Levigatura flessibile nel centro di lavorazione

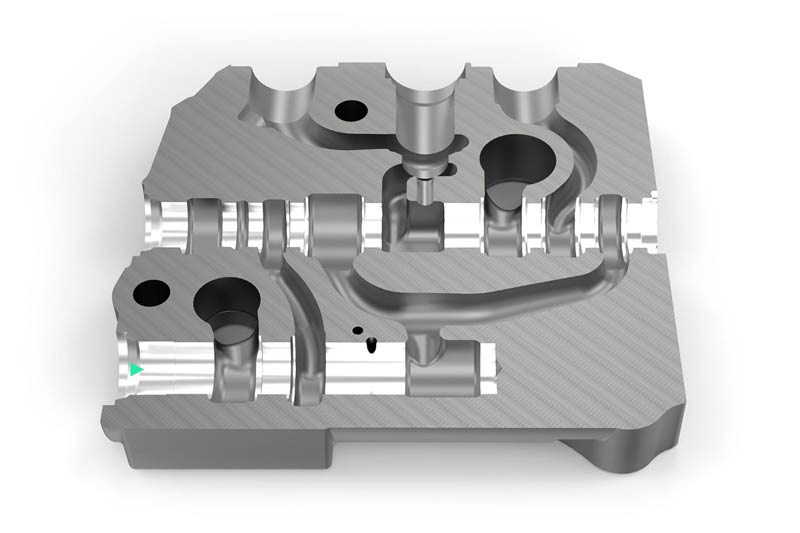

Corpo valvola EN-GJS-400-15 – Foro di compensazione della pressione / Levigatura

Situazione di partenza del cliente

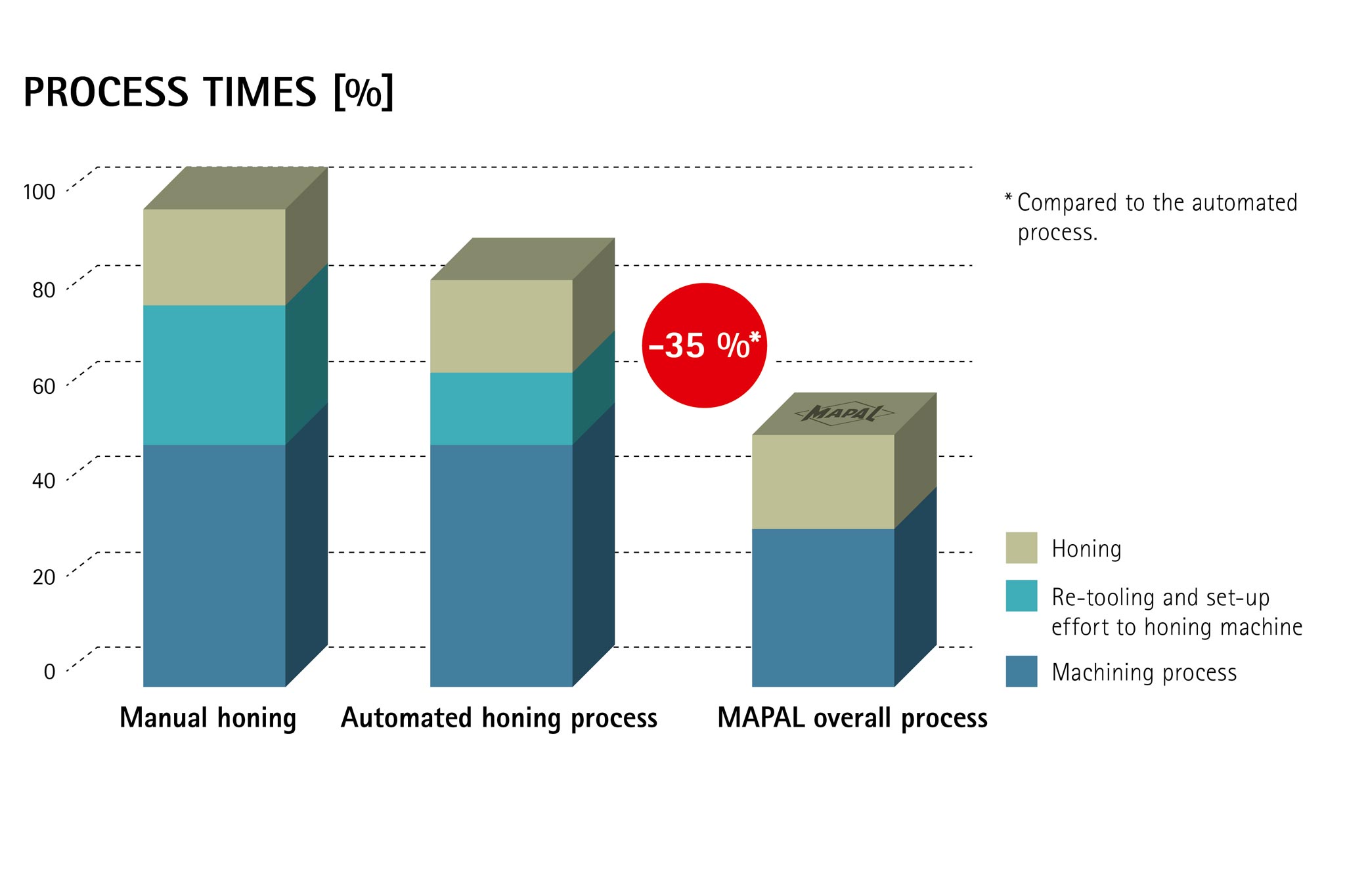

- Necessità di ridurre i costi accessori

- Centro di lavorazione convertito a TOOLTRONIC

- Levigatura per la realizzazione di prototipi e per serie di produzione piccole e medie

- Necessità di risparmiare il processo di levigatura su una macchina separata

Particolarità della soluzione

- Importante asse NC, incorporato nell’unità di comando della macchina

- Riduzione dei tempi di produzione e dei lead time

- Qualità di superficie migliorata

- Maggiore fedeltà alla forma richiesta

Foro di compensazione della pressione

Lavorazione di precisione tramite levigatura

- Riduzione significativa dei tempi di produzione e dei lead time

- Maggiore fedeltà alla forma richiesta

Levigatura con TOOLTRONIC

La lavorazione con TOOLTRONIC di MAPAL consente di ottenere un’elevata qualità della superficie e misure precise in caso di tolleranze di produzione estremamente ridotte, nonché una notevole flessibilità della produzione. L’usura delle barre di levigatura viene compensata da una movimentazione interna ad elevata precisione e sensibilità (sistema EAT).

