02.03.2023

The overall process makes the difference

Comparative test at Umformtechnik Radebeul with resounding success

In the die & mould sector, it’s usually difficult to directly compare precision tools from different manufacturers because there are always different parts with different requirements to be produced. When MAPAL was given the opportunity to take over the complete machining of a die at Umformtechnik Radebeul GmbH, the manufacturers were amazed at how much time could be saved.

Umformtechnik Radebeul (UFT) is a specialist in forged aluminium. A particular strength of the company is thin-walled drop forgings with intricate geometry, which are in demand when high-quality products require more stability than cast aluminium can offer.

In total, the factory in Radebeul has existed for 120 years, during which ownership and business fields have changed repeatedly. The more recent history begins in 1957 with the construction of a drop forge, from which today’s Umformtechnik Radebeul GmbH emerged. In 2001, the production structure was changed to aluminium forgings. The company, which in the meantime operated in parts as “Aluminiumtechnik Radebeul GmbH”, took on its current form in 2006 with the areas of toolmaking, prototype production, parts machining and assembly.

In 2017, the Radebeul-based manufacturer was taken over by UKM Fahrzeugteile GmbH from Reinsberg. The companies’ business areas complement each other. The UKM Group is a supplier to the automotive industry with a focus on the high-precision machining of metal components. UFT manufactures complex aluminium forgings for many different applications. At around 60 per cent, parts for motorbikes account for the largest share.

Motorbike forge with great manufacturing depth

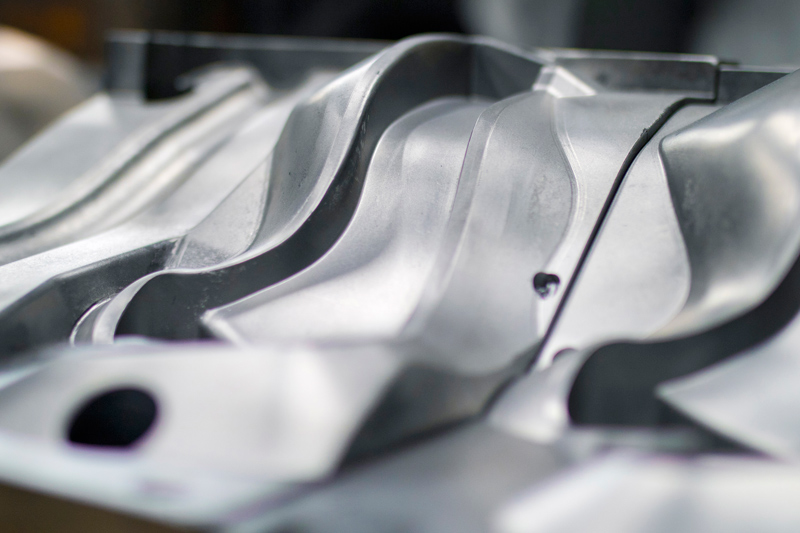

For motorbikes of major manufacturers, UFT produces, among other things, triple clamps, foot brake and foot shift levers, side supports, and footrest plates. In addition to the sometimes delicate shapes and complicated geometries, the demanding surface design is a challenge during machining. On top of two-wheeler parts, joints and connectors for awnings, ski bindings as well as hose couplings and other parts for fire engines are also produced in Radebeul. The company was also able to win over customers from the aerospace industry.

Typical order quantities are somewhere between 10,000 and 100,000 parts. However, small series and prototypes of high quality are a particular strength of the factory in Radebeul. UFT is characterised by short delivery times.

On a tour of the manufacturing halls, the extraordinary manufacturing depth is striking. The company’s own tool shop manufactures forging tools, press brake tools, milling jigs as well as measuring and testing devices for UFT’s forges. Prototypes are machined from blanks. A hardening shop is also located in the building, as is a mechanical manufacturing facility where the parts are given their final appearance and are also partly assembled. Only the surface treatment is carried out by partner companies in the immediate vicinity.

At UFT, 15 of the total 170 employees work in toolmaking. “They are all trained cutting machine operators”, says Steffen Albrecht, Head of Tool Production at UFT, explaining the efficiency of this area. Occasionally, tools are also produced for external customers, but the majority are intended for internal use. UFT has around 500 finished forging tools in stock at any given time, and with every new part more are being added. For the spare parts market of some customers, the tools have to be kept in stock for up to 15 years.

The toolmakers mill the forging tools out of blocks of tool steel. Felix Wendler, Product Specialist Die & Mould at MAPAL, used his many years of personal contact with the manufacturers to encourage them to try out new tools for their machining. Because at UFT, they were quite satisfied with the existing cutting tools.

This did not immediately change, even when a ball nose milling cutter from MAPAL was tested. “The milling cutter from MAPAL was no worse, but also no better than the one we already had”, states Albrecht. Even an improved version of the milling cutter from MAPAL could not persuade the toolmakers to jump ships. “That was certainly also due to the fact that we are already working at a very high level”, explains Albrecht.

