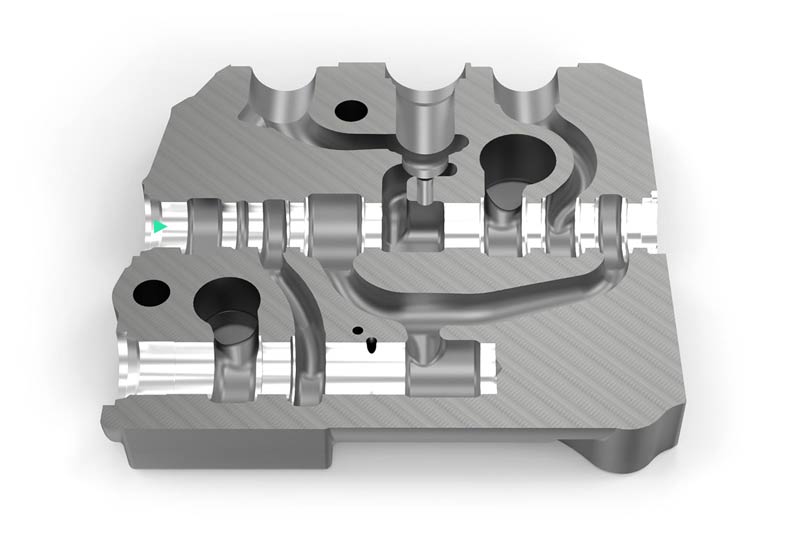

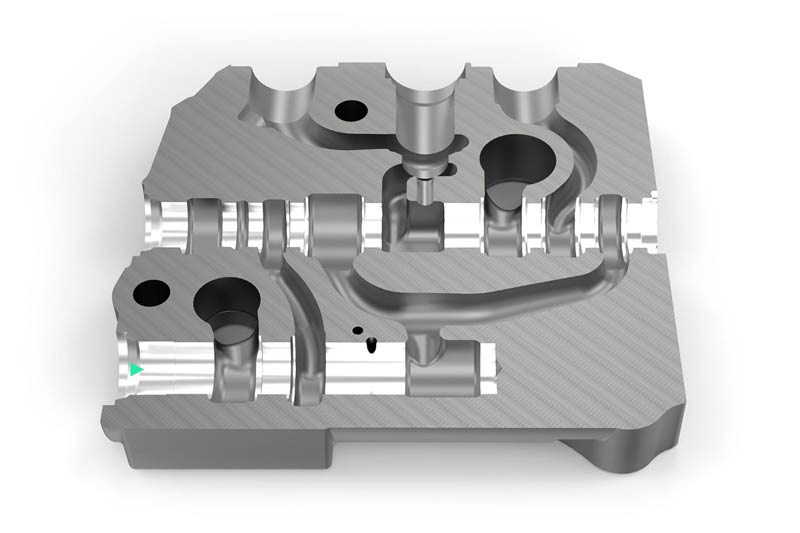

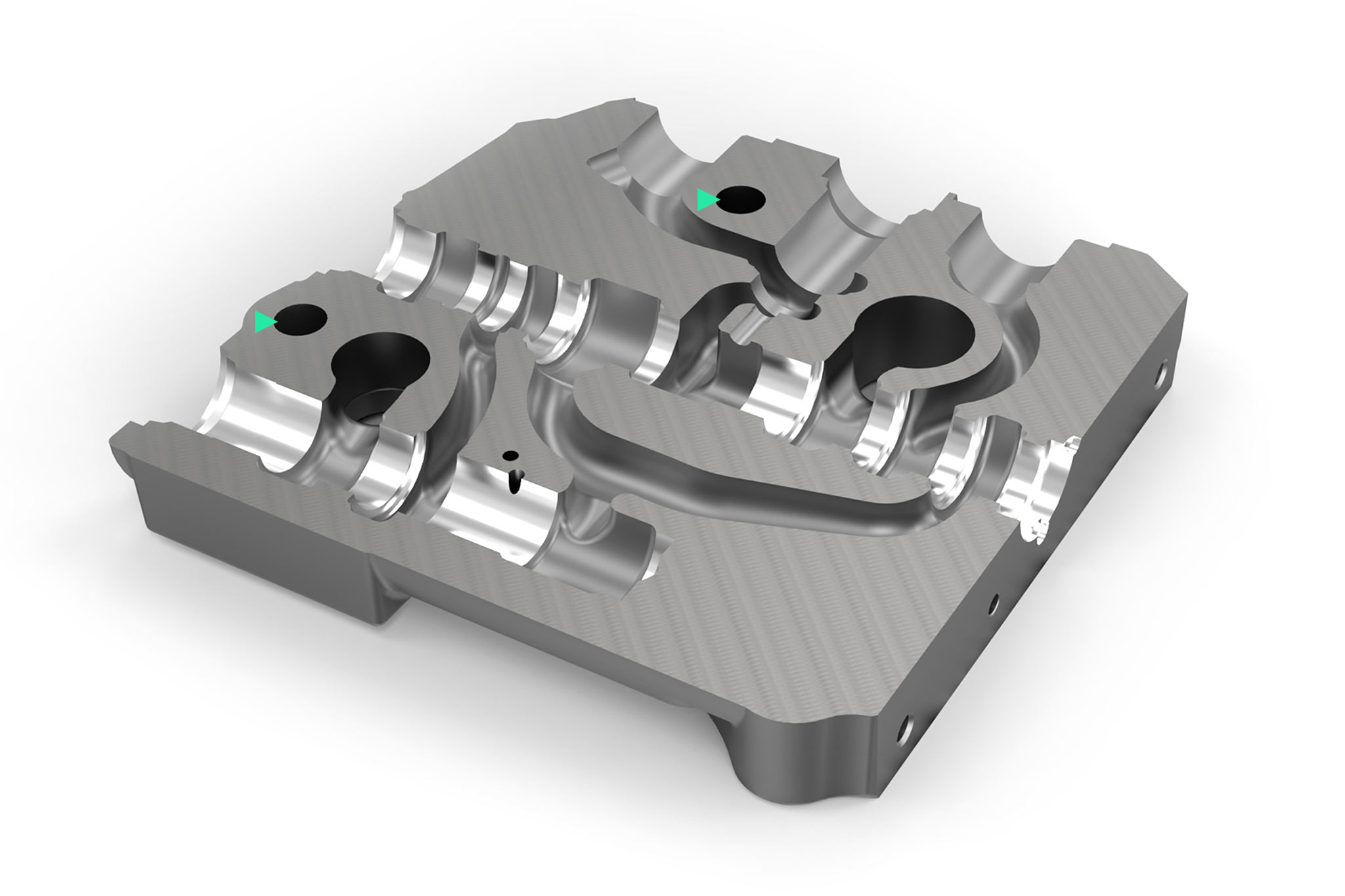

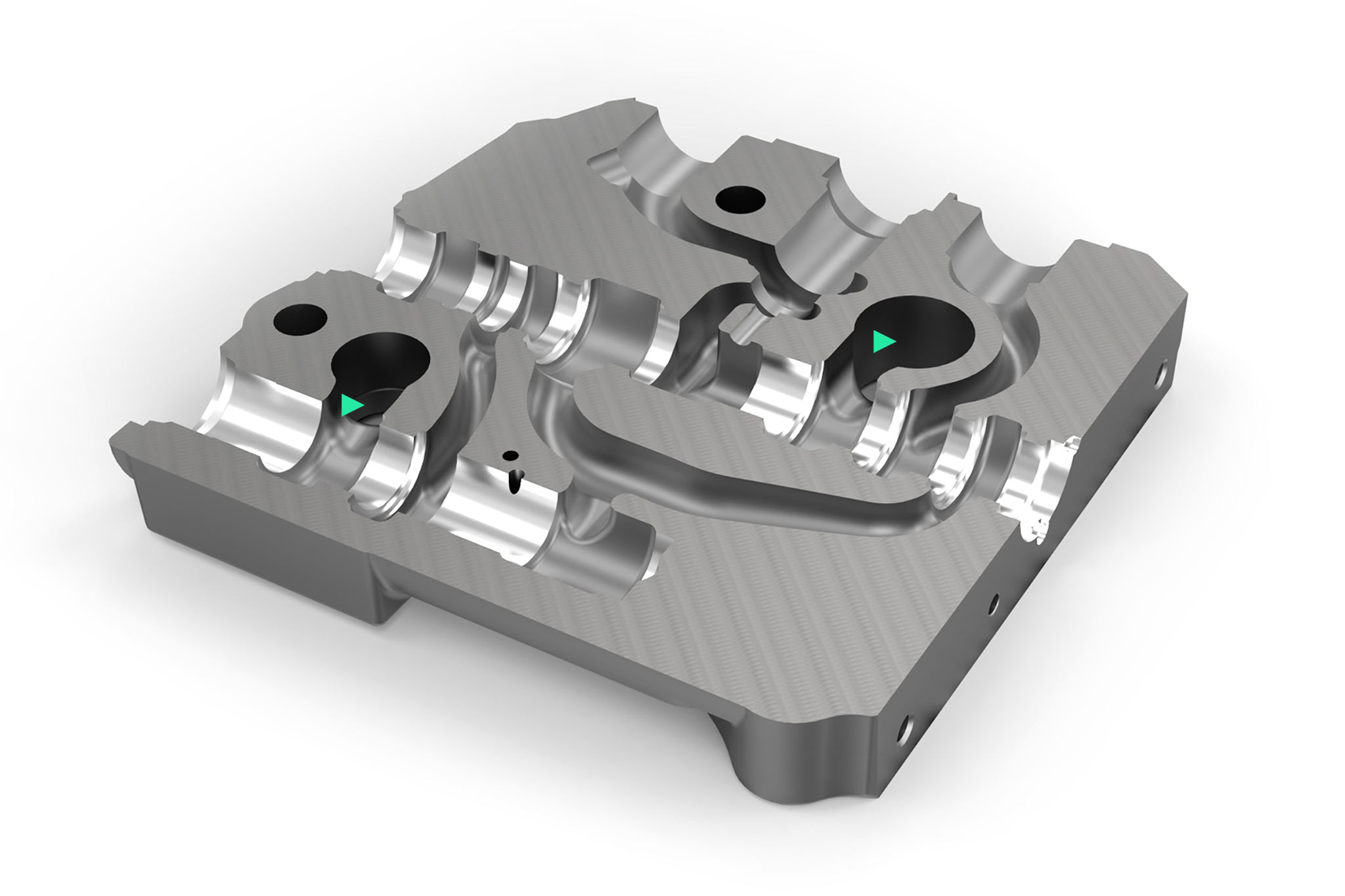

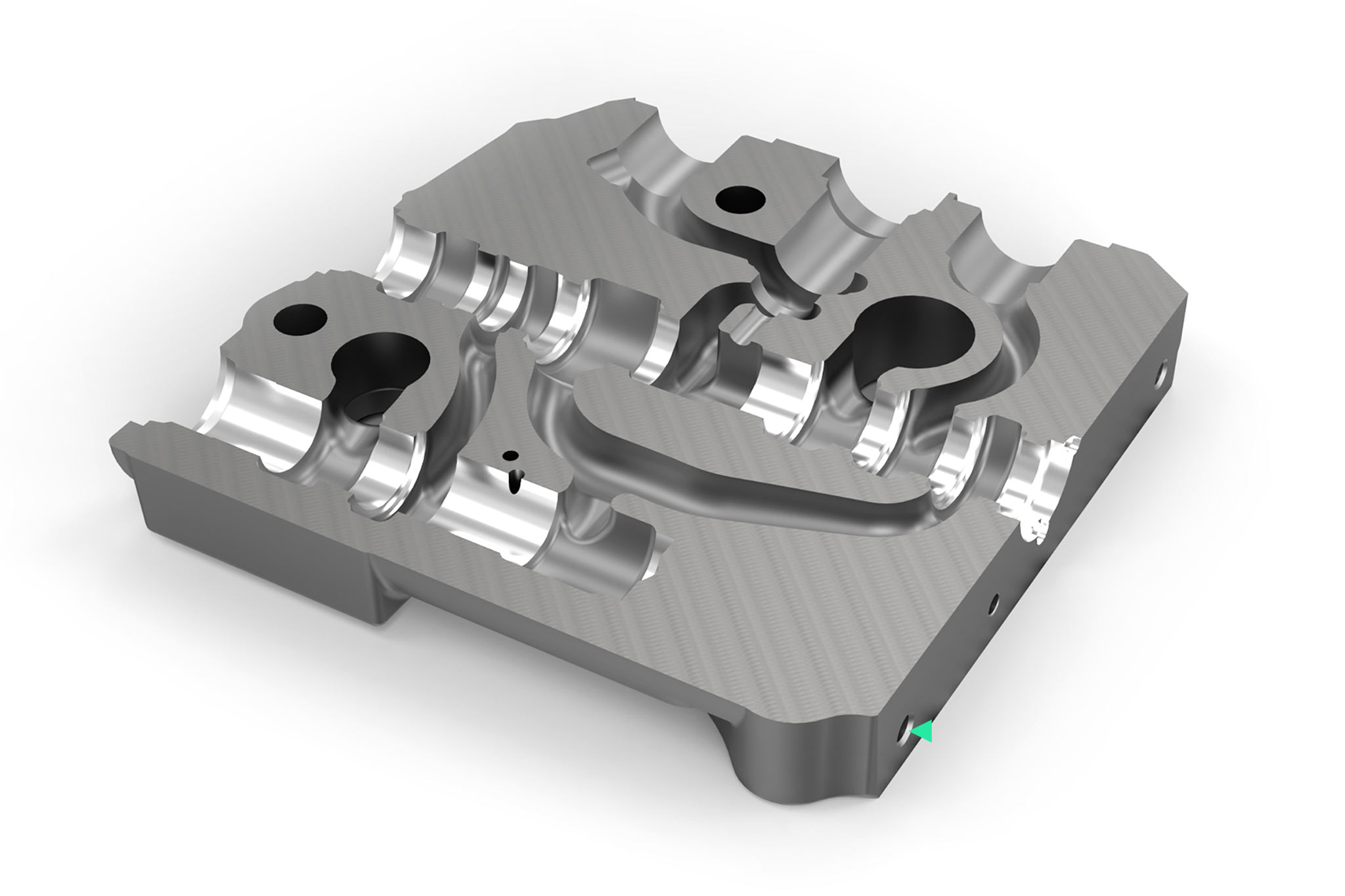

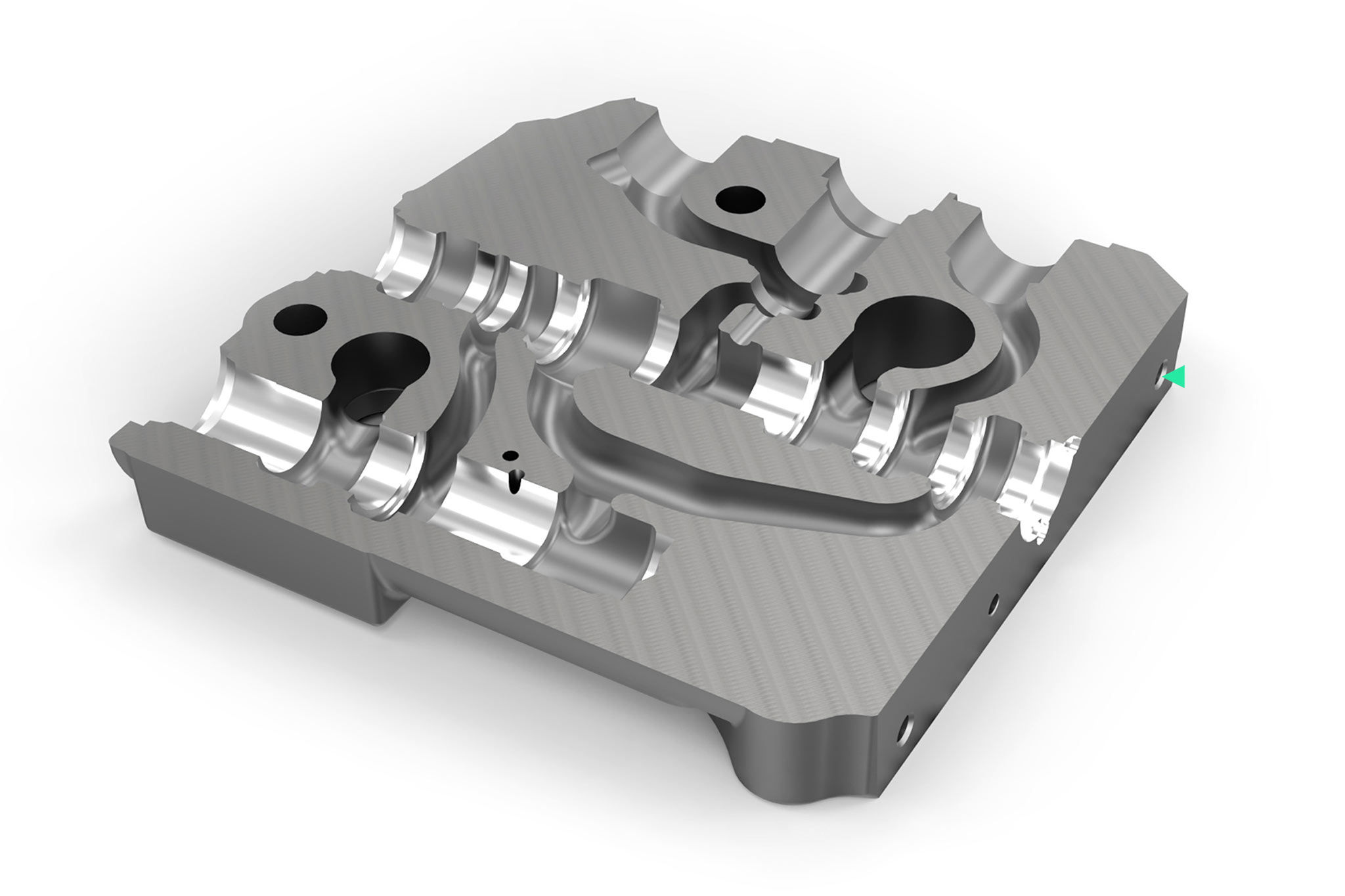

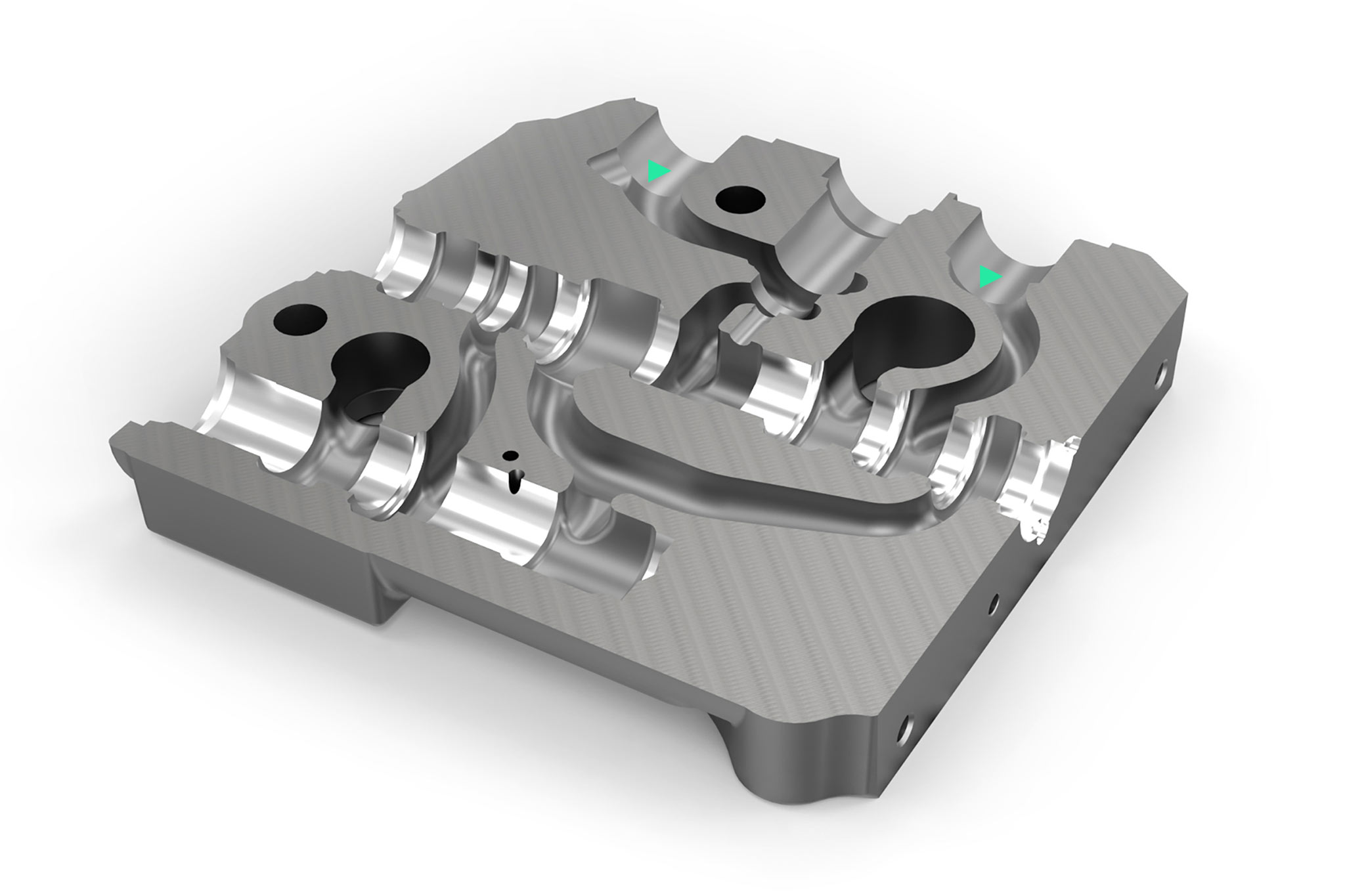

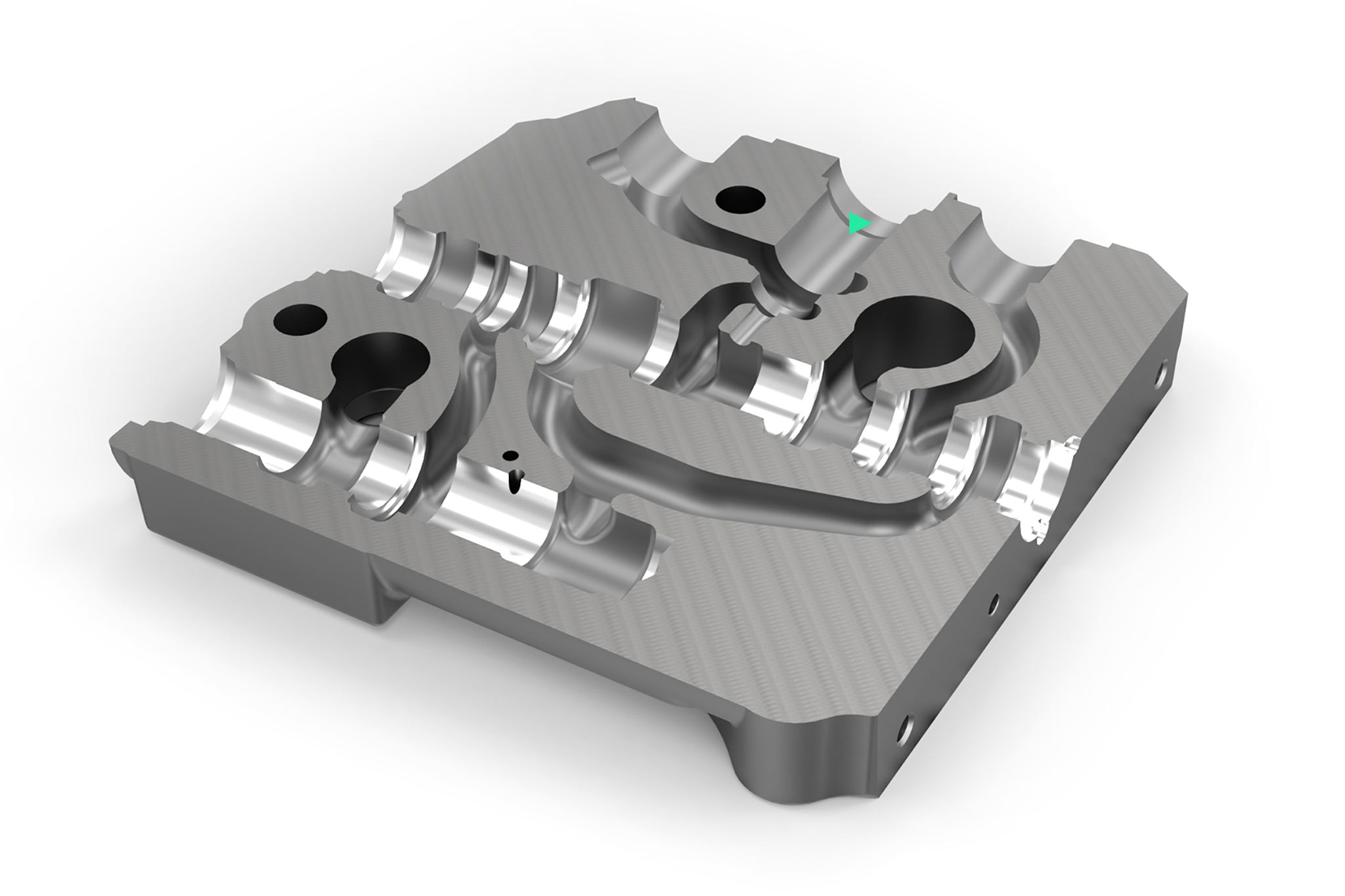

Hydraulic valve housing

