/Design-ohne-Titel-15-.jpg)

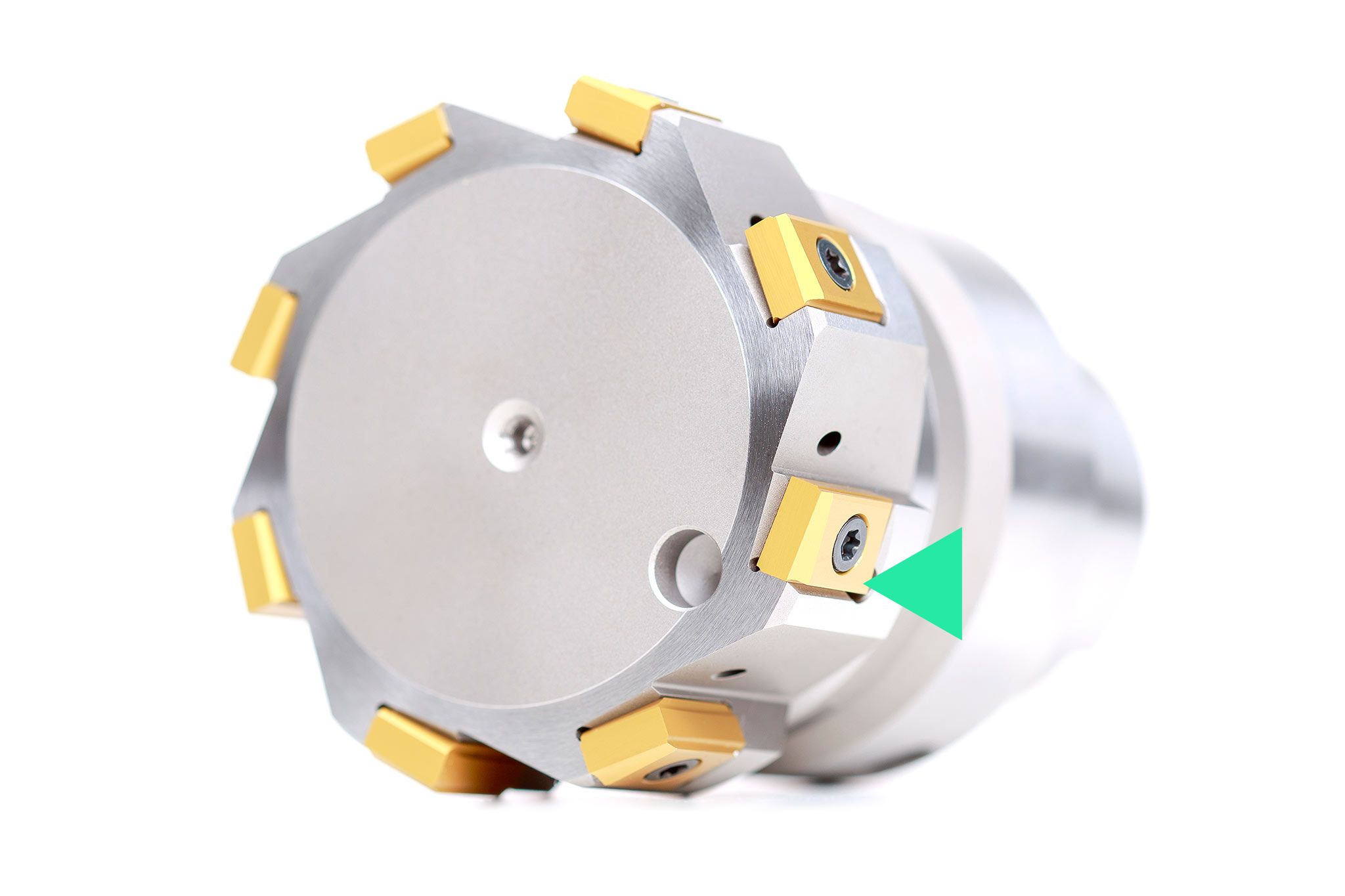

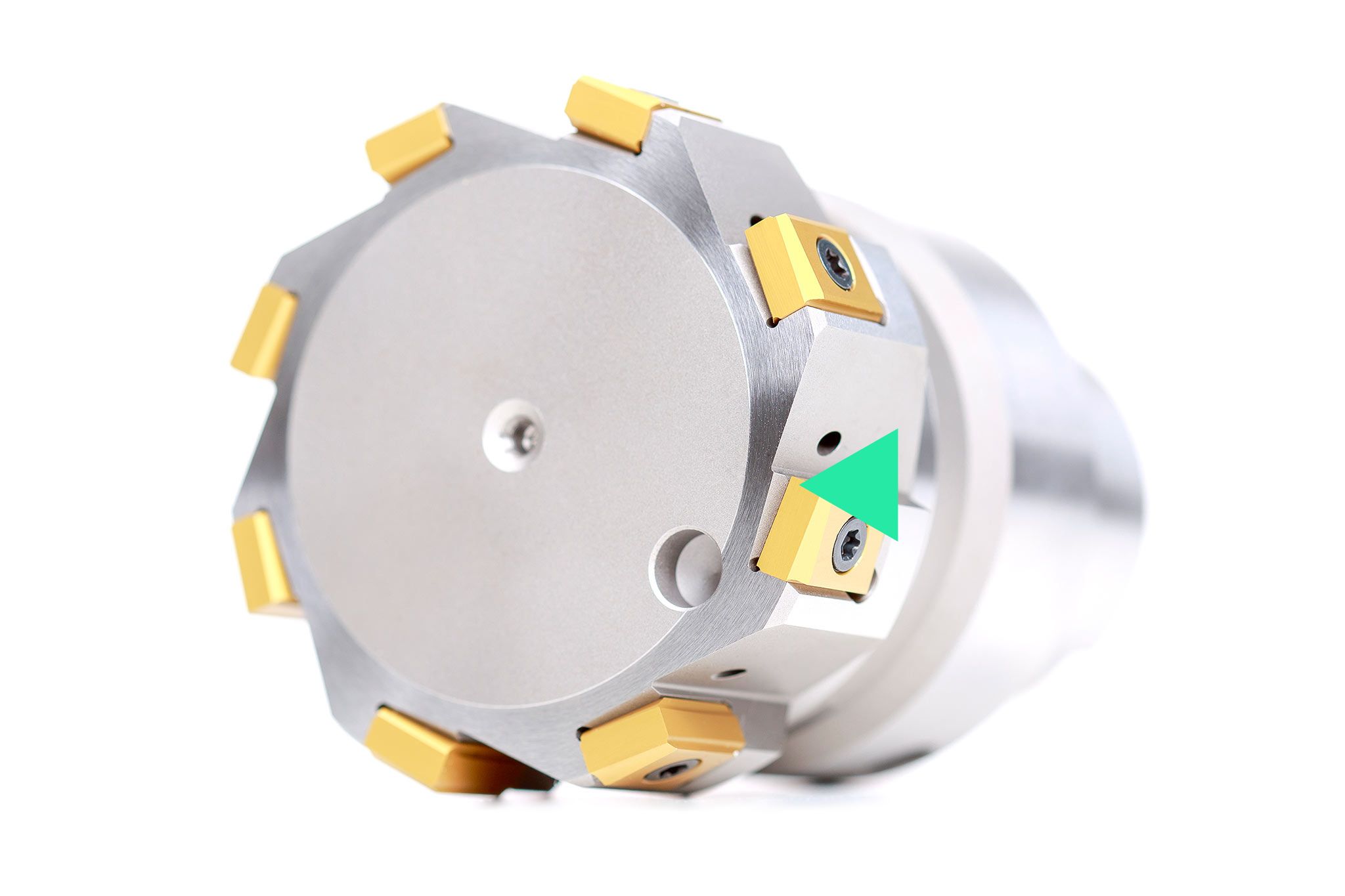

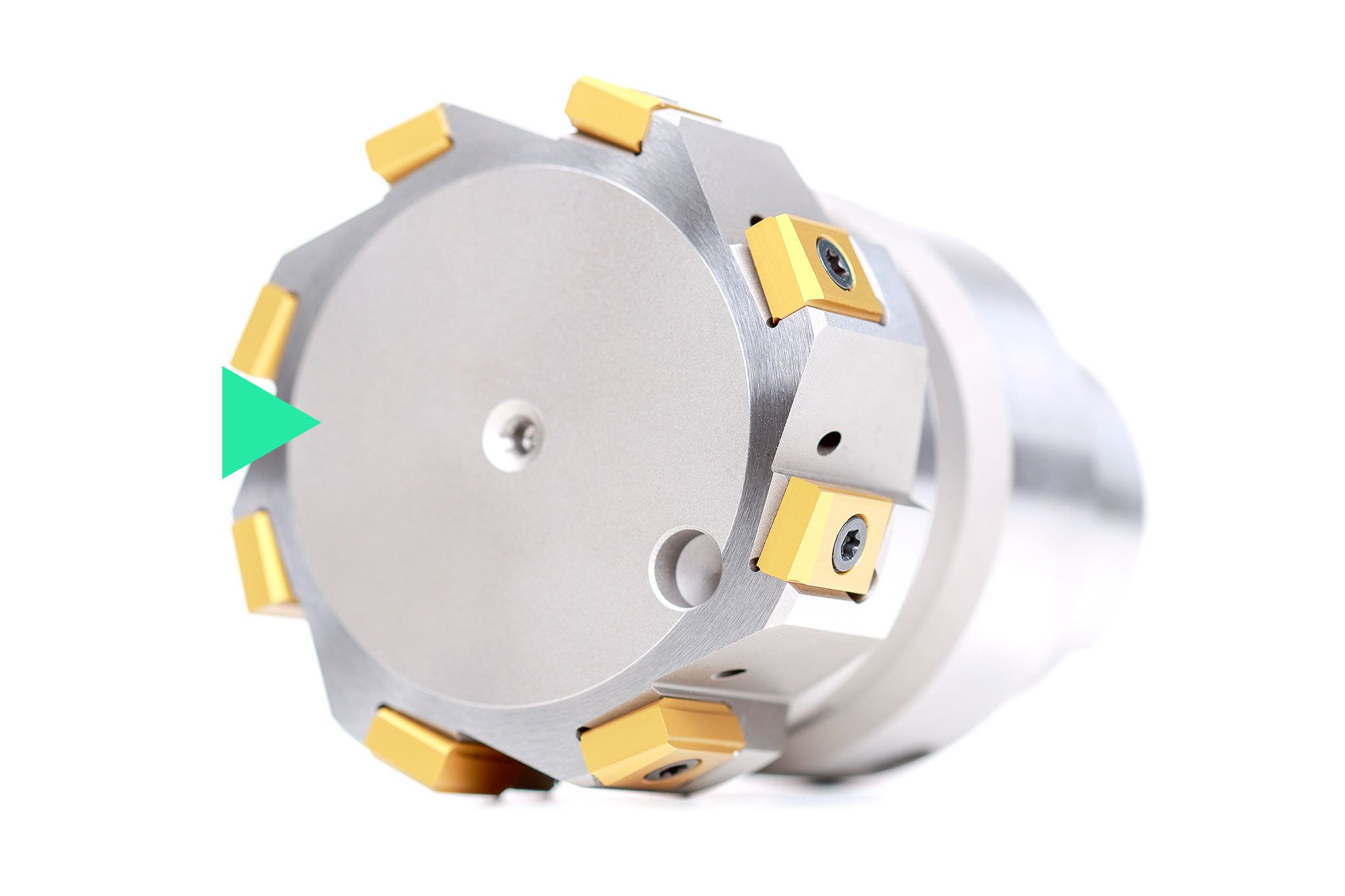

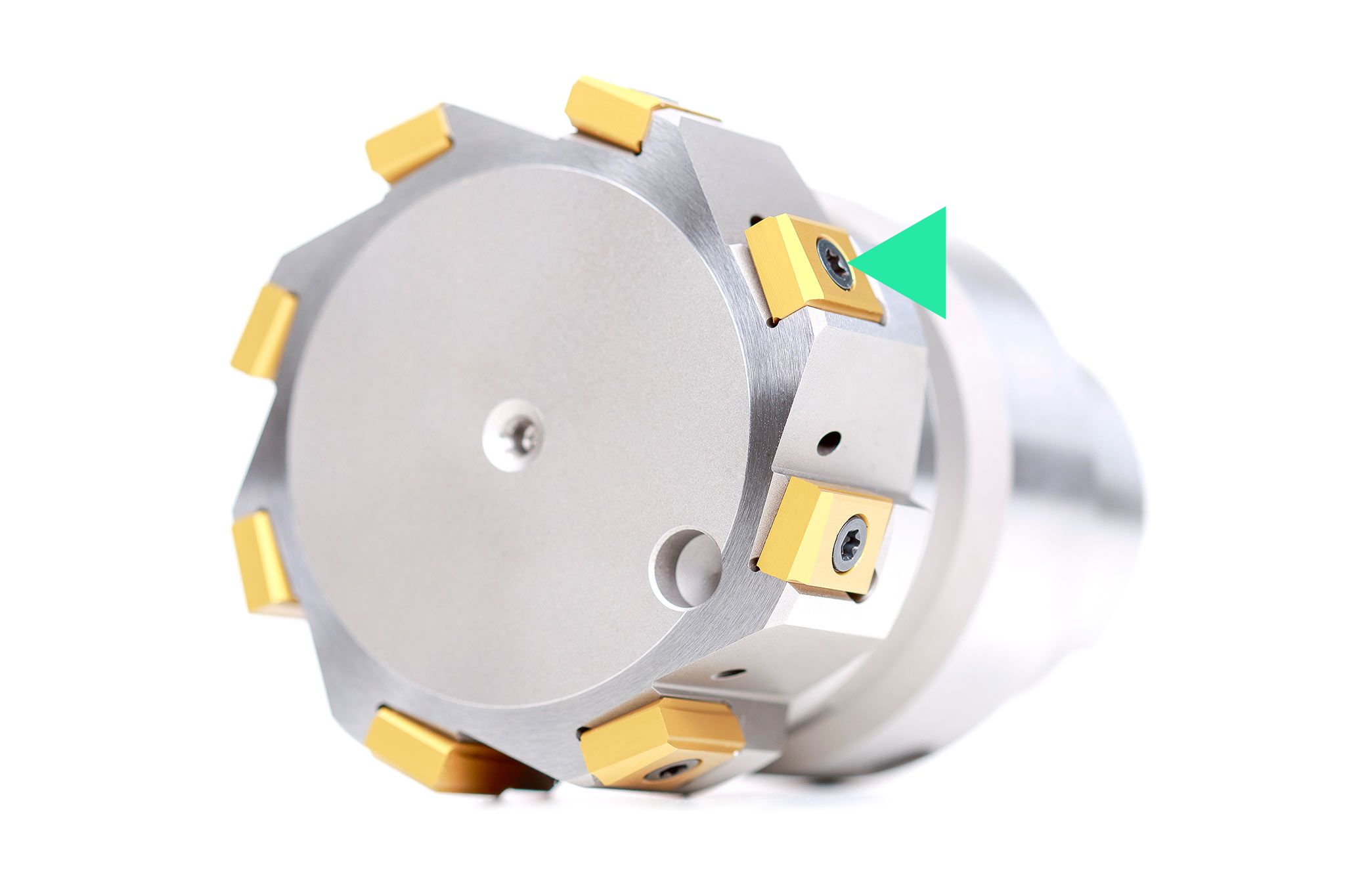

New innovative solutions for the HPR400 system

More productivity and process reliability with four new solutions for the HPR400 system

Complex processes and high quality requirements call for fine machining systems that are

effective, precise and easy to use. With HPR400 and HPR400 plus for ultra-productive reaming of large diameters, MAPAL is meeting precisely these requirements. The multi-bladed tool systems offer the advantage that the inserts with one (HPR400) or four (HPR400 plus) cutting edges can be exchanged by the customer directly on site and ensure maximum accuracy thanks to high-precision insert seats.

effective, precise and easy to use. With HPR400 and HPR400 plus for ultra-productive reaming of large diameters, MAPAL is meeting precisely these requirements. The multi-bladed tool systems offer the advantage that the inserts with one (HPR400) or four (HPR400 plus) cutting edges can be exchanged by the customer directly on site and ensure maximum accuracy thanks to high-precision insert seats.

With the four new solutions, MAPAL offers vehicle construction and fluid power customers

future-forward tools for demanding machining applications.

future-forward tools for demanding machining applications.