Competence Reaming and Fine Boring

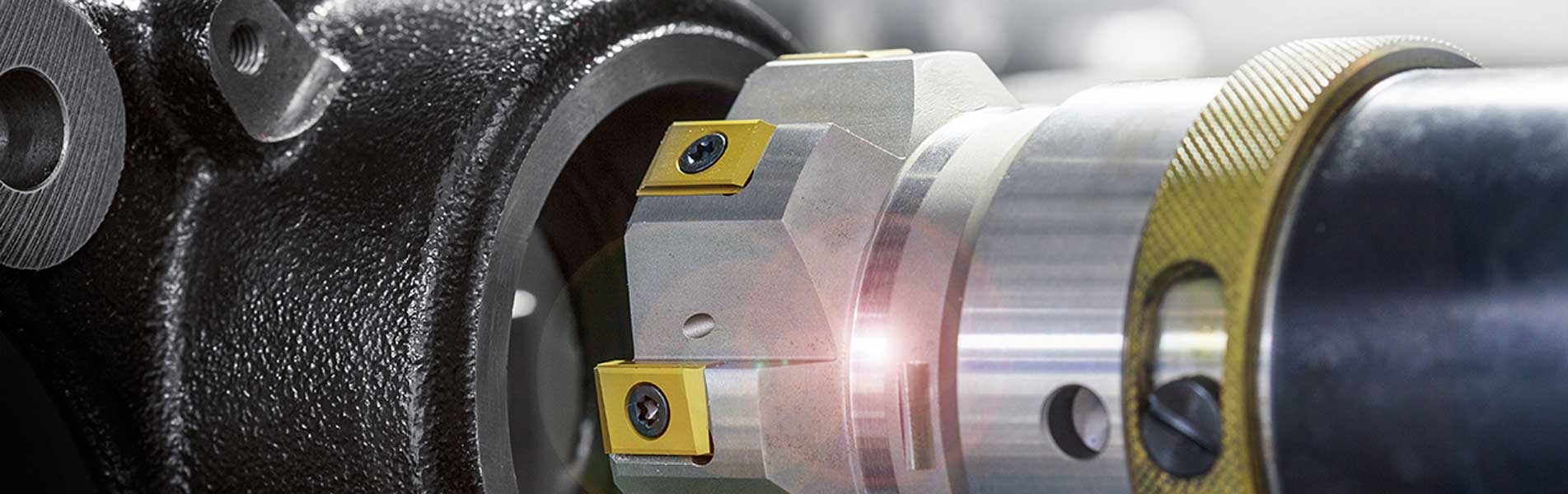

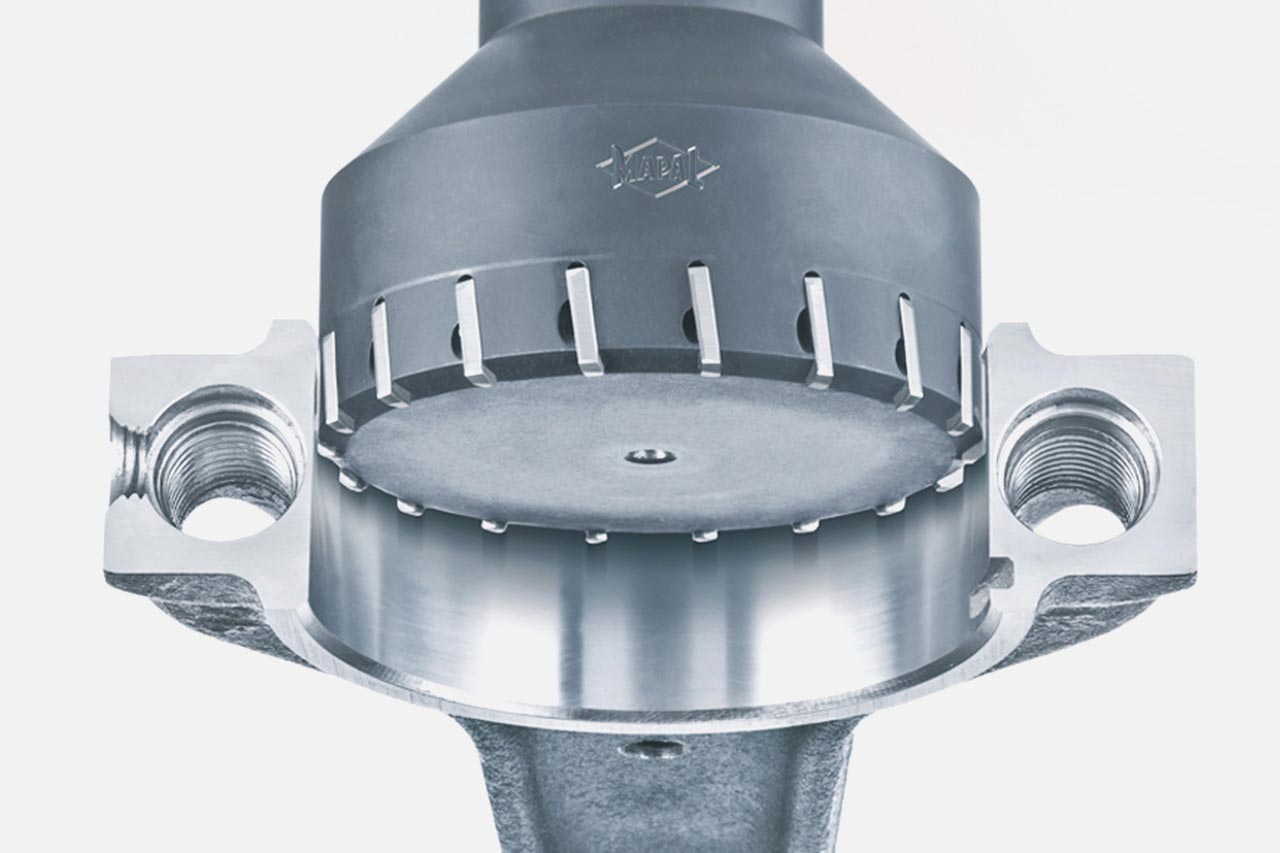

Precision tools for reaming and fine boring of bores are the core competence of MAPAL. The company is continuing to write its success story related to this area that started with the "original reamer" in 1954.

Thanks to decades of experiences and continuous further development and optimisation, MAPAL can offer its customers the optimum tooling solution, perfectly tailored to the complexity of the machining operation and the precision requirements.

