Vérin pneumatique

Vérin de guidage pneumatique en aluminium AW – Al Mg0,7Si – T66

Situation initiale du client

- Propriétés de dureté variables du matériau de coulée continue

- Moyennes à grandes quantités de pièces

- Fabrication automatisée

- Exigences élevées concernant les composants (forme et position, absence de bavures et surface)

Special features of this solution

- Chip breaker adapted to workpiece material and machining solution → Reliable chip control while machining long-chipping aluminium and varying hardness properties

- Long tool life and consistent quality for automated series production and varying degrees of workpiece material quality thanks to premium PCD tools

- Premachining with solid carbide → Precisely aligned processes from a single source

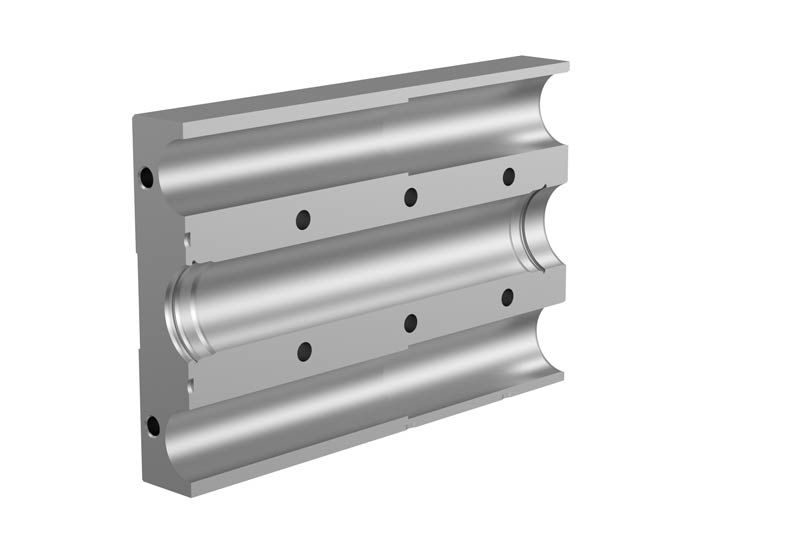

Piston bore

Boring

- PCD boring tool for finishing bearing seats in the pilot bore

- PCD cutting material combined with six inserts

- Short cycle time

- Long tool life

- Very good form and position

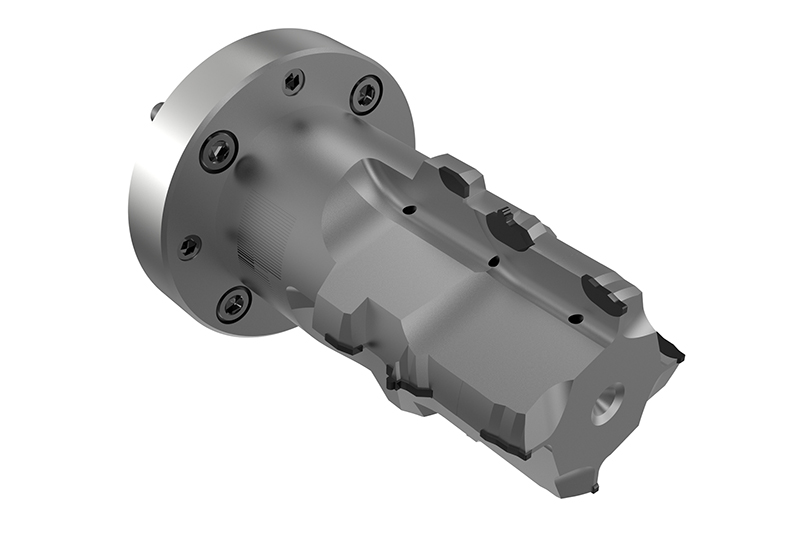

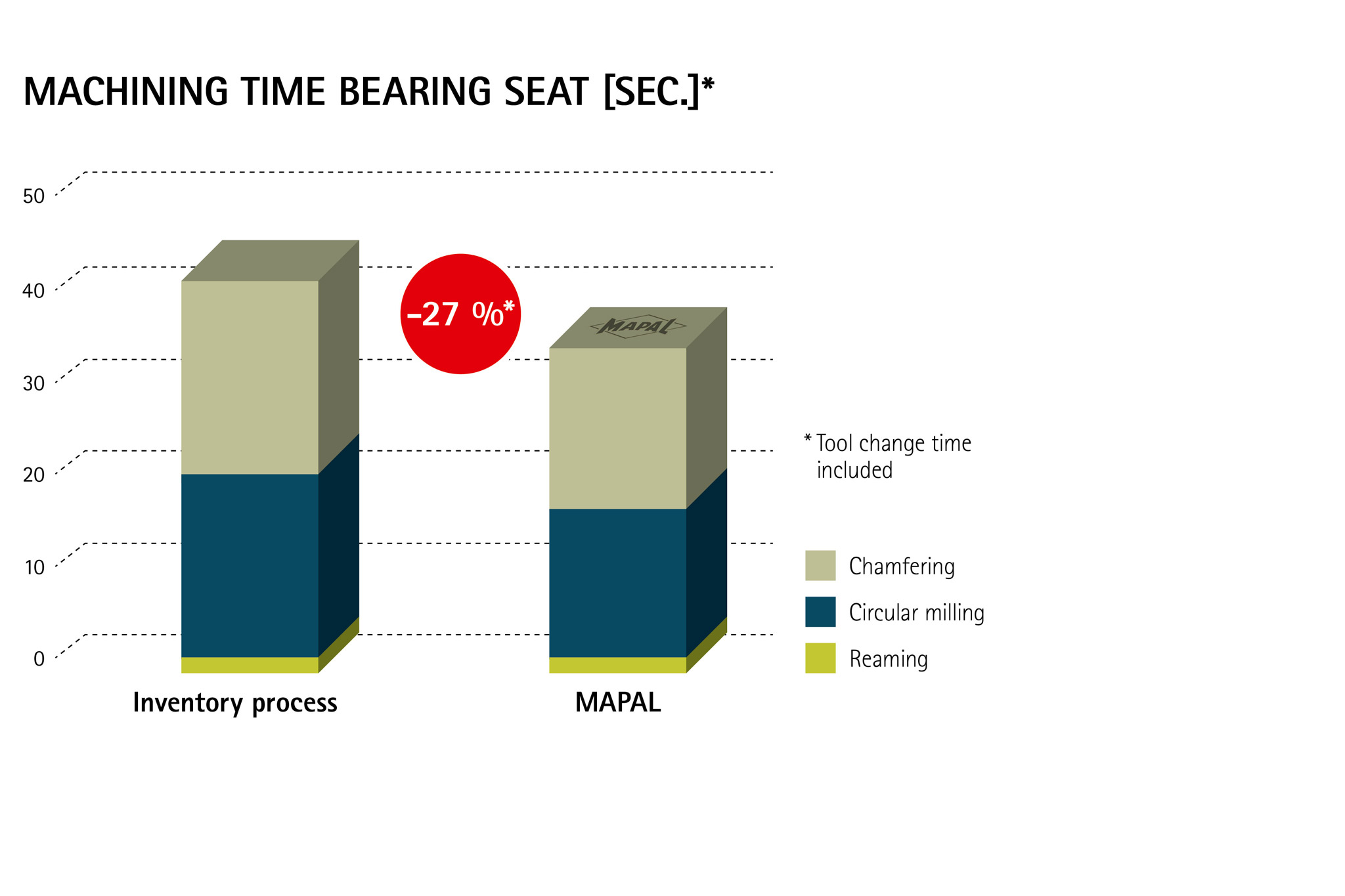

