05.05.2022

Problem solver even for tricky cases

Sometimes coincidence plays a role when it comes to convincing new customers of the benefits of a tool manufacturer‘s products. A product specialist from MAPAL visited HaGeForm Sachsen GmbH at precisely the time when the machinists there were getting stuck on a tricky task – and he also happened to have the right tools with him. Since then MAPAL has been called in time and time again to solve problems.

HaGeForm was founded in 1992 as a branch of a company from North Rhine-Westphalia in Lößnitz in the Erzgebirge. Following a change of ownership, the company established a new site in Stollberg in Saxony. In 2012, Sebastian Baier and his father took over the business together. Since 2018, he has managed HaGeForm Sachsen with its 15 employees as Technical Managing Director along with his sister Stefanie Baier, who serves as Commercial Managing Director.

Around 90 percent of their customers are located within a radius of 50 kilometres. This proximity is a big plus for the manufacturer, since fast delivery times are becoming more and more crucial. „We do a lot of things on demand,“ explains Baier. „We usually bring the parts to the customer by car, so there are no long haulage routes.“ In addition to parts for the Die & Mould sector, components for general machining and all sorts of other industries are being produced in Stollberg as well.

From toothbrushes to Formula 1

The region‘s automotive suppliers make up a large part of its broad spectrum of customers. The parts produced by HaGeForm are mostly used in forming, cutting or spray-coating sheet metal. Often they‘re one-off productions, sample parts, prototypes and small batches. The orders have included everything from moulds for toothbrushes to parts for Formula 1. Even when the scientists at the Technology Campus of Chemnitz University of Technology come up with „crazy new things“, as Baier says, his company, which has extensive experience in fulfilling special customer requests, is called upon to provide the manufacturing expertise. The required tolerances are usually in the hundredths range, but accuracies of 5 µm are also feasible in Stollberg.

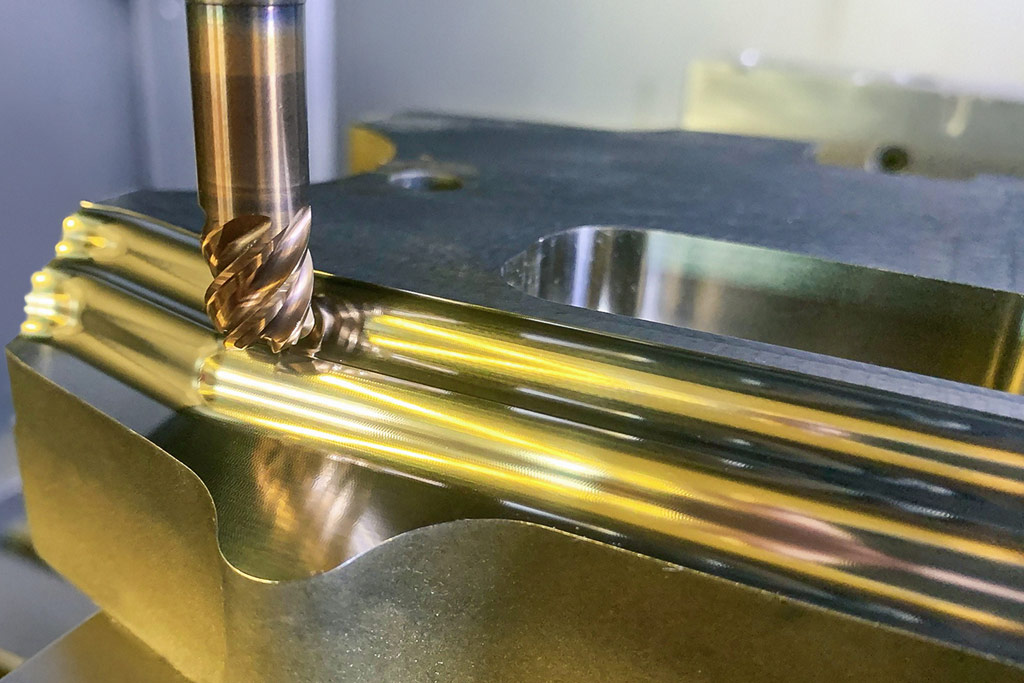

The manufacturing department has a variety of technologies at its disposal. In addition to four wire erosion machines, two die-sinking erosion machines and a grinding machine, there are three milling centres with three, four and five axes available. Parts that are to be machined by both milling and EDM are shifted to the respective areas depending on the workload. To reduce process times, the company strives to mill as much as possible, since die-sinking erosion takes much longer, making the process also more expensive. Milling currently accounts for almost half of the orders, and the trend is rising. Parts that until recently had to be eroded can now also be milled. HaGeForm‘s partnership with MAPAL has also contributed to this.