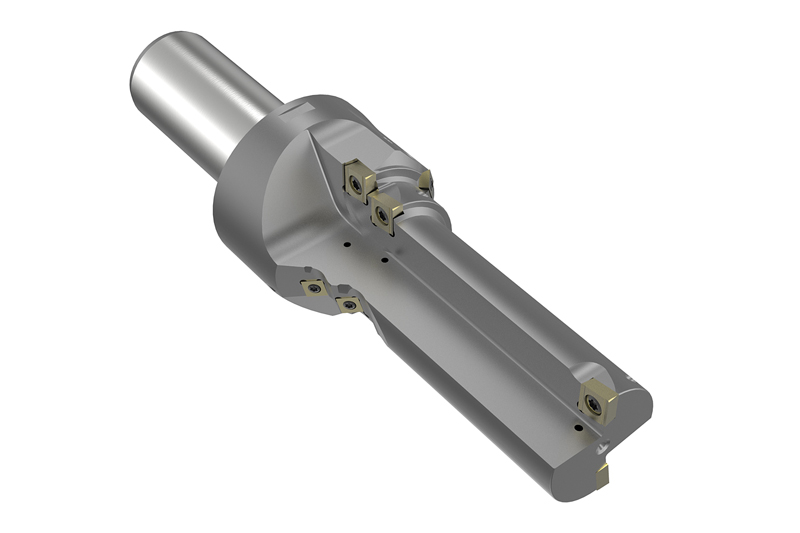

Everything depends on the main bore. Manufacturing valve housings is the supreme discipline in the world of fluid power. For years, MAPAL’s expertise has been in demand for the spool bore. The gap dimension with the spool depends on the accuracy of this bore, so that the hydraulic oil can only flow in the required direction without leaking. This is very narrowly defined in modern hydraulic valves. The roundness, cylindrical form, straightness and surface finish of this bore are therefore crucial.

Exigências da usinagem

- Situação flutuante da tolerância do fundido

- Corte interrompido severo

- Evitar a formação de anéis durante o mandrilamento e garantir a remoção segura dos cavacos

- Evitar falhas macroscópicas nas bordas de controle no processo de mandrilamento

- Exigências elevadas para tolerância de forma e posição

- Remoção constante de material antes do brunimento

- Consideração da variação dos componentes e os espaços limitados de armazenamento das ferramentas no conceito de usinagem

