Propulsores eléctricos

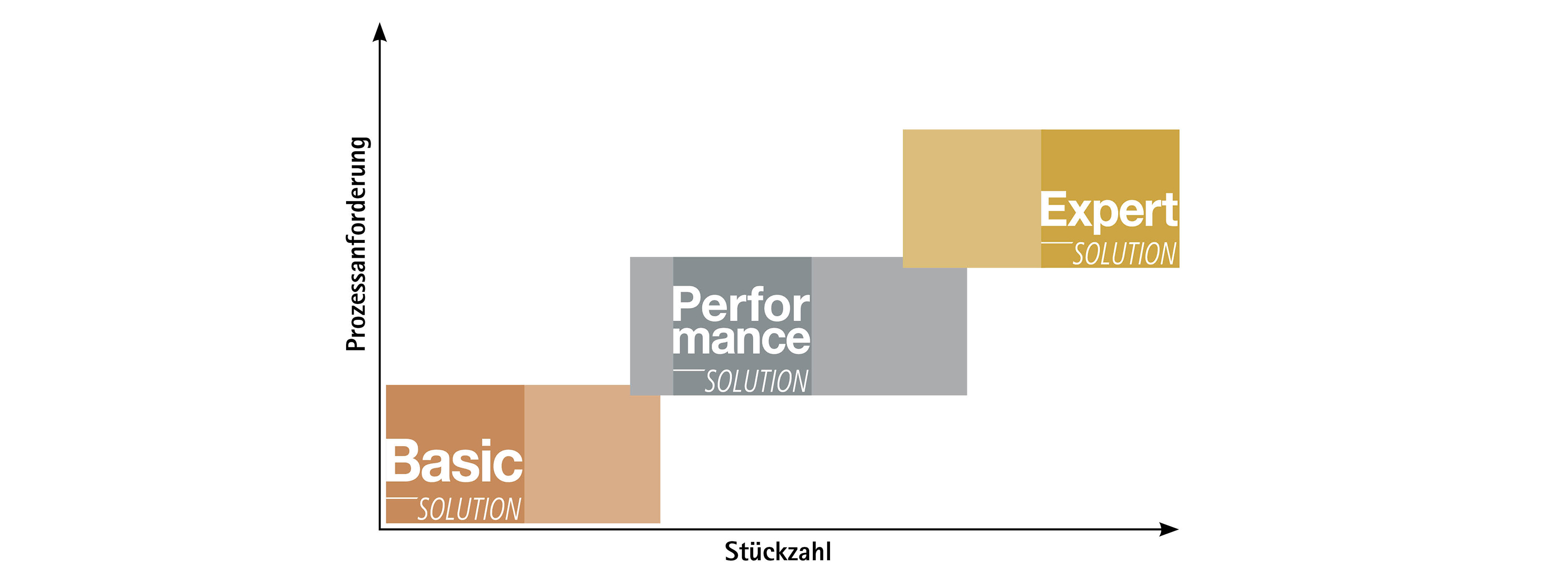

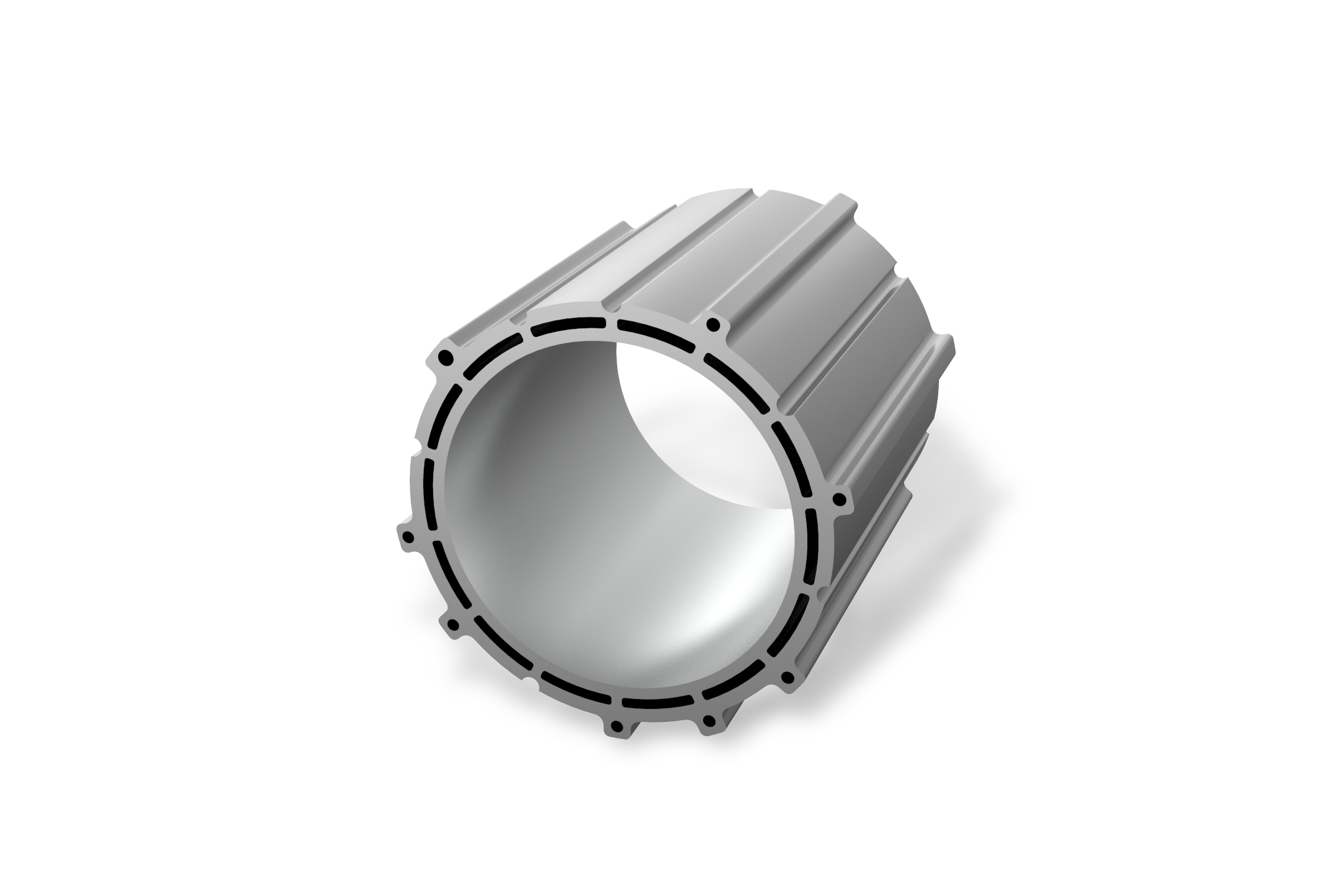

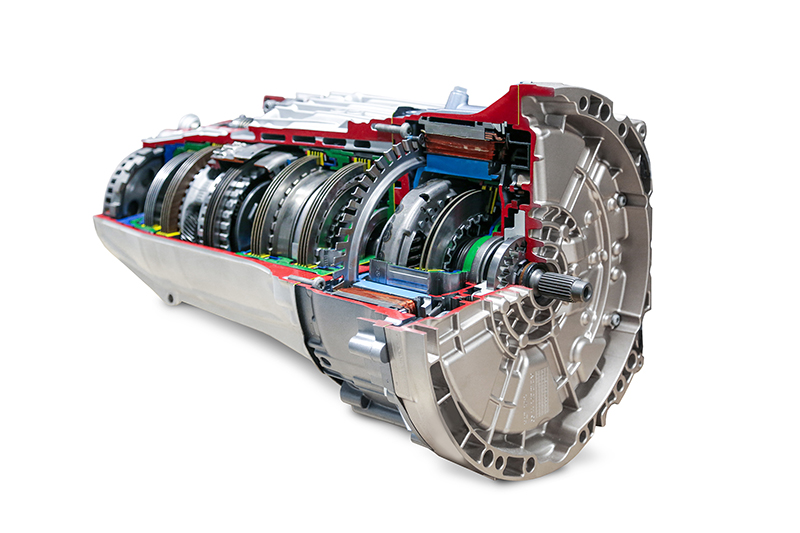

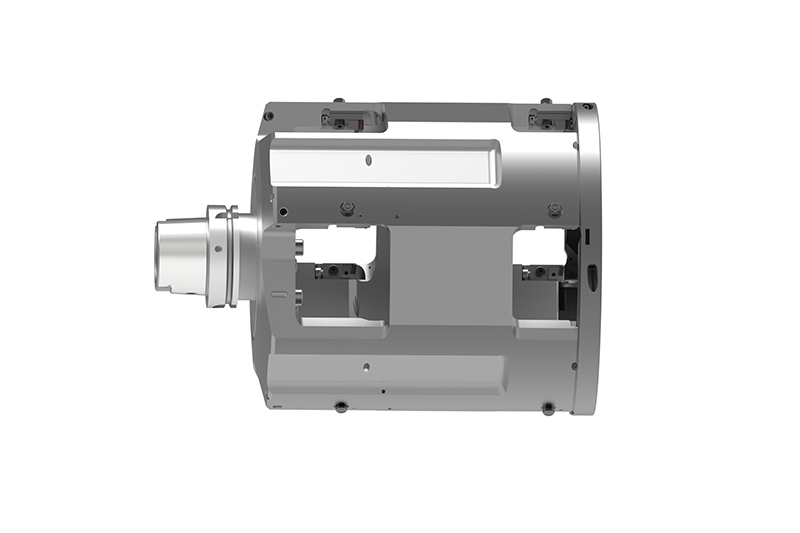

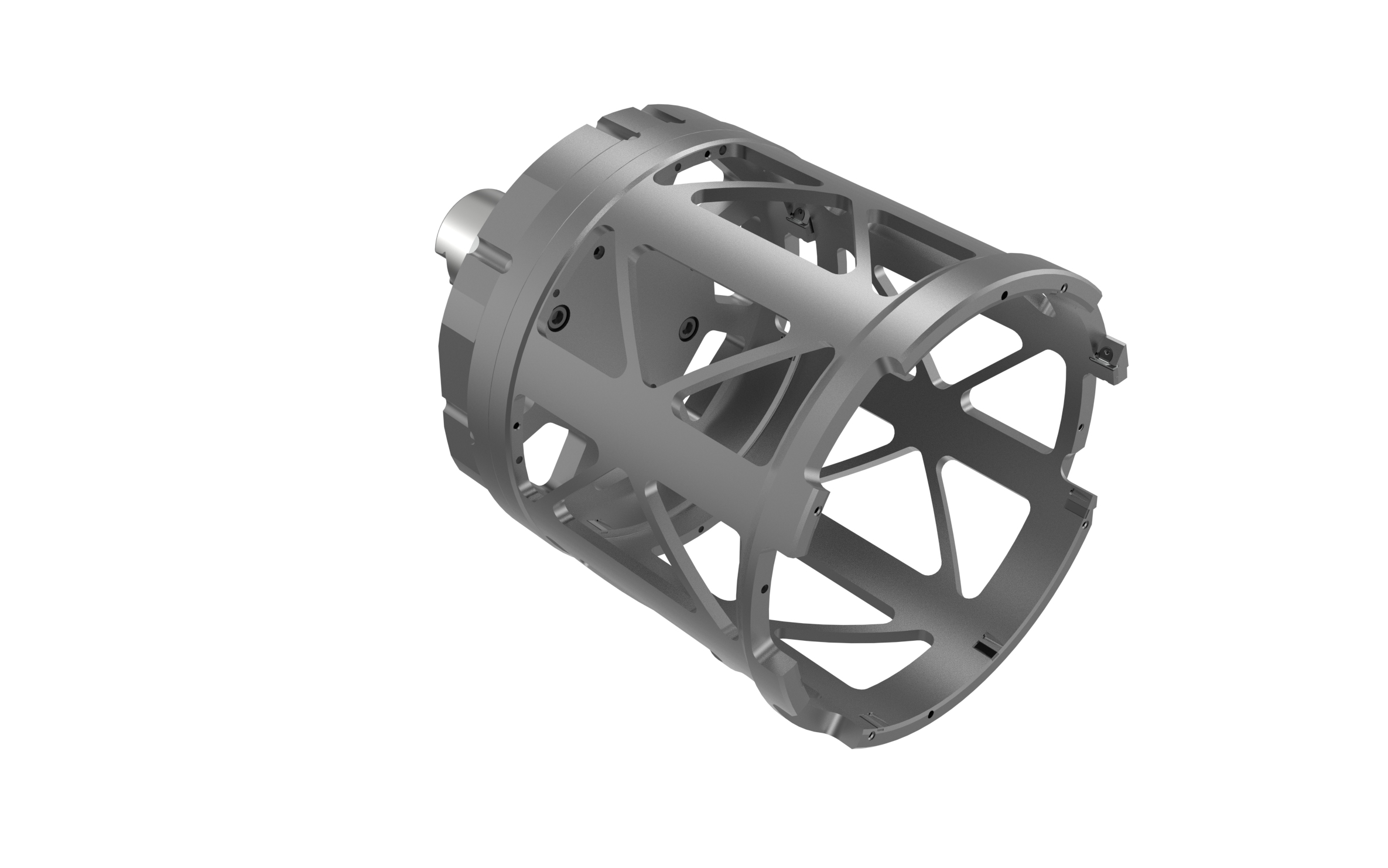