Successfully tested prototype

Better off milling quickly than spending a long time eroding

For some parts, the transition to complete machining was successful. For example, a fineblanking die made of powder-metallurgical metal used to be removed from the machine after milling for subsequent vertical erosion of small corner radii with shoulders. „We couldn‘t imagine doing it any other way,“ admits Seibt. „Now we can cover all that with milling, which is quite an innovation. “ In the meantime, the OptiMill-3D-HF-Hardened high-feed milling cutter and the OptiMill-3D-BN-Hardened ball nose milling cutter are also regularly used for hard machining at HaGeForm. The trochoidal milling cutter OptiMill-Tro-Hardened is used for two-dimensional roughing directly in the hard material. This allows full utilisation of the cutting edge length, which always corresponds to 3xD with this tool, for machining material hardnesses up to 65 HRC without any problems and guarantees maximum cost-effectiveness through the highest stock removal rates in the shortest possible time.

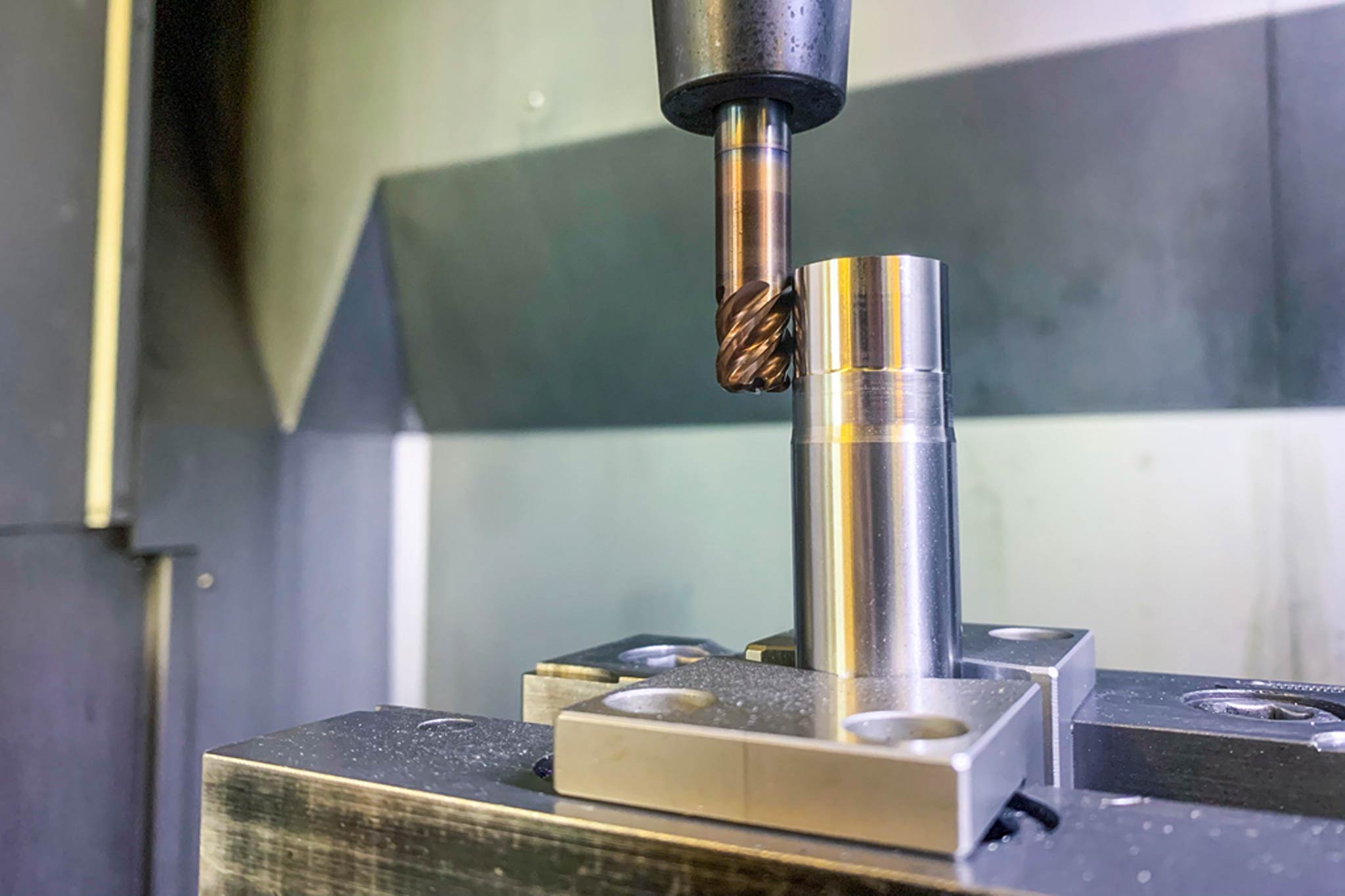

MAPAL has come to be appreciated as a problem solver. For very complex titanium parts, a possible machining strategy was mulled over for a long time. In the end, MAPAL was called. Felix Wendler came to Stollberg with the right milling cutters for titanium and also stayed until a suitable programme for the complicated part was created and the machining was up and running. Complex shapes combined with special materials always place new demands on the manufacturers. „We receive really great support from MAPAL in this respect, “ praises Maik Seibt. „When we encounter problems, all it often takes is a phone call. It‘s good to have a competent contact person to ask.“

