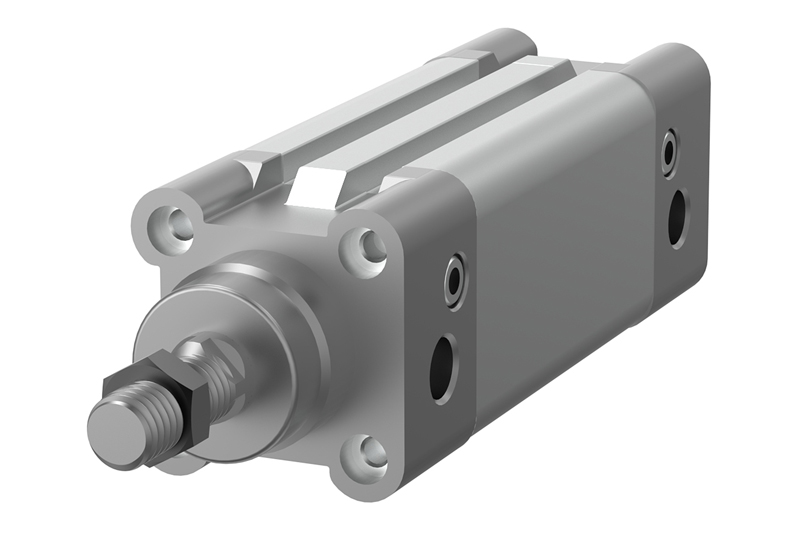

Pneumatik

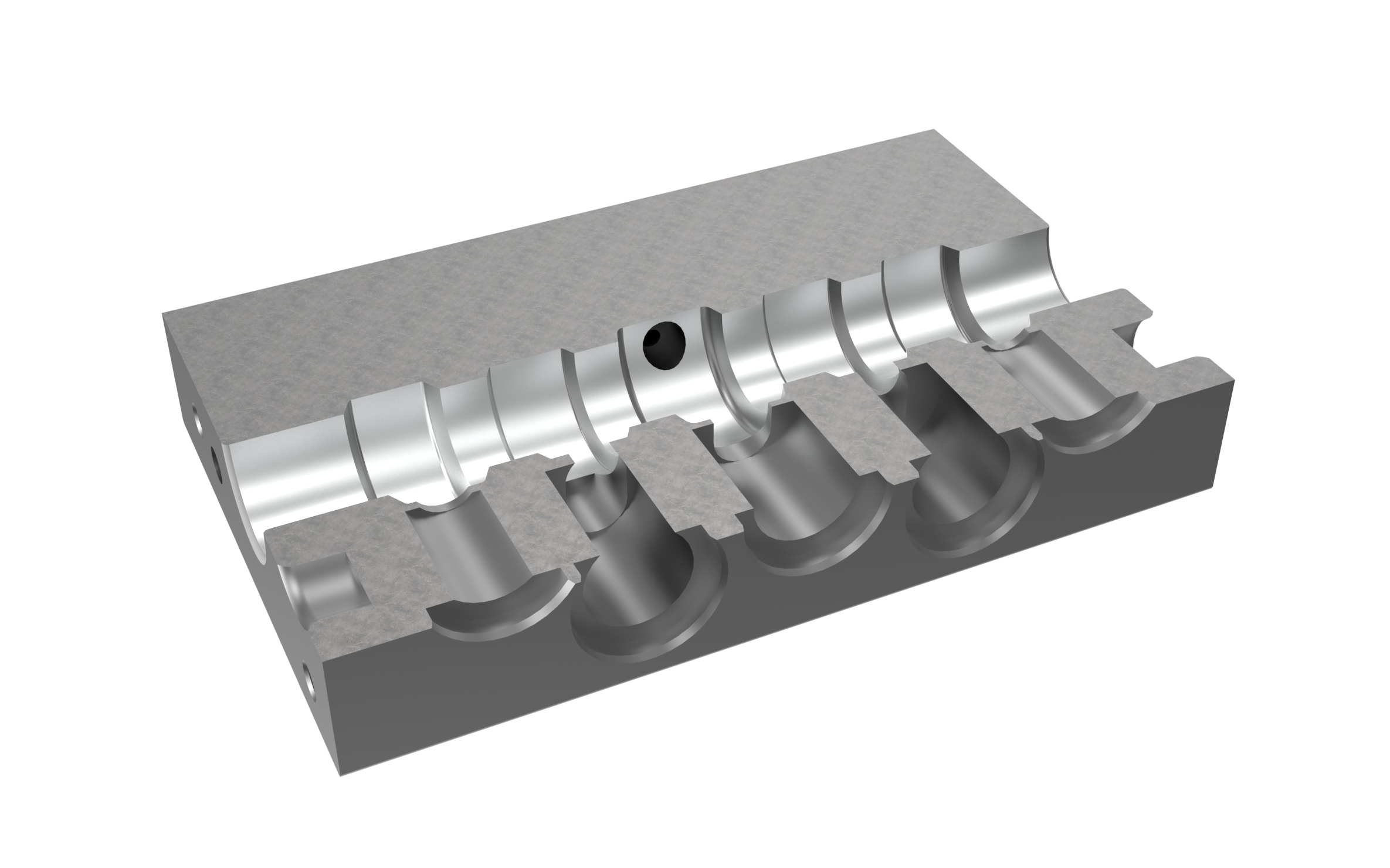

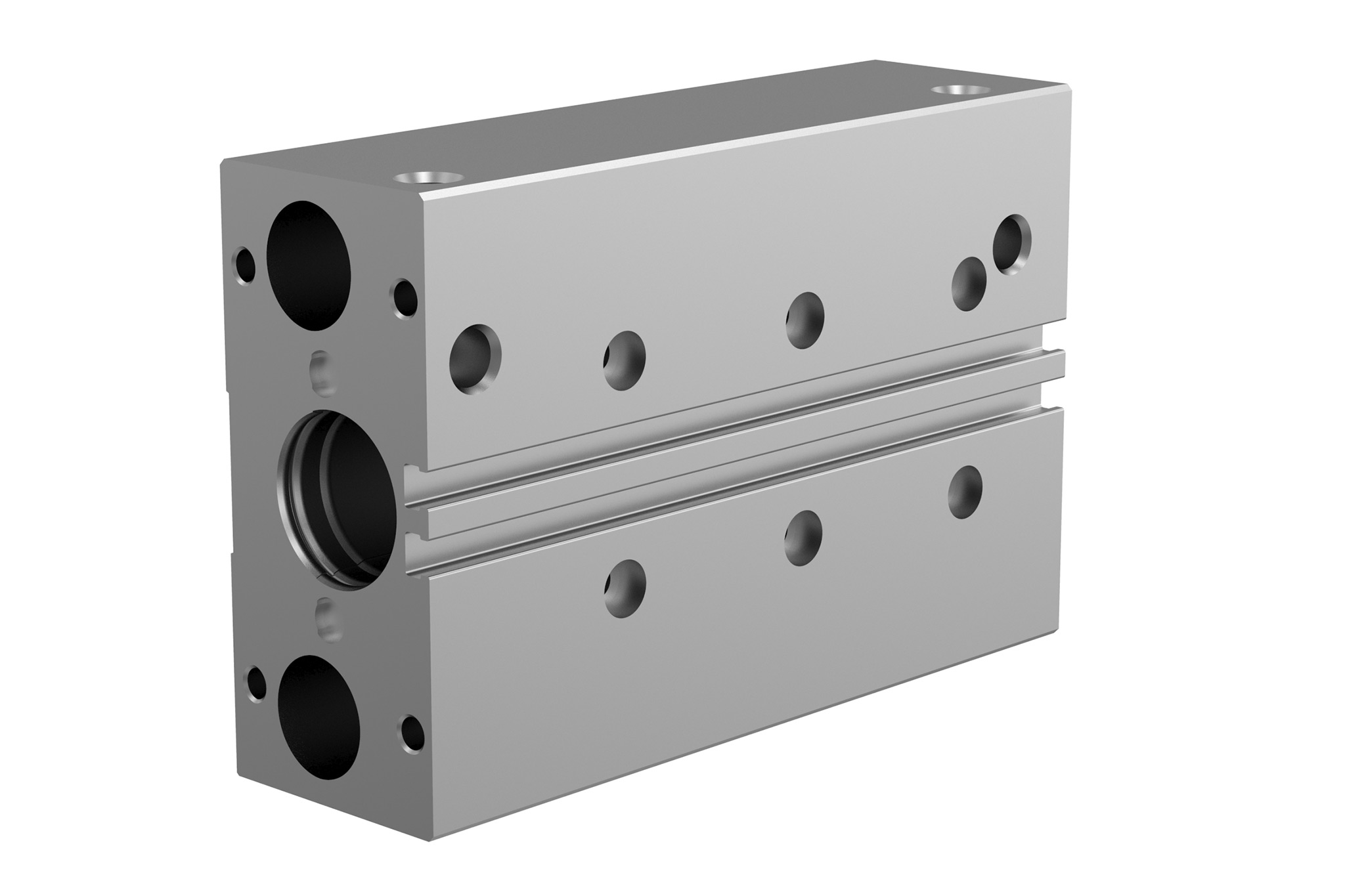

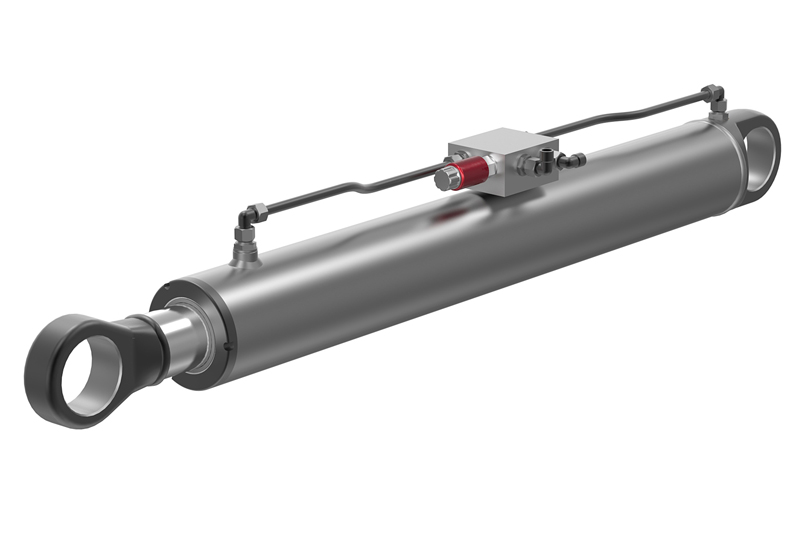

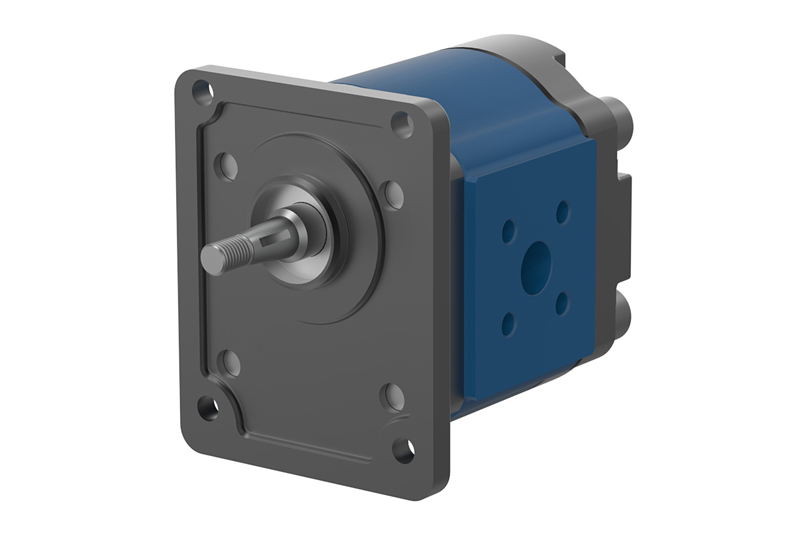

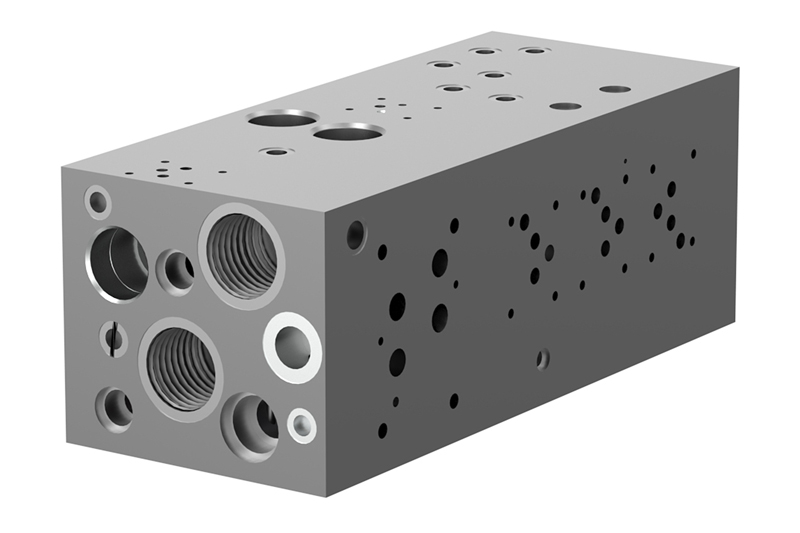