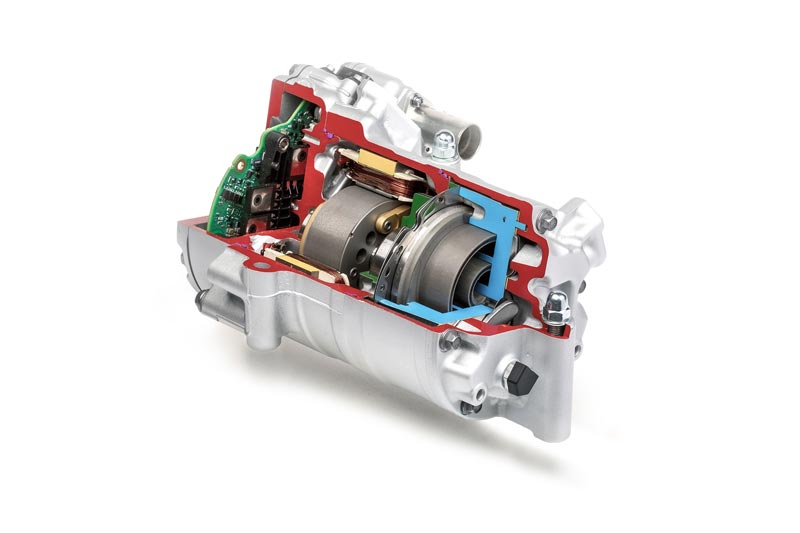

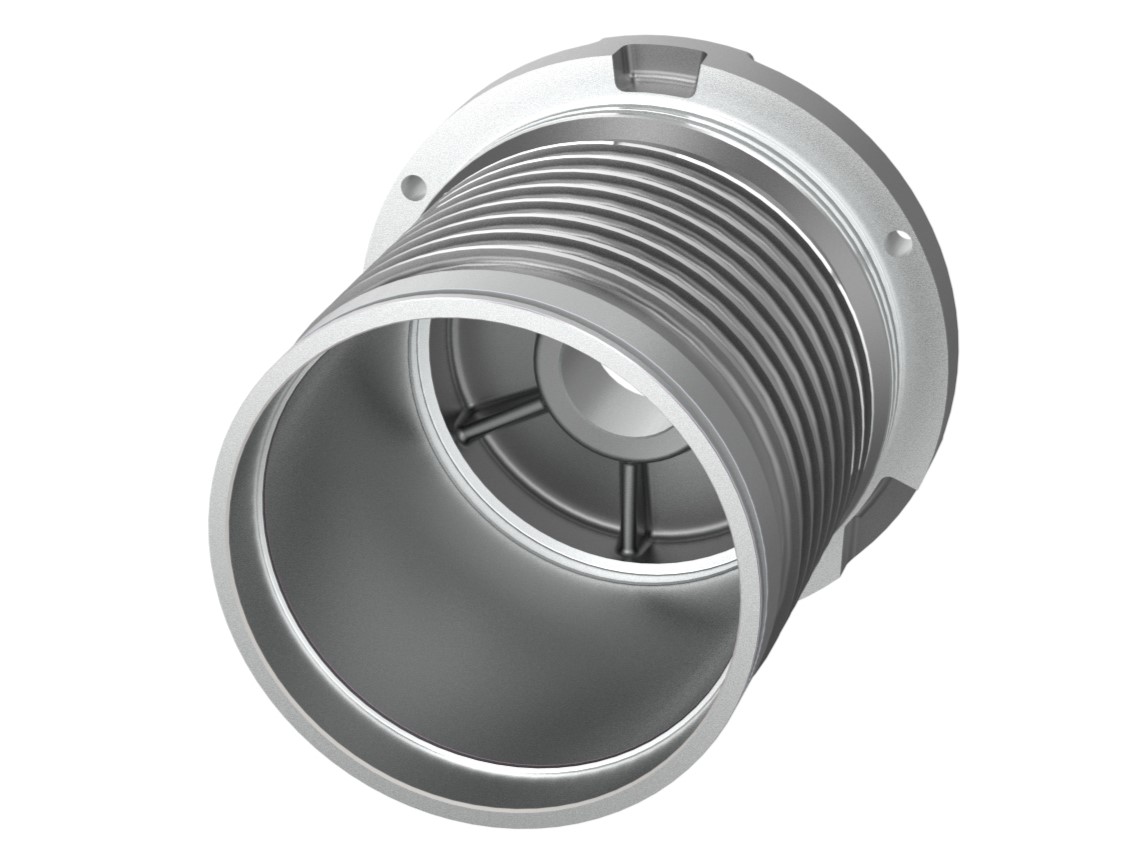

Los fabricantes y proveedores de automóviles se enfrentan a nuevos retos en lo que respecta a los componentes para motores eléctricos. El ejemplo de la carcasa de un motor