MAPAL in numbers

-

1

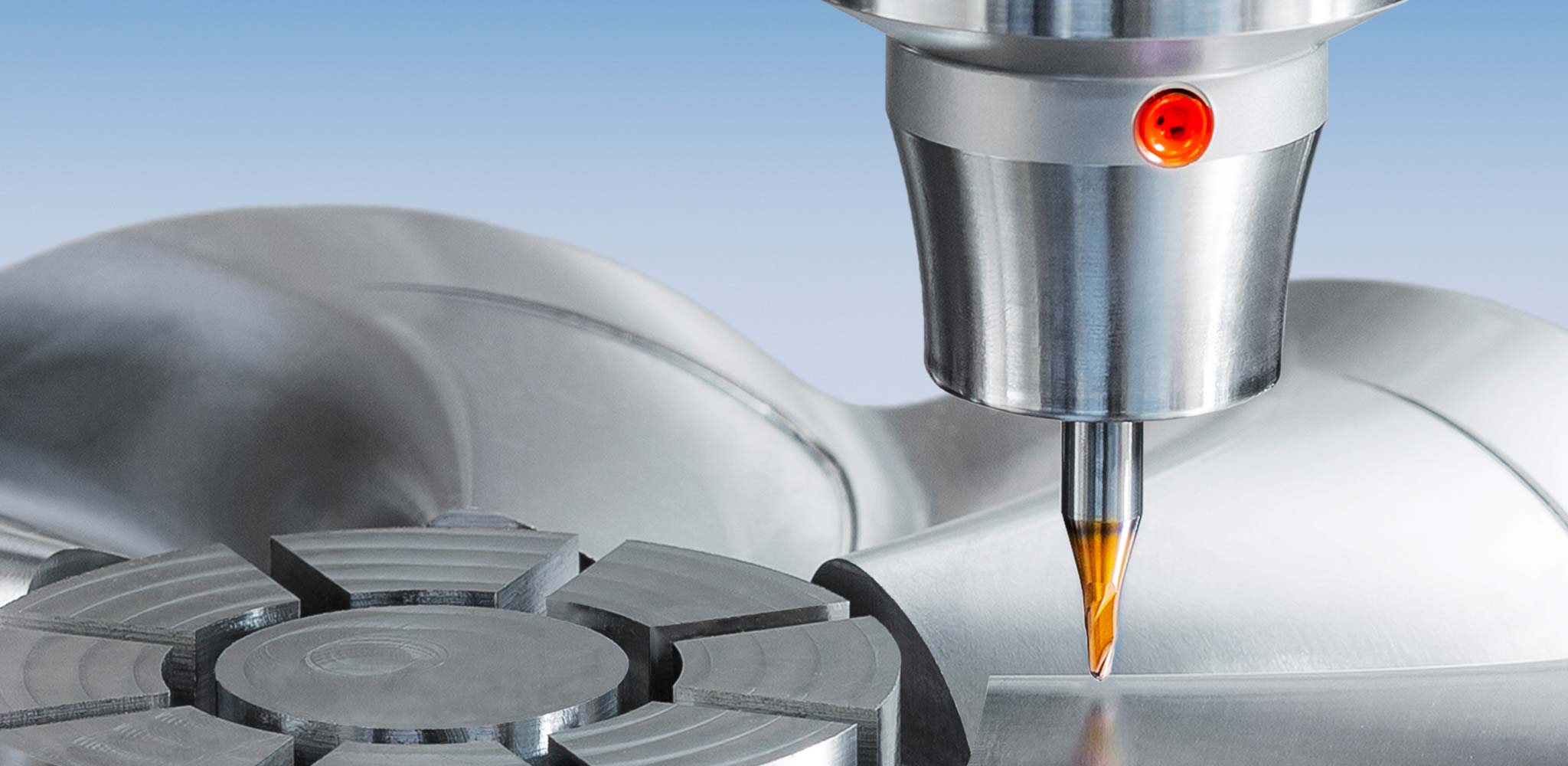

Technology leader for the machining of cubic parts

-

6

Annual investment in research and development of 6% of turnover

-

25

Subsidiaries with production, sales and service in 25 countries

-

300

More than 300 trainees worldwide

-

450

Over 450 technical consultants on the road

-

4,850

Our most important asset: almost 4,850 employees worldwide

From trainee to the specialist – people at MAPAL

The more than 4,850 employees in 25 countries are an essential element of the success of MAPAL. MAPAL builds on the know-how and the commitment of its employees and in return offers the best conditions for a successful, secure future. With interesting, varied jobs, extensive opportunities for personal and professional further development, and modern working conditions in a global environment, MAPAL sets the course for a long-term partnership with its employees.

One focus is the training and retention of young people. This is achieved by a broad training programme that includes more than 300 trainees and dual study course students every year. Modern training centres and a consistent teaching concept ensure that these trainees can start work seamlessly on completing their training. In addition, students have the opportunity to implement their theoretical knowledge directly in practice during internships or student placements. They can write their thesis and in this way build up an initial network of contacts at MAPAL.

One focus is the training and retention of young people. This is achieved by a broad training programme that includes more than 300 trainees and dual study course students every year. Modern training centres and a consistent teaching concept ensure that these trainees can start work seamlessly on completing their training. In addition, students have the opportunity to implement their theoretical knowledge directly in practice during internships or student placements. They can write their thesis and in this way build up an initial network of contacts at MAPAL.

MAPAL Executive Team

Information about the corporate management of the MAPAL Group

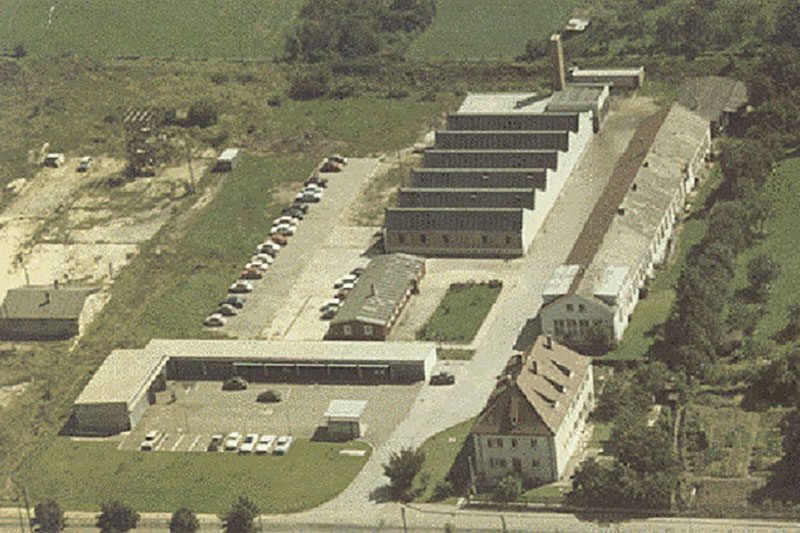

History of the MAPAL Group

MAPAL can look back on a successful corporate history. From the very beginning, this history was characterised by continuity and an innovative spirit that is nourished by Swabian ingenuity and creativity, as well as by the entrepreneurial courage of the Kress family as the company's owners.

