Primi passi nel settore della costruzione di stampi e matrici

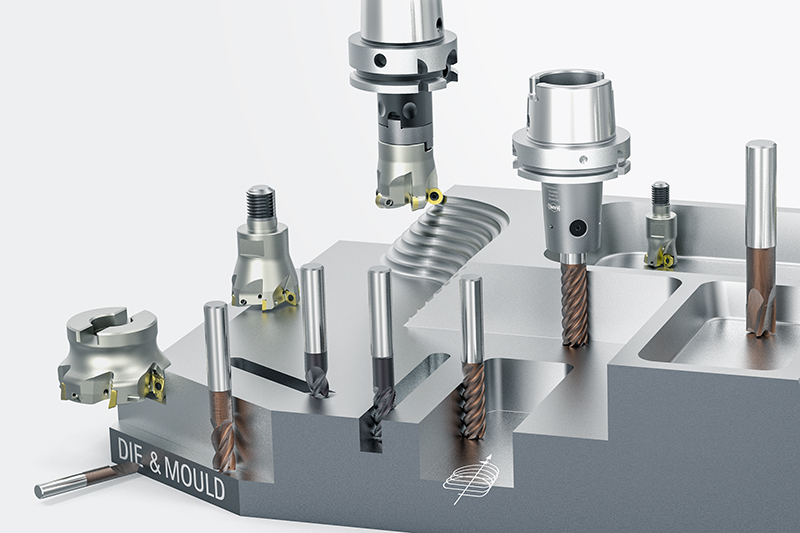

Questi sono gli aspetti che hanno determinato il successo di MAPAL in settori come l'industria automobilistica, l'ingegneria meccanica o l'industria aerospaziale. È quindi logico che il produttore di utensili di precisione offra anche soluzioni efficienti ed economiche per l'intero processo di lavorazione nella costruzione di stampi e matrici. Utensili ad alte prestazioni versatili e precisi, nonché portautensili specifici con contorni sottili e concentricità precisa minimizzano il lavoro di lucidatura e rilavorazione, assicurando una qualità di superficie costante durante il processo di fresatura. Essi consentono inoltre notevoli risparmi sui costi dell’intero processo.