eléctrico muestra la magnitud de estos retos: En comparación con la carcasa de una caja de cambios, debe fabricarse con tolerancias mucho más estrictas, ya que la precisión tiene una influencia decisiva en la eficiencia del motor.

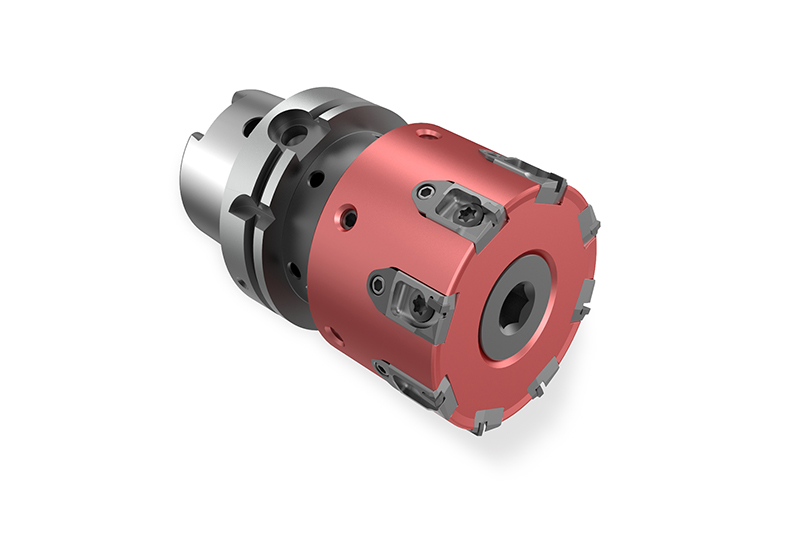

Además, la carcasa del motor eléctrico suele tener paredes mucho más finas que la carcasa de una caja de cambios debido a su diseño especial, como los canales de refrigeración integrados. En algunas de estas carcasas además se han insertado casquillos de rodamientos de materiales de acero. Las placas de protección especiales de la herramienta sirven para que las virutas de acero no entren en contacto con las superficies de aluminio y las dañen durante el mecanizado.

