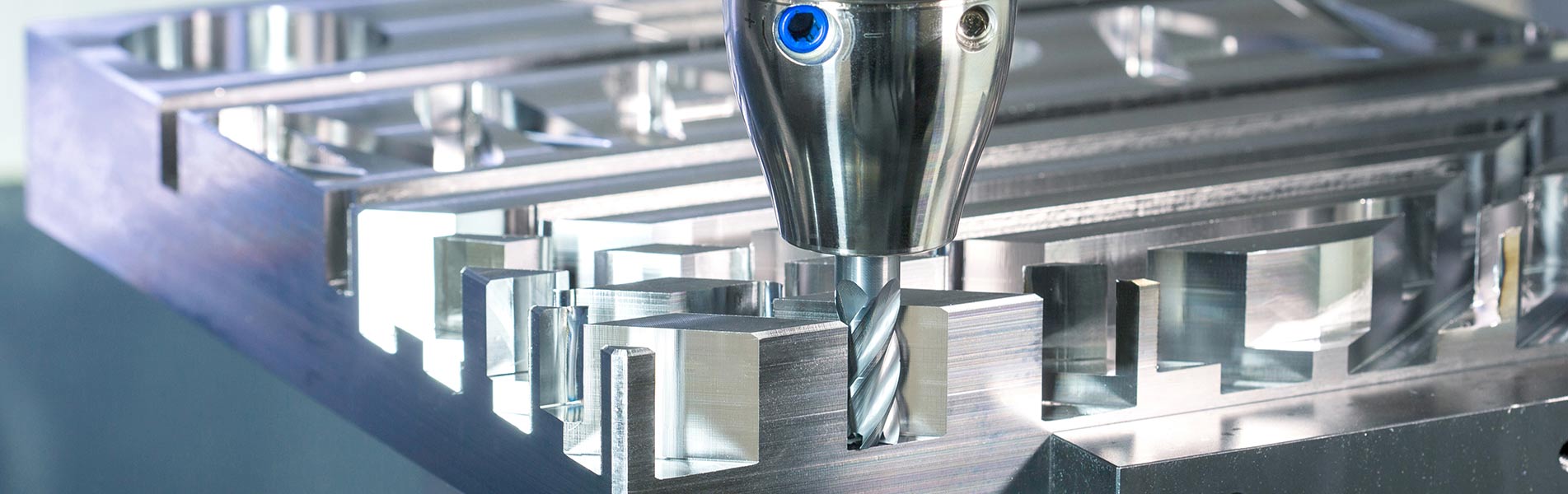

OptiMill®-Uni-HPC

Nova geração para a máxima confiabilidade do processo

A MAPAL apresenta a terceira geração da fresa de metal duro integral OptiMill-Uni-HPC – otimizada para produção automatizada e alto desempenho de corte.

The new OptiMill-Uni-HPC for machining steel, stainless steel and castings has been specially

developed for automated processes and meets the highest requirements for process reliability, stability and resistance to wear.

developed for automated processes and meets the highest requirements for process reliability, stability and resistance to wear.

The newly developed cutting material has a high ductility, reducing the risk of tool breakage.

Combined with wear-resistant coatings and optimised geometry, this results in a tool that’s ultra-reliable, even in dynamic machining.

Combined with wear-resistant coatings and optimised geometry, this results in a tool that’s ultra-reliable, even in dynamic machining.

A version with an integrated chip breaker is a new addition to the OptiMill-Uni-HPC range. It

creates short chips that are easy to remove – offering clear benefits for air cooling and high

cutting performance and enabling high infeed depths.

creates short chips that are easy to remove – offering clear benefits for air cooling and high

cutting performance and enabling high infeed depths.

The result: Longer machine running times, lower monitoring efforts and higher process reliability – ideal for unmanned shifts and automated workflows.

From September 2025, the milling cutter is available in three versions:

- Short without chip breaker (ø 3–20 mm)

- Long without chip breaker (ø 3–25 mm)

- Long with chip breaker (ø 6–25 mm)

This sees MAPAL draw on the targeted development of a tried-and-tested concept – for more

efficiency, process reliability and versatility in modern machining.

efficiency, process reliability and versatility in modern machining.