Assortimento di utensili per la costruzione di stampi

Componenti e materiali

- Acciaio e acciaio temprato

-

Acciaio e acciaio temprato

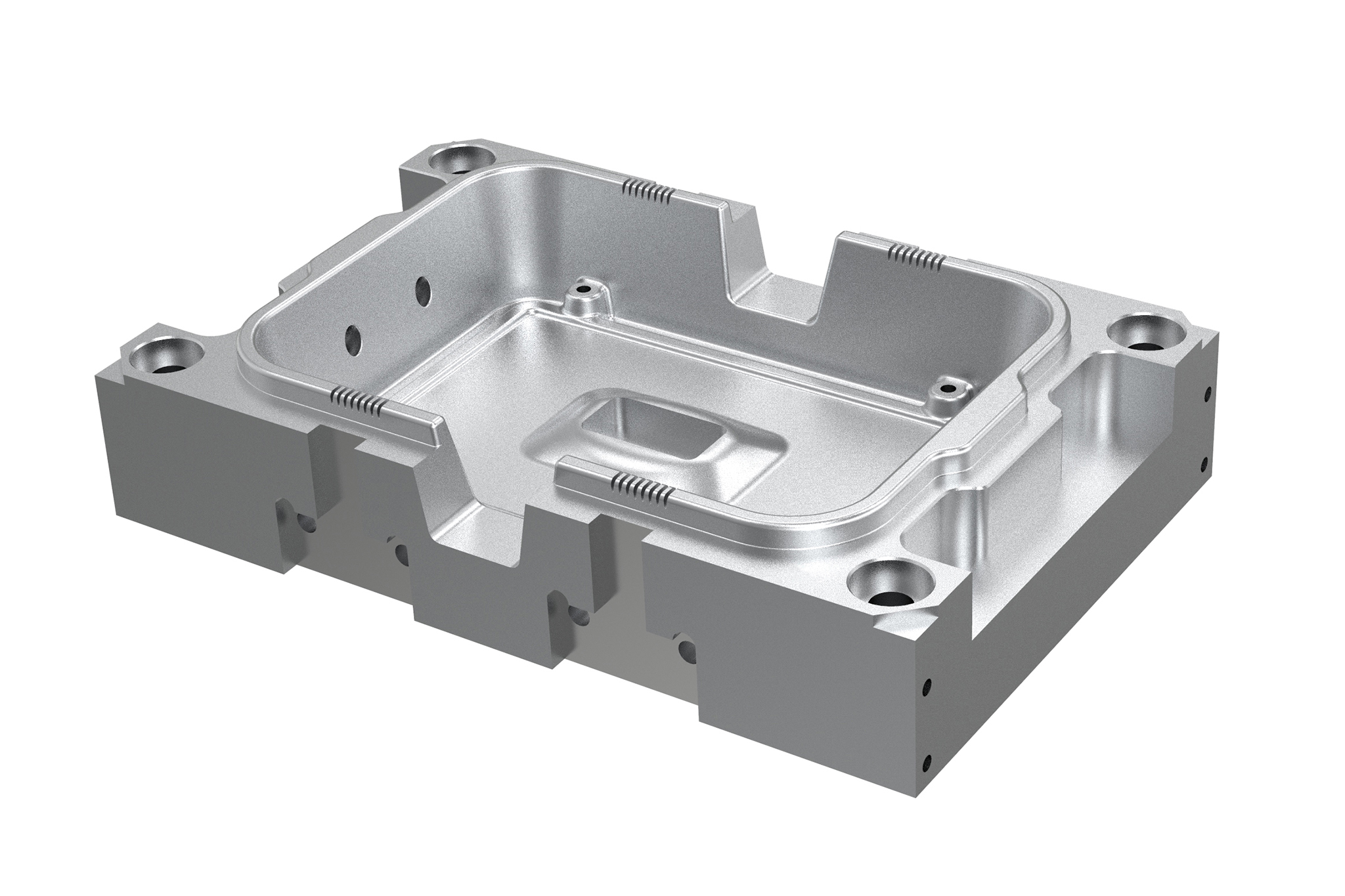

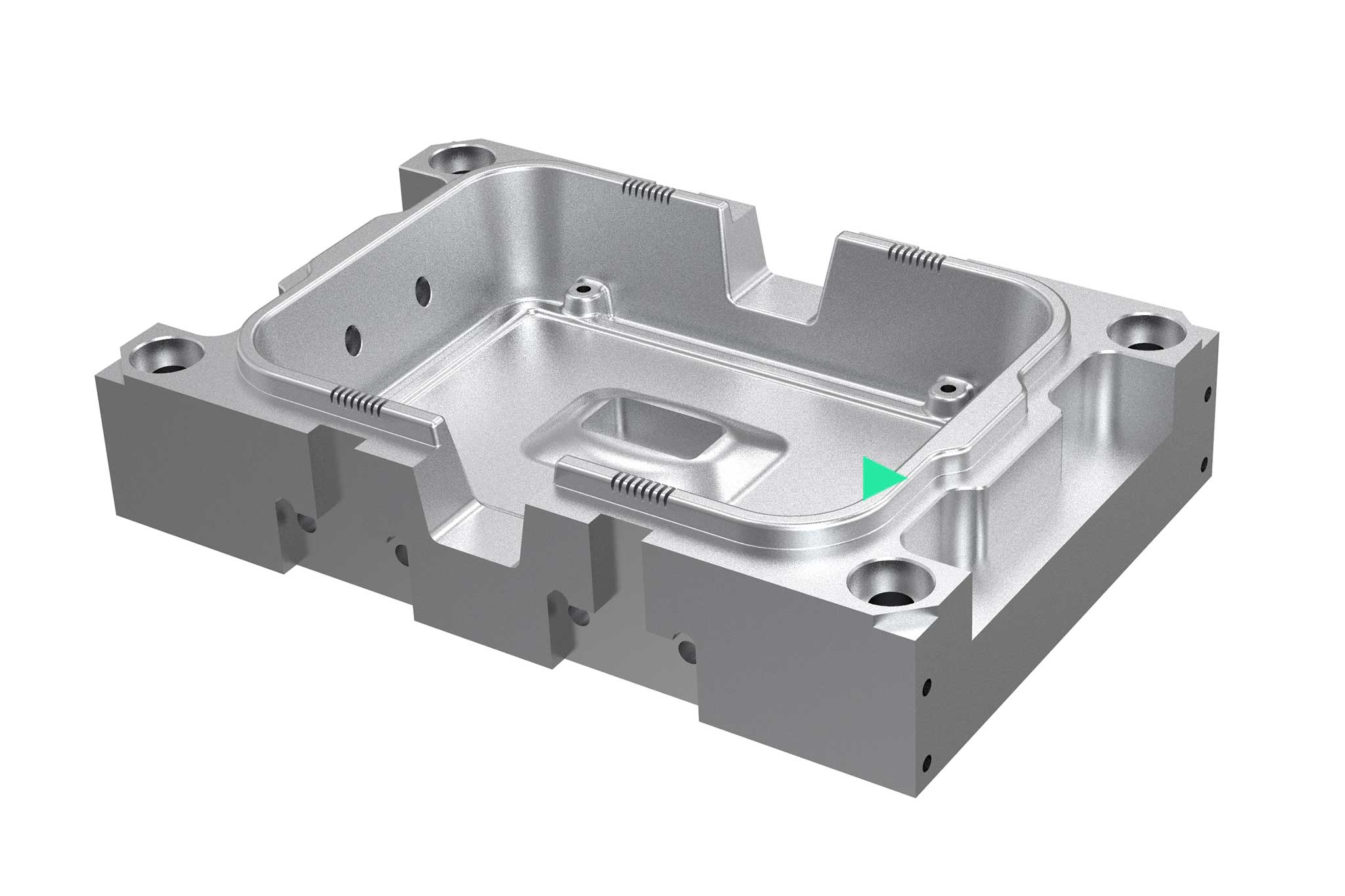

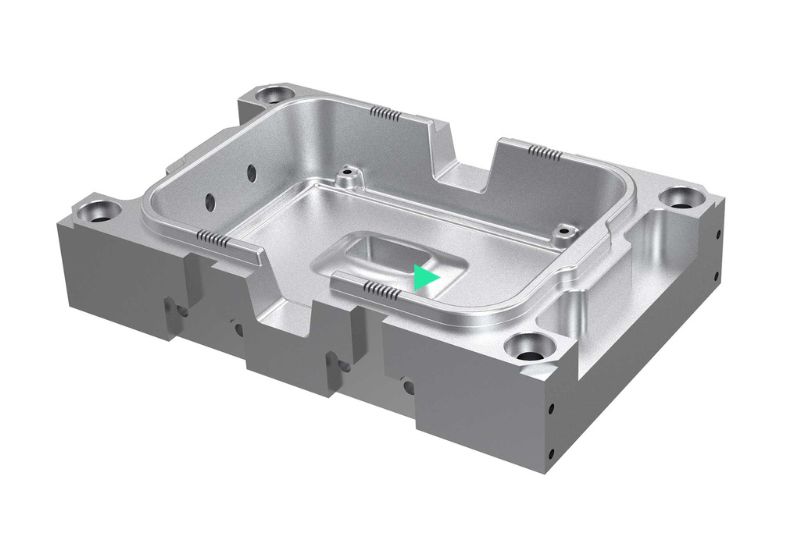

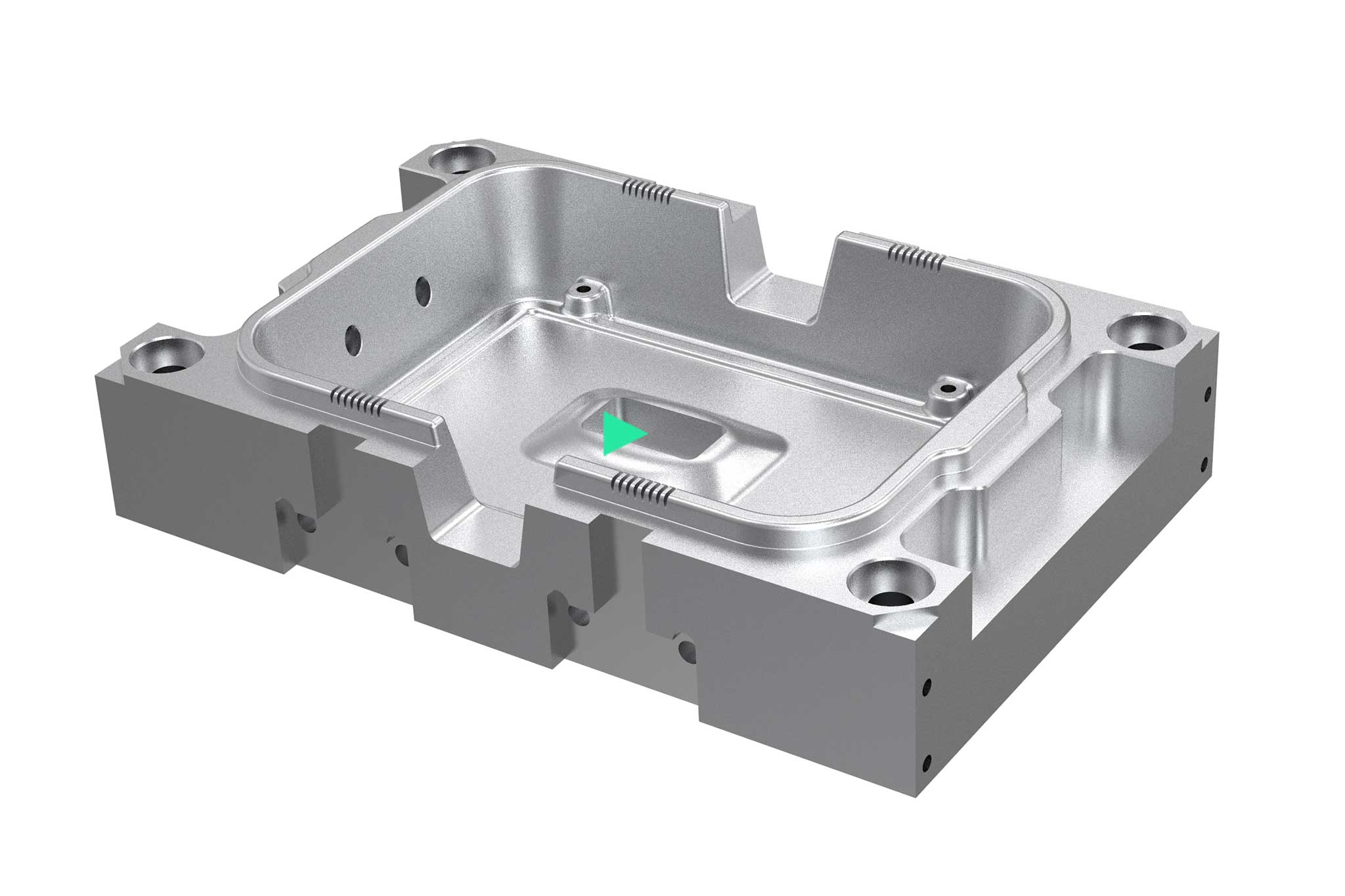