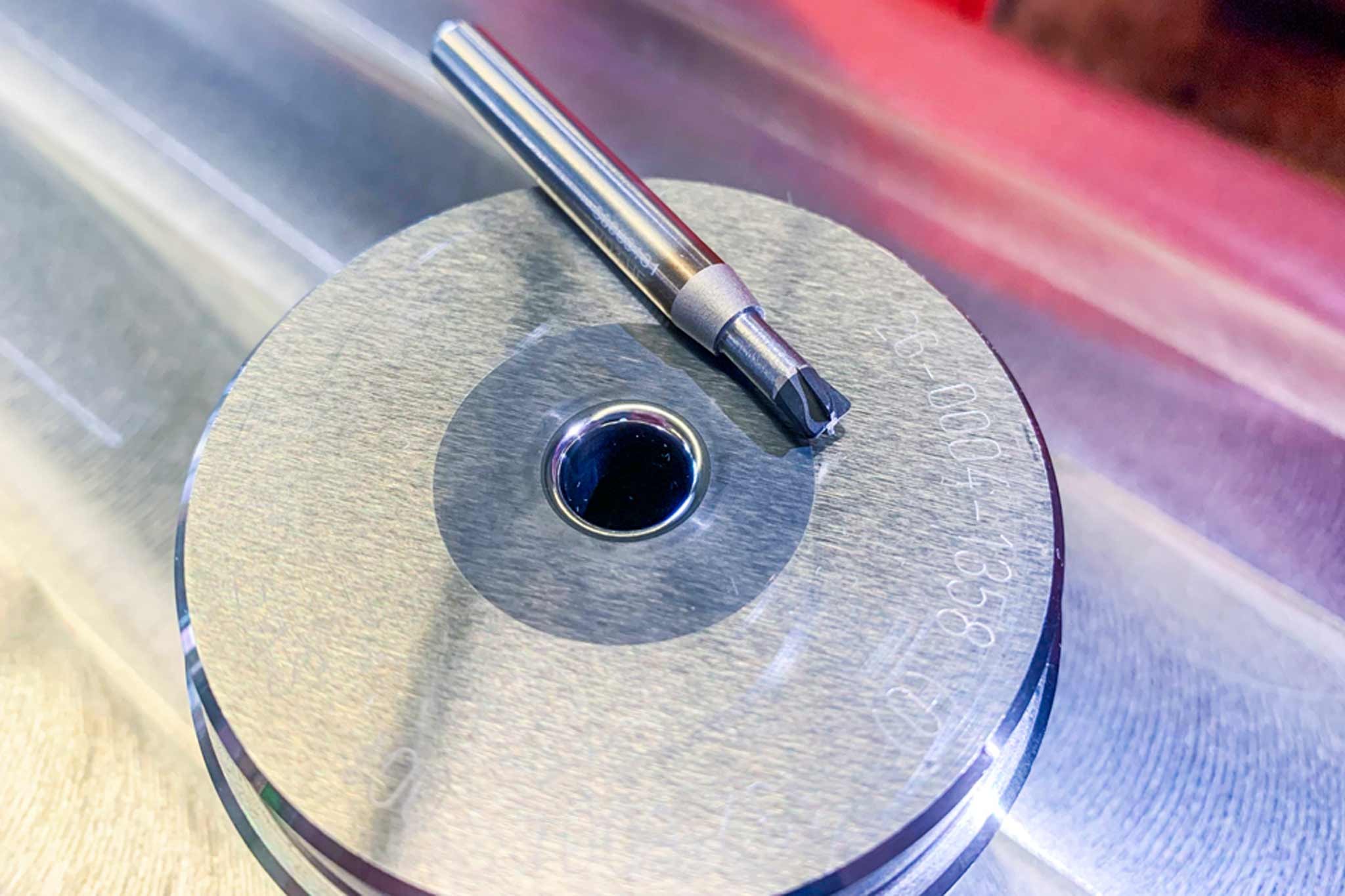

Solid PCD for carbide

This PCD tool was also a winner at HaGeForm. It produced absolutely smooth surfaces and still looked like new after a few uses, which already suggested a long tool life. Felix Wendler sees market advantages for the Saxon manufacturers: „Very few companies are currently able to machine carbide reliably and, most of all, economically. HaGeForm is really good at that.“

The partnership is set to be maintained. The next step will be thread milling cutters for hardened material, because HaGeForm had complained that the tools from the previous supplier did not last long enough. MAPAL‘s aim is now to use a newly developed milling cutter to reliably insert as many threads as possible at material hardnesses of up to 65 HRC.

Contact

Kathrin Rehor Public Relations Kathrin.Rehor@mapal.com Phone: +49 7361 585 3342