Markets and sectors

In many years of close collaboration with its customers, MAPAL has obtained a deep understanding of the processes for almost all methods and applications in machining manufacture. MAPAL machining solutions are used in application areas in a very wide range of sectors.

For the challenges of the automotive industry and the related underlying large-scale series production, MAPAL prepares innovations that are used successfully in the chassis and power train areas, as well as inelectric mobility,

MAPAL is also an accredited partner for the aerospace industry and sets trends and standards in manufacturing and machining technology.

A comprehensive product range is available evenfor the newest field of competence, tool and mould making.

For the challenges of the automotive industry and the related underlying large-scale series production, MAPAL prepares innovations that are used successfully in the chassis and power train areas, as well as inelectric mobility,

MAPAL is also an accredited partner for the aerospace industry and sets trends and standards in manufacturing and machining technology.

A comprehensive product range is available evenfor the newest field of competence, tool and mould making.

Tool and process solutions combined with comprehensive services

MAPAL has a comprehensive portfolio of products and services. As such, individually designed custom tools and high-performance standard products are used to create machining solutions that optimally address the requirements for process reliability, precision and cost-effectiveness.

Supplemented by intelligent services, the customer receives a complete package for the machining process.

Supplemented by intelligent services, the customer receives a complete package for the machining process.

Innovative power

MAPAL places great value on continuous research to be able to offer customers solutions for the implementation of megatrends using innovative products. Close contact with customers, partners and institutes forms the basis for this activity. The systematic development of specific products and services from ideas to market maturity is a hallmark of MAPAL.

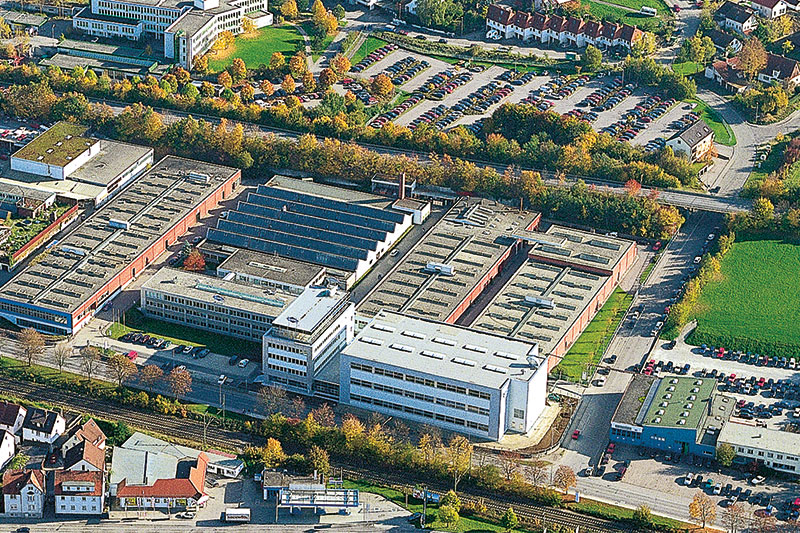

Globally consistent production

MAPAL attaches great importance to globally consistent, highly modern production. Continuous investments in machines, systems and NC programs, in quality assurance and certification, as well as in the training and further training of employees ensure the innovative MAPAL products are produced to the same high quality worldwide.

Technically orientated field service

Proximity to the customer is not just a slogan at MAPAL, instead it is an essential part of the corporate identity. Only by means of regular contact on equal terms is it possible to become familiar and understand in detail customers' processes and the challenges in the different sectors and markets. And to make more and more improvements on this basis. This is what more than 450 employees in the technically orientated field service stand for worldwide.