Comparative test under identical conditions

However, MAPAL was still to be given a real chance to prove itself. According to Albrecht, it is very rare for UFT to produce two identical parts, but when it came to forging tools for the manufacture of footrests for a large motorbike manufacturer, two dies had to be produced at the same time. In the case of very sensitive orders, production uses exchangeable inserts to be able to run the process without major disruptions. UFT produces 20,000 footrests per year. A die can handle about 10,000 parts before it needs to be replaced.

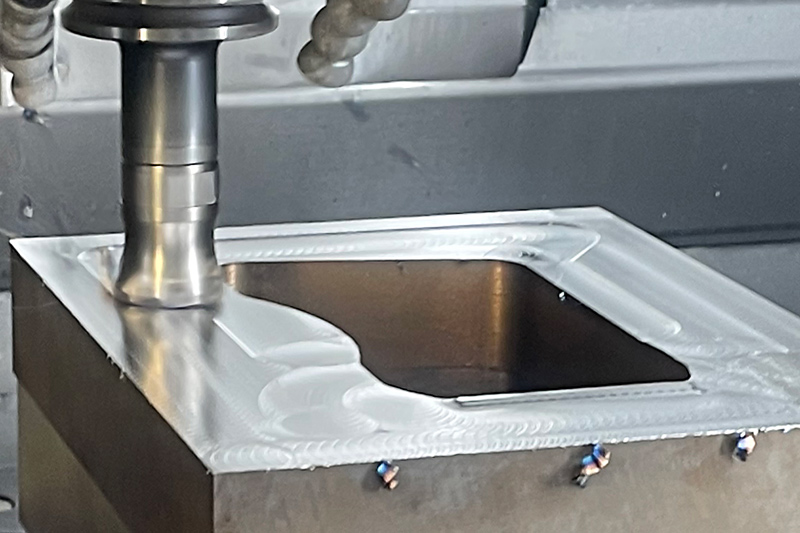

This provided the perfect opportunity to test the tools of two manufacturers against each other under identical conditions – with the same connections and on the same machine, a Hermle C40. In addition, it was a demanding part with complex machining. When the die is machined, less than half of the material remains at the end. To produce all the contours, relatively small tools sometimes plunge deep into the material.

“We decided to let MAPAL machine a part completely from start to finish in order to determine what the tool manufacturer is actually capable of”, says Albrecht. “In terms of testing conditions, it couldn’t have been better.” Wendler took advantage of the freedom granted and worked out a machining strategy. In order to match geometries and avoid problems with tolerances and tool restrictions, he oriented himself to the tools previously used and selected 18 suitable tools from the MAPAL portfolio to compete against them.

MAPAL sent its high-feed milling cutter NeoMill-4-HiFeed-90 into the race against the proven classic round-insert milling cutter. The result amazed the manufacturers in Radebeul: The machining time could be reduced by 28 percent. “It was a big wake-up call when we realised that we could save so much working time and, consequently, money on a single part”, admits Albrecht.

It all depends on the right preparatory work

In order to create the best conditions for the subsequent machining steps, Wendler used a 35 mm milling cutter instead of the previous 52 mm cutter. Production Manager Albrecht was very surprised about this: “I was sceptical because with that size difference I didn’t think the small tool could work faster.” But Wendler had his reasons. The 52 mm milling cutter is simply too large for the existing SK40 machines, and the potential of the larger tool cannot be fully exploited. The smaller NeoMill-4-HiFeed-90 high-feed milling cutter he chose, on the other hand, was able to run exactly the cutting data needed. With less cutting width and cutting depth, work was faster in the end.

There was also another factor that contributed to the time savings in the process. The smaller diameter of the milling cutter allows for closer contour machining, leaving less residual material in the corners. This reduces the effort required for further machining. According to Wendler, this is crucial: “Shorter times can hardly be achieved in finishing alone, because the machine is the limiting factor for most users. So I try to create the best conditions already during roughing to gain time overall.”

Thanks to the extremely positive outcome of the project, UFT wants to expand cooperation with MAPAL and tackle further machining work together. “With MAPAL, we have a partner who knows what it is doing. Unfortunately, that’s becoming rarer and rarer”, Albrecht praises. “Having a permanent contact person who can help or give tips if we ever have a problem is a good basis for cooperation.”

The workers have their favourite tool

One milling cutter from MAPAL has become the favourite of machine operators within a short space of time: the OptiMill-3D-HF-Hardened, an extremely powerful solid carbide roughing tool that can be used from soft mild steel to 68 HRC hard powder metallurgical tool steel. “If a tool can actually make the operator beg to be allowed to use it, then we’re really on to something”, Albrecht comments. There are reasons why the tool is so well received: It’s quieter than its predecessor, cuts more smoothly and is therefore more pleasant in terms of volume alone. Operators know up to which tool life they can work with the tool without hesitation before they have to listen more closely during machining.

Another joint project under discussion is the introduction of the UNIBASE-M tool dispensing system, which could be used not only by the UFT tool shop but also by the mechanical finishing department right next door. Tools from MAPAL are also used there, but it is also possible to store third-party tools in the system. The tool stock can be monitored and kept in line with requirements via the digital tool management system c-Com. The adaptive system ensures that as few tools as possible are stored, but that the customer is always fully capable of action – after all, production should run smoothly.

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342