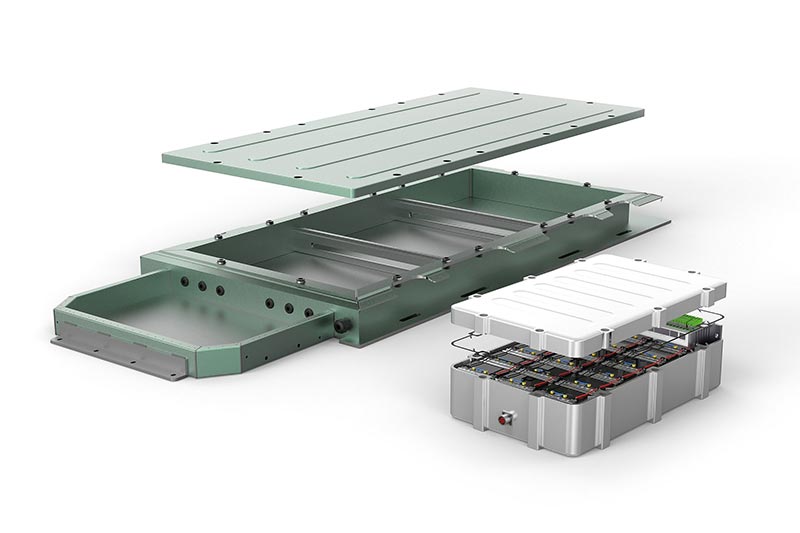

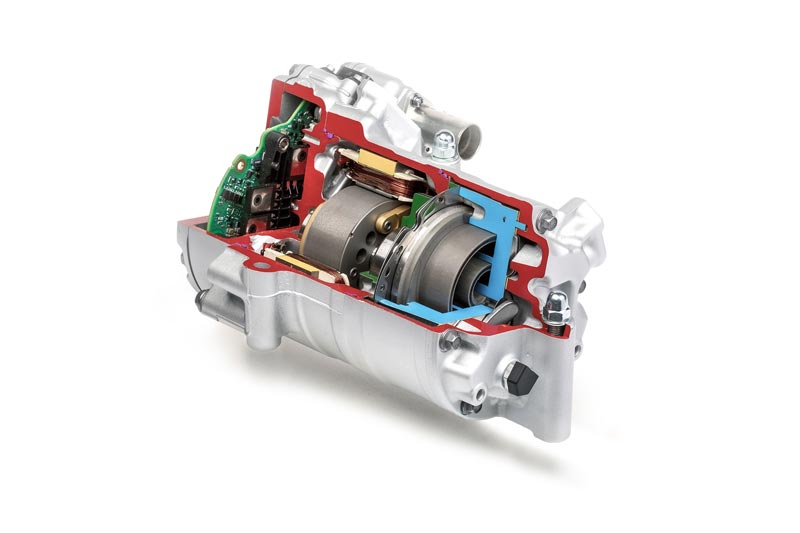

Electrified auxiliary units

As a result of electrification in the automotive industry, more and more drive tasks

of the internal combustion engines are being performed by electrified components.

By electrifying the auxiliary units, these components can be used as required and

depending on the load, and thus contribute to reduced energy consumption. They

stand out thanks to their high reliability and low noise emissions as well as excellent

energy efficiency.

of the internal combustion engines are being performed by electrified components.

By electrifying the auxiliary units, these components can be used as required and

depending on the load, and thus contribute to reduced energy consumption. They

stand out thanks to their high reliability and low noise emissions as well as excellent

energy efficiency.

