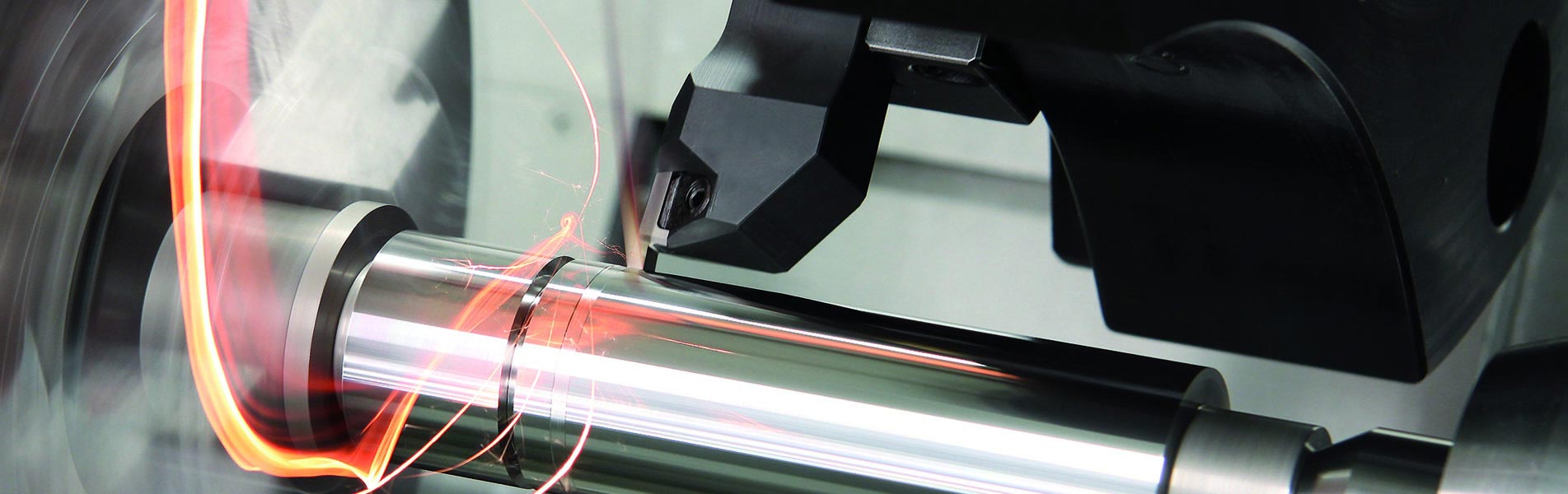

Turning competence - Rational, exact and efficient

Building on extensive experience with the extremely hard cutting materials PcBN and PCD from the area of boring, milling and reaming, MAPAL has also obtained a profound understanding of the turning process. A clear focus is on hard turning.

The range from MAPAL includes special tool solutions for scroll-free turning for complete machining of sealing faces, bearing surfaces and bearing seats on the lathe. This saves time-consuming re-clamping of the workpieces on grinding machines.

To utilise optimally costly PcBN round inserts, MAPAL has developed a system with indexable round inserts that makes simply defined rotation of the insert in the machine possible. In this way the insert can be utilised optimally.

Maximum stability during hard grooving with PcBN is ensured by the grooving system VersaCut. It offers the optimal prerequisites for the special requirements of hard machining.

Today MAPAL offers a broad selection of PCD and PcBN-tipped indexable inserts for hard turning with an extensive selection of cutting materials and cutting edge design.

The range from MAPAL includes special tool solutions for scroll-free turning for complete machining of sealing faces, bearing surfaces and bearing seats on the lathe. This saves time-consuming re-clamping of the workpieces on grinding machines.

To utilise optimally costly PcBN round inserts, MAPAL has developed a system with indexable round inserts that makes simply defined rotation of the insert in the machine possible. In this way the insert can be utilised optimally.

Maximum stability during hard grooving with PcBN is ensured by the grooving system VersaCut. It offers the optimal prerequisites for the special requirements of hard machining.

Today MAPAL offers a broad selection of PCD and PcBN-tipped indexable inserts for hard turning with an extensive selection of cutting materials and cutting edge design.