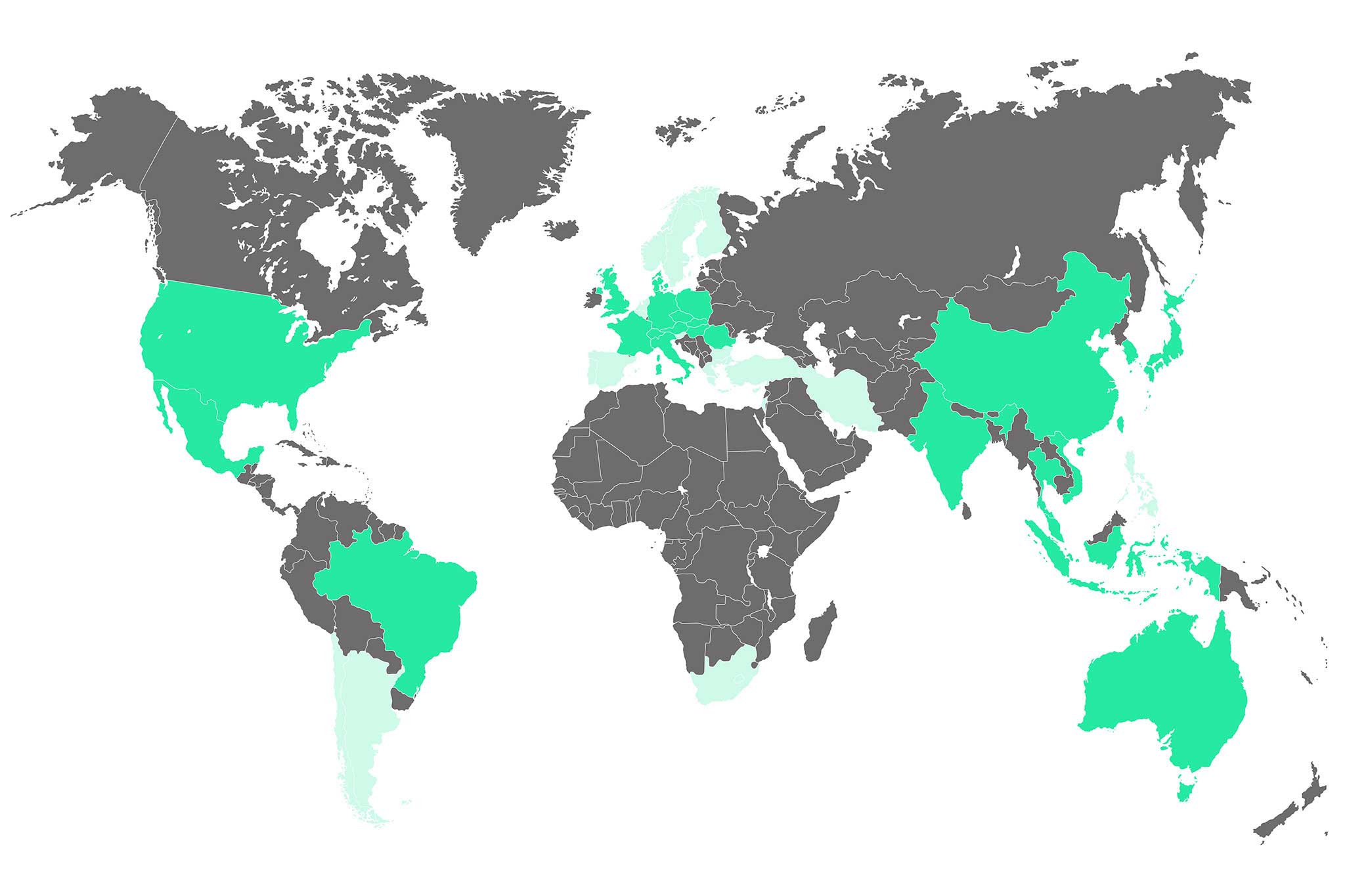

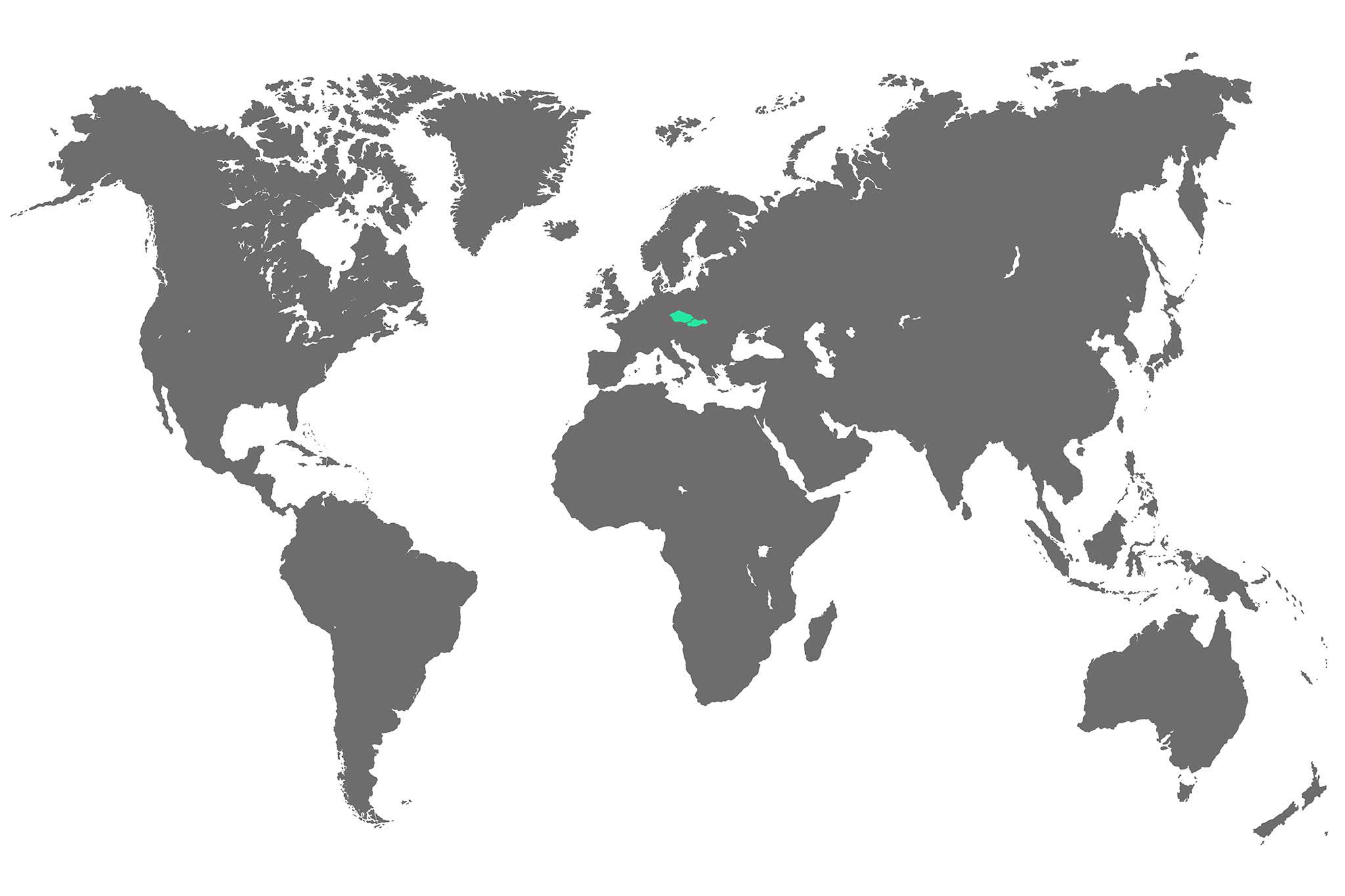

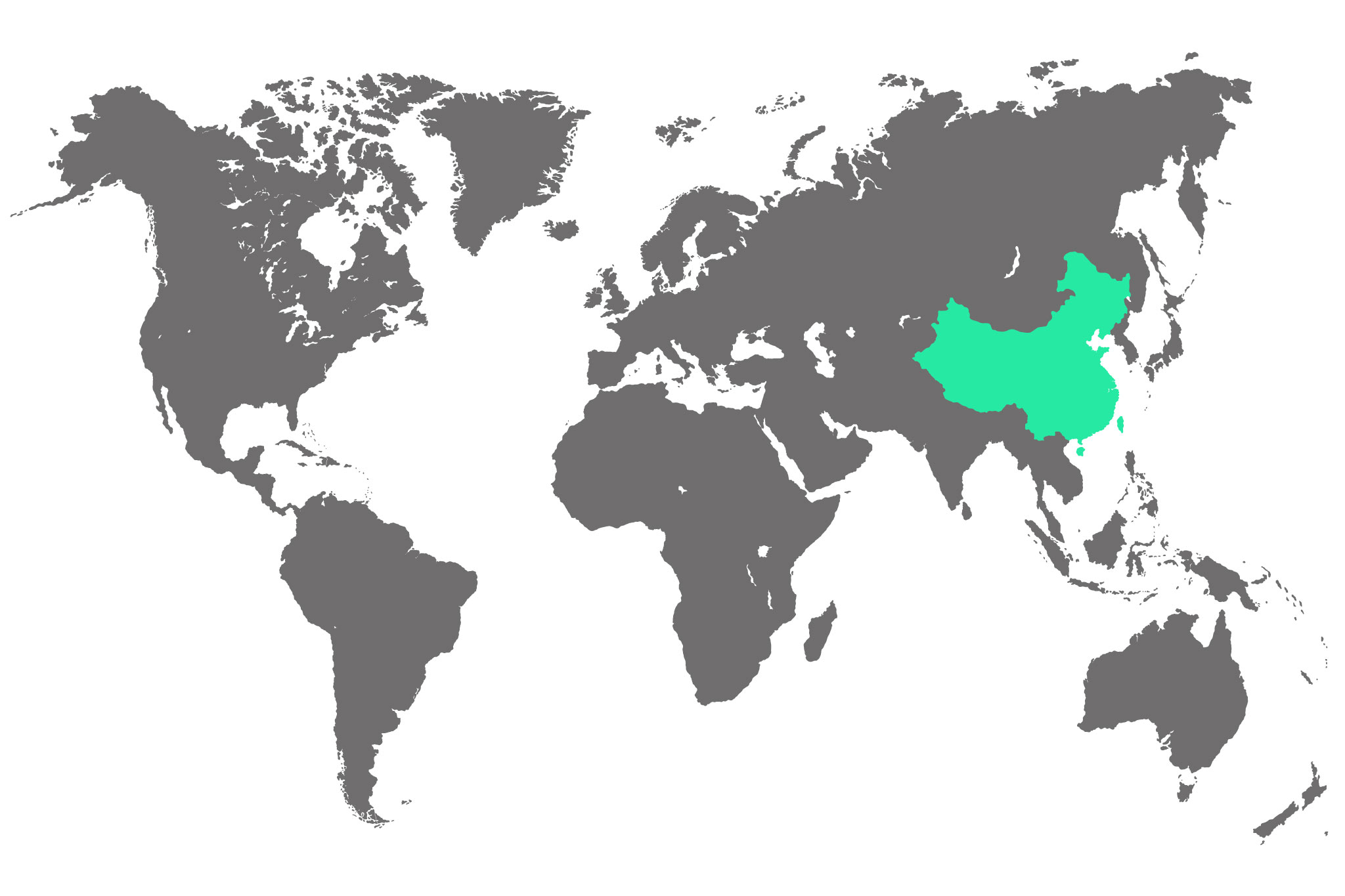

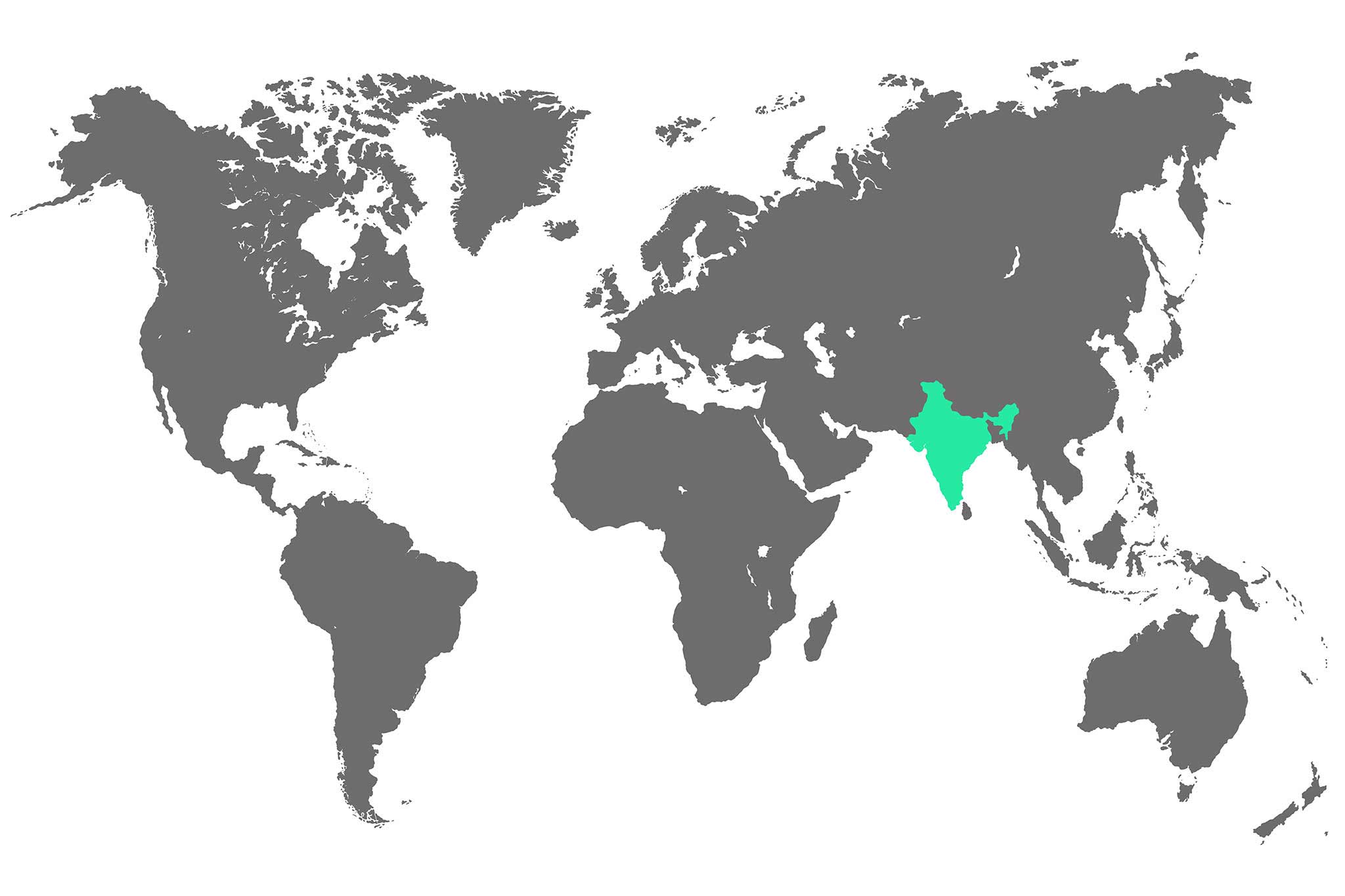

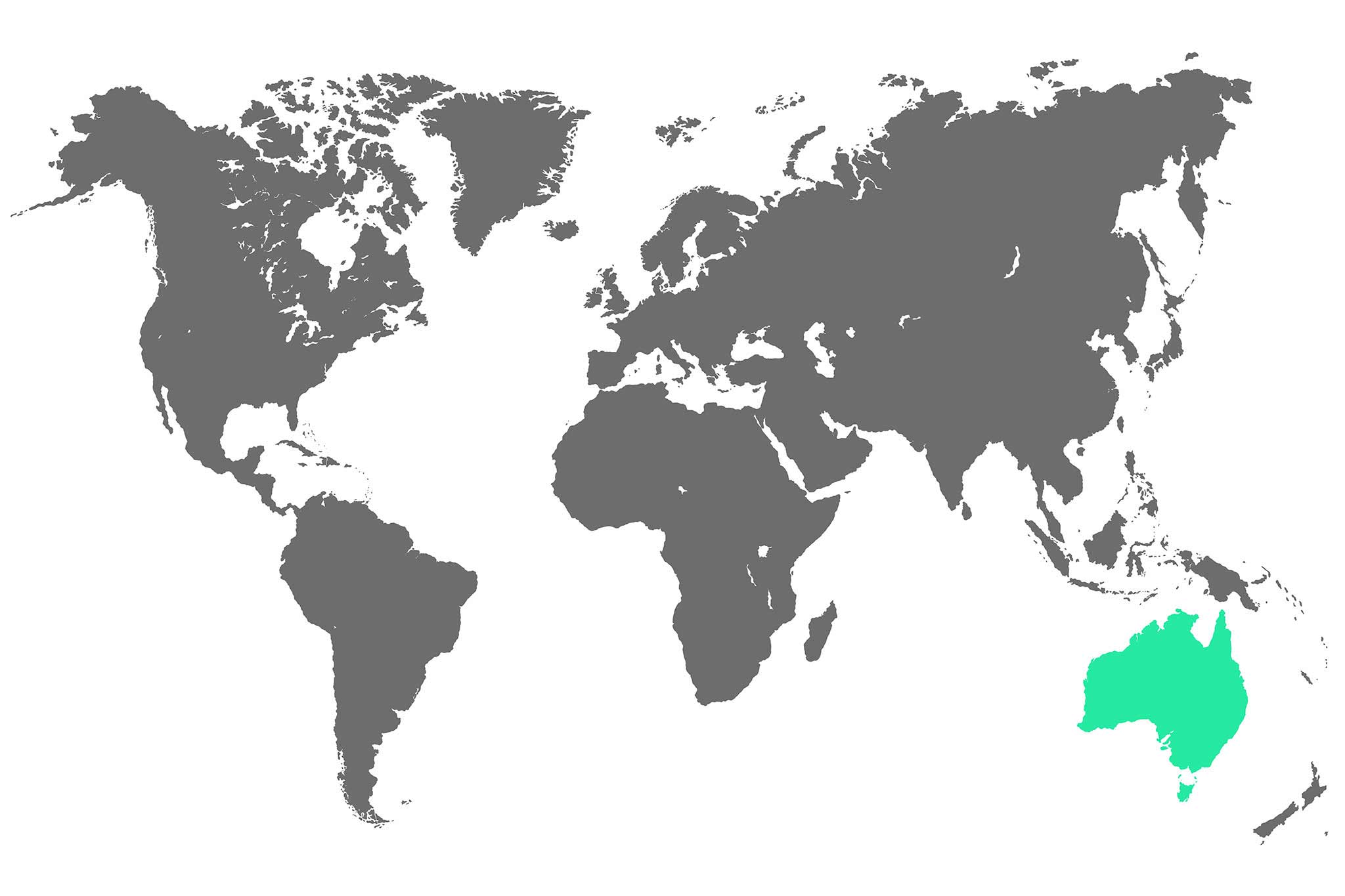

Close to the customer - worldwide

The close dialogue with customers and therefore also the early identification of technological requirements and approaches for innovations are an essential pillar of corporate policy for MAPAL. Accordingly, MAPAL is represented directly with production subsidiaries and sales subsidiaries in 25 countries. As such, short distances, personal contacts and long-term partnerships are possible. Along with its subsidiaries, MAPAL products are available

in 19 further countries via sales representatives.

