Chassis & Brakes

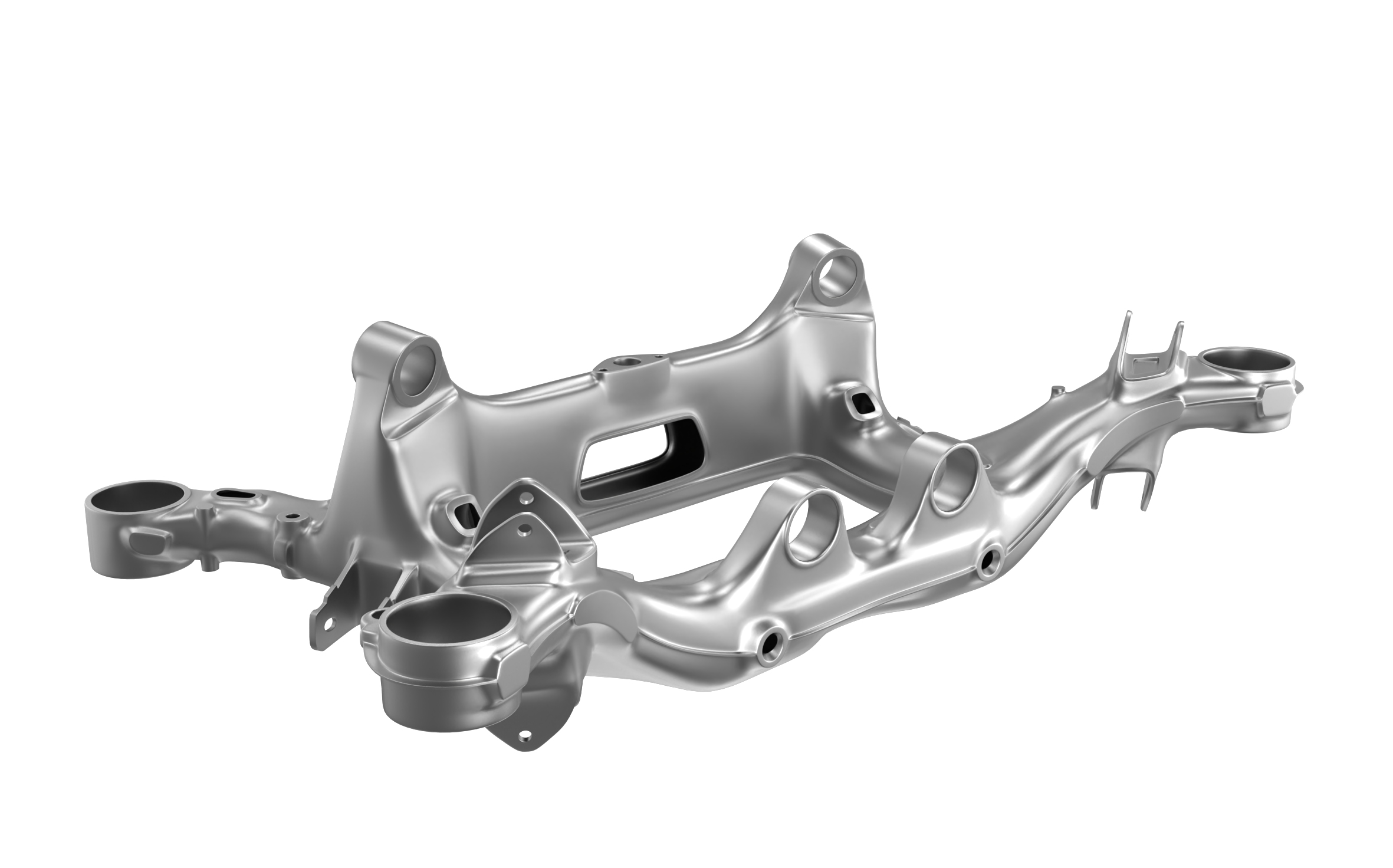

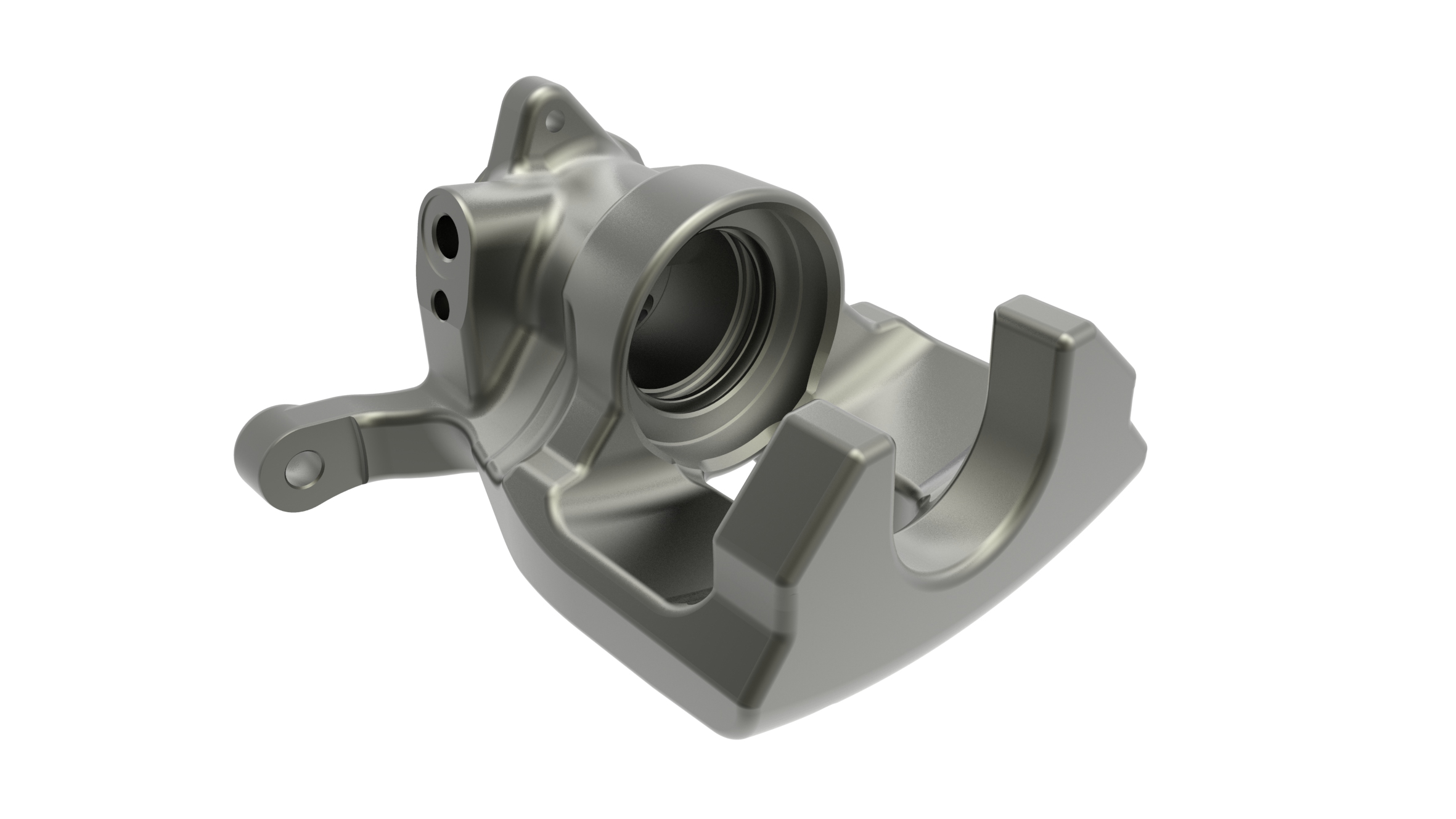

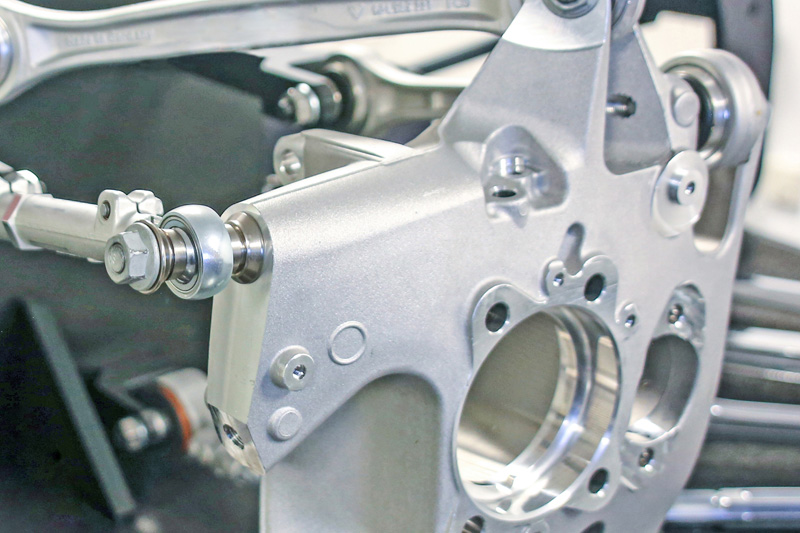

Due to the battery systems, which lead to increased vehicle weight, the proportion of aluminum in chassis and brake components is increasing. This is because aluminum ensures both high stability and reduced weight. At the same time, innovative technologies such as steer-by-wire and brake-by-wire as well as autonomous driving mean that components are constantly being developed further. In addition, new production methods such as gigacasting/megacasting are opening up new possibilities, such as larger component dimensions, which means that parts of a body can be produced in a single piece.