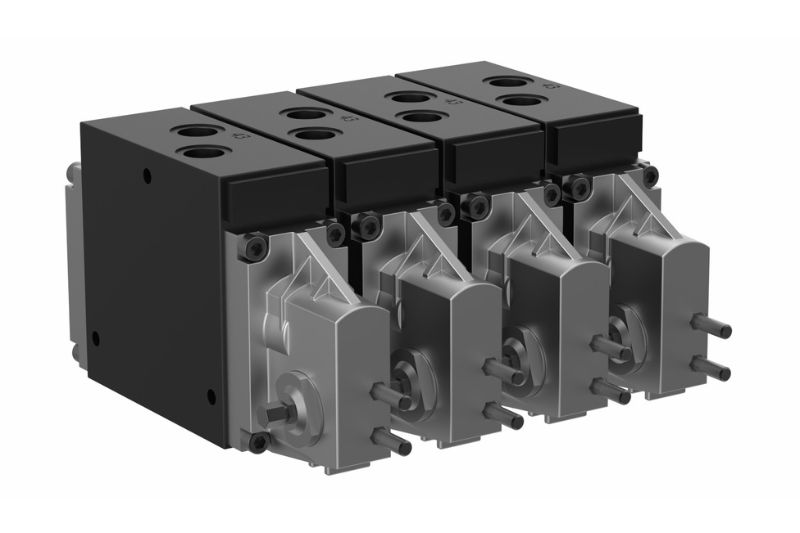

Válvula direcional

As válvulas direcionais são válvulas acionadas mecânica ou eletronicamente com várias posições de comutação. Dependendo da posição especificada da bobina ao longo das bordas de controle, um fluxo com volume é definido para operar o equipamento conectado. O compensador de pressão individual ajusta uma queda de pressão com carga constante através da borda de controle de alimentação do êmbolo, de modo que um controle de fluxo com volume independente da pressão de carga seja obtido em toda a faixa de ajuste, também na operação paralela (compensação de carga). O sistema deve estar livre de vazamentos, para evitar quedas acidentais da carga, mesmo nas operação em paralelo.