Requisitos de mecanizado y características de los distintos tipos de carcasas

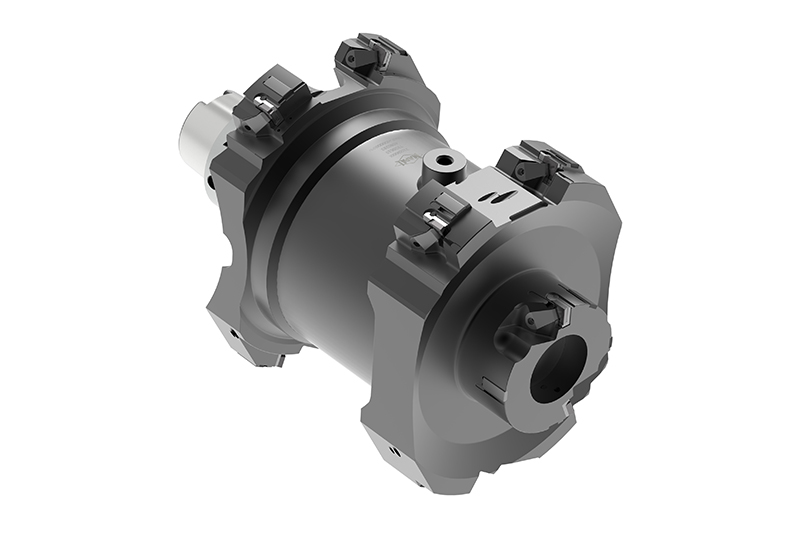

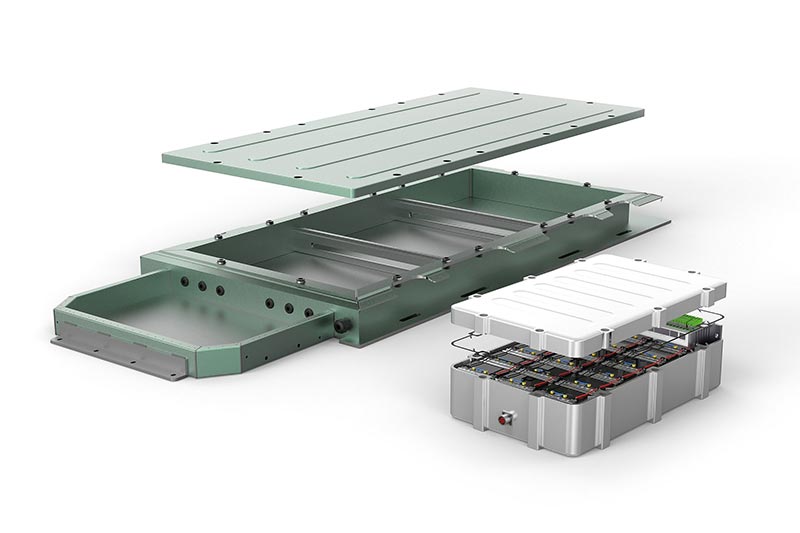

- Carcasa altamente integrada

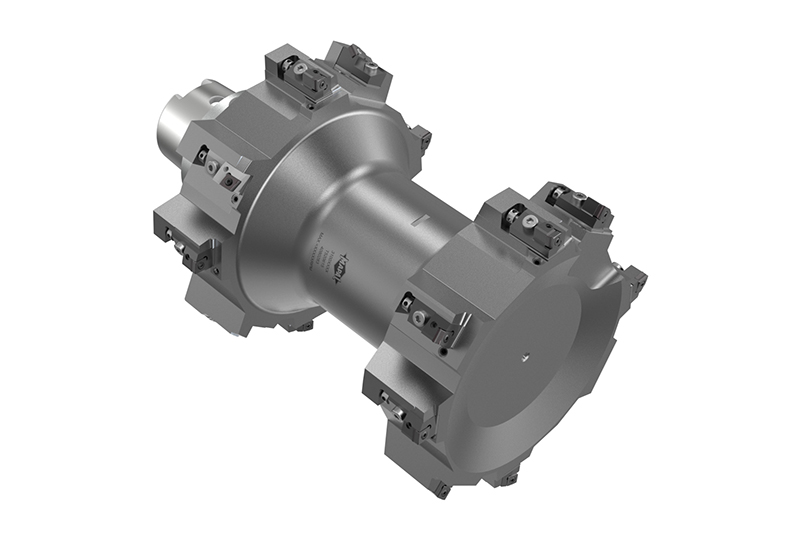

- Carcasa en forma de recipiente cilíndrico

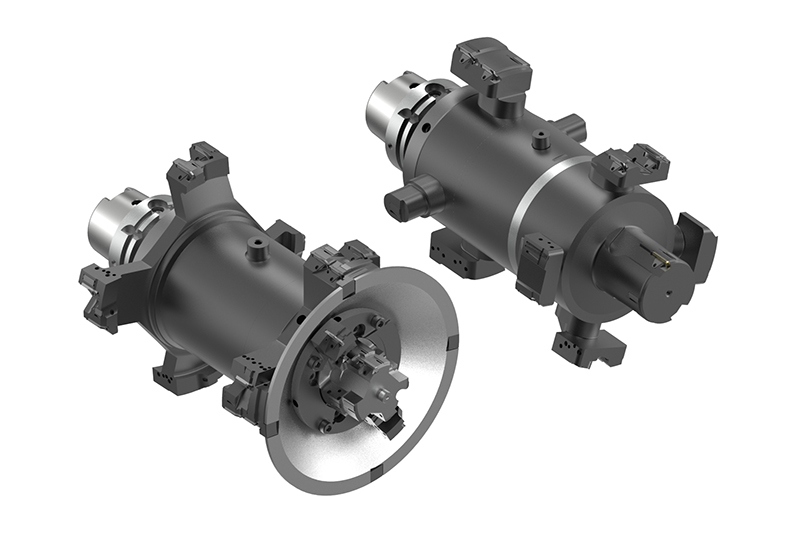

- Carter tubulaire

- Carcasa híbrida

