UNIQ® DirectCool

Decentralised cooling for maximum precision

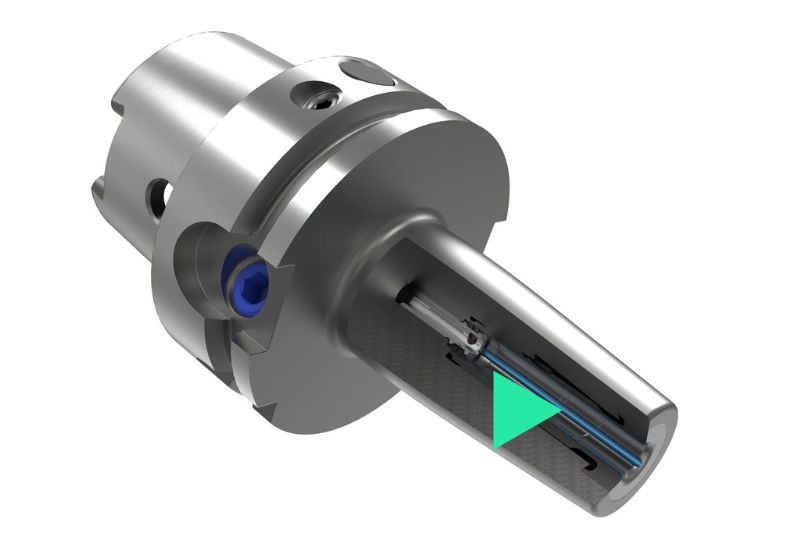

MAPAL is expanding the UNIQ hydraulic chucks to include an innovative cooling technology for higher process reliability and tool life.

With UNIQ DirectCool, MAPAL is bringing a future-forward solution for modern machining

processes onto the market. The new option for hydraulic chucks in the UNIQ series enables precise decentralised cooling along the tool shank to the cutting edge via three integrated

cooling channels. This ensures even temperature distribution, little thermal distortion and low levels of tool wear.

processes onto the market. The new option for hydraulic chucks in the UNIQ series enables precise decentralised cooling along the tool shank to the cutting edge via three integrated

cooling channels. This ensures even temperature distribution, little thermal distortion and low levels of tool wear.

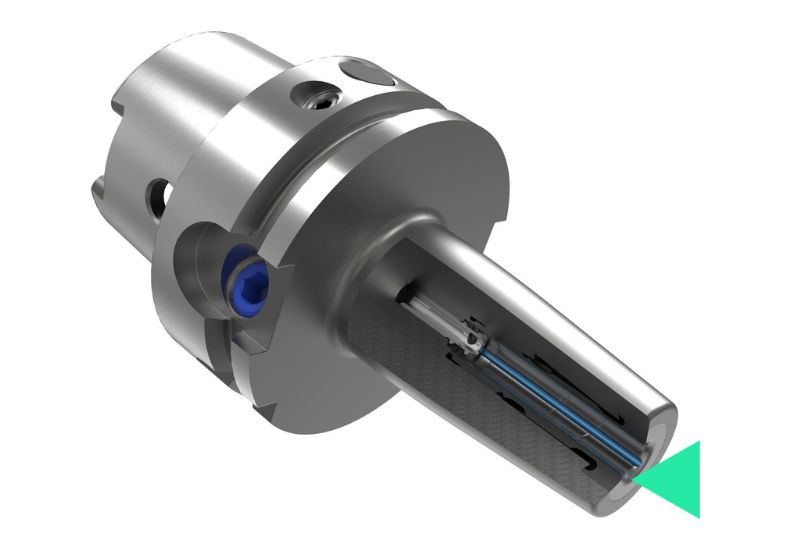

Particularly in boring processes, DirectCool displays its strengths, enabling reliable cooling and

preventing tool breakage with effective chip removal.

preventing tool breakage with effective chip removal.

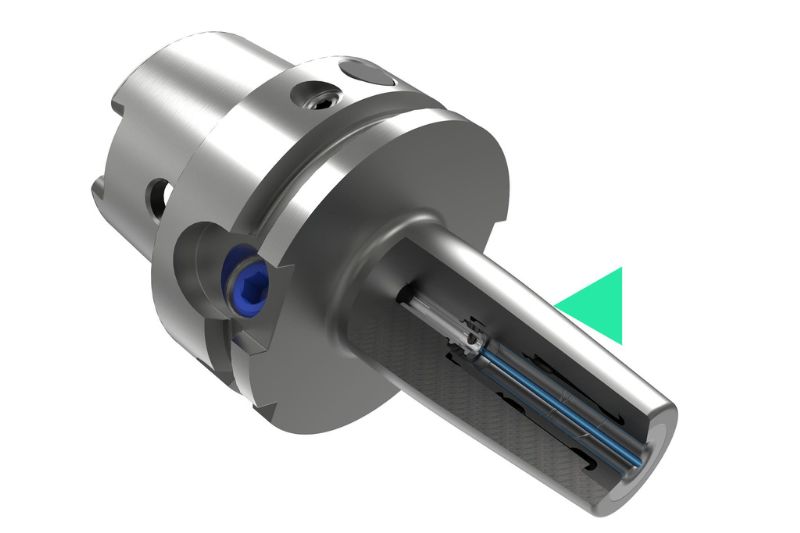

The new technology improves surface quality and boosts process reliability – without adjusting

existing processes. After all, the UNIQ hydraulic chucks already available feature unlimited

DirectCool compatibility. The tool restriction remains unchanged, and no specific shank grooves are necessary.

existing processes. After all, the UNIQ hydraulic chucks already available feature unlimited

DirectCool compatibility. The tool restriction remains unchanged, and no specific shank grooves are necessary.

With its smart cooling channel guidance, UNIQ DirectCool is initially available for UNIQ Mill

Chucks HA and UNIQ DReaM Chucks with 4.5° geometry in diameters from 6 to 32 mm from autumn 2025.

Chucks HA and UNIQ DReaM Chucks with 4.5° geometry in diameters from 6 to 32 mm from autumn 2025.