Product highlights

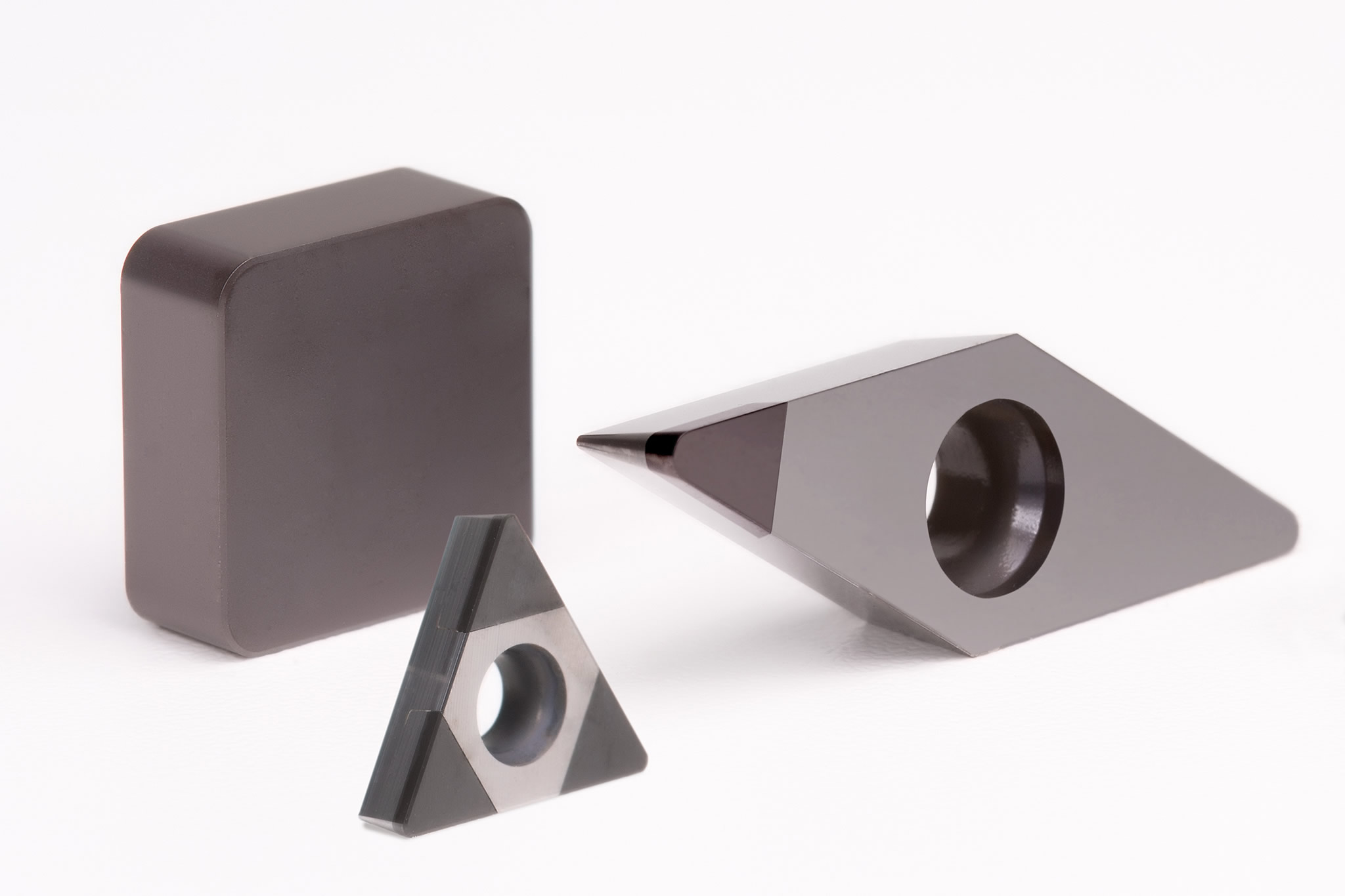

PcBN and PCD indexable inserts

MAPAL has an extensive programme of PCD- and PcBN-tipped indexable inserts for applications with particularly high requirements. The two extremely hard cutting materials polycrystalline diamond (PCD) and polycrystalline cubic boron nitride (PcBN) are indispensable in today's production world.

PcBN indexable inserts

PcBN cutting materials from MAPAL create the ideal prerequisites for cost-effective machining due to their high hot hardness, wear resistance and edge strength.

As a result, the machining times and as a consequence the workpiece costs can be reduced significantly with very good part quality at the same time.

Advantages:

As a result, the machining times and as a consequence the workpiece costs can be reduced significantly with very good part quality at the same time.

Advantages:

- PcBN grades for continuous cut and interrupted cuts

- Large selection of standard geometries and chamfer designs available for optimal tool life and quality

- Multiply tipped designs for greater cost-effectiveness of the tools

- Indexable inserts with high-accuracy G tolerance

PCD Indexable inserts

Due to its hardness and wear resistance even with extremely abrasive materials, high cutting values and tool lives can be achieved with the PCD cutting material.

MAPAL started to rely on PCD during the design of high-performance tools at an early stage and has obtained broad know-how and many years of experience. Different machining tasks with varying requirements in relation to abrasiveness, part geometry and machines are realised with PCD.

Advantages:

MAPAL started to rely on PCD during the design of high-performance tools at an early stage and has obtained broad know-how and many years of experience. Different machining tasks with varying requirements in relation to abrasiveness, part geometry and machines are realised with PCD.

Advantages:

- Highest cutting data and cost-effectiveness

- High accuracy of the cutting edge geometries

- Latest manufacturing methods offer additional possibilities