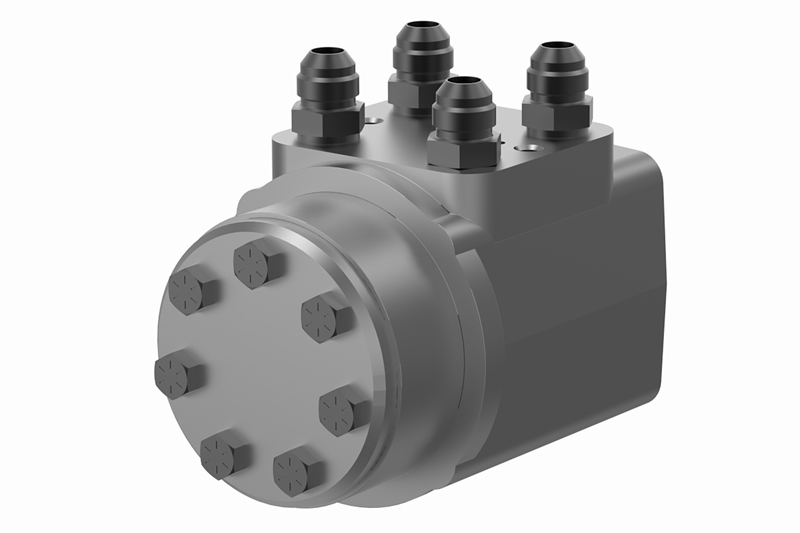

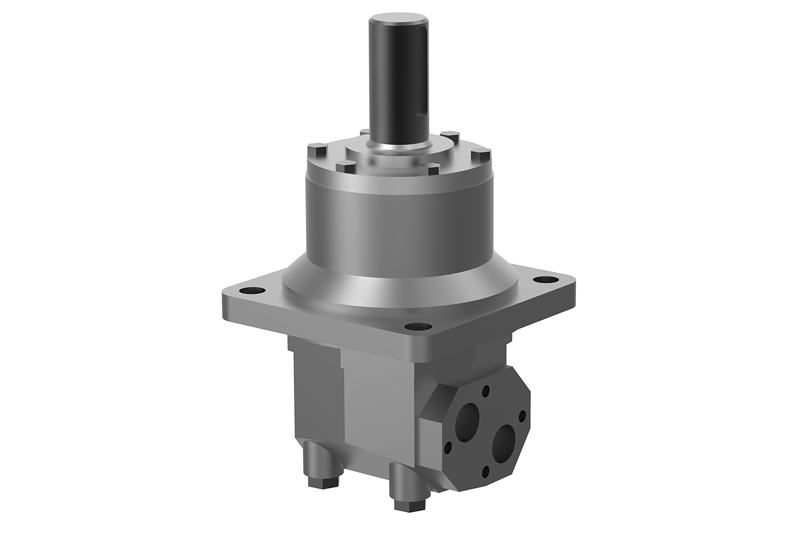

Für die in der Fluidtechnik oft eingesetzten Werkstoffe Gusseisen, Stahl, rostfreie Stähle und Nichteisenmetalle bietet MAPAL durch eine große Kompetenz sowohl in der Bohrungsbearbeitung als auch in Fräsanwendungen wirtschaftliche Prozesslösungen an. Insbesondere bei anspruchsvollen Bearbeitungen für Hydraulik- und Pneumatikteile in unterschiedlichen Dimensionen setzen Kunden seit Jahren auf die Expertise von MAPAL.

Weitere Werkzeughighlights

Weitere Lösungen in der Fluidtechnik

MAPAL unterstützt bei der Komplettbearbeitung weiterer Fluidtechnik-Komponenten in fast allen Bauteildimensionen mit leistungsfähigen Lösungen für funktionsrelevante Zerspanungsanforderungen.