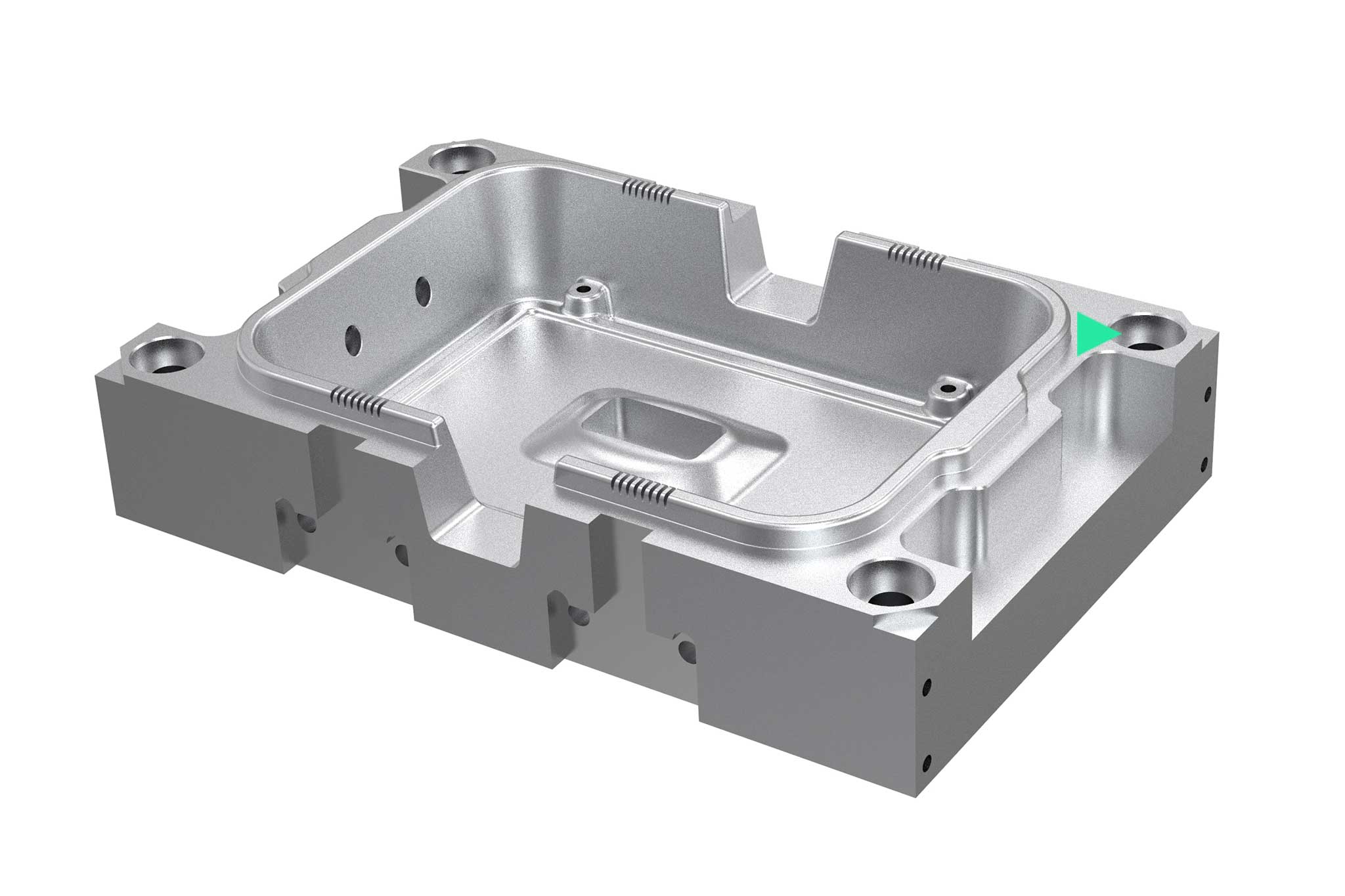

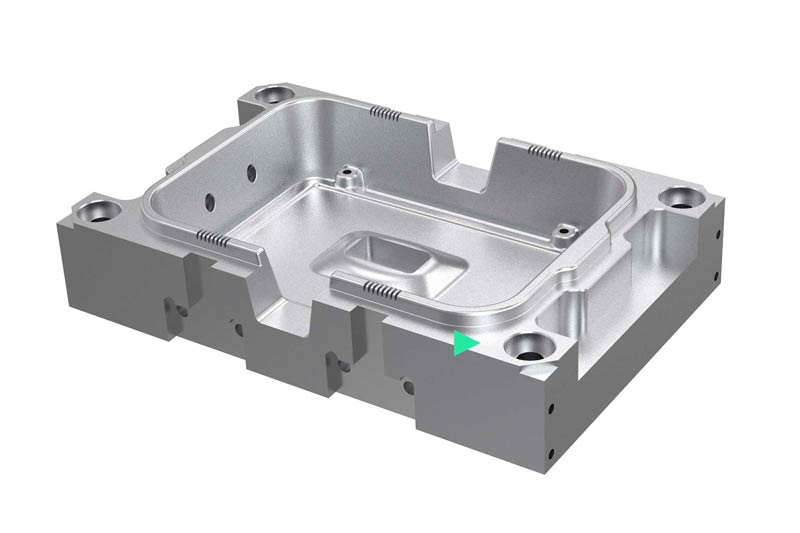

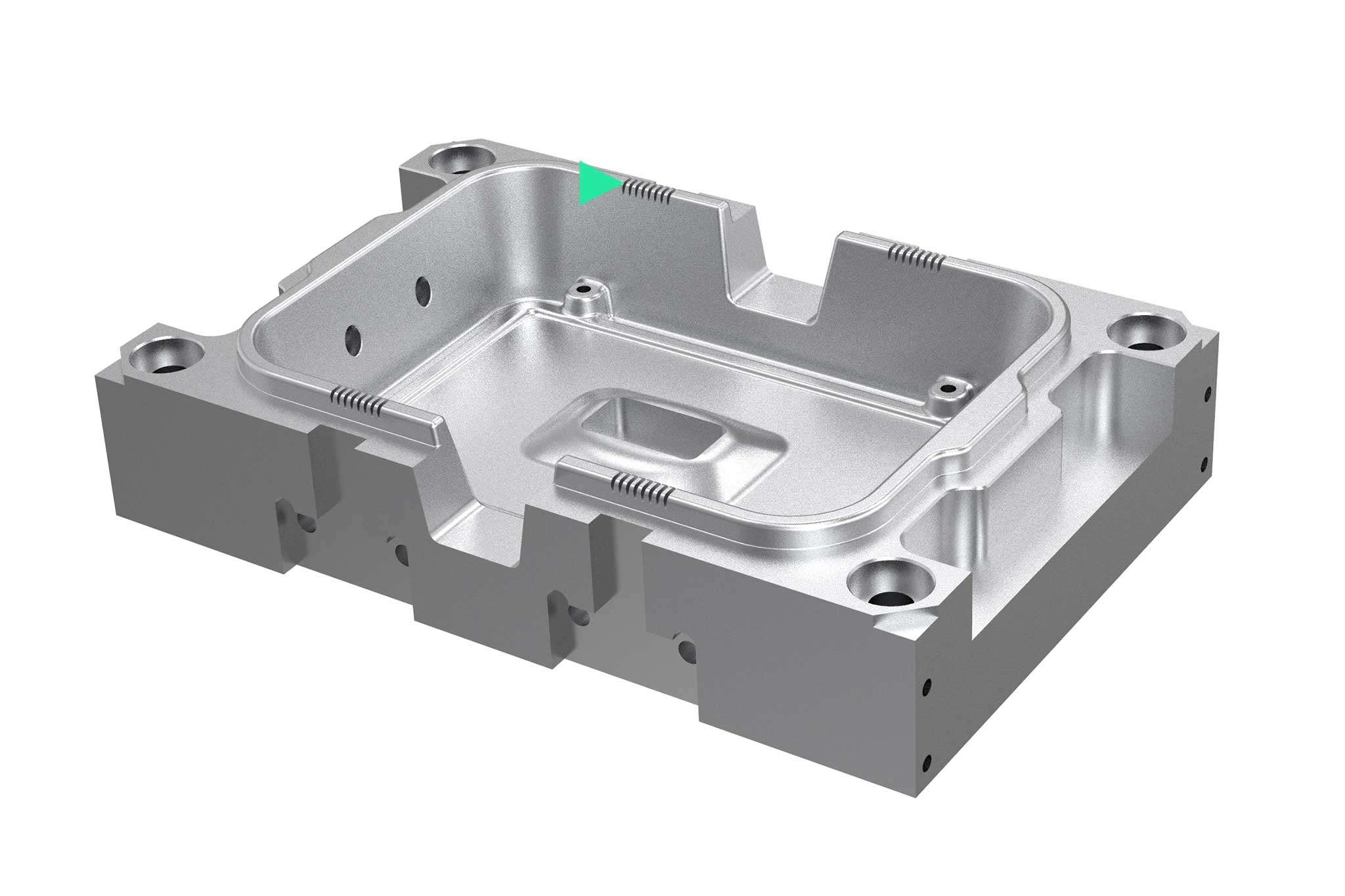

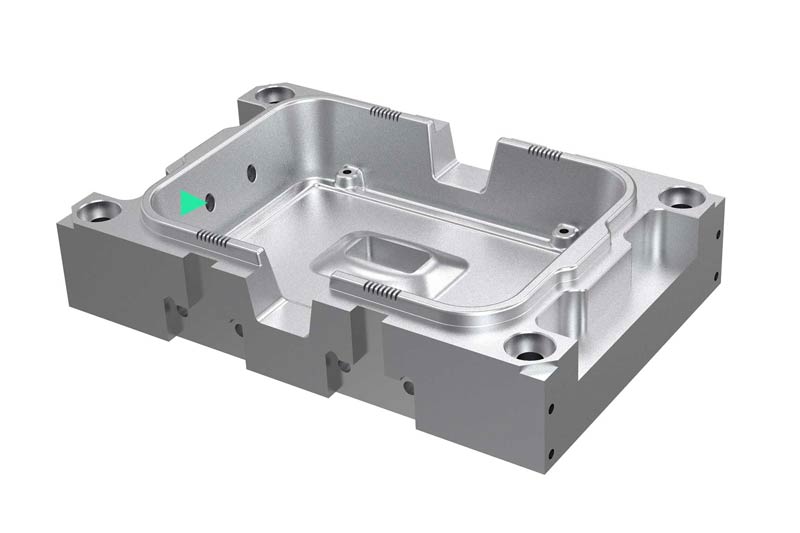

I componenti di crescente complessità e con cavità sempre più profonde, nonché le nervature di stampaggio e di irrigidimento negli stampi per iniezione plastica e pressofusione, rendono necessario l'uso di utensili molto lunghi, anche con diametri di taglio molto ridotti. Le complesse geometrie delle parti e la varietà delle caratteristiche dei materiali, impongono elevate esigenze in termini di lavorazione e di durata dell’utensile.

Esempi di applicazione:

- Stampo per iniezione plastica

- Stampo per pressofusione

- Ghisa

-

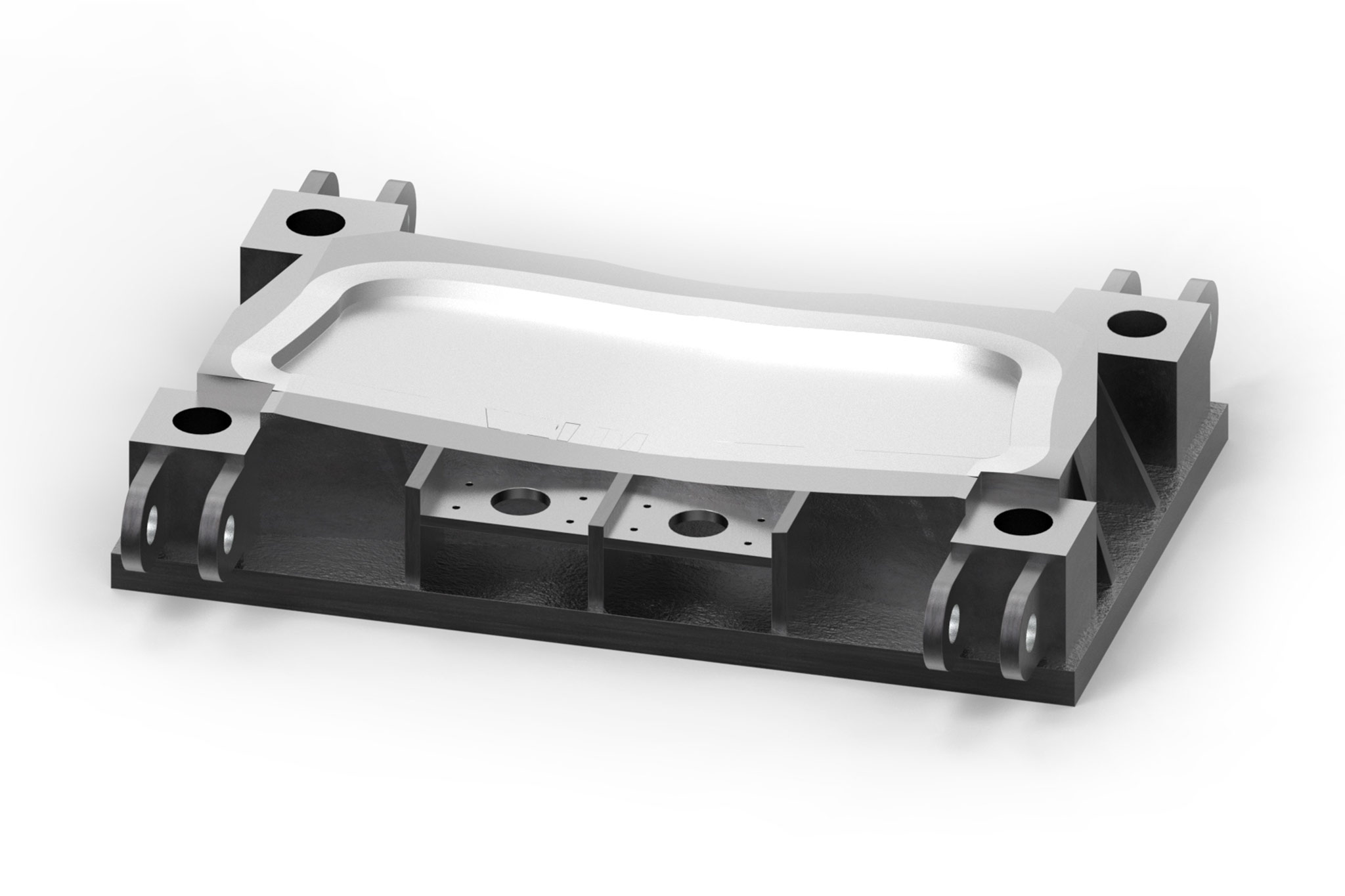

Ghisa

La ghisa è spesso utilizzata nella progettazione, ingegneria e costruzione di matrici di formatura a freddo di medie e grandi dimensioni, grazie alle proprietà di questo materiale, come resistenza alla compressione e facilità di lavorazione. I componenti principali sono in questo caso basamenti e casse porta stampo. MAPAL ha una grande esperienza nelle operazioni di fresatura (2D e 3D) e di foratura (foratura, alesatura, filettatura).

Esempi di applicazione:

- Basamenti porta stampo

- Casse porta stampo

- Alluminio

-

Alluminio

Quando si tratta di stampi di pre-produzione o di prototipi, non è raro usare materiali facili da lavorare. Si usano spesso leghe di alluminio o ureol (resine utilizzate per realizzazione di prototipi stilistici). In questi casi, gli utensili in metallo duro integrale con taglienti positivi e lappati o lucidati, o ancora meglio gli utensili con punta in PCD, garantiscono un'alta produttività e tempi di lavorazione brevi.

Esempi di applicazione:

- Stampi pre-serie

- Stampi prototipo

- Rame

-

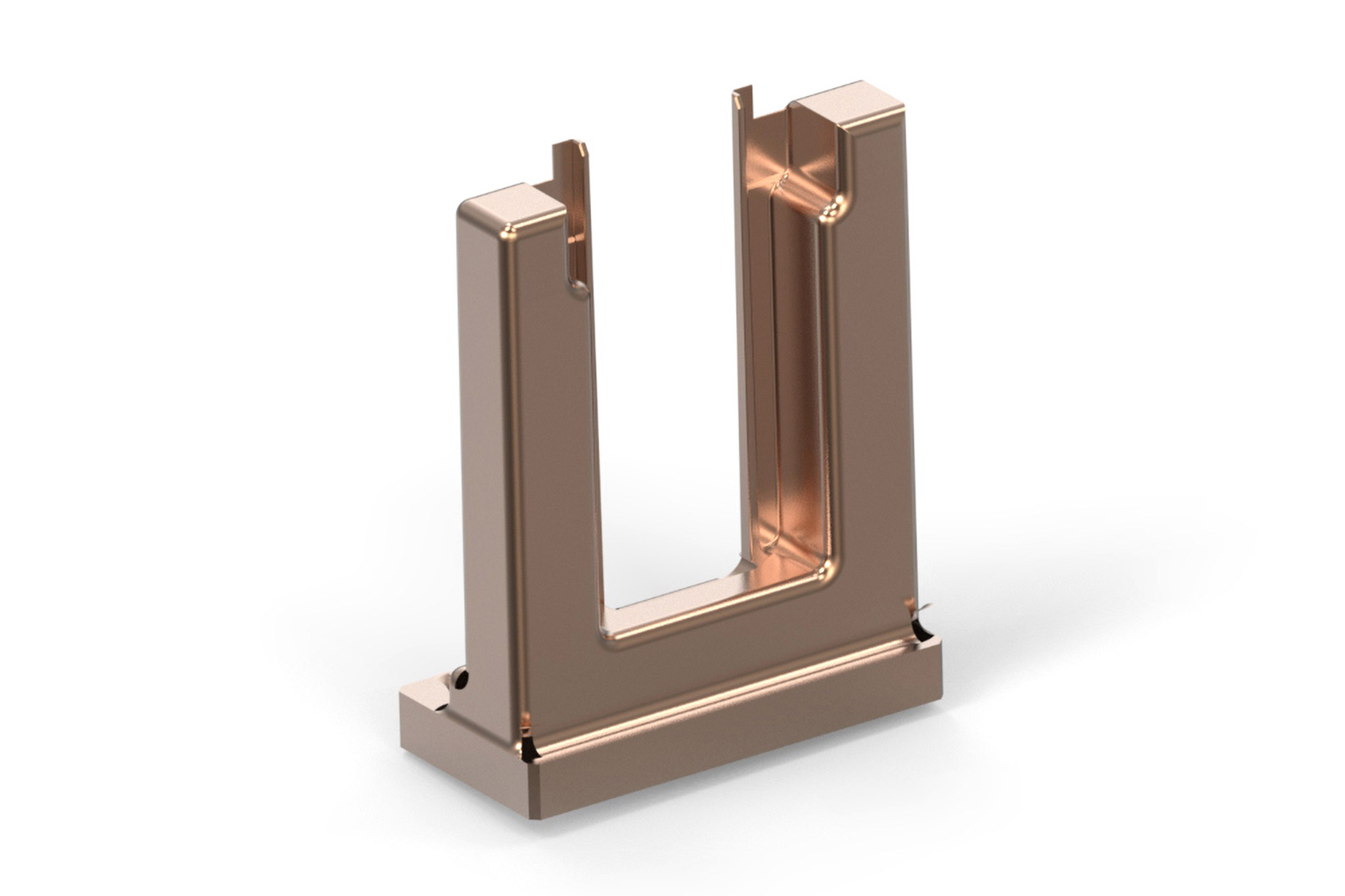

Rame

La produzione di elettrodi per i processi EDM richiede la lavorazione di leghe di rame e grafite. La scelta del materiale dell'elettrodo dipende dai requisiti dello stampo da produrre. Le leghe di rame sono relativamente costose e sono generalmente usate negli elettrodi per la finitura quando sono richieste un'alta qualità della superficie e precisione della forma. Le frese in metallo duro integrale con geometrie speciali di MAPAL garantiscono qui risultati di lavorazione ad alta precisione.