Piston bore (bearing seat)

Boring + circular milling + chamfering

- PCD combination tool for complete machining of the piston bore’s bearing seat with minimal scratching

- Boring and circular milling operations efficiently united in just one tool

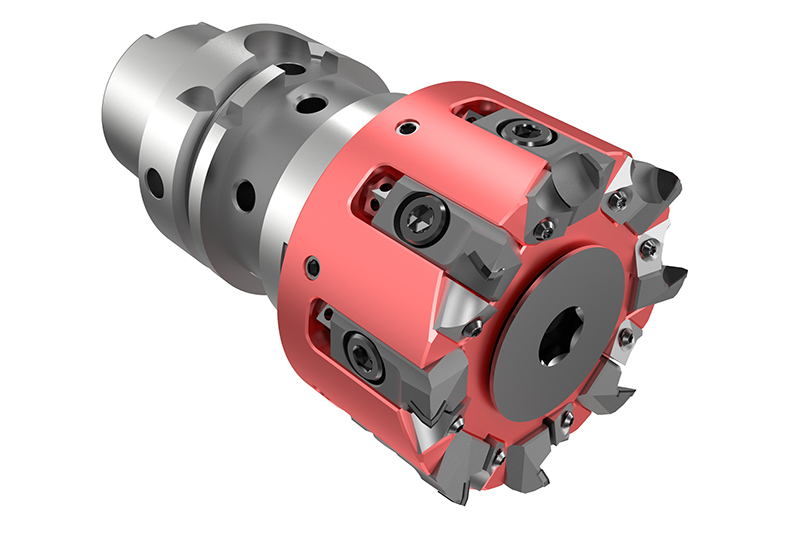

Milling machining

Face milling

- PCD face milling cutter for economical face milling operations in series production

- Machining of cylinder housing with minimal burr formation for optimal functionality

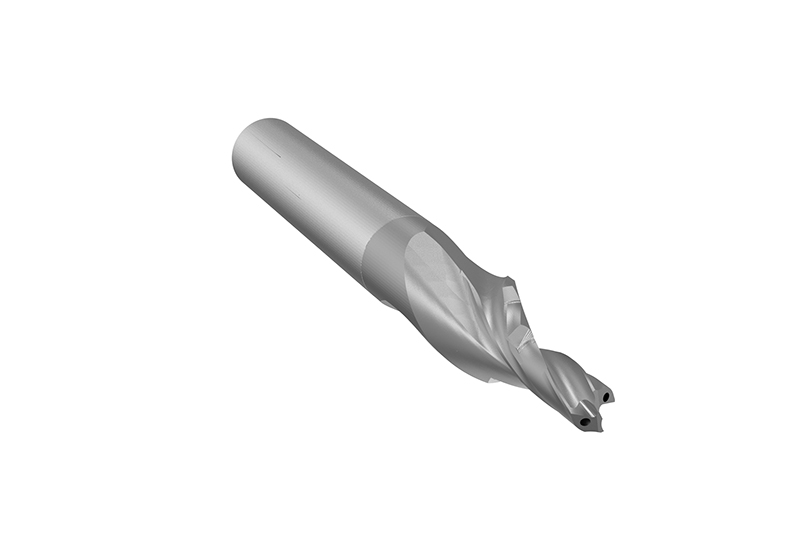

Air connection bore

Drilling from solid

- Step drill made of solid carbide with special multi-cut technology and chip guiding stage

- Ideal chip control

- Frequent regrinding possible when machining air connection and fixing bores

Advantages

- High process reliability and machining with minimal burr formation for medium to high parts quantities and a high degree of automation

- Combination tools save cycle times while maintaining part quality and functionality

- Perfect surfaces as well as form and position tolerance thanks to tool solutions tailored to client requirements