Compresor de espiral como equipo secundario

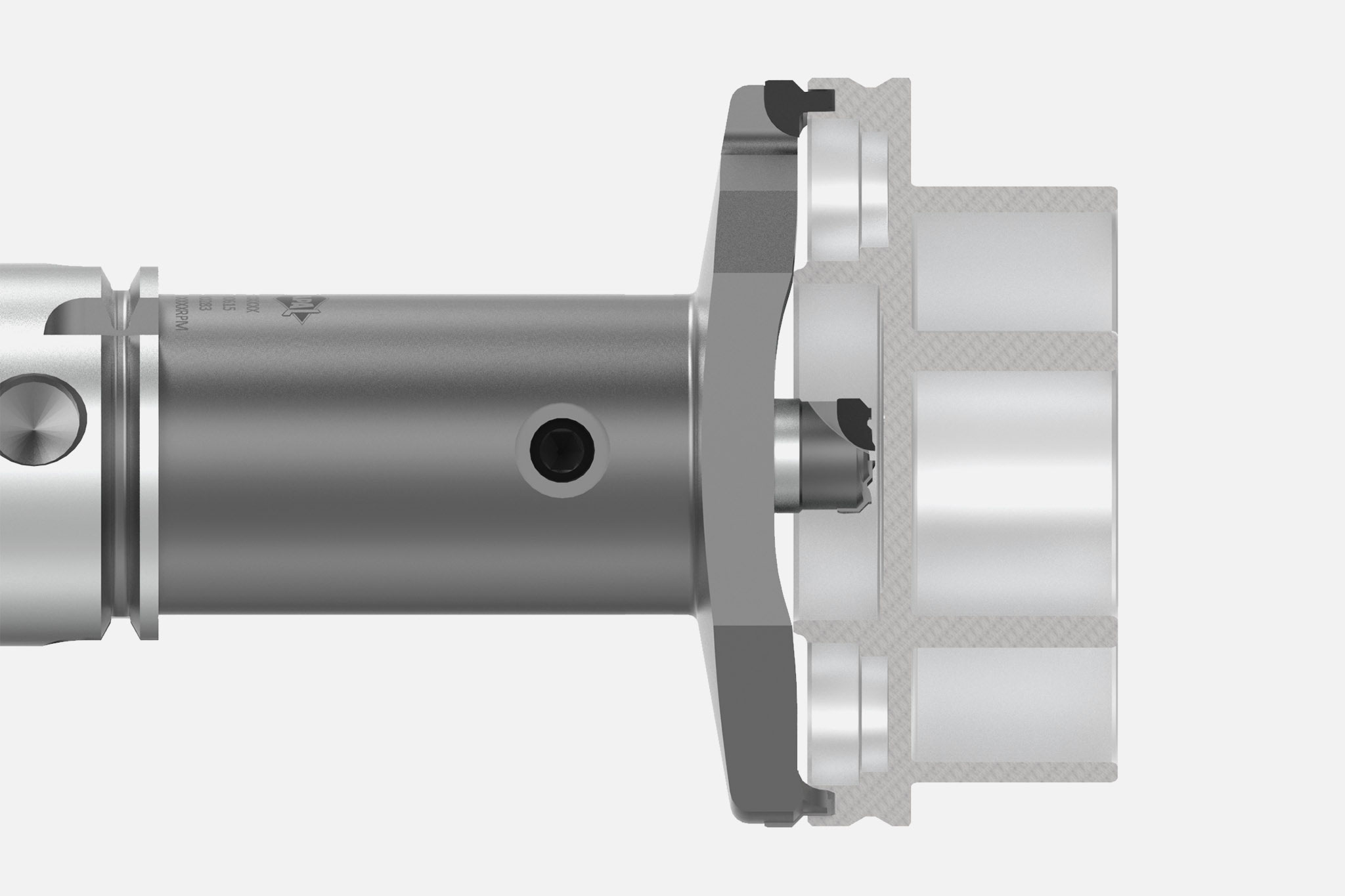

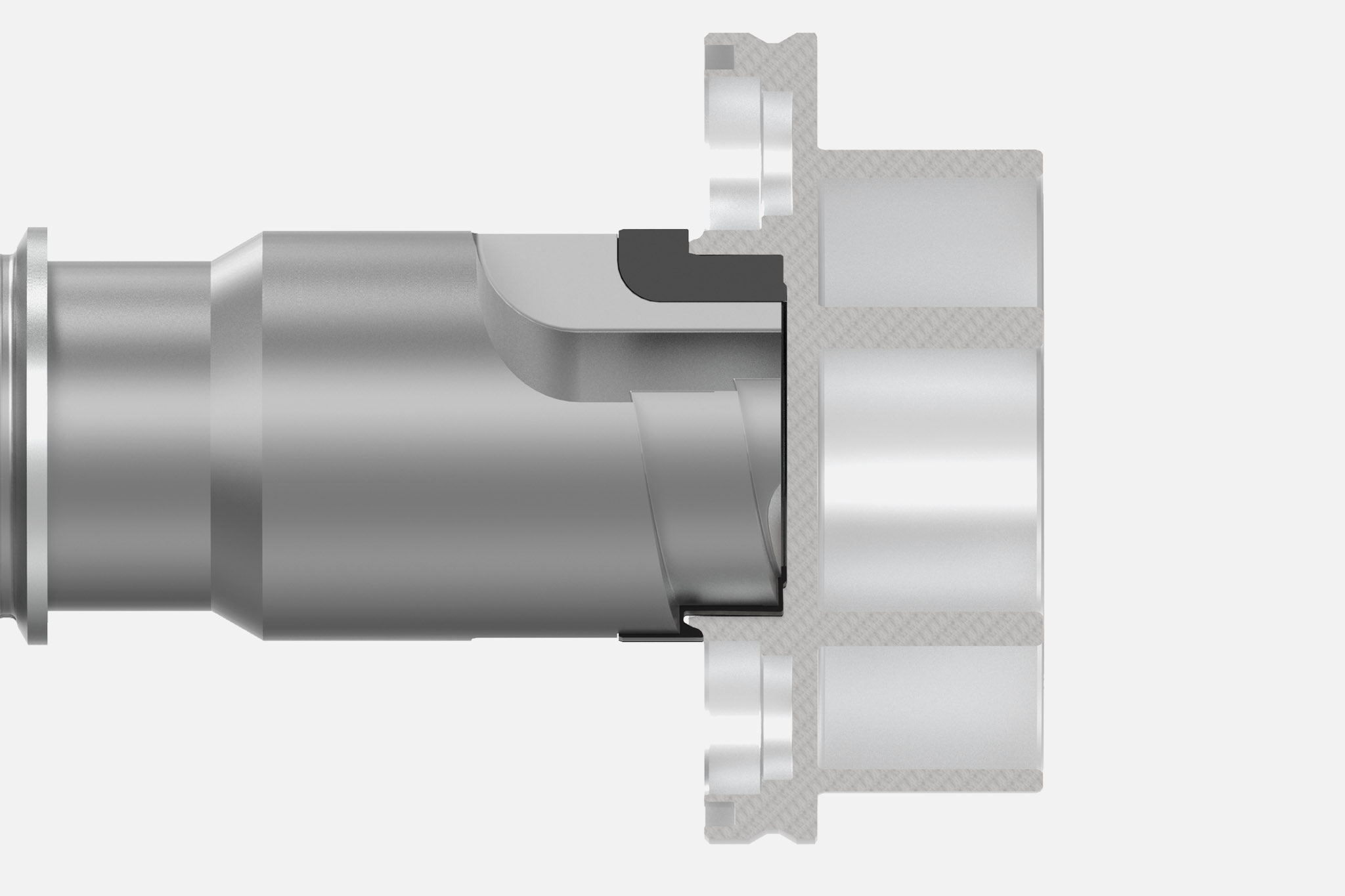

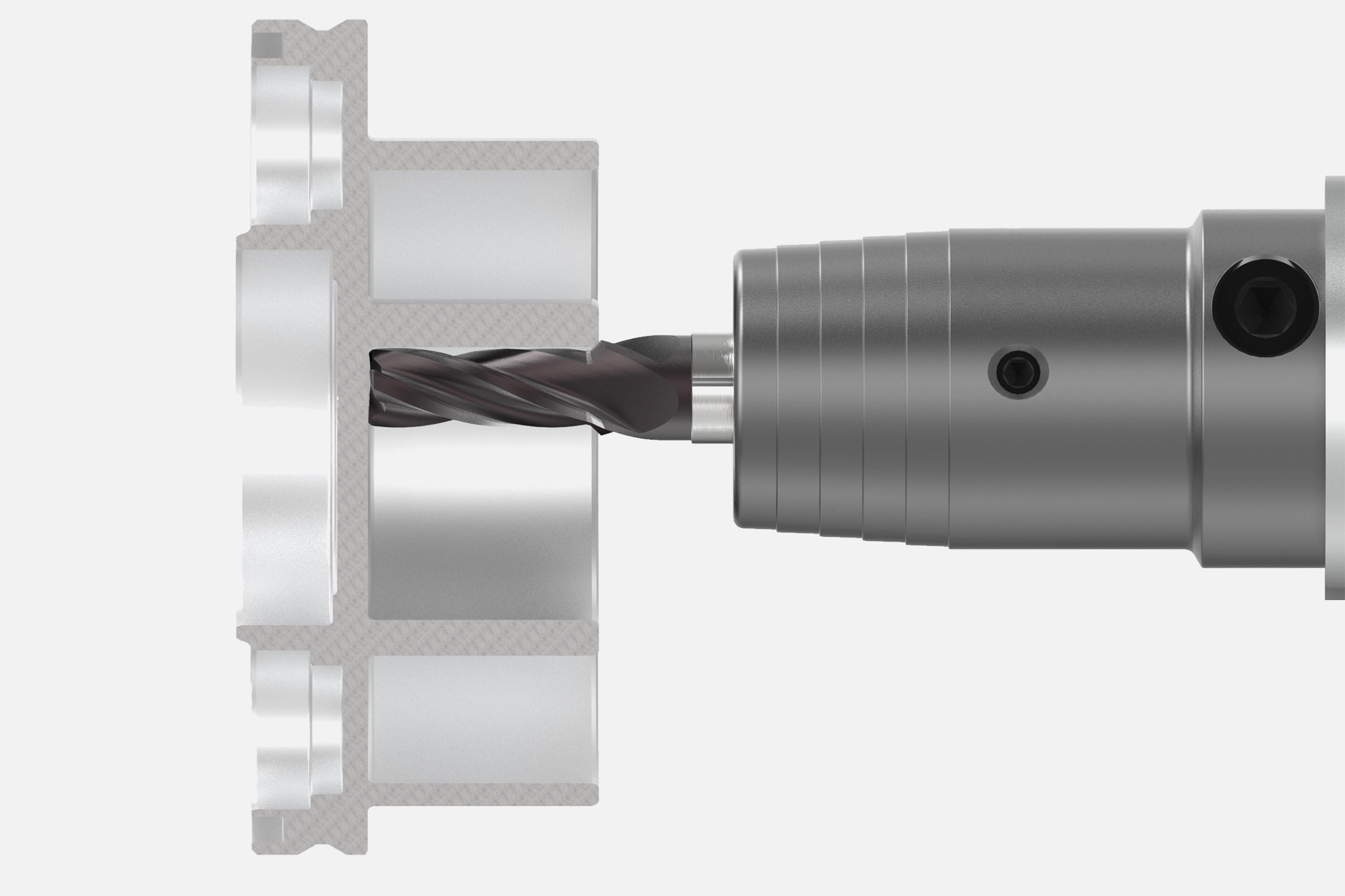

Un ejemplo de un equipo secundario electrificado es el compresor de espiral, que se utiliza como compresor de refrigerante eléctrico en la gestión térmica. Como ejemplo se presentan tres mecanizados específicos en un compresor de espiral de aluminio para su uso en un vehículo eléctrico.

CARACTERÍSTICAS

- Piezas esenciales Orbit y Fixed Scroll

- La precisión de la geometría y el alojamiento es decisiva

- Posicionamiento exacto de las espirales entre sí

REQUISITOS DE MECANIZADO

- Alta precisión dimensional de las espirales (≤ 20 μm)

- Alta perpendicularidad de los flancos respecto a la superficie base (≤ 20 μm)

- Paralelismo y planicidad de ≤ 10 μm

- Aspereza superficial (Rz) en el rango de una cifra

- Combinación perfecta de máquina y herramienta