Esempio di utilizzo:

- Elettrodi per elettroerosione a scintilla (processi EDM)

- Grafite

-

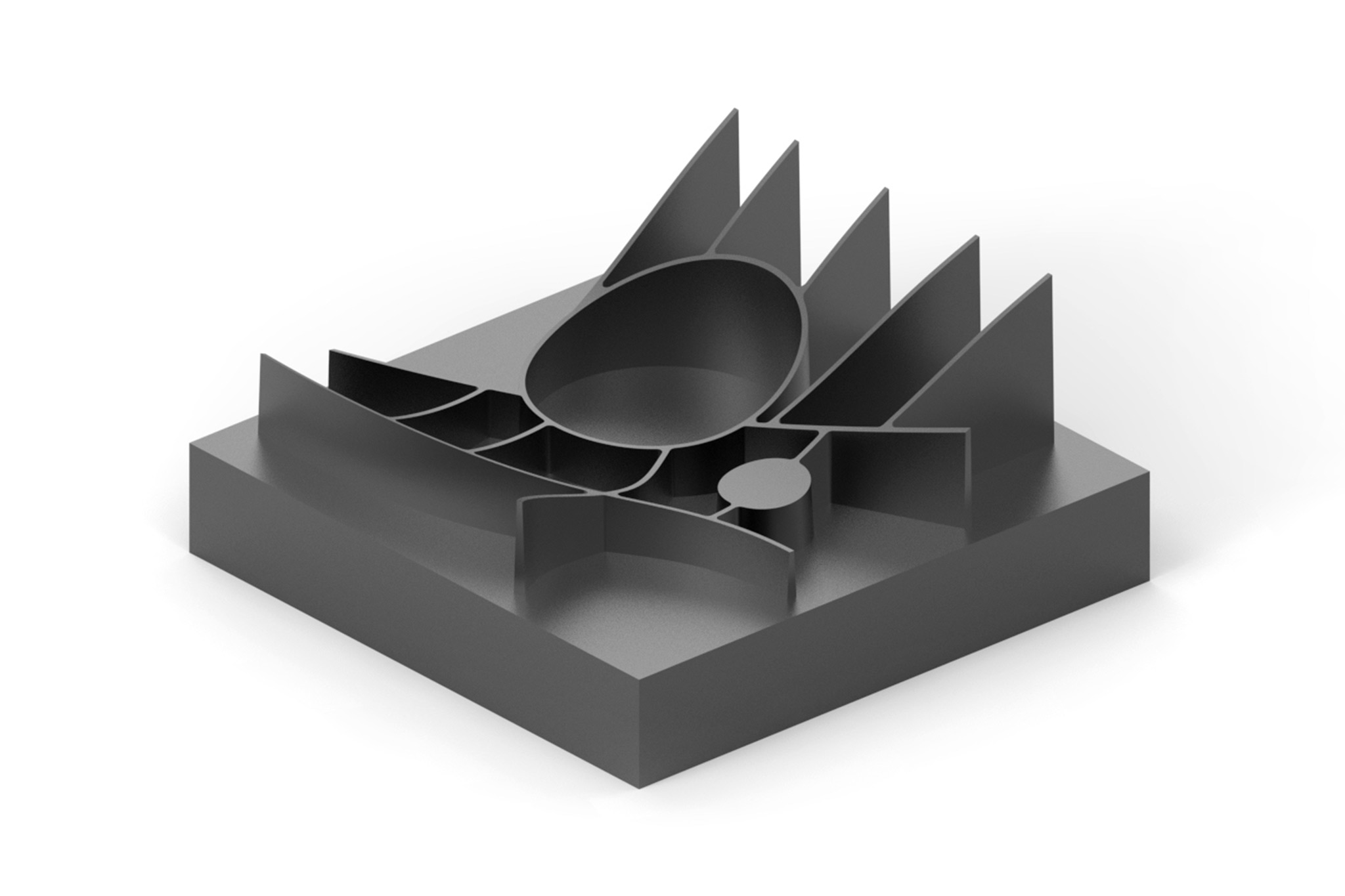

Grafite

La grafite ha un effetto altamente abrasivo sull'utensile e provoca una forte usura del tagliente. Con l'aumentare dell'usura, i profili da lavorare tendono a scheggiarsi e rompersi. Pertanto, un utensile con una geometria adeguata e un materiale da taglio ottimale è un prerequisito indispensabile. MAPAL utilizza utensili in metallo duro integrale con rivestimento diamantato o utensili con riporto in PCD per la lavorazione della grafite.

Esempio di utilizzo:

- Elettrodi per elettroerosione a scintilla (processi EDM)

Dal pezzo grezzo al pezzo finito

-

1 / 8

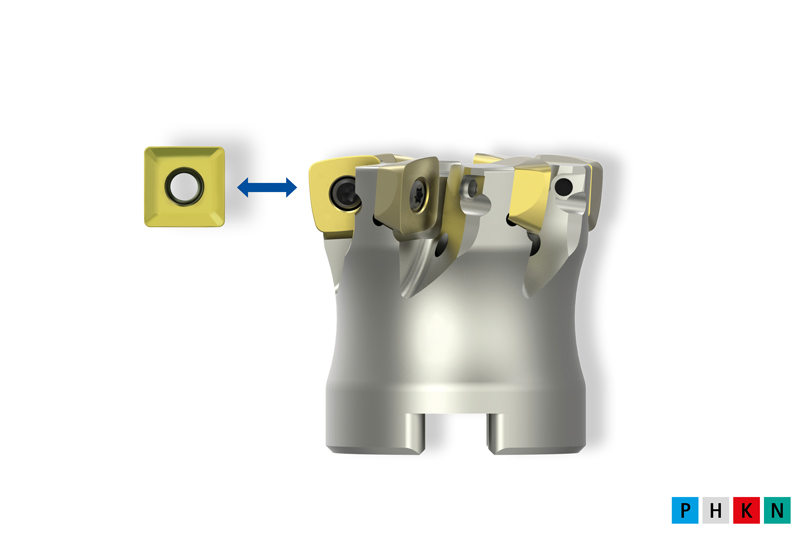

Superfici 2D

Da un lato, questa categoria comprende i processi di lavorazione eseguiti direttamente sulla macchina, come la fresatura a spianare e la fresatura di tasche e pareti dritte. Dall’altro, include anche le operazioni per geometrie complesse che vengono programmate tramite un software CAM.

