Replaceable head reamers

It is possible to replace the tool head directly on the machine. The strength and accuracy of tools with HFS and CFS connection are no worse than monolithic tools.

Due to the high precision of the connections, the tools are actually even stiffer. The replaceable head tools achieve the tool lives of monolithic tools with reduced process costs.

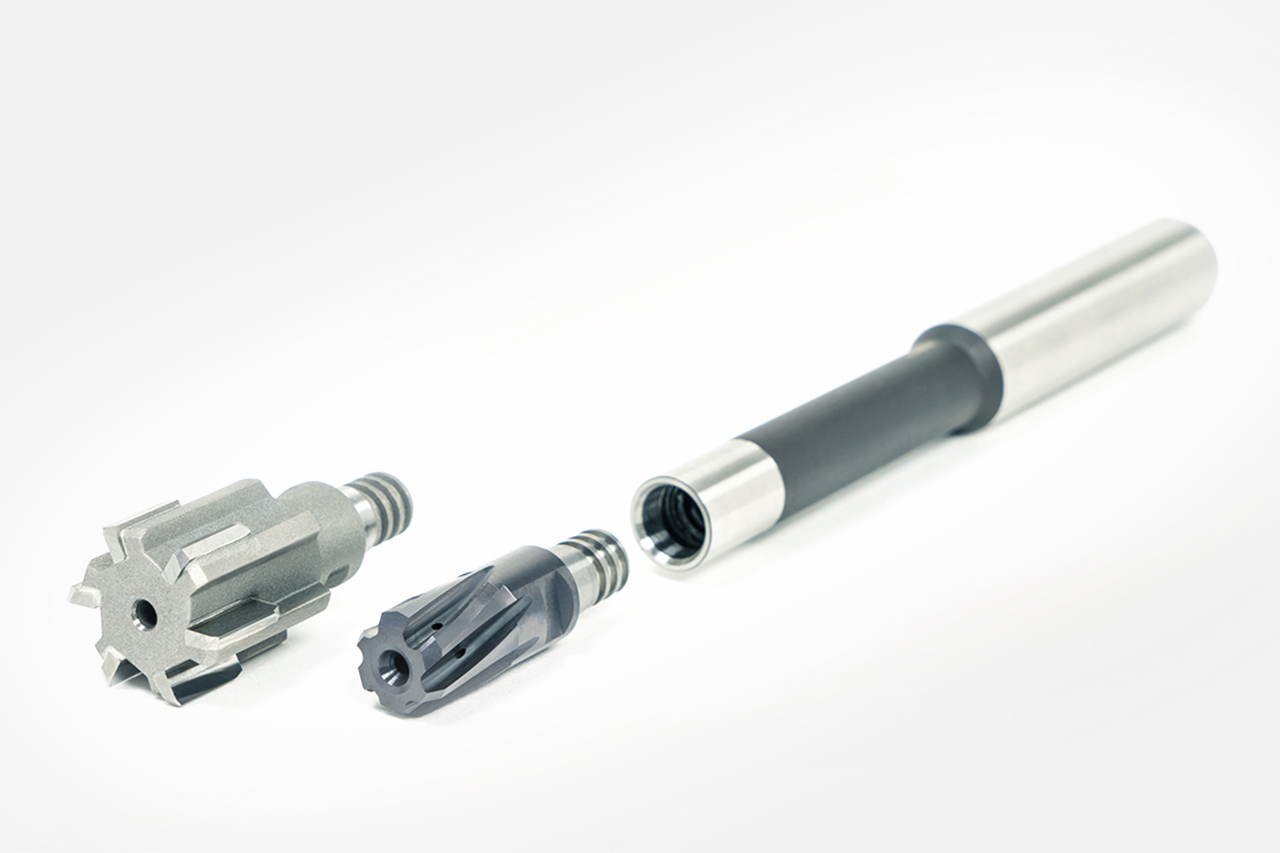

HPR Replaceable head reamers

The HPR range of replaceable head reamers includes series for through and blind bores from a diameter of 8.00 mm. The replaceable head reamers are available either of fixed design (series 100) or of finely adjustable design (series 200) and can be tipped with different cutting materials such as carbide, cermet, PcBN or PCD. High-performance CVD and PVD coatings increase tool lives and the cost-effectiveness of the reamers.

The innovative CVD coating HC419 reliably machines the complete range of cast iron materials, with high cutting speeds and maximum productivity.

The reamers can be configured in the diameter range from 8.00 to 65.00 mm in steps of 0.10 mm; the tolerance range can also be configured. A broad range of H7 dimensions is available as a preferred series.

The related holders with the HFS (Head Fitting System) feature exact radial run-out and changeover accuracy, along with safe and simple handling, particularly during assembly and dismantling of the tool head.

HFS guarantees high precision and power transmission, here changeover and radial runout accuracies less than 3 μm can be achieved reliably. Due to the simple construction with direct coolant supply to the cutting edge, the system is suitable for minimum quantity lubrication (MQL).

CPR Replaceable head reamers

The CFS connection for the Complete Performance Reamers CPR is designed such that the highest possible stability and rigidity is achieved by a taper and a face connection. The special design and manufacture to the μ of the thread and taper-face section guarantee the highly precise radial run-out accuracy of 5 μm. Thanks to the simple and safe handling, the reaming heads can be replaced in the machine tool quickly and easily.

The range of CPR replaceable head reamers includes heads made of solid carbide and heads with brazed cutting edges. The replaceable head reamers are available either of solid carbide design (series 500) or can be tipped with different cutting materials such as carbide, cermet, PcBN or PCD (series 600). High-performance CVD and PVD coatings increase tool lives and the cost-effectiveness of the reamers. The innovative CVD coating HC419 reliably machines the complete range of cast iron materials, with high cutting speeds and maximum productivity.

The reamers can be configured in the diameter range from 8.00 to 40.00 mm in steps of 0.10 mm; the tolerance range can also be configured. A broad range of H7 dimensions is available as a preferred series.