Nuova geometria rompitruciolo per la barenatura di precisione

Nuova soluzione per l’asportazione truciolo di acciai a truciolo lungo

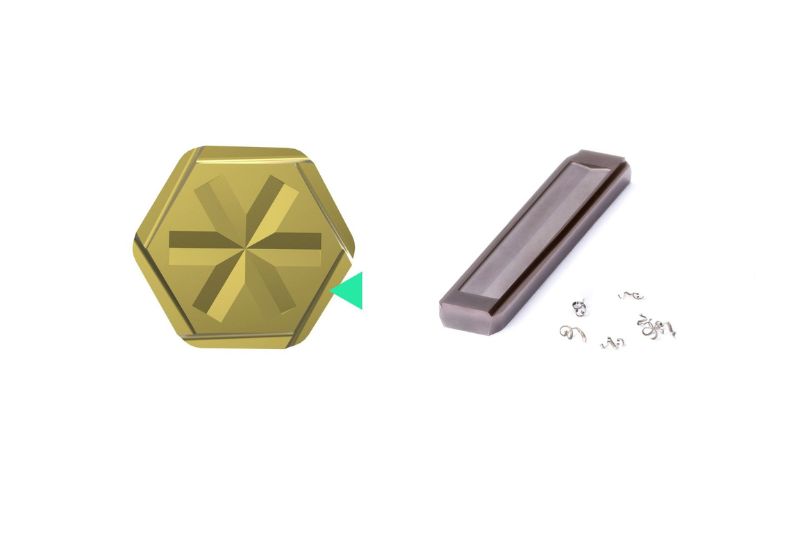

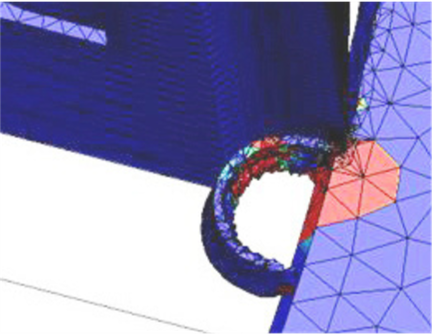

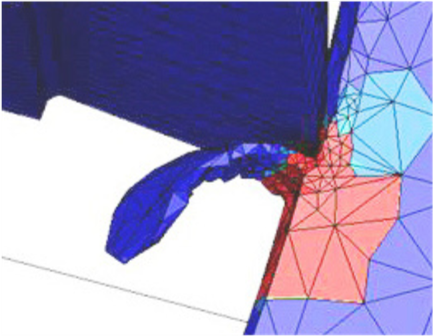

Nella lavorazione dei metalli, la formazione dei trucioli gioca un ruolo fondamentale per quanto riguarda la sicurezza dei processi, la durata degli utensili e la qualità delle superfici. La formazione controllata dei trucioli è fondamentale soprattutto nella lavorazione di finitura di acciai non legati, legati e inossidabili.

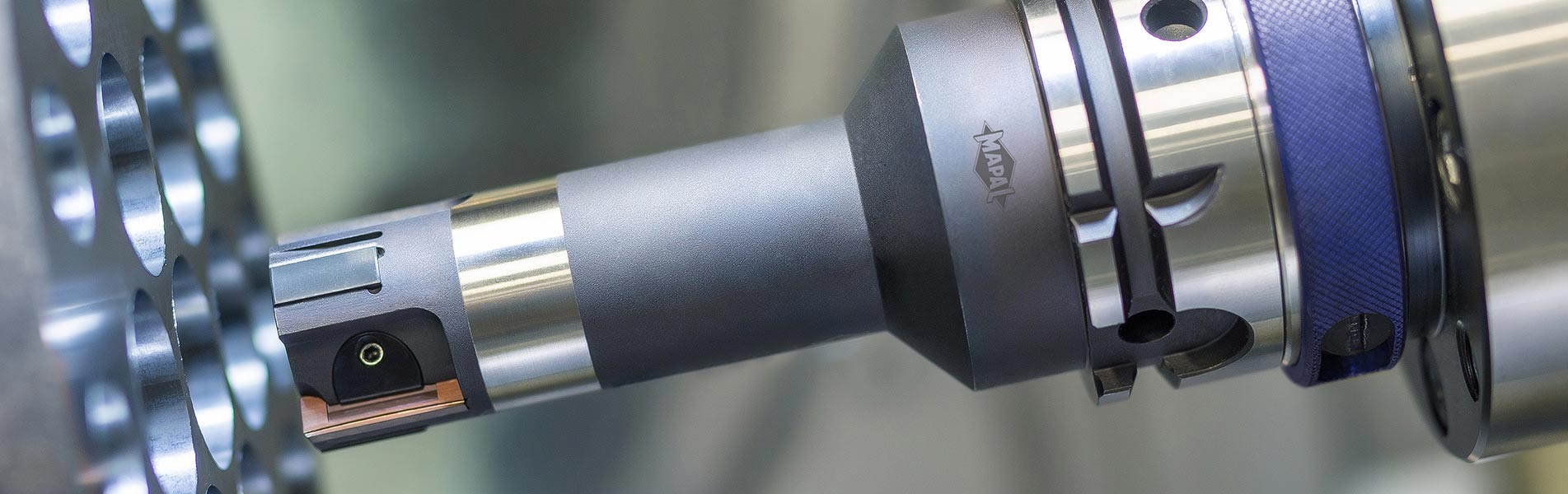

Con la nueva geometría estandarizada del rompevirutas para taladros de precisión, MAPAL ofrece una solución innovadora que combina la precisión técnica con el valor agregado económico.

La geometría del ángulo de corte y del ángulo de inclinación, definida con precisión, se adapta óptimamente a los valores y profundidades de corte. Esto permite un control de la formación de virutas, incluso con materiales complejos.

Las ventajas para el usuario resultan claras: eliminación de virutas óptima, baja generación de calor y una estabilidad de proceso muy alta.

La tecnología no solo contribuye a la alta calidad de las piezas mecanizadas, sino también a la eficiencia de la producción. Las escasas paradas de la máquina, el menor desgaste de las herramientas y la alta precisión dimensional garantizan ventajas económicas apreciables.

MAPAL traslada su dilatada experiencia en el desarrollo de rompevirutas a una solución lista para la producción en serie, que estará disponible desde el otoño de 2025 con geometrías y recubrimientos definidos.

/Design-ohne-Titel-7-.jpg)

/Design-ohne-Titel-8-.jpg)

/Design-ohne-Titel-9-.jpg)