Vai all’assortimento di prodotti per la lavorazione di superfici 2D -

2 / 8

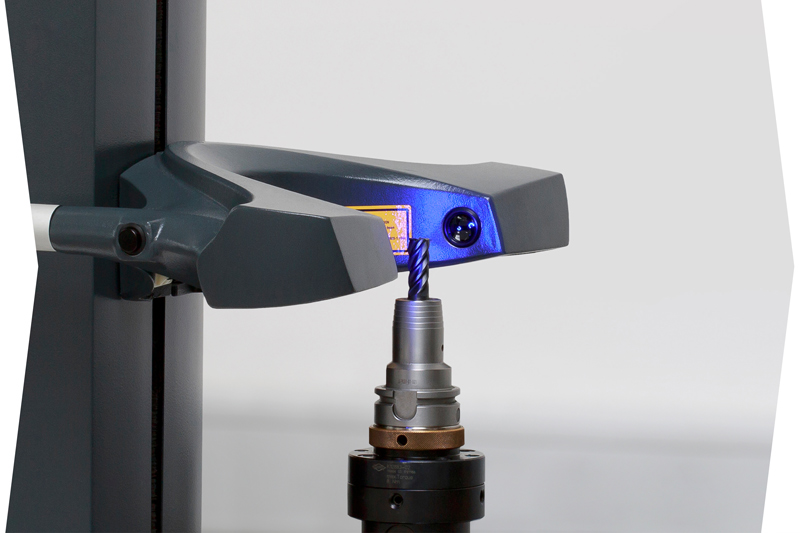

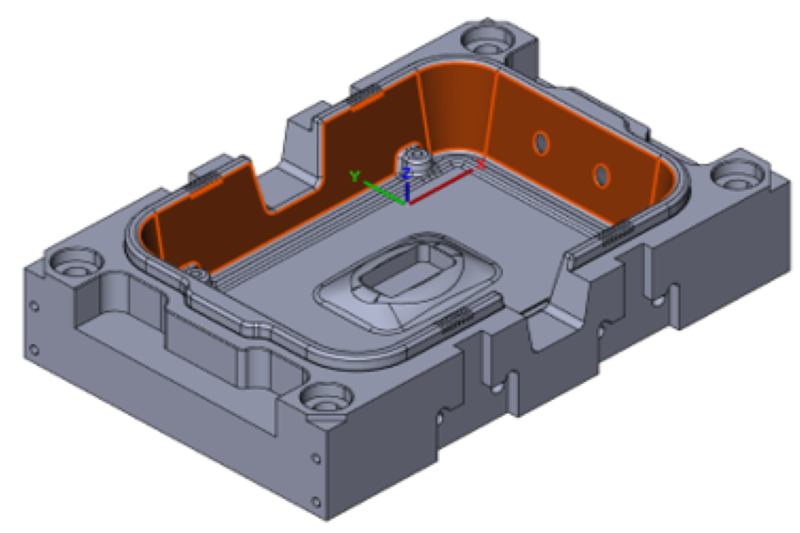

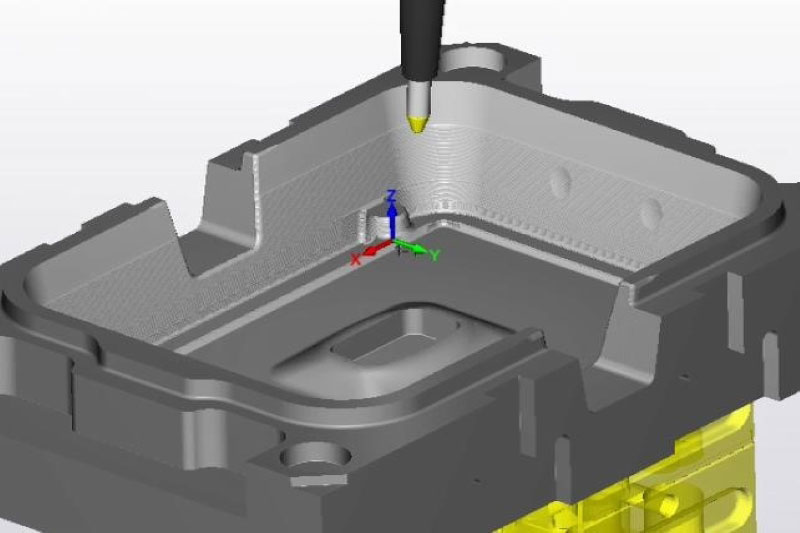

Superfici 3D

Nella costruzione di stampi e matrici, la produzione di stampi sempre più complessi è parte della vita quotidiana. I continui sviluppi delle macchine utensili e del software CAM portano le prestazioni e la produttività a un livello ancora più elevato. Ne consegue che anche gli utensili utilizzati devono andare di pari passo con il più recente stato dell’arte. Per ottenere risultati ottimali, all’inizio della progettazione si esegue un’analisi del processo.

Vai all’assortimento di prodotti per la lavorazione di superfici 3D -

3 / 8

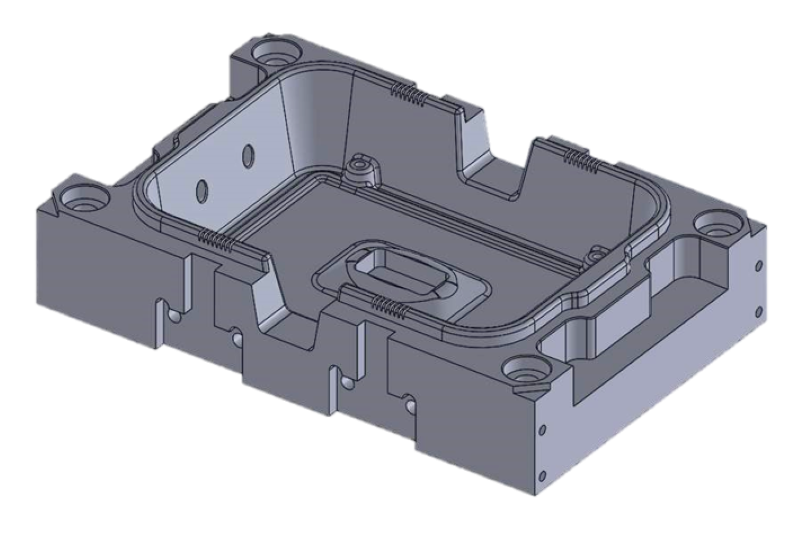

Tasche aperte

Le casse porta stampo presentano anche operazioni di lavorazione necessarie per la fusione o per diversi elementi integrativi. Gli utenti utilizzano in misura crescente frese trocoidali per lavorare le tasche aperte (lavorazioni periferiche). Tale metodo permette di ottimizzare i tempi di lavorazione e di estendere la durata dell’utensile.

Vai all’assortimento di prodotti per la lavorazione di tasche aperte -

4 / 8

Tasche chiuse

Le tasche chiuse vengono prodotte per lo più tramite la sgrossatura nei piani Z. L’ingresso di lavorazione viene spesso individuato utilizzando un’inclinazione durante la fresatura. La scelta dell’utensile dipende dalla profondità delle pareti e dai piani inclinati da riprodurre sul componente. L’ampio portfolio MAPAL di sistemi modulari include anche la lavorazione di tasche più profonde con grandi diametri.

Vai all’assortimento di prodotti per la lavorazione di tasche chiuse -

5 / 8

Interpolazione elicoidale

Uno degli obiettivi principali delle lavorazioni di fresatura è costituito dalla riduzione del tempo di lavorazione. Spesso è possibile eliminare il processo di preforatura grazie alle geometrie specifiche dell’utensile volte alla lavorazione di tasche chiuse e rotonde. Nell’interpolazione elicoidale, i tracciati di fresatura vengono impostati con ingressi elicoidali idonei alle dimensioni delle tasche.

Vai all’assortimento prodotti di interpolazione elicoidale -

6 / 8

Superfici piane

Le operazioni volte a creare superfici piane sono molto frequenti e ricorrono in diversi settori nella costruzione di stampi e matrici, sia che si tratti di componenti, di strategie dovute alla rispettiva lavorazione di fresatura o ai requisiti delle superfici di chiusura degli stampi, dei tagli e delle fustelle. L’utensile corretto viene quindi selezionato in base all’applicazione e al requisito.