Usinagens de furos

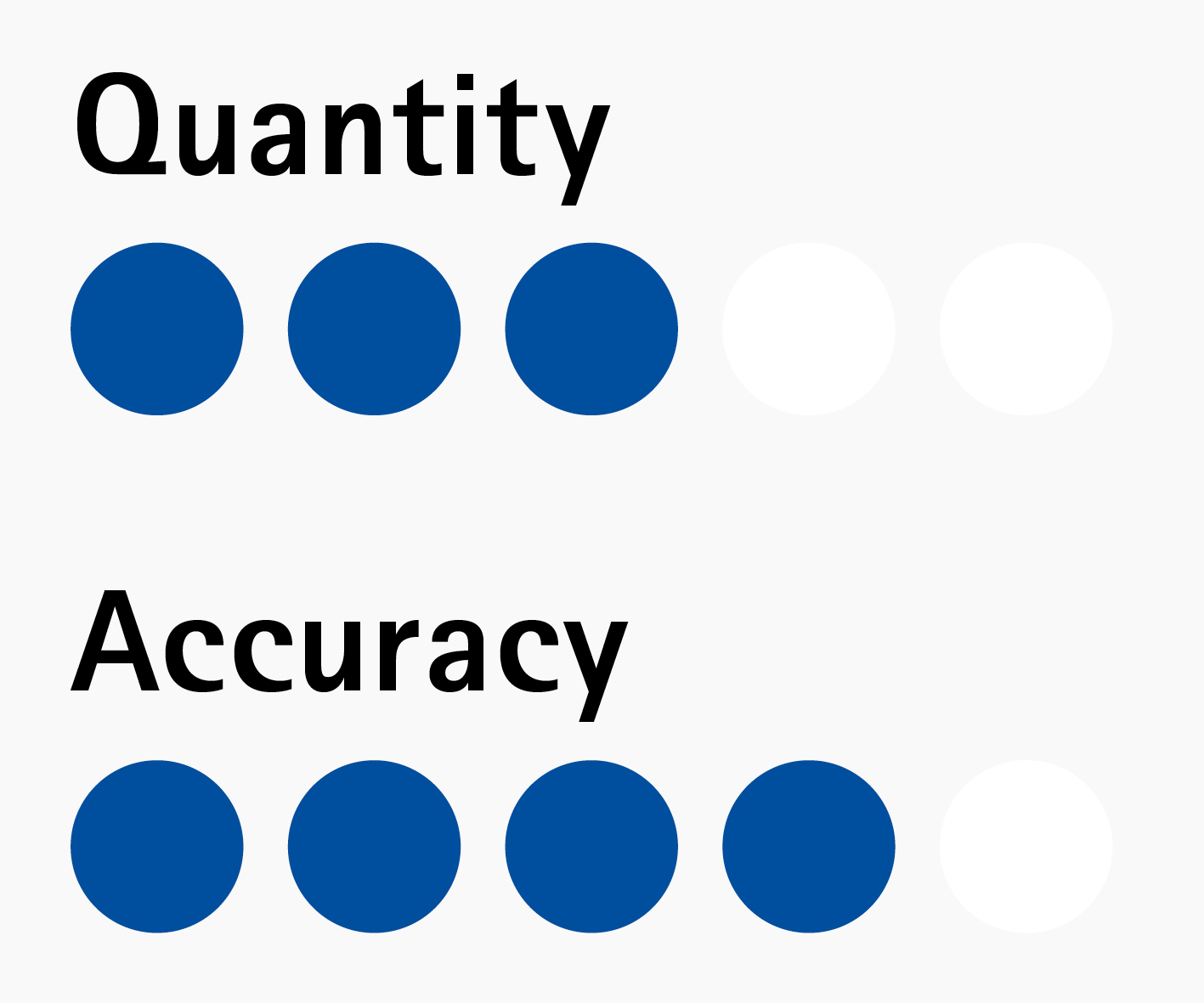

应用解决方案

1 – 使用固定刀具实现中、小批量

2 - 使用固定和可调刀具实现大批量

3 - 小批量 - 通过使用组合型刀具减少刀具更换次数

4 - 在加工中心上的灵活珩磨

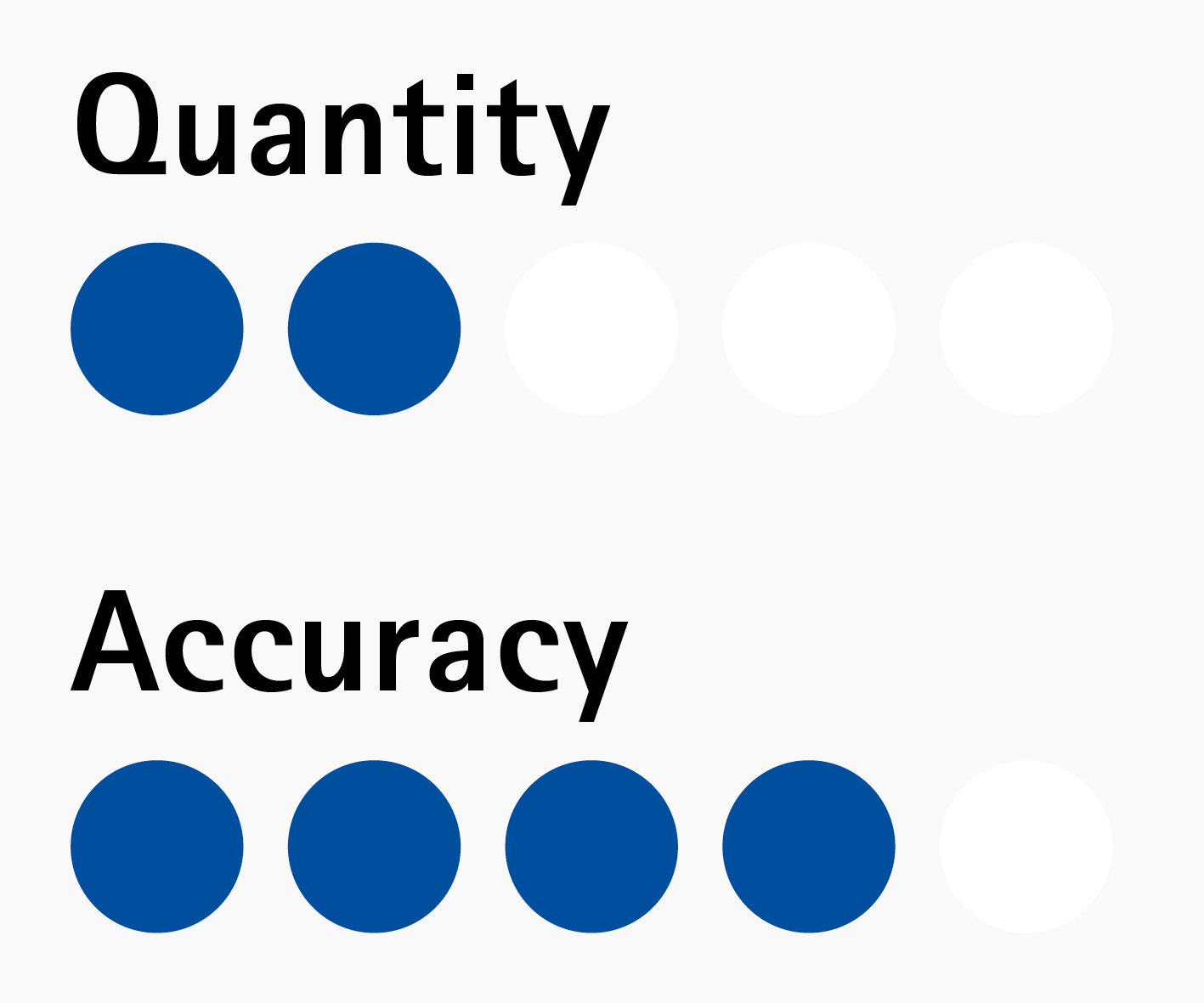

客户的初始情况

阀门外壳 EN-GJS-400-15 - 压力天平孔/珩磨加工

- 减少额外成本的要求

- 现有加工中心改装为 TOOLTRONIC

- 用于原型样板件制造以及中/小批量的珩磨加工

- 要求将珩磨流程对单独的机床不采用