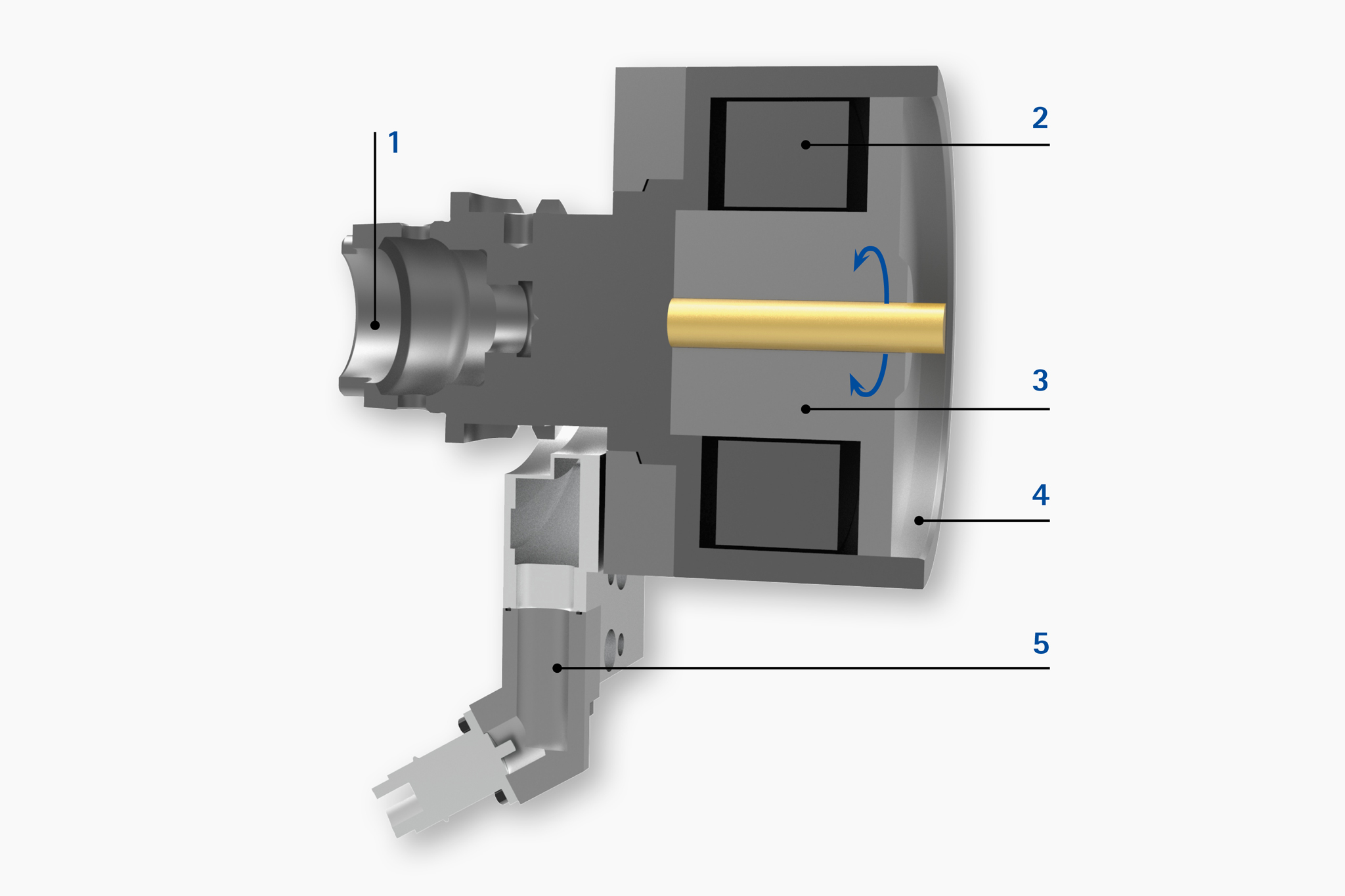

MAPAL TOOLTRONIC: Estrutura e vantagens

加工中心的 TOOLTRONIC 的结构:

- 床接口

- 电子系统

- 带有定义连接位置的电机单元

- 模块化接口

- 定子(立式单元)

这种珩磨加工的优点:

- 最严格的制造公差和制造灵活性

- 高的表面质量和尺寸精度

- 原型样板件、中/小批量的巨大节省和质量潜力

- 可避免耗时的改装流程

优点

- 要达到的公差:直径精度 IT 6 和圆度 < 5 μm

- 对于固定、牢固夹紧的组件进行车削加工

- 可实现无毛刺、圆角的过渡区

- 减少/少量的专用刀具数量

- 采用偏心展开式刀具(EAT 系统),系统维护成本低

- 几乎所有加工中心都可以改装为 MAPAL TOOLTRONIC 技术

- 可以避免由于改装为珩磨机而引起的换夹误差

- MAPAL公司可以提供压力天平孔的完整流程(最高的成本效益和工艺可靠性)