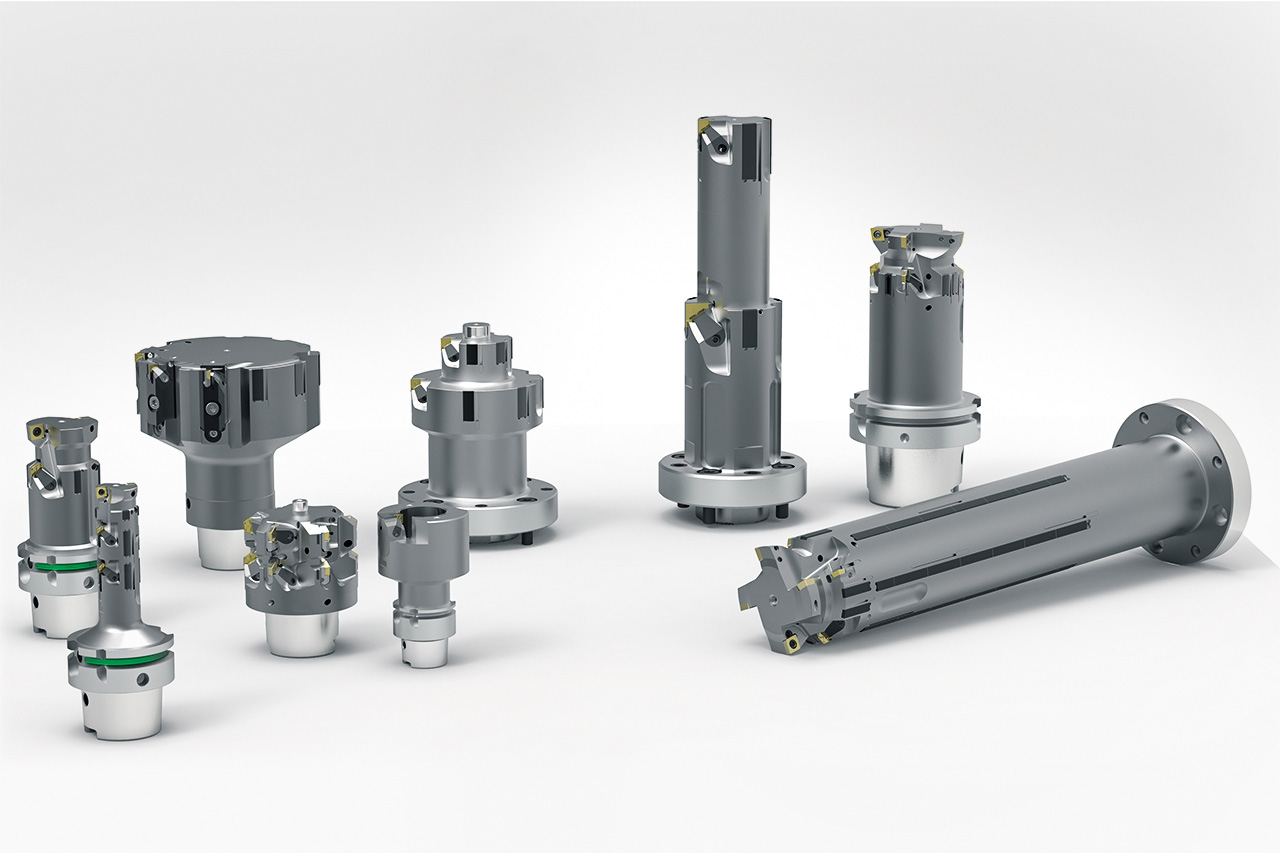

Next to tailor-made custom solutions, MAPAL offers a broad standard programme of tools for reaming and fine boring.

Thanks to decades of experiences and continuous further development and optimisation, MAPAL can offer its customers the optimum tooling solution, perfectly tailored to the complexity of the machining operation and the precision requirements.

Next to tailor-made custom solutions, MAPAL offers a broad standard programme of tools for reaming and fine boring.