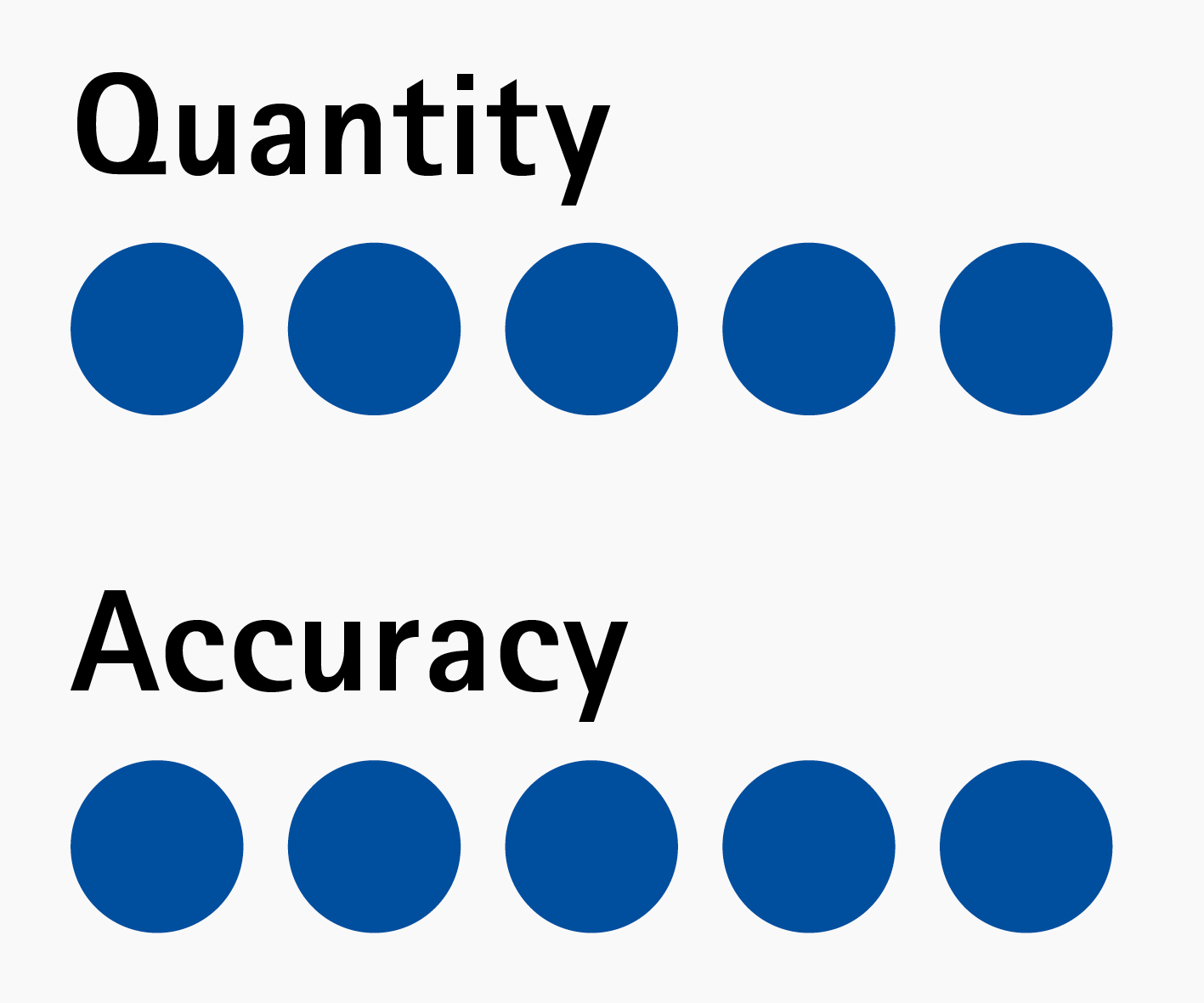

5 – Tool management

Initial situation at the customer

Valve housing EN-GJS-400-15 – complete machining

- High inventories

- Processes in the tool-setting area not optimal, and incomplete data quality

- Cost transparency is not sufficient

- High fluctuation due to general lack of skilled workers

