never heard of this special alloy”, Steffen Nüssle admits. Jens Ilg, who works in the Aerospace & Composites segment at MAPAL, agrees: “The material was exotic for us, too.” They discovered that TA15m is a workpiece material that is manufactured powder-metallurgically. The sintered material is redensified in a special process, whereby the workpiece acquires the characteristics of a forged part.

The customer did not provide any blanks to design the machine with. Thus, the project partners had no other choice but to take a titanium bar and mill the form of the blank with its measurements from the solid block. In this way, a blank was imitated, which represented the starting point of manufacturing for the customer. This preparatory work alone took 30 hours of machining time.

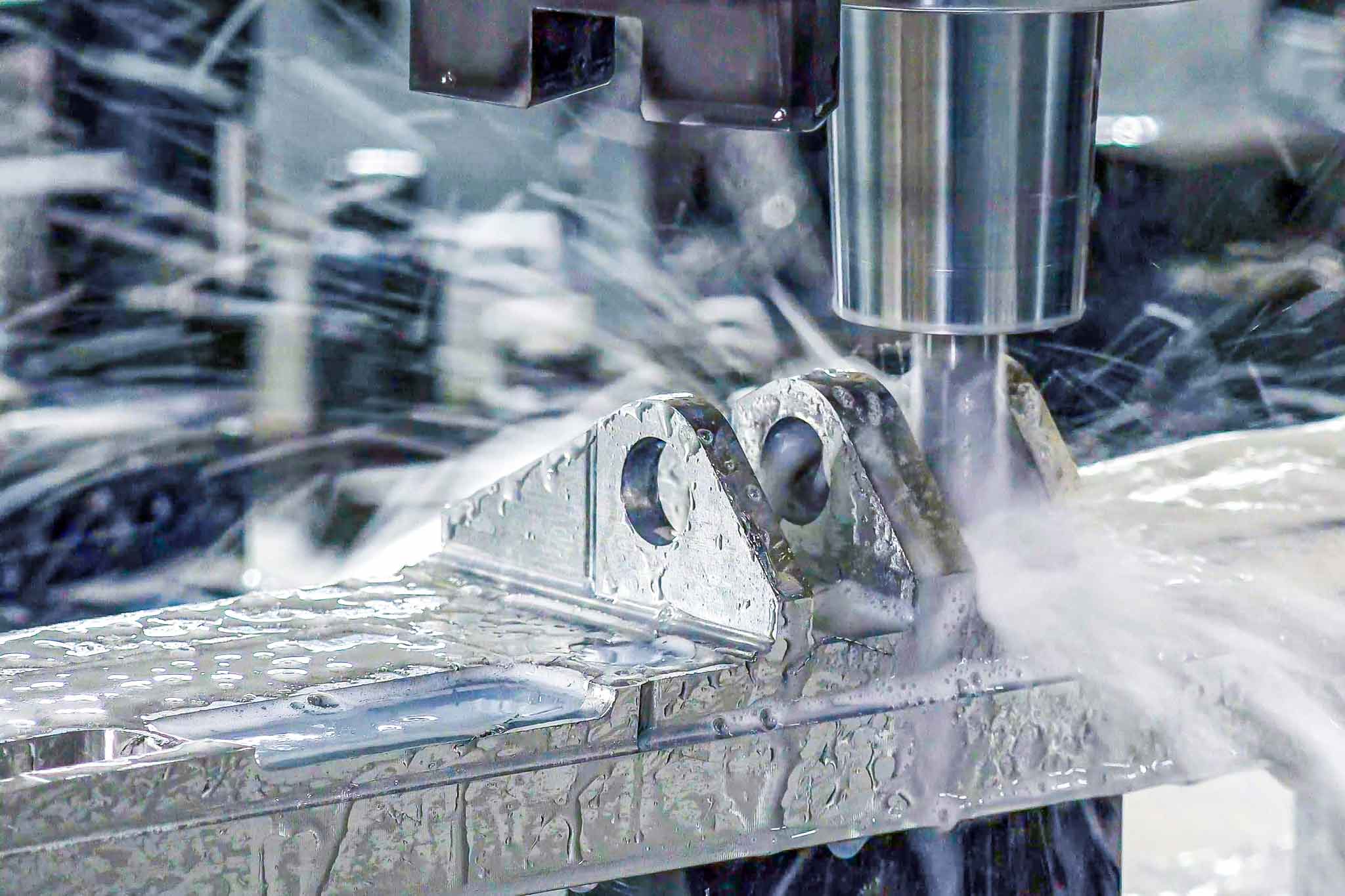

At the same time as the machine was being constructed by Zimmermann in Neuhausen, MAPAL began with tool tests in Aalen. The tool manufacturer could rely on a new generation of titanium tools for this purpose. In order to achieve high removal rates, the NeoMill-Titan shell end face milling cutter was chosen. MAPAL developed the new topography of the indexable insert in such a way that the chips are optimally formed and removed. An equally new cutting material concept minimises wear and tear and the formation of built-up edges.

Even experienced application engineers were surprised how smoothly and almost silently the tool works. The tool life is also impressive. The 60 minutes that Bernd Scheurenbrand expected were exceeded considerably. “Some of the tools were at work for almost seven hours – that’s a sensational tool life”, the experienced application engineer from Zimmermann praises. This result was made possible, among other reasons, due to the modern protective coating with a good adhesion to the tool, an effective temperature barrier and a very smooth surface that reduced heat on the cutting area.

Convincing new tool generation

Excellent cooling is essential when machining titanium to remove the heat that develops. MAPAL MillChucks with integrated coolant supply were used to bring the coolant pressure to the milling cutter. Zimmermann chose the company Blaser Swisslube as a further project partner to provide the cooling lubricant as their coolants are ideally suitable for high pressures.

For the bores on the sides of the lug, MAPAL developed a custom tool with angular drill head based on the MEGA-Speed-Drill-Titan. The drill bores, then deburs back in the countersink step and finally produces a chamfer in reverse.

Line boring from two sides

