Empower Your Aluminium Machining

Engineering is the key

With decades of experience in the design, production and application of tools for aluminium machining, MAPAL is the leading technology partner for the machining of aluminium components. In order to be able to offer customers optimum machining processes, MAPAL provides market, material and engineering expertise in addition to a comprehensive product and application portfolio. The full potential of a machining process can only be realised through the interaction of all influencing factors and cooperation in a spirit of partnership - this is what MAPAL stands for.

Focus on the customer

Sectores y componentes

Herausforderungen der Aluminiumzerspanung

Produkte und Anwendungen

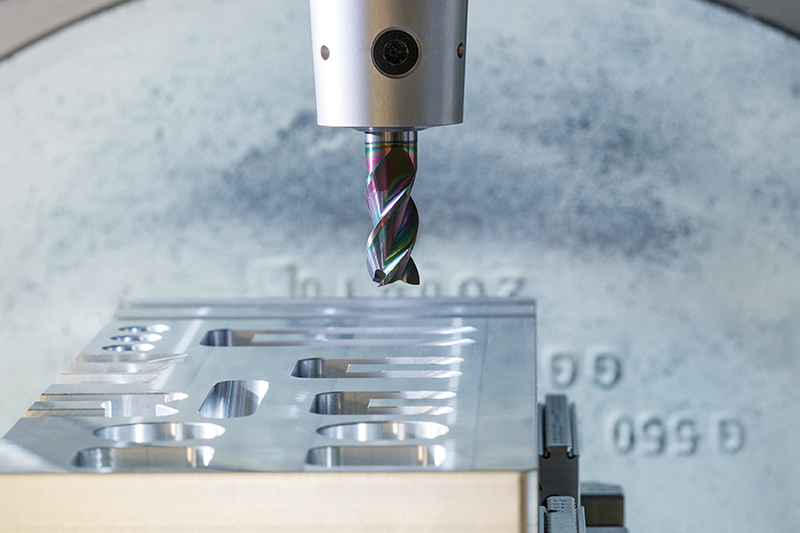

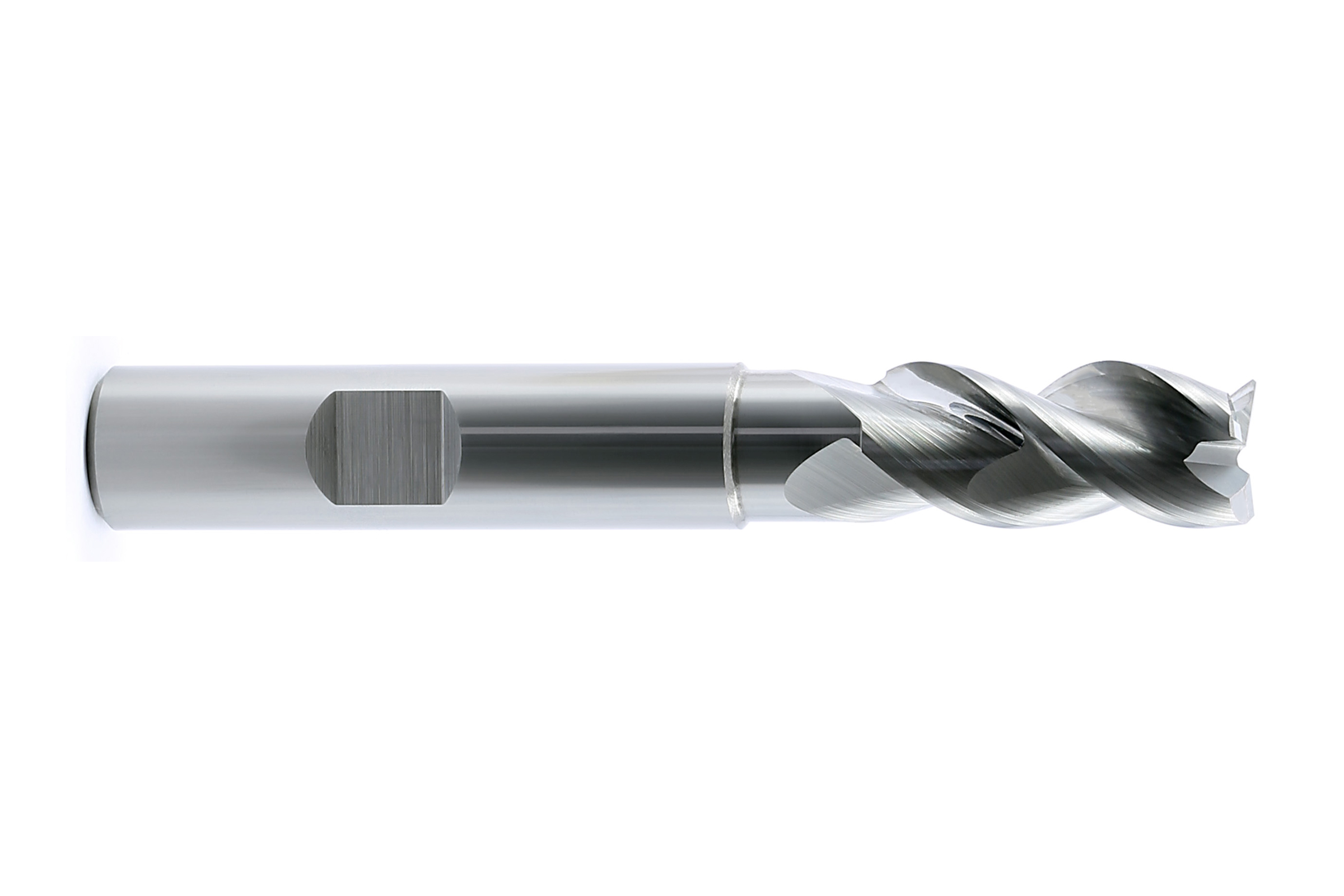

Fräsen mit Vollhartmetall

Fraisage avec PCD

Fraisage avec plaquettes amovibles

Perçage

Alésage

クランピング

Exemples issus de la pratique

MAPAL Services

Avec le module de service d'ingénierie, MAPAL garantit une production rapide, précise et sûre. D'autres potentiels d'économie peuvent être exploités dans le domaine de la logistique et de la maintenance. Dans le domaine de la formation, MAPAL veille à ce que le savoir-faire des spécialistes soit mis à la disposition des clients de manière transparente et exhaustive, en vue de donner aux clients une avance décisive sur la concurrence.

Toutes les offres de service de MAPAL sont axées sur des processus optimaux et un accompagnement complet orienté sur l'industrie 4.0. Toujours dans le but d'apporter une contribution significative à une production fluide, productive et économique chez le client.

Avantages :

- Solutions pour des composants complets incluant les outils, les dispositifs, le programme NC et la mise en service

- Conception et mise en œuvre complètes des processus à partir d'une source unique

- Assistance rapide et flexible sur site dans le monde entier

- Technologie d'outils efficace avec optimisation des coûts

- Adaptation optimale de l'outil, de la pièce, du dispositif et de la machine

- Qualité de produit, fiabilité des processus et rentabilité maximales dès le départ

- Passage rapide de la planification à la mise en œuvre avec une sécurité de planification maximale

/-P3A1692-1-.jpg)