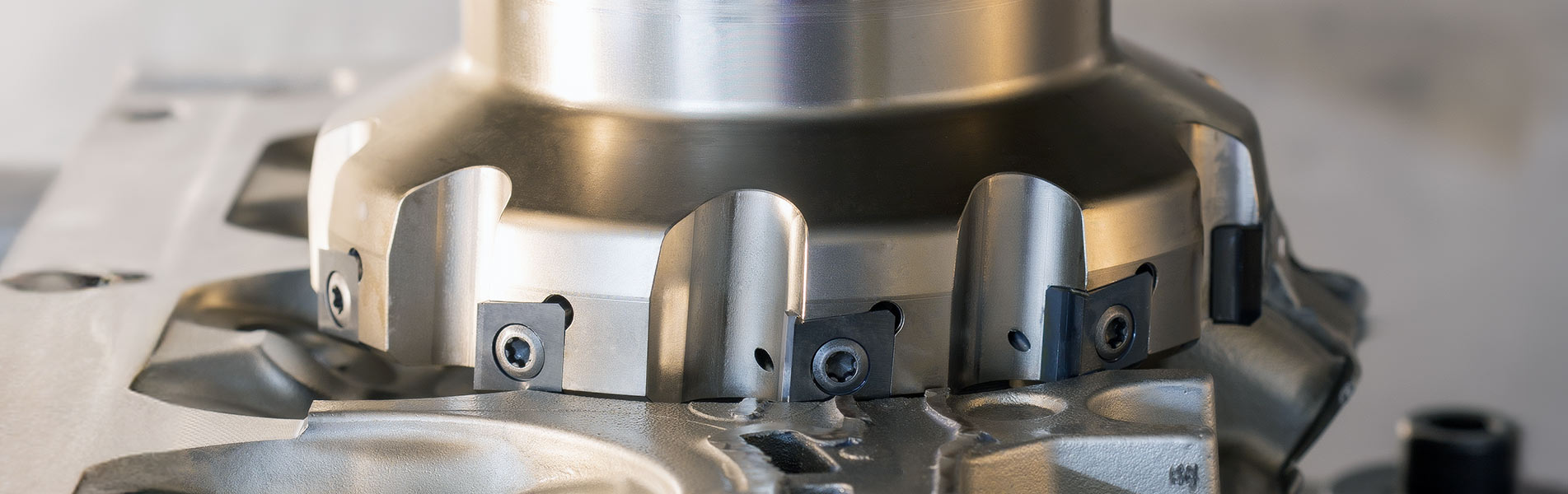

NeoMill®-Alu-Rough

Une puissance maximale pour l'ébauche de l'aluminium

Avec la fraise à plaquettes amovibles NeoMill-Alu-Rough, MAPAL a conçu une solution puissante pour l'usinage ébauche de composants en aluminium.

The milling tools are tailored specifically to the requirements of the automotive and mechanical

engineering industry. The NeoMill- Alu-Rough boasts maximum effectiveness, including at high chip volumes.

engineering industry. The NeoMill- Alu-Rough boasts maximum effectiveness, including at high chip volumes.

The standard range includes shoulder milling cutters with a single row of inserts with diameters

from 50 to 160 mm. Versions with multiple rows of inserts are available as shell end face milling cutters with diameters of 63, 80 and 100 mm. Customer-specific tool solutions can also be configured – for maximum adjustment to individual manufacturing processes.

from 50 to 160 mm. Versions with multiple rows of inserts are available as shell end face milling cutters with diameters of 63, 80 and 100 mm. Customer-specific tool solutions can also be configured – for maximum adjustment to individual manufacturing processes.

The combination of large chip flutes, tangential indexable inserts and a wide selection of cutting materials (PCD, coated or uncoated carbide, CVD diamond) ensure reliable chip removal and high flexibility.

The NeoMill-Alu-Rough highlights MAPAL’s expertise in aluminium machining and adds a future-forward solution for maximum productivity to the existing portfolio. The roughing cutter is available from autumn 2025.