The 685 mm line boring bar with a diameter of 17 mm, which does the fine machining in the end, has two adjustable inserts and is led between the lugs in guide bushes. The first insert bores the main bore, thus eliminating any offset that might have occurred during pre-machining. The second insert then completes the final diameter in H7 quality. The long boring bar reminds Jens Ilg of a lightsabre: “The swinging motion that positions the tool on the part brings Star Wars to mind.” The gantry machine, a six-axis FZ42 with a VH60 milling head, offers more than enough room for the machine’s spectacular lunges. The working area is 8.50 x 3.90 x 1.50 m large and is separated in an area with a fixed machine table and an area with a round table for further processing.

Transferring the results from MAPAL’s test centre to the machine in Neuhausen was a critical stage of the project, Steffen Nüssle remembers: “After the successful test runs in Aalen, we knew where we were headed. Our gantry machine is a lot bigger than the machining centre in Aalen, has bigger moving masses and lever lengths. Thus, it isn’t quite as rigid.”

The misgivings were quickly allayed: The desired accuracy was achieved with high process reliability in Neuhausen, as well. This was particularly true for the middle of the workpiece, where the bores meet each other from both sides and a small offset could occur. The measured results prove that the machining was symmetrical. Just 8 µm difference was measure here. The line boring process ensures that the precision that is once reached can be reproduced for years to come, as the machine only provides the feed and spindle speed, while the actual geometrical guidance is provided by the fixture.

Zimmermann paid close attention to vibration dampening while designing their fixture. The many buckles and clamps however also resulted in many tool restrictions. Here, the machine manufacturer harnessed its expertise in model making to first create a blank out of plastic. “If the first attempt failed, we would have neither damaged the expensive titanium or the tool, let alone the machine,” says Nüssle. But it worked from the get go. Only the cutting parameters had to be adjusted for the first titanium part.

Steffen Nüssle was very impressed by the good cooperation between Zimmermann and MAPAL: “I’ve already been involved in many turnkey developments but have never experienced a project that went as smoothly as this. It was a lot of fun.” The geographical proximity between Neuhausen and Aalen was also a big advantage: They only had to drive an hour to be able to discuss the next steps together right at the machine.

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342