Vai all’assortimento di prodotti per la lavorazione di superfici piane -

7 / 8

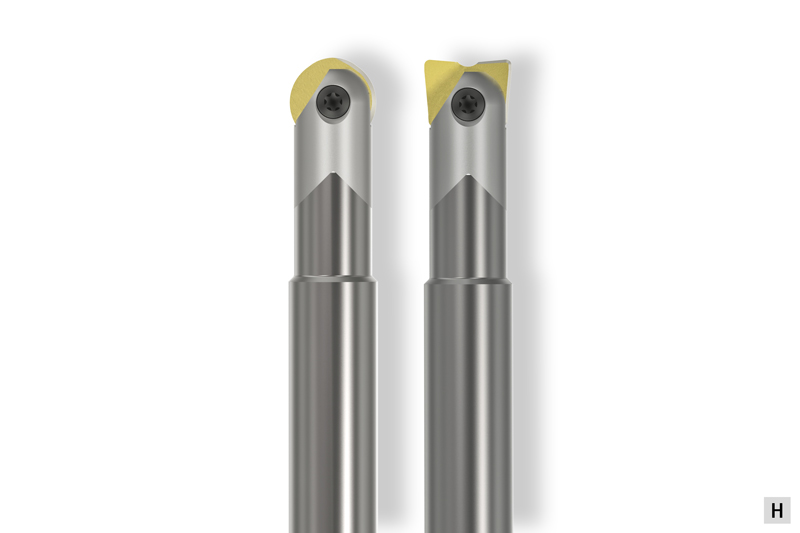

Pareti sottili e nervature

Plastic injection moulds and die casting moulds often have ribs and thin walls. Ribs, for example, are increasingly being milled, as this process is more cost-effective than EDM (spark eroding). As a rule, long or extra-long carbide tools with small diameters are used. Customer-specific solutions (RibCutter) to match the respective rib shape are also possible here.

Go to the product range for machining thin walls and ribs -

8 / 8

Fori di grandi e piccole dimensioni

La costruzione di stampi e matrici comprende una vasta gamma di operazioni di foratura integrale: dai fori di grandi dimensioni per colonne di guida, attraverso fori profondi per sistemi di raffreddamento fino ai fori ad alta precisione per perni espulsori. MAPAL offre un portfolio completo di utensili di foratura e alesatura per le singole fasi di lavorazione.

Vai all’assortimento di prodotti per la lavorazione di fori di grandi e piccole dimensionis

Soluzione chiavi in mano

Engineering Workflow: dalla teoria alla pratica

Further items about the die&mould area

-

02.12.2025

Large tool package for Mangner Zerspanungstechnik

MAPAL has equipped Mangner GmbH with a comprehensive tool package for drilling operations.

-

04.03.2025

CORMOL relies on milling cutters such as the OptiMill-3D-HF from MAPAL for tool making

CORMOL from Portugal manufactures stamping tools, for which it has been working closely with MAPAL since 2022. With the OptiMill-3D-HF, CORMOL has found a reliable and economical tool solution.

#Productos #Industries #CaseStudies #Technology #Die&Mould #Milling

-

25.06.2024

Efficient production in die and mould making: Krämer+Grebe and MAPAL

The mouldmaking company Krämer+Grebe optimises production with MAPAL reamers and milling cutters and ensures process reliability in international competition.

#CaseStudies #Productos #Industries #Reaming&FineBoring #Milling #Die&Mould

Our retail partners

Responsibility according to postcode areas

-

1 / 16

Postcode 35

FRITZ WEG GmbH & Co. KG

Ahornweg 41

35713 Eschenburg-WissenbachPhone: +49 2774 701-0

Fax: +49 2774 701-39

Email: info@fritzweg.de

Web: www.fritzweg.de -

2 / 16

Postcode 44

Jansen Schneidwerkzeuge Vertriebs GmbH

Im Käsebrink 12

58840 PlettenbergPhone: +49 2391 9177-0

Fax: +49 2391 9177-20

Email: info@j-s-v.com

Web: www.j-s-v.com -

3 / 16

Postcode 51

Jansen Schneidwerkzeuge Vertriebs GmbH

Im Käsebrink 12

58840 PlettenbergPhone: +49 2391 9177-0

Fax: +49 2391 9177-20

Email: info@j-s-v.com

Web: www.j-s-v.com -

4 / 16

Postcode 56, 57

FRITZ WEG GmbH & Co. KG

Ahornweg 41

35713 Eschenburg-WissenbachPhone: +49 2774 701-0

Fax: +49 2774 701-39

Email: info@fritzweg.de

Web: www.fritzweg.de -

5 / 16

Postcode 58, 59

Jansen Schneidwerkzeuge Vertriebs GmbH

Im Käsebrink 12

58840 PlettenbergPhone: +49 2391 9177-0

Fax: +49 2391 9177-20

Email: info@j-s-v.com

Web: www.j-s-v.com -

6 / 16

Postcode 60, 61

Heinrich Meier GmbH

Herrenwaag 31

75417 MühlackerPhone: +49 7041 9530-0

Fax: +49 7041 9530-30

Email: info@heinrich-meier.de

Web: www.heinrich-meier.de -

7 / 16

Postcode 63 - 69

Heinrich Meier GmbH

Herrenwaag 31

75417 MühlackerPhone: +49 7041 9530-0

Fax: +49 7041 9530-30

Email: info@heinrich-meier.de

Web: www.heinrich-meier.de -

8 / 16

Postcode 70 - 73

Dieter Schätzle GmbH & Co. KG

Präzisionswerkzeuge

Unter Haßlen 12

78532 TuttlingenPhone: +49 7462 9465-0

Fax: +49 7462 9465-50

Email: info@schaetzle-werkzeuge.de

Web: www.schaetzle-werkzeuge.de -

9 / 16

Postcode 74, 75

Heinrich Meier GmbH

Herrenwaag 31

75417 MühlackerPhone: +49 7041 9530-0

Fax: +49 7041 9530-30

Email: info@heinrich-meier.de

Web: www.heinrich-meier.de -

10 / 16

Postcode 76 - 79

Dieter Schätzle GmbH & Co. KG

Präzisionswerkzeuge

Unter Haßlen 12

78532 TuttlingenPhone: +49 7462 9465-0

Fax: +49 7462 9465-50

Email: info@schaetzle-werkzeuge.de

Web: www.schaetzle-werkzeuge.de -

11 / 16

Postcode 80 - 87

AB1-Tools e.K.

Goethering 45

91732 MerkendorfPhone: +49 9826 333-2241

Fax: +49 9826 333-3691

Email: info@ab1-tools.com

Web: www.ab1-tools.com -

12 / 16

Postcode 88, 89

Dieter Schätzle GmbH & Co. KG

Präzisionswerkzeuge

Unter Haßlen 12

78532 TuttlingenPhone: +49 7462 9465-0

Fax: +49 7462 9465-50

Email: info@schaetzle-werkzeuge.de

Web: www.schaetzle-werkzeuge.de -

13 / 16

Postcode 90 - 97

AB1-Tools e.K.

Goethering 45

91732 MerkendorfPhone: +49 9826 333-2241

Fax: +49 9826 333-3691

Email: info@ab1-tools.com

Web: www.ab1-tools.com -

14 / 16

Danmark

EDECO TOOL APS

Naverland 2

2600 Glostrup

DanmarkPhone: +45 7060 2029

Email: info@edeco.dk

Web: www.edeco.dk -

15 / 16

Italy

TEKNOS S.r.l.

Via A. Pigafetta, 2

35011 Campodarsego (PD)

ItaliaPhone: +39 049 8877061

Email: info@teknositalia.it

Web: www.teknositalia.it -

16 / 16

Portugal

Álamo-Ferramentas Unipessoal Lda

Rua da ETAR, Lote 9

Zona Industrial de Oiã

3770-059 Oiã

Phone: +351 234 728-193

Email: geral@alamo-ferramentas.com