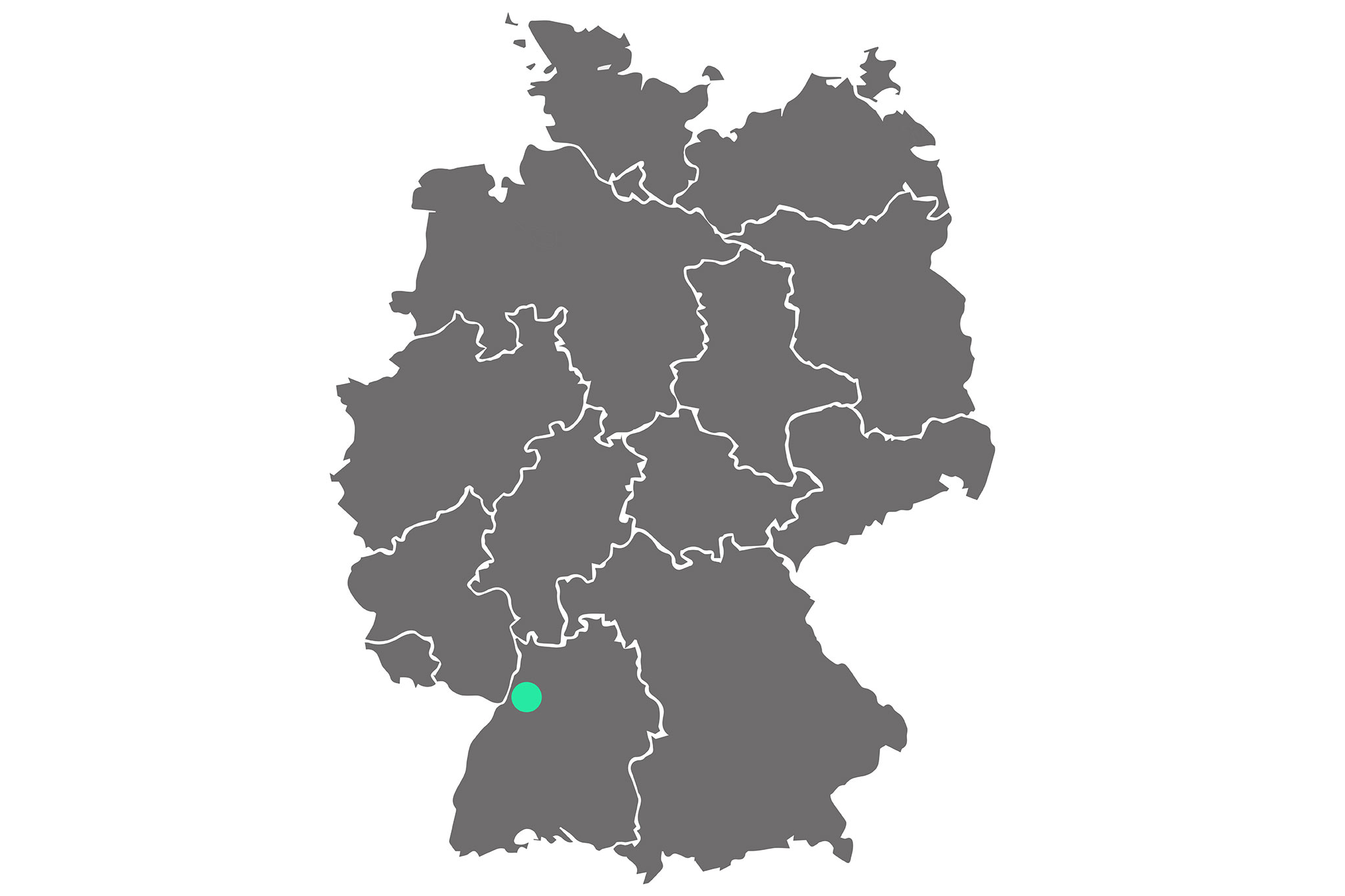

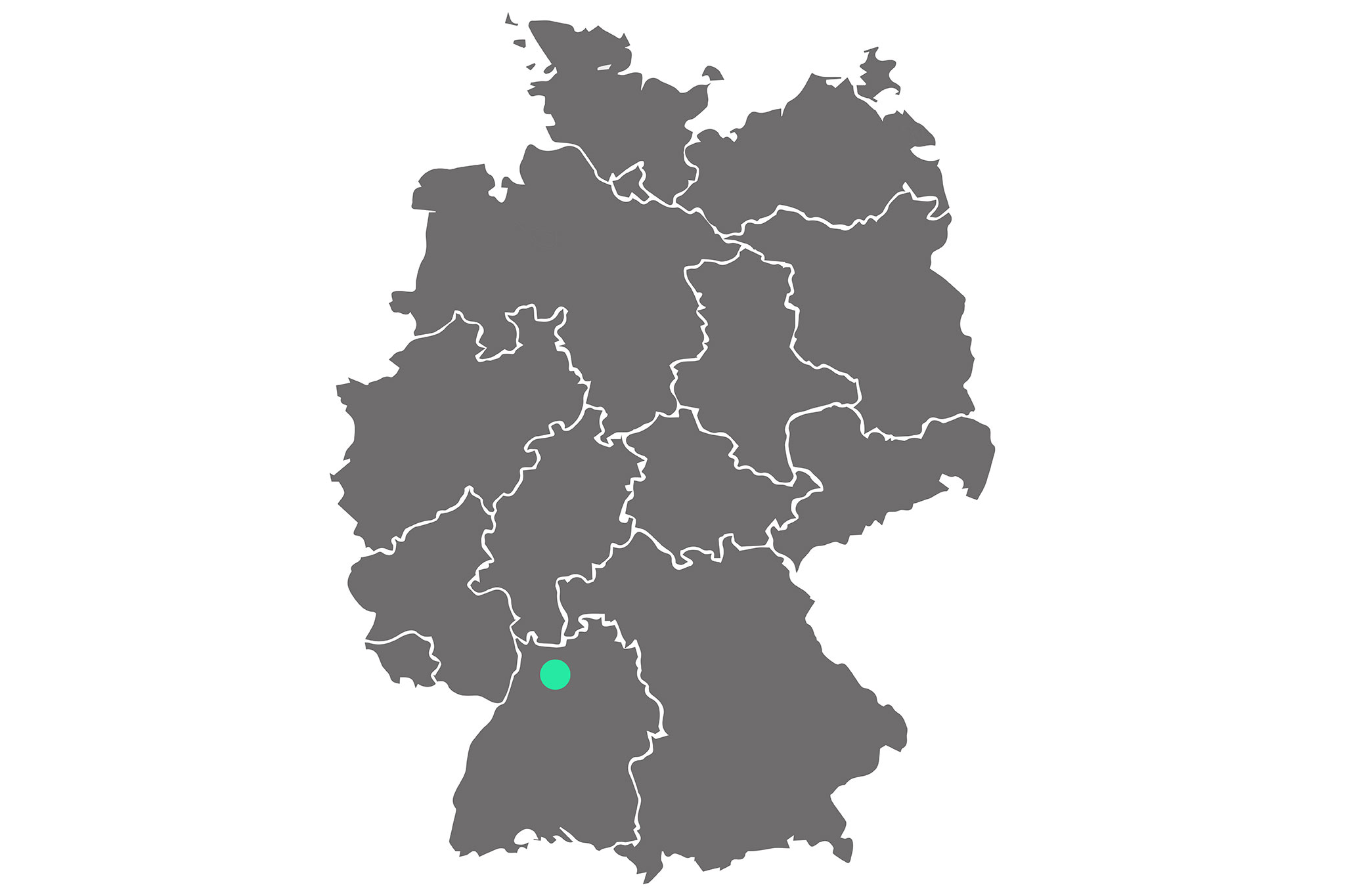

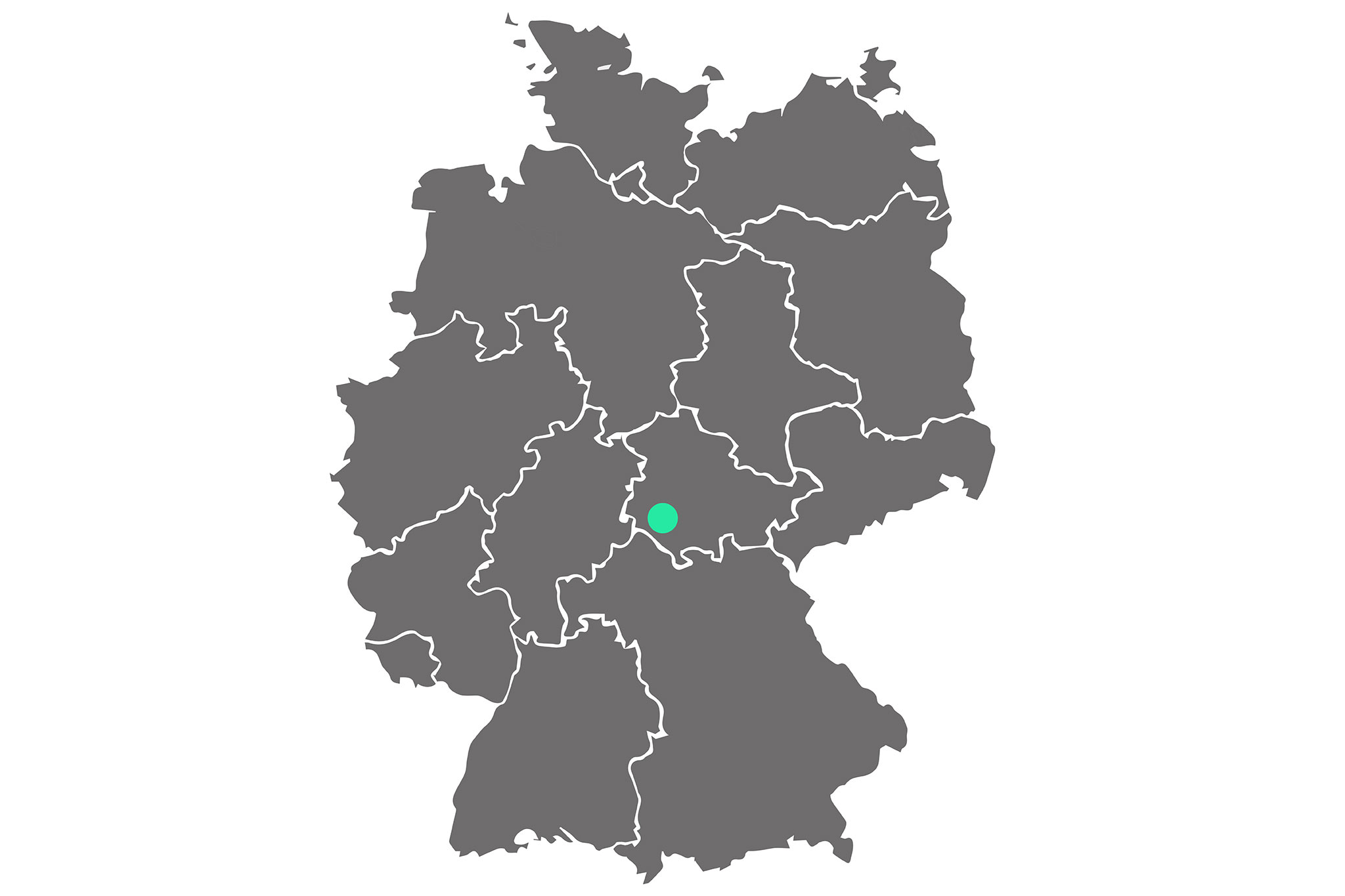

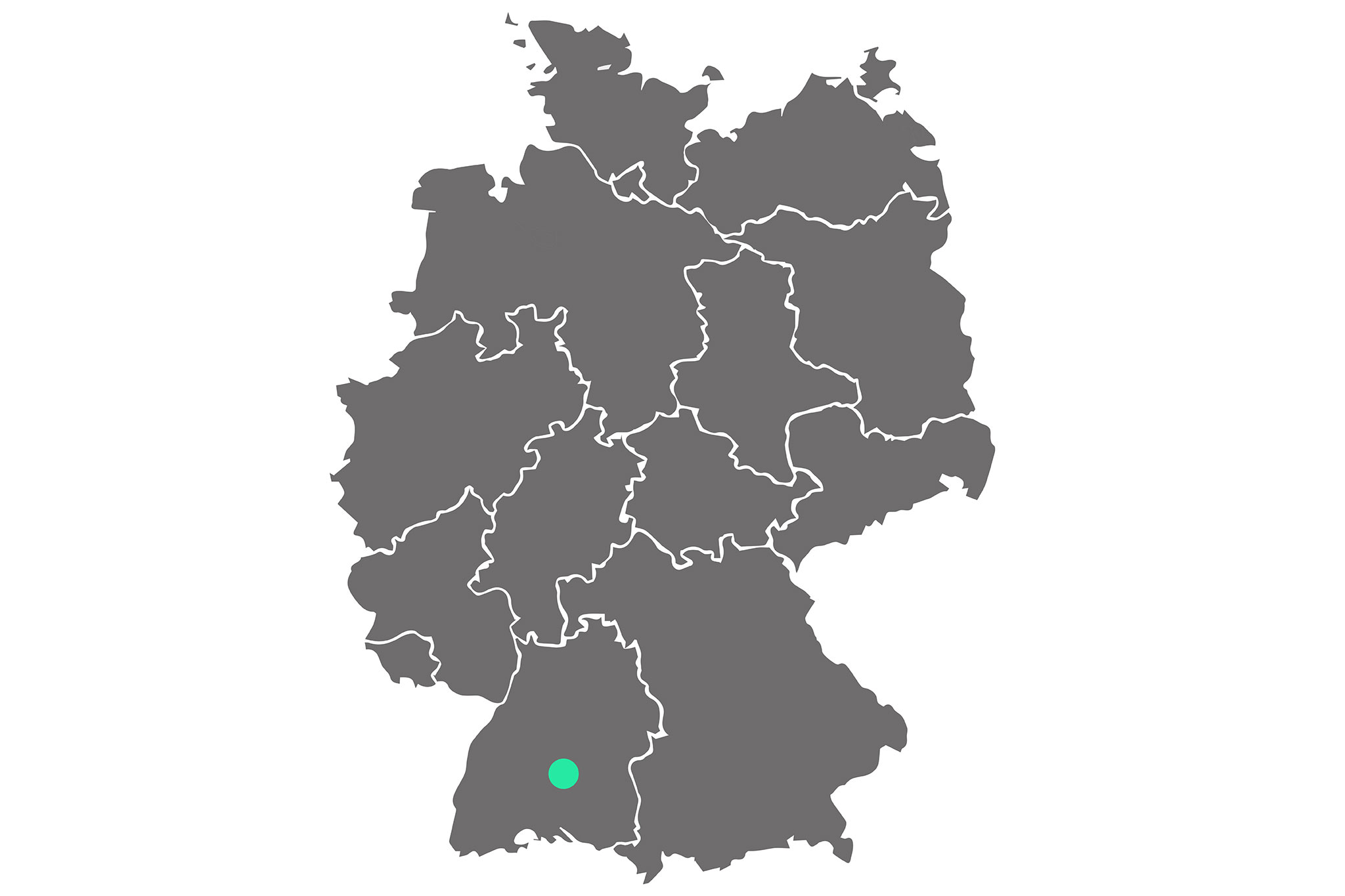

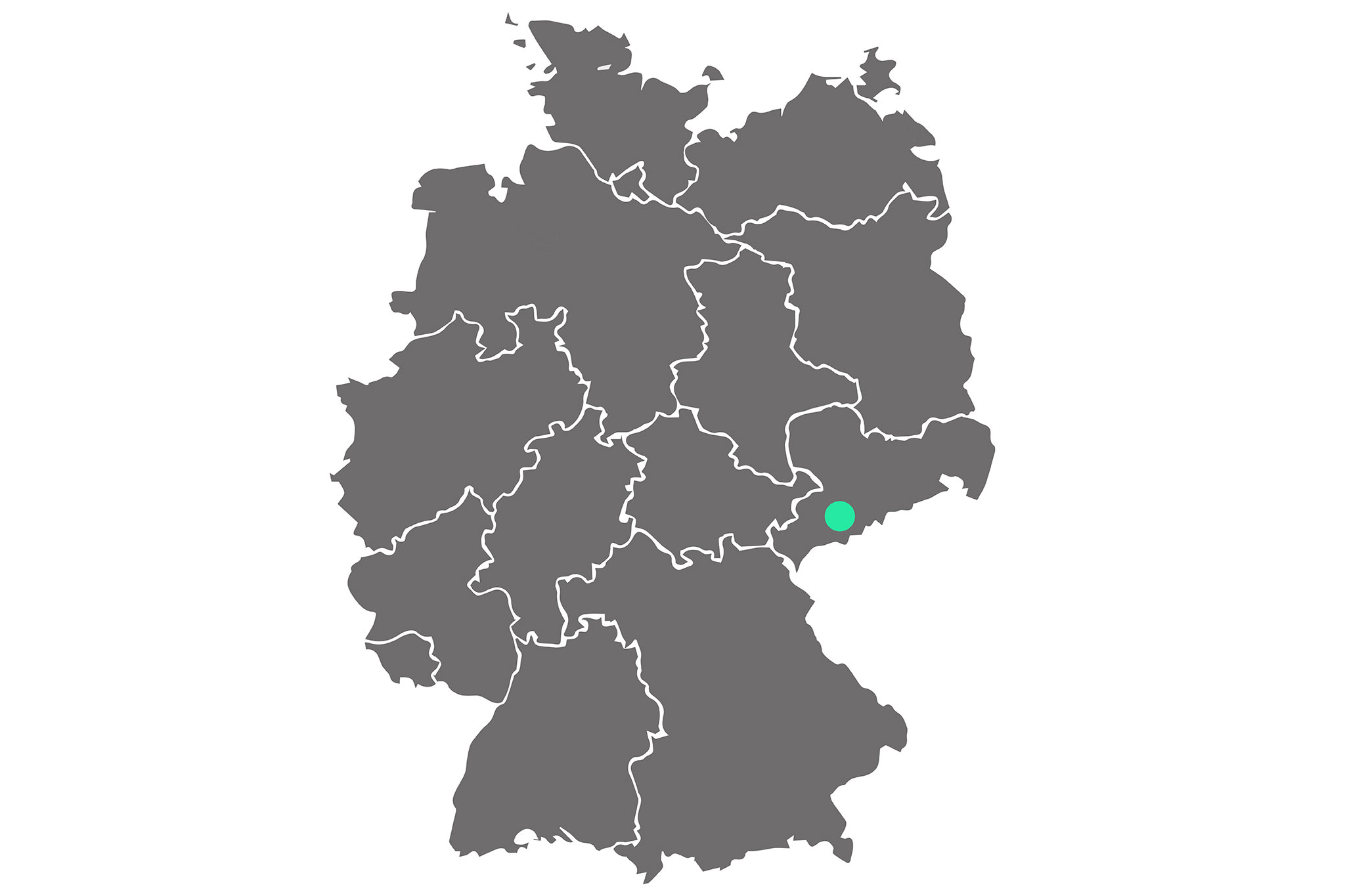

In addition to the headquarters of the MAPAL Group in Aalen, there are eight further sites in Germany representing technologically leading tool solutions. The centres of competence, as acknowledged specialists in their area, safeguard a high standard of production, support regional sales and are responsible for the transfer of knowhow and expertise to the subsidiaries worldwide.

in 19 further countries via sales representatives.