- Problems with tool breakage

- High tool costs

Tool solutions

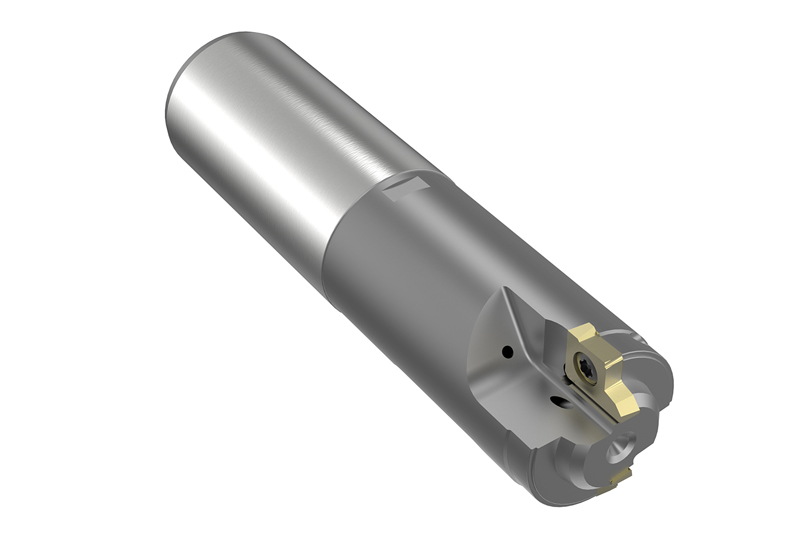

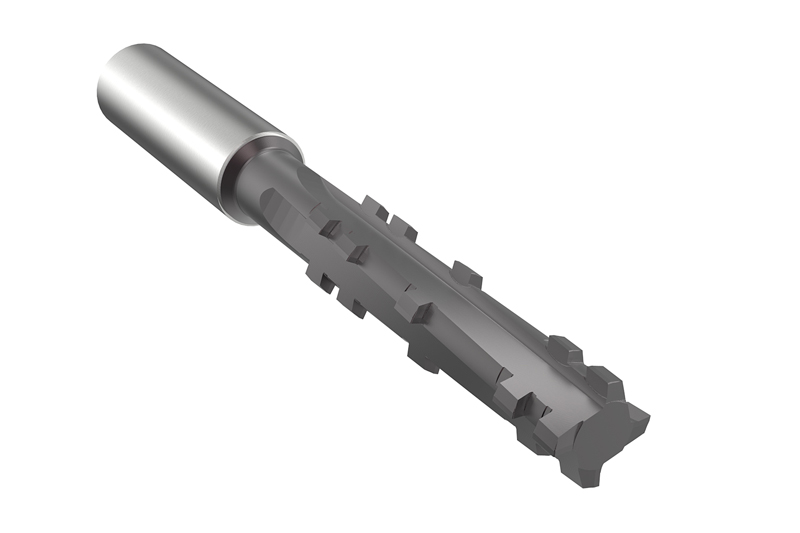

Piloting and boring

Lavorazione delle gole

Reaming and fine boring

Usinage final par pierrage

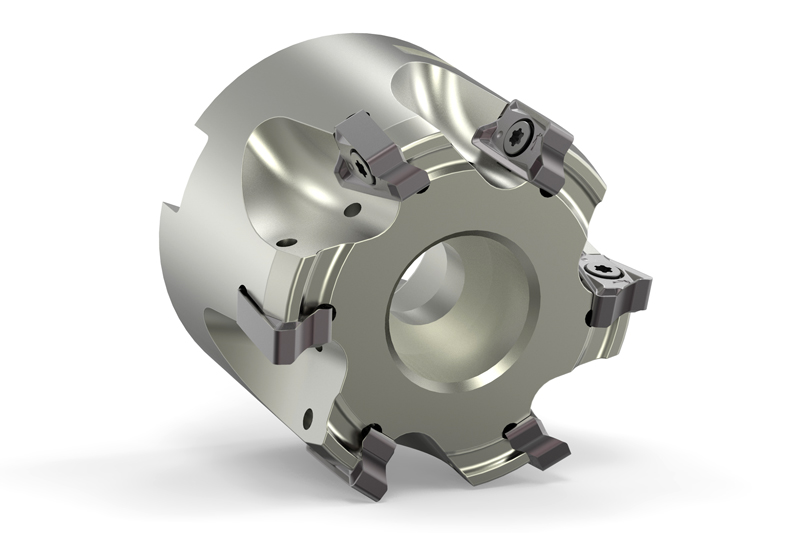

Fresatura

Sistemi di serraggio