Procedimiento básico para el mecanizado de carcasas de estátores

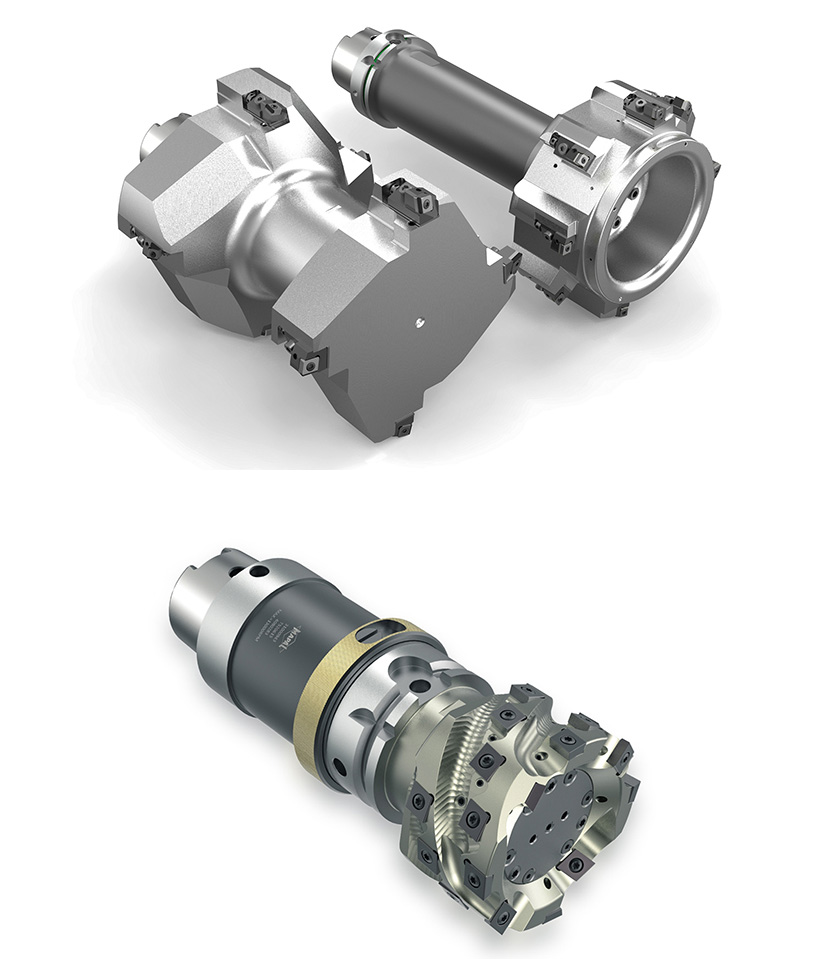

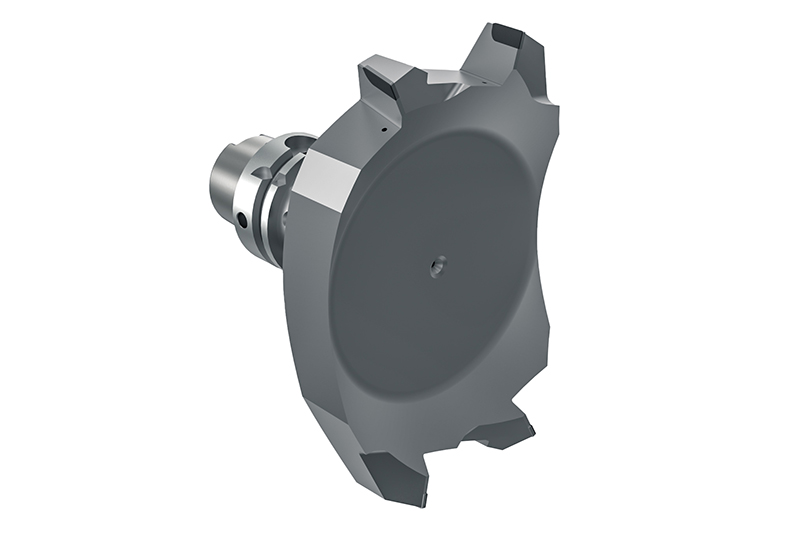

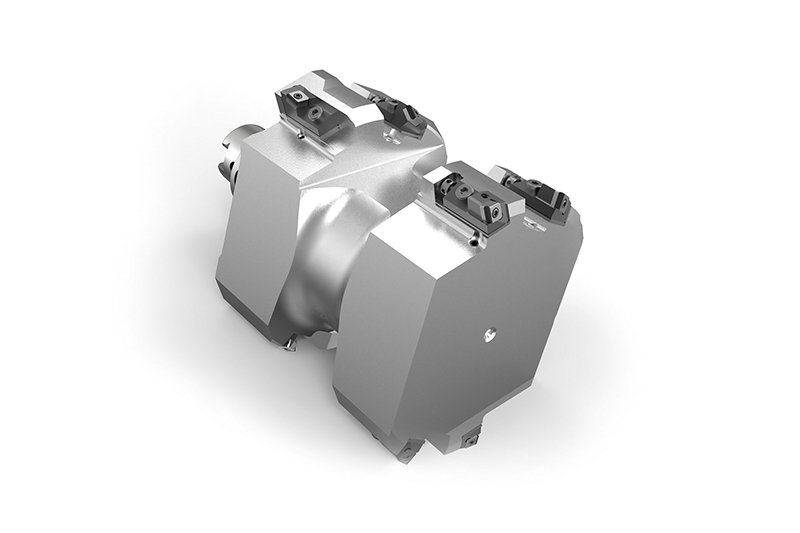

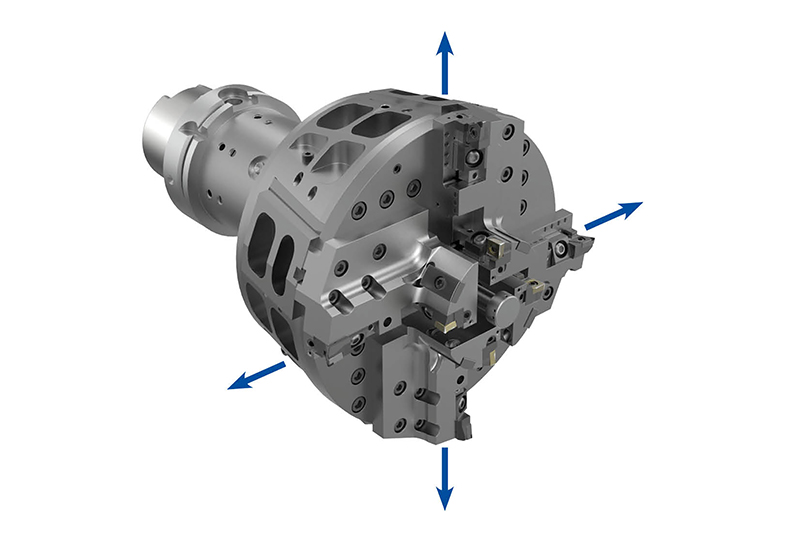

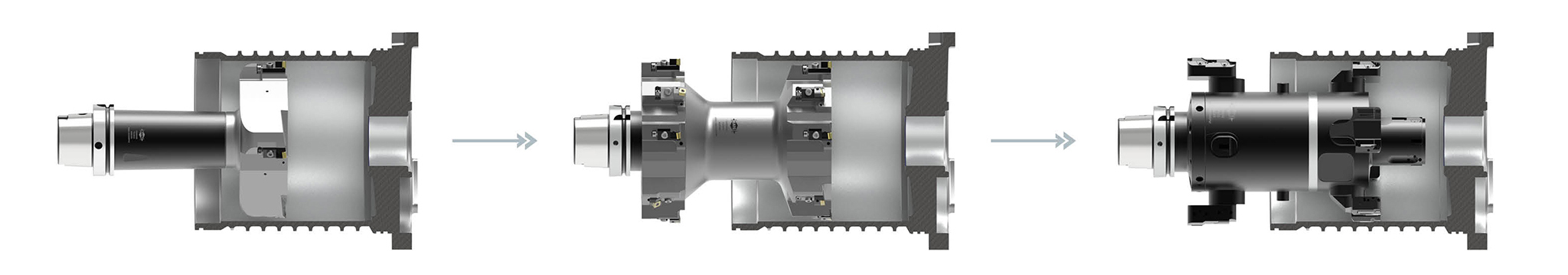

El proceso de mecanizado, así como las herramientas, se diseñan individualmente según la situación de medida, el parque de máquinas y la configuración de sujeción. De este modo, las fuerzas de corte que actúan sobre el componente se mantienen lo más bajas posible. El mecanizado del orificio del estátor se divide en tres pasos: Premecanizado, semiacabado y mecanizado de acabado.

Usinage extérieur de boîtiers de stator

Solutions d'usinage pour…