In addition to the headquarters of the MAPAL Group in Aalen, there are eight further sites in Germany representing technologically leading tool solutions. The centres of competence, as acknowledged specialists in their area, safeguard a high standard of production, support regional sales and are responsible for the transfer of knowhow and expertise to the subsidiaries worldwide.

MAPAL in Germany

Sales Representations

Argentina

WSM Herramientas de Precision, S.R.L

Mancicidor 5032

C.P. 2804 Campana

Buenos Aires

Republica Argentina

Phone: +54 911 50023763, +54 9 351 3928093

E-Mail: daniel.stephan@wsm-srl.com.ar, javier.molina@wsm-srl.com.ar

http://www.wsm-srl.com.ar/

Mancicidor 5032

C.P. 2804 Campana

Buenos Aires

Republica Argentina

Phone: +54 911 50023763, +54 9 351 3928093

E-Mail: daniel.stephan@wsm-srl.com.ar, javier.molina@wsm-srl.com.ar

http://www.wsm-srl.com.ar/

Belgium

| KOMET R. Cools N.V. Boomsesteenweg 454-456 2020 Antwerpen Phone: +32 3 2379837 Fax: +32 3 2163316 Email: info@komet.be |

OPTIMAX Hoge Haar 25 2970 Schilde Phone: +32 3 3853897 Email: sales@optimax.tools http://www.optimax.tools |

Bulgaria

Hofmann Consult Bulgaria EOOD

Okolovrasten pat 66

1415 Sofia

Bulgaria

Phone: +359 2 9609010

Fax.: +359 2 9609011

E-Mail: office@hofmannconsult.net

https://www.hofmannconsult.net/

Okolovrasten pat 66

1415 Sofia

Bulgaria

Phone: +359 2 9609010

Fax.: +359 2 9609011

E-Mail: office@hofmannconsult.net

https://www.hofmannconsult.net/

Denmark

EDECO TOOL APS

Naverland 2

2600 Glostrup

Danmark

Phone: +45 7060 2029

email: info@edeco.dk

https://edeco.dk/

Finland

Maanterä Oy

Keinumäenkuja 2

PL 70

01511 Vantaa

Phone: +358 9 615322

E-Mail: maantera@maantera.fi

http://www.maantera.fi/

Keinumäenkuja 2

PL 70

01511 Vantaa

Phone: +358 9 615322

E-Mail: maantera@maantera.fi

http://www.maantera.fi/

Netherlands

Laagland B.V.

Dalkruidbaan 149

2908 KC Capelle aan den IJssel

Phone: +31 10 2922222

E-Mail: mapal@laagland.nl

http://www.laagland.nl/

Dalkruidbaan 149

2908 KC Capelle aan den IJssel

Phone: +31 10 2922222

E-Mail: mapal@laagland.nl

http://www.laagland.nl/

Norway

A.S. Nor-Swiss

Rybenstubben 5

0679 Oslo

Phone: +47 2324 1020

E-Mail: norswiss@norswiss.no

http://www.norswiss.no/

Rybenstubben 5

0679 Oslo

Phone: +47 2324 1020

E-Mail: norswiss@norswiss.no

http://www.norswiss.no/

Portugal

Alamo-Ferramentas Unipessoal Lda

Mr. Rui Moreira

R da Variante 120, Marco da Raposa

ZI Águeda Norte

3750-753 Travassô

Phone: +351 936 959 556

E-Mail: rui.moreira@sapo.pt

Mr. Rui Moreira

R da Variante 120, Marco da Raposa

ZI Águeda Norte

3750-753 Travassô

Phone: +351 936 959 556

E-Mail: rui.moreira@sapo.pt

Sweden

Colly Verkstadsteknik AB

P.O. Box 6042

16406 Kista

Phone: +46 8 7030100

E-Mail: info@vt.colly.se

http://www.collyverkstadsteknik.se/

P.O. Box 6042

16406 Kista

Phone: +46 8 7030100

E-Mail: info@vt.colly.se

http://www.collyverkstadsteknik.se/

Switzerland

REALTOOLS AG/SA

Industriestr. 28

2555 Brügg

Phone: +41 32 3744010

E-Mail: info@realtools.ch

http://www.realtools.ch/

Industriestr. 28

2555 Brügg

Phone: +41 32 3744010

E-Mail: info@realtools.ch

http://www.realtools.ch/

Slovenia

MB-Naklo trgovsko podjetje d.o.o.

Ul. Toma Zupana 16

4202 Naklo

Phone: +386 4 2771700

E-Mail: info@mb-naklo.si

http://www.mb-naklo.si/

Ul. Toma Zupana 16

4202 Naklo

Phone: +386 4 2771700

E-Mail: info@mb-naklo.si

http://www.mb-naklo.si/

Spain

AYMA HERRAMIENTAS S.L.

Bº Sta. Lucía s/n

20709 Ezkio-Itsaso (Gipuzkoa)

Phone: +34 943 729070

E-Mail: ayma@ayma.es

http://www.ayma.es/

Bº Sta. Lucía s/n

20709 Ezkio-Itsaso (Gipuzkoa)

Phone: +34 943 729070

E-Mail: ayma@ayma.es

http://www.ayma.es/

South Africa

Spectra Carbide Tooling Technology

24 Desmond Street Korsten

6056 Port Elizabeth

Phone: +27 41 4031500

E-Mail: spectra@spectra-sa.co.za

http://www.spectra-sa.co.za/

24 Desmond Street Korsten

6056 Port Elizabeth

Phone: +27 41 4031500

E-Mail: spectra@spectra-sa.co.za

http://www.spectra-sa.co.za/

Taiwan

Hung Chih Limited Company

No. 35, Chung Cheng Rd.

Tainan

Phone: +886 6 2252216

E-Mail: hclhsu@hungchih.com

No. 35, Chung Cheng Rd.

Tainan

Phone: +886 6 2252216

E-Mail: hclhsu@hungchih.com

Turkey

AK MAKİNA LTD ŞTİ

İstanbul Anadolu Yakası OSB

Aydınlı Mah. 6. Sok. No: 9

34953 Tuzla / İstanbul

Phone: +90 216 4707070

E-Mail: akmakina@akmakina.com

http://www.akmakina.com/

İstanbul Anadolu Yakası OSB

Aydınlı Mah. 6. Sok. No: 9

34953 Tuzla / İstanbul

Phone: +90 216 4707070

E-Mail: akmakina@akmakina.com

http://www.akmakina.com/